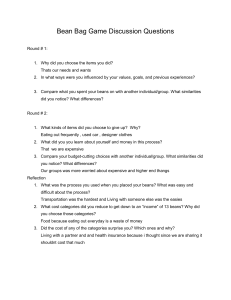

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/278940317 Production of Tempeh from various indigenous Ethiopian legumes Article in World Journal of Microbiology and Biotechnology · January 1991 CITATIONS READS 8 77 2 authors: Mogessie Ashenafi Martin Busse College of Development Studies, Addis Abab… Coburg University of Applied Sciences and Arts 105 PUBLICATIONS 998 CITATIONS 11 PUBLICATIONS 205 CITATIONS SEE PROFILE SEE PROFILE Some of the authors of this publication are also working on these related projects: Internet of Things View project All content following this page was uploaded by Mogessie Ashenafi on 12 December 2015. The user has requested enhancement of the downloaded file. World Journal of Microbiology and Biotechnology 7,72-79 Production of tempeh from various indigenous Ethiopian beans M. Ashenafi and M. Busse Tflmpeh was prepared from unacidifled and acidified horse-bean, pea, chickpea and soybean. At the completion of fermentation, the various beans were compactly bound together by white mycelia, had a bland or yeast-like odour and a firm texture that sliced readily. Weight Increase was noted during soaking (75 to 80%) and fermentation resulted In a slight decrease In weight (1.4 to 5.4%). A sharp increase in pH and temperature was noted following active mycelial growth on the bean mass. Fermen­ tation resulted in loss of dry maHer. Only slight changes were observed In total crude protein. Water-soluble solids and water­ soluble proteins Increased by more than 60 and 40%, respectively. In sensory evalu­ ation tests, sauces made of the various products compared favourably with sauces made of meat or egg. Acceptable and nutritious tempeh can, thus, be produced from Indigenous Ethiopian beans. M, Ashenafi is with the Department of Basic SCiences. Awassa College of Agriculture, Addis Ababa University. P,O, Box 5, Awassa. Ethiopia; M, Busse is with. the Bakteriologisches Institut, S,V.F,A,. Weihen­ stephan. Technische Universital Munchen, 0-8050 Freising, Germany. M. Ashenafi is the corresponding author, • © 1991 Rapid Communications of Oxford Ltd, The use of microorganisms to process foods goes back to ancient times, Ferment~d foods are essential parts of diets in all regions of the world, A number of food fermentation processes, including those that yield dairy products, sausages, pickles, sauerkraut and bread have been extensively investigated and documented. But many other foods prepared by the action of diverse species of fungi, bacteria and yeasts on plant materials are little known outside their native countries (Hesseltine & Wang 1980). Food fermentation processes have several advantages, such as improving keeping quality and flavour (Hesseltine 1983), and addition of desirable nutrients not present in the original product (Steinkraus 1983a). Typically, fermentation does not greatly alter the amino acids in cereals and soybeans, but often it makes proteins more available (Au & Fields 1981). In many fermentations using soybeans, undesirable beany flavours are destroyed (Van Veen & Steinkraus 1970), trypsin inhibitor is inactivated (Hesseltine 1983) and flatulence factors are elimi­ nated (David & Verma 1981). Finally, in many instances, the use of microorgan­ isms to produce tasty, nutritious food requires less energy than conventional processing (Steinkraus 1983b). One of the several methods of legume fermentation that generate meat-like flavours and improve nutritional value is the tempeh process where partially cooked soybean cotyledons are knitted into a compact cake that can be used as protein-rich meat substitutes in soups. Indonesian timpeh offers the world a process of making low-cost protein-rich meat analogues of excellent nutritional quality (Steinkraus 1983b). Tempeh has been suggested as a possible source of low-cost protein for child-feeding programs in developing countries (Autret & Van Veen 1955). Although the most important and popular typ~ of tunpeh is made from soybeans, it may also be made from a variety of other substrates (Djien & Hesseltine 1979). The diet of the average Ethiopian consists of only a limited number of foods. ,For the most part, these are based on cereals supplemented, in certain cases, by a stew made of mainly pulses. Although the protein content of these legumes is about 20 to 25%, the traditional processing involved in preparing the stew decreases the protein content down to 14 to 17% (Agren et al. 1987). Thus it was attempted, in this study, to prepare tetnpeh from some of the legumes commonly consumed in Ethiopia, namely horse-bean, pea and chickpea, evaluate 72 '-~--------------~....- -.. - -...- -.. - -... Tempeh from Ethiopian beans its physical properties and nutritional quality and assess its acceptability if introduced into the country. Materials and Methods Preparation of Tempeh from the ~Various Legumes Tempeh was prepared following the methods of Steinkraus et al. (1965) with some modifications as described by Ashenafi & Busse (1989). For every experiment, 200 g hull-free, cracked horse-bean, pea or chickpea seeds were thoroughly washed with hot water and soaked in 600 ml tap water at 30°C for 24 h in 1000 ml beakers. Equal amounts of the various beans were also processed in a similar way, except that 1.5 ml of glacial acetic acid was added to the soak water. Soaking was at 30°C for 24 h. Soybeans were processed similarly for comparative purposes. The soaked beans were then cooked in the soak water at 100 c C for varying periods (see Table 1). After cooking, the beans were drained while still hot and immediately spread on a layer of sterile cloth and covered with another layer of sterile cloth, thus giving them a fairly dry surface. The beans were allowed to cool to about 37°C and mixed with spores of Rhizopus oligosporus (CBS 338.62) to give 1.2 x 106 spores/100 g cooked beans. R. oligosporus cultures were obtained from Centraalbur­ eau voor Schimmelcultures, The Netherlands. Spores of R. oligosporus were harvested with 5 ml sterile water from a growth on slants of 4% malt extract/0.5% peptone/1.5% agar, at pH 5.4 after incubation at 30°C for 5 days. Inoculated beans, 200 g, were packed into thin polyethylene bags which had perforations, made with a sewing needle, at 1 cm intervals on both sides (Djien & Hesseltine 1979). The bags were sealed and incubated at 30°C for about 35 to 40 h until the beans were tightly bound together into a compact cake by white mycelia. On completion of fermentation, the extent of Rhizopus growth on the beans and the odour and texture of the fermented products were evaluated. Determination of Temperature and pH The temperature of the fermenting beans was measured by placing the probe of a digital temperature measuring device (THERM 2283-2, West Germany) inside Table 1. Changes in weight during the different steps of tempeh processing from various beans. Weight (g) Substrate ----Dry beans Soaked and cooked beans Tempeh Horse-bean Unacidified Acidified 200 200 372 (86%) 352 (79%) 352 (-5%) 344 (-4%) Pea Unacidified Acidified 200 200 371 (86%) 365 (83%) 364 (-2%) 360 (-1%) Chickpea Unacidified Acidified 200 200 359 (80%) 350 (75%) 344 (-4%) 340 (-3%) Soybean Unacidified Acidified 200 200 407 (104%) 408 (104%) 400 (-2%) 396 (-3%) Figures in parentheses indicate percentage increase or decrease in weight. 73 M. A shenaji and M. Busse the fermenting bean mass. The pH of the samples was measured by placing the electrode of the pH meter into a slurry containing 1 in 5 dilution of the sample in sterile water. Proximate Ana!ysis Raw dehulled horse-bean, pea, chickpea and soybean and tempeh made from the various beans were analysed for dry matter, crude protein, crude fat, crude fibre, ash, nitrogen-free extracts, soluble proteins and soluble solids, as described by Krishina & Ranjhan (1980). Sensory Evaluation The various fermented products were cut into small pieces and separately cooked into wOf, a traditional Ethiopian hot spiced stew. A total of 100 students of A wassa College of Agriculture were requested to evaluate the odour, flavour and overall acceptability of the stew by sampling it with enjerra, a traditional Ethiopian pancake made of flours of Eragrostis tef. A nine-point hedonic scale was used, ranging from 'like extremely' (9 points) to 'dislike extremely' (1 point). The results were analysed using analysis of variance, and where two preparations were evaluated, the mean scores were compared using the t-test (Ihekoronye & Ngoddy 1985). Results Physical Properties of the Various Products On completion of fermentation, the cake was composed of the cooked beans compactly bound together by white mycelia. Sporulation did not occur unless incubation was continued for more than 45 h. During the fermentation process, mycelial growth was relatively slower in acidified beans than in unacidified ones. In general, excellent mycelial growth was seen, although, in a few cases, a slimy product with a foul odour was produced in unacidified horse-bean and pea tempeh. The odour of the fermented products was bland or yeast-like. Tempeh from horse-bean, pea and soybean, in general, had a bland odour. Tempeh from chickpea tended to have yeast-like odour. Tempeh made from the various beans, generally, had a firm texture and could be readily sliced. Chickpea tempeh tended to be much firmer than the other products. Yield of Tempeh All beans increased in weight (75 to 86%) during soaking (Table 1). Weight increase in horse-bean, pea and chickpea soaked in unacidified water was sig­ nificantly higher than in beans soaked in acidified water (P < 0.01). Fermentation resulted in loss of weight (1.4 to 5.4%) in all beans. pH and Temperature Changes The initial average pH of the various unacidified beans ranged between 5.0 and 5.5 and started to rise after about 18 h of fermentation until it reached the final value of 6.4 to 6.7 for chickpea and soybean tempeh and 7.2 to 7.4 for horse-bean and pea tempeh. Rise in pH always corresponded to active mycelial growth on the substrates. The a verage pH of the various acidified cooked beans ranged between 4.8 and 5.2. Similar increase in pH was noted during the fermentation process. Acidifica­ tion of beans usually delayed the appearance of mycelia by about 1 h, thereby delaying the corresponding rise in pH. The final pH of the acidified fermented products was 6.8 to 7.4 for horse-bean and pea tempeh, and 6.4 to 6.7 for chickpea and soybean tempeh. 74 Tempeh from Ethiopian beans Temperature of the fermenting beans did not increase until active mycelial growth started. It then rose steadily until the end of fermentation, where it reached lOoe to 12°C above the incubation temperature (Figure 1). Proximate Analysis of the Various Tempeh Products The fermentation of the various beans into tempeh resulted in loss of dry matter and decrease in crude fat and nitrogen-free extracts (Table 2). Although changes in total crude protein were slight, a marked increase in water-soluble proteins and water-soluble solids was noted. 45 45 PT HBT 40 40 ~ 35 35 -o o ......... 0.. E 30~~-+--~~-+~--+-~ o 30~~-+--~~-+~--+-~ o 5 10 15 20 25 30 35 40 Time (h) 45 45 CPT 00 5 10 15 20 25 30 35 40 Time (h) SBT h 40 40 35 35 30~~-+--~+--+-4--+-~ 30 i!?---I--+--+I--1---11---4---+1--11 o 5 10 15 20 25 30 35 40 Time (h) ........­ 0.. E (]) I­ o 5 10 15 20 25 30 35 40 Time (h) Figure 1. Temperature changes during the fermentation of unacidified (0) and acidified (6) horse-bean tempeh (HBT), pea tempeh (PT), chickpea tempeh (CPT) and soybean tempeh (SBT). 75 M. A shenaji and M. Busse Table 2. Proximate analysis of Tempeh made from the various beans. Dry maHer (%) Crude protein (%)* Crude fat (%)* Crude fiber (%)* Ash (%)* NFE (%)* Soluble protein (%)* Soluble solids (%)* Horse-bean (raw) Tempeh % increase 95.5 42.2 -55.8 26.8 28.1 +4.6 2.3 0.9 -60.8 6.8 10.9 +37.6 3.9 4.6 +15.2 69.8 55.5 -20.5 4.4 11.2 +60.7 7.3 12.4 +41.1 Pea (raw) Tempeh % increase 89.8 39.7 -55.8 22.6 25.7 +12.1 1.6 1.0 -37.5 1.6 2.6 +38.5 3.8 4.6 +17.4 70.4 66.1 -6.1 3.7 9.8 +62.3 4.1 7.4 +44.6 Chickpea (raw) Tempeh % increase 94.3 39.5 -58.1 22.6 24.1 +6.2 6.5 4.3 -38.9 3.0 4.8 +37.8 3.1 4.2 +26.2 64.8 62.6 -3.4 3.8 10.2 +62.7 4.3 7.6 +43.4 Soybean (raw) Tempeh % increase 93.7 34.2 -63.5 34.7 38.4 +9.6 16.7 12.1 -27.6 4.2 6.7 +37.3 4.0 5.1 +21.6 40.4 37.7 -6.7 3.8 11.3 +66.4 12.9 25.1 +48.6 * Dry matter basis. Sensory Evaluation of the Products Frequency distribution of scores for the various tempeh stews is presented in Figure 2. Stew made of horse-bean, pea or chickpea tempeh was liked to varying degrees by a large proportion of the judges (Figure 3). Only a small proportion detected a beany flavour in the various stews (Table 3). The various stews compared favourably with stew made of meat or egg. There was a significant difference between samples and judges (P < 0.05). Stew made of horse-bean tempeh scored 40 Horsebean tempeh Pea tempeh -- 30 D I/) Q) en "0 .20 Chickpea tempeh 20 '#. lliillillillill 9 8 7 6 5 4 ~ 3 10 2 c=J o Hedonic scale Figure 2. Frequency distribution of hedonic scores given to stews made of various tempeh products: 9---like extremely; 8---like very much; 7-like moderately; 6--like slightly; 5-neither like nor dislike; 4--dislike slightly; 3--dislike moderately; 2-dislike very much; 1-dislike extremely. 76 TempehJrom Ethiopian beans Table 3. Hedonic scores and tastes of various stews made from horse-bean, pea, and chickpea tempehs. Basis of stew Hedonic score* X Horse-bean Tempeh 7.14 Pea tempeh 6.52 6.72 Chickpea tempeh * 9--like % ludges SO Max Min Stew from meat 1.53 1.81 1.69 9 9 9 2 1 38 Stew from egg yolk Stew from beans 88 42 12 7 20 17 5 71 extremely; 5-neither like nor dislike; 1-dislike extremely. significantly higher than the other two stew samples (P < 0.05). No significant difference was observed between scores for stew samples made of pea or chickpea tempeh. Discussion Fresh tempeh made from the various beans was bound into a white compact cake as reported for soybean tempeh (Hesseltine & Djien 1979; Kronenberg 1984; Sutardi & Buckle 1985). Good mycelial growth on horse-bean was previously reported by David & Verma (1981) and Berghoffer & Werzer (1987). However, Robinson & Kao (1977) reported that chickpea and soybean tempeh had a yellowish colour, whereas horse-bean tempeh was greyish. According to our observations, the final colour of the finished product seems to depend on the extent of mycelial growth on the fermenting beans. Incubation for more than 45 h was usually followed by sporulation, although there is a report where sporulation started after 26 h of horse-bean tempeh fermentation (David & Verma 1981). Acidification of soak water resulted in a better mycelial growth and delayed sporulation. An earlier sporulation is not desired because it is usually accompanied by signs of deterioration, such as loss of pleasant taste, smell of ammonia and darkening of colour (Sudarmadji & Markakis 1978). The odour of fresh tempeh may vary depending on the type of substrate or even the variety of the same substrate. The odour of soybean tempeh is, for example, expressed as bland or slightly nutty (Hesseltine & Djien 1979), mushroom-like (Kronenberg 1974) or clean and pleasant (Steinkraus et al. 1960). Chickpea and horse-bean tempeh were reported to have alcoholic and ester-like aromas (Robinson & Kao 1977). The various types of tempeh in this study were firm and could be readily sliced, although Robinson and Kao (1977) reported a soft texture for horse-bean tempeh. The physical appearance of tempeh depends on the degree of microbial spoilage during fermentation (unpublished data). Unless the count of aerobic spore formers is not high enough to cause visible spoilage resulting in a slimy and putrid product, a relatively firm tempeh can be produced from all beans. Although unacidified beans have undergone some acidification during soaking, spoilage was often seen during the fermentation of unacidified horse-bean and pea tempeh. A proper acidification of the beans during soaking or use of a suitable lactic acid bacteria during fermentation (Ashenafi & Busse 1989) may inhibit an early proliferation of aerobic spore fonners, favour a good growth of mycelia and guarantee the production of an acceptable tempeh. Soaking and cooking are reported to result in loss of material by leaching (Steinkraus et al. 1960). Material loss in the form of heat was also observed during fermentation (Steinkraus et al. 1960). The sharp rise in temperature in our 77 Ai. A shenafi and M. Busse fermenting beans is in agreement with the observations of other workers (Stein­ kraus et al. 1960; Berghoffer & Werzer 1986). Deep penetration of Rhizopus hyphae in the bean cotyledon (Jurus and Sundberg 1976) and the production of extracellular enzymes by the mould (Wang & Hesseltine 1965) result in an extensive breakdown of the bean constituents (Steinkraus 1983a,b). Increase in soluble protein in the various beans in this study is in agreement with other reports (Steinkraus et af. 1960; Van Buren et af. 1972; Robinson & Kao 1977; Berghoffer & Werzer 1986; Paredes Lopez et af. 1987). Utilization of nitrogen-free extracts by the growing fungal mycelia may result in an increase of reducing sugars (Berghoffer & Werzer 1986). Decrease in crude fat is due to the lipolytic activity of R. oligosporus, which results in an increase of free fatty acids (Wagenknecht ef al. 1961). Since plant proteins are generally considered to be less available to humans, the high level of water-soluble proteins in the fermented beans is of significant importance in improving the diets of many people in developing countries. The results of the sensory evaluation tests imply that the product, although not yet introduced into Ethiopia, has a chance of being accepted by the population. The high comparability of the tempeh stews to meat and egg stews indicates the possibility of using tempeh as an analogue to the otherwise expensive animal proteins. Acceptability of fermented fempeh made from various beans is also reported by other workers (Berghoffer & Werzer, 1986; Paredes Lopez ef af. 1987). Acknowledgements Due thanks go to the Nutrition Laboratory of the Department of Animal Sciences and Technology, Awassa College of Agriculture, for performing the proximate analysis, and the Nutrition Laboratory of the Department of Home Science and Technology, Awassa College of Agriculture, for conducting the sensory evaluation tests. The technical assistance of Haile Alemayehu and Etenesh Tesfaye IS acknowledged. References AGREJ'.:, G., EKLUND, A. & LIEDEN, S.A. 1975 Food Composition Table jor Use in Ethiopia. Uppsala: Almqvst & Wiksell. ASHENAFl, M. & BUSSE, M. 1989 Inhibitory effect of Lactobacillus plantarum on Salmonella injantis, Enferobacter aerogenes and Escherichia coli during tempeh fermentation. Journal oj Food Protection 52, 169--172. Au, P.M. & FIELDS, M.L. 1981 Nutritive quality of fermented sorghum. Journal oj Food Science 40, 652~654. AUTRET, .M. & VAN VEEN, A.G. 1955 Possible sources of proteins for child feeding in underdeveloped countries. A merican Journal oj Clinical Nutrition 3, 234-238. BERGHOFER, E. & WERZER, A. 1987 Herstellung von Tempeh mit einheimischen Bohnen. Chemie, Mikrobiologie und Technologle der Lebensmittel10, 54-62. DAVID, 1.M. & VERMA, J. 1981 Modification of tempeh with the addition of Bakla (I 'icia jaba). Journal oj Food Technology 16, 39--50. DIlEN, K.S. & HESSELTINE, CW. 1979 Tempeh and related foods. Economic Microbio­ logy 4, 115-140. HESSELTINE, CW. 1983 The future of fermented foods. Nutritional Review 41, 293-301. HESSELTINE, CW. & WAJ'.:G, H.L. 1980 The importance of traditional fermented foods. Bioscience 30, 402-404. IHEKORONYE, A.I. & NGODDY, P.O. 1985 Integrated Food Science and Technology jor the Tropics. London: Macmillan. JURUS, A.M. & SUNDBERG, W.]. 1976 Penetration of Rhizopus oligosporus into soybean in tempeh. Applied and Environmental Microbiology 32, 284-287. KRlSHINA, G. & RANJHAN, S.K. 1980 Laboratory "A,fanual jor Nutritional Research. ~ew Delhi: Vikas. KRONENBERG, H. J. 1984 Reduction of incubation time for tempeh fermentation by use of pregerminated inoculum. Economic Botany 38, 433-438. 78 Tempehfrom Ethiopian beans PAR;\DES-LOPEZ, 0., H;\RRY, G.I. & MO!>.iTES-RIVERA, R. 1987 Development of a fermentation procedure to produce a tempeh-related food using common beans as substrates. Biotechnological Letters 9, 333-338. ROBINSON, R.J. & KAO, C. 1977 Tempeh and miso from chickpea, horse bean and soybean. Cereal Chemistry 54, 1192~ 1197. STEI:-.JKRAUS, K.H. 1983a Traditional food fermentations as industrial resources. Acta Biotnhnology 3, 3-12. STEINKRAUS, K.H. 1983b Progress in preservation of food through fermentation. In Chemistry and World Food Supplies .. The Nnv Frontiers. CHEMRA If/N Il, ed. Shemilt, LW. pp 421~435. Oxford: Pergamon Press. STEINKRAUS, K.H., HWA, Y.B., VAN BUREN, J.P., PROVVIDENTI, M.L & HA:-.JD, D.B. 1960 Studies on tempeb--an Indonesian fermented soybean food. Food Research 25: 777~788. STEINKRAUS, K.H., VAN BUREN, J.P., HACKLER, LR. & HAND, D.B. 1965 A pilot plant process for the production of dehydrated teJllpeh. Food Technology 19, 63-68. SUDARMADJI, S. & MARKAKIS, P. 1978 Lipid and other changes occurring during the fermentation and frying of tempeh. Food Chemistry 3, 165-170. SUTARDI, & BUCKLE, K.A. 1985 Phytic acid changes in soybean fermented by traditional inoculum and six strains of Rhizopus oligosporus. Journal of Applied &fteriology 58, 539--543. VAN BUREN, J.P., HACKLER, L.R. & STEINKRACS, K.H. 1972 Solubilization of soybean tempeh constituents during fermentation. Cereal Chemistry 49, 20&-21 L VAN VEEI', A.G. & STEINKRAUS, K.H. 1970 Nutritive value and wholesomeness of fermented foods. Agrifulturaf and Food Chemistry 18, 576-578. WAGENKNECHT, A.C., :Y1ATTICK, L.R., LEWIN, L.M., HAND, D.B. & STEINKRAUS, K.H. 1961 Changes in soybean lipids during tempeh fermentation. Journal of Food Science 26, 3H376. WANG, H.L. & HESSELTINE, C.W. 1965 Studies on the extracellular proteolytic enzymes of Rhizopus oligosportls. Canadian Journal of Microbiolqgy 11, 727~ 732. (Received 14 June 1990; ret'ised 3 September 1990; accepted 25 September 1990) 79 -----~ View publication stats ..... -~.~.-~ ...... -~.~----- ..... ----~ ..... ---~