Getting Started with Electronics Build Electronic Circuits! ( PDFDrive ) (1)

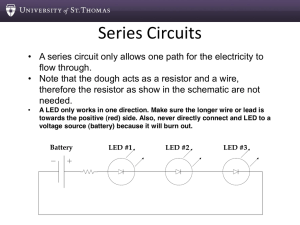

advertisement