FOUNDATION Fieldbus Wiring & Installation Guide

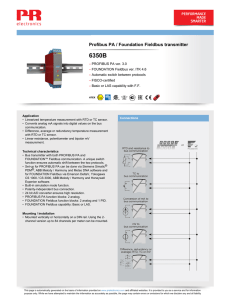

advertisement