Publication Okello UGA203 Deom 2015 Groundnut Seed Production Manual for Uganda

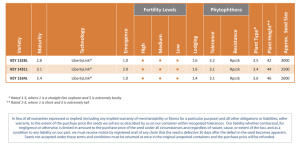

advertisement