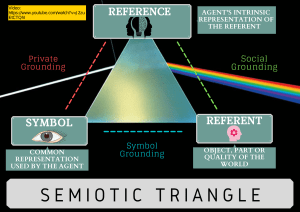

Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x 1 Eviation Wiring Guidance This document provides guidance for the installation of the Eviation Flight Control Computer (FCC) modules. 1.1 Installation The FCC_Module_O&I_Drawing (part number TBD) provides the dimensions of the FCC modules includes the mounting surface and keying of the backshell connectors. 1.2 Shielding, Bonding and Grounding Proper electrical shielding, bonding, and chassis grounding are key factors in ensuring proper system operation under normal conditions and under HIRF and lightning environments. This section and technical specifications referenced here-in must be complied with to satisfy these requirements. 1.2.1 Bonding and Grounding All units shall be electrically bonded to the airframe. This is accomplished by ensuring that the mating surfaces between the LRU mounting feet provides a low impedance ( < 2.5 milliohm) electrical path. The mating surfaces must be free of all paint and other non-conductive elements and should be burnished to ensure a good bond. If the aircraft mating surface is not conductive, a bonding strap of at least 1/4 inch wide (preferably 1/2 inch wide) tin coated copper braid can be used between the LRU and the nearest airframe grounding point. The FCC mounting feet must be electrically bonded to a conductive mounting surface by a low resistance path of with a maximum resistance of 2.5 milliohms. The 2.5 milliohm value applies to (1) the initial FCC installation, and (2) anytime the FCC is loosened or removed after the initial 2.5 milliohm buyoff test. Due to the gradual degradation of a new electrical bond over time, the maximum in-service resistance value can be up to 5 milliohms. In-service readings higher than this will require a re-bonding with an ‘as new’ bonding limit of 2.5 milliohms. NOTE: The total resistance from the FCC mounting feet to the central aircraft ground reference structure must be less than 10 milliohms. Typically this would include the following bonding points: FCC mounting feet to aircraft mounting shelf - 2.5 milliohms max new Conductive mounting surface to aircraft central ground reference - 2.5 milliohms max new 1.2.2 Shield Grounds Full circumference shielding (also referred to as 360 degree shielding) is recommended for critical systems or systems that have high susceptibility to EMI. 1-1 Use or disclosure of information on this page is subject to the restrictions on the title page of this document. Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x 1.2.2.1 Multi Point Shield Grounding The majority of the shielded wires in the FCCs have the shields grounded at both ends. This is called multi point shield grounding and is specified to minimize the adverse effects of HIRF and lightning. Examples of multi point shield grounding methods without bulkhead connectors are shown in Figure 1.2.2.1-1 through Figure 1.2.2.1-2. Examples of multi point shield grounding methods with bulkhead connectors are shown in Figure 1.2.2.2-1 through Figure 1.2.2.2-2. ARINC 429 OUTPUT J1 H 1 J1 8 H L 2 9 L ARINC 429 INPUT Figure 1.2.2.1-1. Multi-Point Shield Grounding W/O Bulkhead Connector (Example) ARINC 429 OUTPUT ARINC 429 INPUT J1 H 1 J1 5 H L 2 6 L ARINC 429 INPUT J1 H 5 L 6 Figure 1.2.2.1-2. Multi-Point Shield Grounding W/O Bulkhead Connector (Example) Note: The arrows on the lines mean twisted wires. 1-2 Use or disclosure of information on this page is subject to the restrictions on the title page of this document. Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x 1.2.2.2 Bulkhead Connector Shield Handling Shielded cables that require multi point shield grounding require that the shields be grounded at both sides of the bulkhead connectors. Examples of bulkhead connector shield handling with multi point shield grounding methods are shown in Figure 1.2.2.2-1 and Figure 1.2.2.2-2. ARINC 429 OUTPUT J1 H 1 A A J1 8 H L 2 B B 9 L ARINC 429 OUTPUT BULKHEAD CONNECTOR Figure 1.2.2.2-1. Multi-Point Shield Grounding with Bulkhead Connector (Example) ARINC 429 OUTPUT J1 H 1 A A J1 5 H L 2 B B 6 L ARINC 429 INPUT BULKHEAD CONNECTOR ARINC 429 INPUT J1 H 5 L 6 Figure 1.2.2.2-2. Multi-Point Shield Grounding with Bulkhead Connector (Example) 1.2.2.3 Procedure to attach a pigtail wire to a shielded cable assembly This procedure describes the technique to attach a pigtail wire to a TSP (twisted shielded pair) or TST (twisted shielded triple) cable using a solder sleeve. All the steps in this procedure are referenced in Figure 1.2.2.3-1. Step 1: Cut the shielded cable outer jacket and shield to provide .25 inches of overall shield braid and 1.5 inches of the insulated inner conductors. 1-3 Use or disclosure of information on this page is subject to the restrictions on the title page of this document. Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x Step 2: Cut an approx. 5 inch length of black 22 AWG MIL-W-22759 thin wall (/18, /32, /33, /44, /45, /46, or equivalent) wire for the pigtail lead. Strip .25 inch of insulation off one end of the pigtail lead. Position the stripped end of the pigtail wire adjacent to the exposed cable shield. The pigtail lead must exit away from the exposed inner cable conductors. Insert a medium size solder sleeve (Alpha P/N FITSLV 24-100, Newark P/N 66F2461) over the pigtail wire and shielded cable. Apply heat to shrink the solder sleeve while holding the pigtail wire in position touching the exposed cable shield. This completes the assembly procedure. Figure 1.2.2.3-1 Attach Pigtail Wire to Shield Cable 1.2.2.4 Shield Grounding Recommendation The recommendation for shield termination is as follows: Terminate at both ends of the connection Nearly zero length pigtail as practical 360 degree EMI backshell 1.2.2.5 Shield Grounding Method for the FCC Backshell Mounted Connectors The shield drain wires are terminated using stainless steel crimp bands. 1.2.2.6 Strain relief The strain relief can be provided at the connector or close to it, in an appropriate manner, depending on the installation of the unit in the aircraft. 1-4 Use or disclosure of information on this page is subject to the restrictions on the title page of this document. Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x 1.2.3 Shielding Over-Braid Installation and Grounding FCC wiring that runs outside of the pressure vessel must be installed within a continuous shielding overbraid material or other enclosed structure that provides similar HIRF, lightning and emissions attenuation as provided by the pressure vessel enclosure. Typically over-braid is constructed as a wire mesh tube with 360 degree grounding connectivity to the pressure vessel enclosure and/or other enclosed structures through which the wiring is routed. 360 degree grounding is required at all over-braid interfaces. Refer to Figure 1.2.3-1. Exposed Area Over-Braid Cable Bundle Protective Enclosure (or Equipment) 360O Low Impedance Connectivity between enclosures and over-braid (example: pressure clamp) Pressure Vessel Enclosure Figure 1.2.3-1 Over-Braid Connectivity Example 1.2.4 Power/Signal Grounds 1.2.4.1 Multi-point Grounding Multi-point grounding of the power and signal grounds can be used only if the aircraft has a ground plane that provides a low impedance path between all the electrical systems and back to the main aircraft power ground. A good aircraft ground plane requires that special attention be paid to the bonding of all the aircraft subassemblies that are part of the ground plane. Good bonding will ensure a low impedance electrical path within the ground plane. Composite structures within a ground plane must be designed to handle the required ground plane currents, and offer the equivalent low impedance of present day aluminum structures. Figure 1.2.4.1-1 shows the multi-point ground plane wiring method. 1-5 Use or disclosure of information on this page is subject to the restrictions on the title page of this document. Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x Ground Wires : DC Grounds AC Grounds Signal Grounds Ground Block Unit 1 Unit 2 Unit N Aircraft Ground Plane Note: Shield grounding requirements are detailed in Section 1.2.2.4 Figure 1.2.4.1-1 Multi-point Ground Plane Wiring If the aircraft cannot satisfy the multi-point ground plane requirements, central point grounding must be used. Central point grounding is detailed in Section 1.2.4.2 1.2.4.2 Central Point Grounding All DC power grounds shall be tied together, all signal grounds shall be tied together, and all lighting grounds shall be tied together. DC power, signal, and lighting ground groups are then tied together at a single point and connected to the airframe. The aircraft grounding diagram below Figure 1.2.4.2-1 illustrates this grounding method. It is very important that this grounding technique be adhered to. Do not tie the various ground wires to multiple aircraft frame points and depend on the aircraft structure itself to provide a low impedance path for the individual grounds. ONLY chassis grounds and shield grounds are grounded at multiple points in the aircraft. 1-6 Use or disclosure of information on this page is subject to the restrictions on the title page of this document. Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x Single Aircraft Grounding Point (Note 1) Central Aircraft Grounding Blocks DC Power Grounds Signal Grounds Lighting Grounds To Various Aircraft Locations Figure 1.2.4.2-1 Central Aircraft Grounding Blocks For signal grounds that are low current, multiple signal grounds can be connected to remote aircraft terminal blocks other than the central grounding blocks as long as these remote terminal blocks are isolated from ground. The various remote signal ground blocks must all be grounded only at the aircraft central grounding point. For example, if ten signal grounds are connected to a remote terminal block, a minimum of one grounding wire must be run from this terminal block to the aircraft central grounding point. 1.3 Interconnect Requirements This section provides interconnect guidance/requirements for each interface type. Section 1.3.6 will provide details of the connector types, pin and wire sizes and shielding to be used for each interface type. 1.3.1 IMB The Intermodule Data Bus (IMB) are dedicated unidirectional data links among the FCCs. The protocol is organized as small, fixed length (design time) packets of parameters passed in a datagram (send and forget) manner. As unidirectional links, a single source module deterministically sends packets at deterministic points in its operational schedule. 1-7 Use or disclosure of information on this page is subject to the restrictions on the title page of this document. Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x The aircraft wiring must utilize 100 Ω controlled impedance twisted-shielded pair cable. Cable breaks and termination points must maintain balanced lead lengths and 360 degree shielding. Individual IMB links shall be limited to less than 150 feet in length with no more than four production breaks. Topology Rules and Link Budget Assumptions: All IMB links have a single transmitter and at most two receivers. High-quality controlled impedance cable must be used with electrical characteristics as defined in Table 1.3.1-1. Connectors deployed typically use pins with approximately 0.254 cm (0.1 inch) spacing. Each interface is likely a slight deviation (~75 ohms) from the ideal impedance. A conservative approach is to assume about 0.2 dB attenuation per disconnect. The transmit source impedance and end terminus receiver impedance are matched to the 100 ohm cable. It is not recommended to mix cable of different characteristic impedances in any installation. Table 1.3.1-1 Recommended P2P (IMB) Cable Characteristics Cable Parameter Characteristic Impedance Nominal Value +/- 10% 100 Ohm Z 0 Wire Gauge 22 AWG or 24 AWG Shunt Capacitance 52 pF/m (16 pF/foot) ~6 dB/100m @ 5 Mhz ~2.8 dB/100m @ 1 Mhz ~30 dB/100m @ 100 Mhz 69% Attenuation Velocity of Propagation Tolerance Consistent through installation Approximate, less than All approximations minimum 1.3.2 Analog Discrete Analog discrete signals should be sized as defined in the interconnect tables found in the EICD. 1.3.2.1 Data Load Discrete There are two discrete inputs used to put the FCC into data load mode. Both inputs need to be grounded in order to enter data load mode. The data load discrete interfaces should follow the same guidelines as other analog discrete interfaces. The switch states are shown in Figure 1.3.2.1-1 1-8 Use or disclosure of information on this page is subject to the restrictions on the title page of this document. Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x FCC 2 FCC 1 DI X DI Y GND Covered Switch Shown in Data Load Enabled State Switches NOT located on flight deck DI X DI Y FCC 3 GND Covered Switch Shown in Data Load Enabled State Switches NOT located on flight deck DI X DI Y GND Covered Switch Shown in Data Load Enabled State Switches NOT located on flight deck Figure 1.3.2.1-1 Data Load Switch Interface 1.3.3 VDT The FCC uses 5-wire VDTs on flight deck controls. The wiring between FCC and VDT are Twisted Shielded Pair (TSP) for excitation, and Twisted Shielded Triple (TST) for feedback. A single VDT will be tied to a single excitation output. Figure 1.3.3-1 shows the interconnect between the FCC and a VDT. Figure 1.3.3-2 shows the position recovery interface from VDT to FCC. This schematic in Figure 1.3.3-2 shows that the VDT to FCC wiring interface has capacitive characteristics, and that the length of the wiring connection introduces capacitance that can affect VDT scaling. These need to be considered when connecting the VDT to FCC. The schematic shows reasonable wiring characteristics that can be achieved when proper cabling is applied. Eviation and/or the wiring integrator is responsible for identifying and selecting cable that meets these characteristics, Eviation should work with the sensor supplier to ensure scaling in the EICD includes potential effects of the wiring (capacitive and resistive) on the signal. It should be noted that the values shown in Figure 1.3.3-2 are for example only. 1-9 Use or disclosure of information on this page is subject to the restrictions on the title page of this document. Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x FCE Excitation Return High Center Low Figure 1.3.3-1. Wire VDT Interconnects FCC 42 pF/ f t High 42 pF/ ft 1 0 k? .2 5 W 7 5 k? .2 5 W 1 0 0p F 8 pF/ f t M M B Z1 2V A L 8 pF / ft 8 pF/ ft 7 5 k? .2 5 W Low 42 pF/ f t 1 0 0p F 1 0 k? .2 5 W M M B Z1 2V A L Figure 1.3.3-2. VDT to FCC Position Recovery Interface 1.3.4 CAN The maximum allowable length of the CAN bus is 62 meters (203 feet). This length is measured from one terminating resistor to the other. The minimum recommended distance between nodes is 31 cm (12 inches). As a recommended practice this “distance between nodes” also includes the distance between the last node connection and the terminating resistor on the end. 1-10 Use or disclosure of information on this page is subject to the restrictions on the title page of this document. Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x The recommended length of stubs (branches) is 3.8 cm (1.5 inches). This length allows the node “T” connection to be housed in the back shell of the FCC connector or the shell of the aircraft harness connector to a servo. This length can be increased to 25.4 cm (10 inches) as long as the stub is shielded and the bus and stub shields are connected together. Two terminating resistors are required. One terminating resistor must be on each end of the CAN bus. The recommended value for the terminating resistors is 124 Ohms each. It is recommended that the wire shielding is connected so as to be electrically continuous. “T’s”, junctions, bulkhead connectors, etc need to have the shielding connected in some way to satisfy this. The recommended shielding termination is to ground at each node through the connector back shell. The daisy chain sequence may be modified to allow efficient wire routing based on LRU locations. 1.3.5 Ethernet The Ethernet used on the Eviation aircraft are used for the flight test interface, but should follow the same guidelines as would be used for an A664 installation. Typical aircraft installations utilize star quad cable, which consists of four parallel wires uniformly twisted around a center filler and encased in an overall shield as shown in Figure 1.3.5-1. One run of this cable is required for each 10/100BASE-T Ethernet Link and may be used with standard contacts (Size 20 or 22) and quadrax contacts. Figure 1.3.5-1 Star Quad Cable The undesired coupling that can occur between the two pairs in the star quad cable is referred to as Near-End Crosstalk (NEXT). The NEXT performance of the cable should be verified across the full range of frequencies (1MHz-100MHz) with minimum deviation when subjected to typical aircraft installation bend radii and clamping conditions. General guidelines for cable NEXT performance criteria are provided in Appendix I of ARINC 664, Part 2. 1-11 Use or disclosure of information on this page is subject to the restrictions on the title page of this document. Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x A connector backshell should be used for shield termination. Not more than 0.20 inch (one twist) of the shield(s) and inner jacket should be removed. These tight dimensions are defined to meet the NEXT and EMI performance specifications. In those cases where it is desired by the system integrator to increase these dimensions, it is possible, by testing the desired configuration, to change the dimensions. Increasing these dimensions may have an impact on the Aircraft Link budget. Connect the shield(s) to the backshell as a chassis ground using a suitable low impedance method. Backshells which provide 360 degree coverage of the shield may be necessary to meet all DO-160 levels. Example connector layouts and additional shield termination guidelines are provided in Appendix B of ARINC 664, Part 2. 1.3.6 Sizing and Shielding This section provides guidance for the FCC interconnects. Table 1.3.6-1 provides suggested pin/wire size correlation, Table 1.3.6-2 provides shielding information, and Table 1.3.6-3 provides general information for the pin/wire size and shielding information for each interface type. Table 1.3.6-1 Pin/Wire Size Pin Size Smallest AWG Largest AWG Size 22D 24 22 Table 1.3.6-2 Shielding Information Type Acronym Type Description TSP Twisted Shielded Pair TST Twisted Shielded Triple TSQ Twisted Shielded Quad BTP P2P Data Bus Wire, TSP with Table 1.3.1-1 characteristics BSQ A664 Data Bus Wire, Star Quad Cable Table 1.3.6-3 Generic Interconnect Information IO BP Description of Signal Function Pin Size AWG Shielding O VDT Excitation Return 22D 22 TSP VDT Excitation 22D 22 TSP I VDT High 22D 24 TST I VDT Low 22D 24 TST O 1-12 Use or disclosure of information on this page is subject to the restrictions on the title page of this document. Header Document Title - Pub. No. REV Revision 1.0.0 wi rin g gu id a n c e .d oc x IO BP Description of Signal Function AWG Shielding VDT Center Pin Size 22D I 24 TST Analog Discrete 22D 24 O Analog Discrete 22D 24/22 B A429 + (H) 22D 24 TSP (L) 22D 24 TSP I B A429 - TST 1 TST B FT Ethernet + (H) 22D 24 BSQ B FT Ethernet - (L) 22D 24 BSQ B IMB + (H) 22D 24 BTP (L) 22D 24 BTP B IMB - B CAN + (H) 22D 24 TSP B CAN - (L) 22D 24 TSP P FCC Power Input 22D 22 TST P FCC Power Ground 22D 22 TST I = INPUT O = OUTPUT B = BUS P = POWER 1 There are high and low current discrete outputs. Low current discrete outputs can use a 24 AWG wire, while high current discrete outputs can use 24 AWG wire for short wire runs but must use 22 AWG wire for long wire runs. 1-13 Use or disclosure of information on this page is subject to the restrictions on the title page of this document.