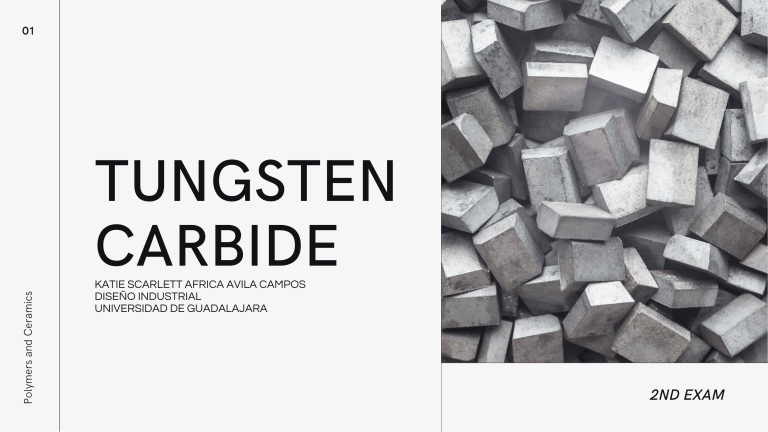

01 TUNGSTEN CARBIDE scimareC dna sremyloP KATIE SCARLETT AFRICA AVILA CAMPOS DISEÑO INDUSTRIAL UNIVERSIDAD DE GUADALAJARA 2ND EXAM 02 Binding tungsten and carbon, it forms an extremely dense crystal structure called hexagonal crystal, whose Young’s modulus is approximately 550 GPa, which is nearly two times that of steel. Properties scimareC dna sremyloP HIGH HARDNESS HIGH STRENGHT AT HIGH TEMPERATURE HIGH RESISTANCE TO CORROSION The Mohs’ hardness of tungsten carbide is “9.” It boasts a level of hardness second to diamond. Since it has high strength at high temperature and low thermal expansion coefficient, it is an optimal raw material for cutting tools to be used in a high-temperature and high-speed environment. Tungsten carbide is an extremely stable substance, and it does not oxidize at normal temperatures in air. In addition, it is not likely to form a solid solution with various elements, and keeps stable characteristics even in severe environments. 03 RESISTANCE TO OXIDATION Oxidation occurs at approximately 300℃ and reaction occurs rapidly at approximately 700℃ to form an oxide (WO₃) when its powder is heated in an oxygen-containing atmosphere. CHARACTERISTICS CHEMICAL RESISTANCE Although it does not dissolve in water, hydrochloric acid or sulfuric acid, it dissolves in nitic acid. scimareC dna sremyloP REACTIVITY Reacts with chlorine at 400℃ or higher. Reacts with fluorine at 18℃. MANUFACTURING PROCESSES OF TUNGSTEN CARBIDE POWDER FROM FINE TO COARSE GRAIN TUNGSTEN OXIDE POWDER HYDROGEN REDUCTION TUNGSTEN POWDER MIXTURE OF CARBON TUNGSTEN POWDER + CARBON POWDER CARBONIZATION PROCESS scimareC dna sremyloP PULVERIZATION PROCESS SIEVING PROCESS TUNGSTEIN CARBIDE POWDER ( 0.5 ~ 15 MICRÓMETRO ) SSECORP NOITCUDER 04 05 THE MANUFACTURING PROCESS OF A TUNGSTEN CARBIDE RING scimareC dna sremyloP Tungsten with carbon and other elements are ground into a powder and then compressed with high heat and pressure dies to form a ring blank. The blank is then fired in an oxygen-free furnace at an astounding 6,200 degrees Fahrenheit. This process called sintering creates the hardest metal alloy used in making jewelry. The ring is then cut and shaped using diamond tools with up to 40 total separate steps required for completion. The cutting and shaping of a tungsten ring is similar in many ways to the cutting and polishing of a rough diamond. Precious metal Inlay rings with gold, silver or platinum are created by grinding a channel in the center of the ring and precisely "swedging" the metal into the channel under extreme pressure. The ring is then skillfully polished with diamond polishing tools and wheels creating a permanent luster and polish not possible with other metals. A Tungsten Carbide ring will remain polished forever, and is virtually impossible to scratch. It is a unique metal that epitomizes today's technologically advanced man more than any other. 06 THE DESIGN: TUNGSTEN CARBIDE RING Tungsten Carbide is the only rare and exotic metal that can promise a permanence in polish and finish that will endure until the end of time with your tungsten wedding bands. The original pattern and design in many gold rings will all but disappear after several years. Tungsten Rings will maintain an everlasting beautiful and shiny finish. The heavy weight and the enduring finish of a tungsten carbide ring, speak of commitment, security and an everlasting bond. Tungsten Rings are the most wear-resistant rings available on the planet. Is about 10 times harder than 18K Gold, 5 times harder than tool steel, and 4 times harder than titanium. Tungsten measures between 8 and 9 on the Mohs hardness scale. (Diamonds are a 10 - the highest.). Due to their extreme hardness, Tungsten Rings will hold their shape and shine longer than any ring on the market, they will not bend, and they have been referred as "permantly polished rings". scimareC dna sremyloP