Lipase Production Optimization: Neural Networks vs. Response Surface

advertisement

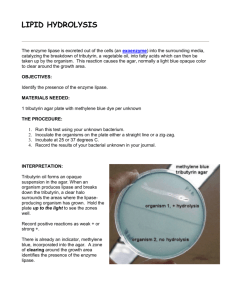

Biocatalysis and Agricultural Biotechnology 25 (2020) 101619 Contents lists available at ScienceDirect Biocatalysis and Agricultural Biotechnology journal homepage: http://www.elsevier.com/locate/bab Comparative study on modeling by neural networks and response surface methodology for better prediction and optimization of fermentation parameters: Application on thermo-alkaline lipase production by Nocardiopsis sp. strain NRC/WN5 Mohamed M. Abdel Aziz a, Eman W. Elgammal a, *, Roba G. Ghitas b a Chemistry of Natural and Microbial Products Department, Pharmaceutical Industries Research Division, National Research Centre, El Buhouth St., Dokki, 12311, Giza, Egypt b Online NeuroSolver Co., El-Sheikh Zayed City, Giza, Egypt A R T I C L E I N F O A B S T R A C T Keywords: Neural networks Response surface methodology Plackett-Burman Box-Behnken Lipase Nocardiopsis sp Artificial neural network is a mathematical approach that has been utilized with great success in system design, modeling, prediction and optimization. Statistical design has been used for long years in improving microbial fermentations. The current work intended to compare both of the two strategies in optimizing production of thermo-alkaline lipase by Nocardiopsis sp. strain NRC/WN5. The preliminary investigation showed intensive effects of fermentation medium type, time course and their interaction on lipase production. In the best medium, significant effects of carbon source, inorganic and organic nitrogen sources were realized (p ¼ 0.0287, p ¼ 0.00076 and p ¼ 0.000015, respectively). Plackett-Burman design showed significant effects of ten variables on lipase production. The most important factors were sodium chloride, time course and medium pH which possessed more than 78% of total effect exerted on lipase production. Basing on these three factors, very sig­ nificant model (p ¼ 0.0005) was conducted through Box-Behnken design. To get the best model of neural network, a comparative study on five different models of neural networks was accomplished. The highly pre­ dictive model was that based on LBFGS optimization function, sigmoid activation function, 150 iterations and 100 neurons in hidden layer. Coupled with genetic algorithm, the predictive model was used to optimize and predict the variables of optimum fermentation which were experimentally validated in comparison with that obtained from two-step statistical designs. Practical validation showed superiority of lipase production in fermentation developed by neural network coupled with genetic algorithm (62.21 � 1.7 U/ml) over that developed by two-step statistical design (50.11 � 2.6 U/ml). 1. Introduction To meet the increasing industrial demand for enzymes, new strate­ gies in optimization of enzyme production should be targeted to get the advantages of increasing the yield as well as getting the privilege of reducing the production cost. Lipases (EC 3.1.1.3) are hydrolases that catalyze hydrolysis, esterification and transesterification reactions of lipids. They have great biotechnological applications in many fields (Bhosale et al., 2016) such as pharmaceutical industries, medical di­ agnostics, fine chemical synthesis, cosmetics, detergent formulation, biofuel production, leather processing, processing of food and feed, acylation reactions, synthesis of esters and separation of racemic mix­ tures (Schmid and Verger, 1998; Sharma et al., 2001; Masomian et al., 2013; Guerrand, 2017). As such, lipases come in the third order after proteases and amylases in the total sales volume (Hasan et al., 2006) and it was predicted that lipase market will reach 590.5 million dollars by 2020 (Bhosale et al., 2016). Microbial lipases generally are preferred than animal and plant li­ pases due to ease of production, their high activity and stability at broad range of pH and temperature (Hasan et al., 2006), their broad substrate specificity and stability in organic solvents (Lescic et al., 2004). More­ over, lipases produced from organisms isolated from extreme habitats, * Corresponding author. Chemistry of Natural and Microbial Products Department, Pharmaceutical Industries Research Division, National Research Centre, El Buhouth St., Dokki, 12311, Giza, Egypt. E-mail address: emanelgammal50@yahoo.com (E.W. Elgammal). https://doi.org/10.1016/j.bcab.2020.101619 Received 28 February 2020; Received in revised form 16 April 2020; Accepted 19 April 2020 Available online 24 April 2020 1878-8181/© 2020 Elsevier Ltd. All rights reserved. M.M. Abdel Aziz et al. Biocatalysis and Agricultural Biotechnology 25 (2020) 101619 like hot springs (Lee et al., 1999) and high salty or sugary environments (Ghanem et al., 2000), were found to have new unique properties due to their special stability. The most common microbes in production of li­ pases of diverse industrial applications are Aspergillus sp., Candida sp., Rhizopus sp., Yarrowia lipolytica., Humicola sp., and Pseudomonas sp. (Guerrand, 2017). Although the genus Nocardiopsis is well known resource of extracellular enzymes (Bennur et al., 2014) and many valuable metabolites (Bennur et al., 2015), its ability to produce lipases was recorded in very few reports (Gandhimathi et al., 2009; Chakra­ borty et al., 2015) without any interest in optimization of lipase production. Many techniques and strategies were employed in recent decades for improving microbial fermentation (Kennedy and Krouse, 1999; Singh et al., 2017). Each of such techniques and strategies has its own ad­ vantages and disadvantages and so employing different optimization techniques in combination helps greatly to attain the ultimate optimi­ zation (Singh et al., 2017). Statistical optimization was employed in considerable large number of literatures (Kennedy and Krouse, 1999; Singh et al., 2017). In most cases, statistical optimization was achieved through preparatory screening step using Plackett-Burman design to assess the effect of different variables with minimum number of runs, and such step should be followed by subsequent step to get a fine depict about the action and interactions between the most affecting factors (Kennedy and Krouse, 1999). Artificial neural network (ANN) is a mathematical approach that has been utilized with great success for system design, modeling, prediction, optimization and control due to its ability to learn, filter noisy signals and generalize information through training procedures (Rajendran and Thangavelu, 2012). The principle behind ANNs is to mimic the func­ tioning and learning process of a human brain using an artificial neuron (Sewsynker-Sukai et al., 2017). Its applications in optimization of mi­ crobial fermentation are in continuous enormous growth (Rajendran and Thangavelu, 2012; Sewsynker-Sukai et al., 2017; Singh et al., 2017). In addition, many studies employed ANNs, in comparison with statisti­ cal methods, for optimizing production of some enzymes such as L-asparaginase (Baskar et al., 2011), protease (Dutta et al., 2004) and lipase (Ebrahimpour et al., 2008). Nevertheless, such studies used single statistical optimization step based on response surface methodology to be compared with ANNs. Genetic algorithm (GA) is an algorithm that mimics the process of mutation and is based upon the principle “survival of the fittest” (Singh et al., 2017). It is used to solve a variety of opti­ mization problems and so to predict the conditions at which the targeted variable (response) get its highest value. Targeting the optimization of lipase production, the current inves­ tigation intended to employ two optimization techniques (response surface methodology and neural network coupled with genetic algo­ rithm) in a comparative study between their effectiveness in optimiza­ tion of fermentation parameters. containing 50 ml of fermentation media. Flasks were inoculated with 0.5 ml/flask of spore suspension (containing 106-107 spore/ml) prepared from five-day old slant of Nocardiopsis sp. strain NRC/WN5. Immediately after inoculation, 1 ml of sterile olive oil (autoclaved separately) was added to each flask under sterile condition. Then flasks were incubated in shaking incubator at 30 � C�2 and 150 rpm. Fermentations was done in duplicate flasks for each treatment and after separate analysis of each flask, results were expressed as arithmetic mean � standard error of the mean. 2.2.1. Fermentation media Four nutritional media were initially tested for its ability to support the highest yield of lipase. Composition of these media (in g/l) was as follow: Medium I, the basal medium used by Aly et al. (2012), contained: glucose, 10 and peptone, 30. Medium II, modified from Veerapagu et al. (2013), contained: peptone, 5; NH4H2PO4, 1; NaCl, 2.5; MgSO4⋅7H2O, 0.4; CaCl2, 0.4; tween 80, 20 drops. Medium III, modified from Rajeshkumar et al. (2013), contained: peptone, 5; NH4H2PO4, 1; NaCl, 1.25; MgSO4⋅7H2O, 0.2 and CaCl2, 0.2. Medium IV, modified from Sel­ vam and Vishnupriya (2013), contained: starch, 20; peptone, 20; NH4Cl, 3.8; MgSO4, 1.0 and K2HPO4, 5.0. For all media, NaCl in a concentration of 5% was added to other components and pH was adjusted at 8 before sterilization. Also, addition of sterile olive oil to each flask (1 ml per volume inside the flask) was done to act as inducer for lipase production. 2.2.2. Investigation of different carbon and nitrogen sources Different carbon sources such as glucose, fructose, mannose, galac­ tose, malt extract, and dextrin were added separately as replacements of starch in a concentration of 20 g/l in medium showed the highest lipase yield (medium IV). The medium free of starch was used to test the ability of olive oil (which would be inoculated in concentration of 1 ml per volume inside the flask) to act as nutritional carbon source beside its role as an inducer for lipase production. Ammonium chloride in medium IV was replaced by different inor­ ganic nitrogen sources which were added in a concentration of 3.8 while organic nitrogen sources were tested as replacements of peptone in a concentration of 20 g/l. The inorganic nitrogen sources were ammonium sulphate, ammonium hydrogen phosphate, ammonium molybdate and potassium nitrate while the organic nitrogen sources included yeast extract, casein hydrolysate, soybean meal and corn steep liquor. 2.3. Lipase activity assay The lipolytic activity was determined by spectrophotometric method using p-nitrophenyl palmitate (p-NPP) as substrate as described by Chakraborty and Raj (2008) with some modifications. Solution of p-NPP (10 mM) in isopropanol was prepared and a volume of 20 μl of this solution was transferred to a test tube containing 300 μl of buffer solu­ tion (50 mm of disodium hydrogen phosphate/sodium hydroxide buffer, pH 11). To this buffered substrate suspension, sample of crude enzyme (30 μl) was added and the test tube was then incubated in a water bath at 55 � 2 � C for 30 min under continuous shaking (150 rpm). Excess so­ dium carbonate solution (3 ml, 0.1 M) was added, to ensure sufficient alkaline medium, and then the contents of each tube were filtered using nylon syringe filter (0.45 μ) before measuring the absorbance at 400 nm by Jasco UV-VIS spectrophotometer. For each sample, blank was pre­ pared typically like the sample without adding p-NPP substrate. Read­ ings of standard p-NP concentrations in Na2CO3 solution (0.1 M) was used to get product concentrations in samples. The coefficient of extinction (ε) of p-NP under the conditions described was determined as 21 mM 1 cm 1. One unit of enzyme activity was defined as the amount of enzyme needed to liberate 1 μM min 1 of p-NP under the standard assay conditions (Mander et al., 2012). 2. Materials and methods 2.1. Microorganism The microorganism used was previously isolated from the high salinity and alkalinity environment and characterized, basing on 16S rRNA gene sequence, as Nocardiopsis sp. strain NRC/WN5 (accession number MG970558). This strain was kindly provided from the culture collection at Natural and Microbial Products Chemistry Department, National Research Centre (NRC), Dokki, Giza, Egypt. Culture was maintained on starch-casein agar slants (Atlas, 1997) supplemented with 5% NaCl and pH was adjusted at 8 before autoclaving. 2.2. Fermentation Fermentation was carried out in Erlenmeyer flasks (250 ml) 2 M.M. Abdel Aziz et al. Biocatalysis and Agricultural Biotechnology 25 (2020) 101619 incubation. In order to realize the significance of the effects of medium type and time course, analysis of variance (ANOVA) for the obtained data was conducted and presented in Table 1. As shown in Table 1, type of medium and incubation time course were of highly significant role (p-value 32 � 10 9 and 28.4 � 10 8 respectively), and there was a significant interaction between them (p-value 27.6 � 10 6) on lipase production. Increased lipase yield in medium I and IV justified a sug­ gestion that the presence of carbohydrates as glucose in medium I and starch in medium IV supported the enzyme production and they were co-metabolized in synergism with lipase production (Arora et al., 2015). Also, the results in Fig. 1 showed that after 5 days of incubation, the production rate decreased which may be attributed to the consumption of the nutrients, change in medium pH or production of proteases that hydrolyze lipase (Nouroozi et al., 2015). 2.4. Statistical design and modeling Statistical designs (Plackett-Burman and Box-Behnken), analysis of variance (ANOVA) of data, regression analysis to get polynomial co­ efficients and equations, three-dimensional response surface plots and predictions of the optimum levels of variables were achieved using the “Design Expert‟ software (Version 7.0.0, Stat-Ease Inc., Minneapolis, USA) statistical package. 2.5. Neural network modeling Artificial neural networks was constructed using MATLAB software version 7.1. 2.6. Statistical calculations 3.2. Effect of different carbon sources on productivity of lipase Calculations of standard deviation, ANOVA single factor and two factors at confidence level of 95% were conducted through Microsoft Office Excel 2007. The standard error is an indicator of how close the sample mean is to the population mean whereas the standard deviation is a measure of how widely values are dispersed from the average value. The standard error of the mean was calculated from standard deviation according to Lee et al. (2015) using the following equation: The most critical factor which affects the microbial enzyme pro­ duction is the carbon source. So, starch in medium number IV was replaced by different carbohydrates such as glucose, fructose, mannose, galactose, malt extract and dextrin. A medium devoid of carbohydrates was applied to test the ability of olive oil (2%) to act as a carbon source for microbial growth beside its role as inducer for lipase. The results depicted in Fig. 2 revealed that lipase production is dependent on the type of sugar as recorded previously in elsewhere (Arora et al., 2015). ANOVA analysis (inside the frame in Fig. 2) helped to ensure that variation in lipase concentration between different carbon sources is significant comparing with variation between replicates. At p-value of 0.0287 which is smaller than 0.05 and with calculated F-value of 4.308 which is greater than F-critical value (F crit ¼ 3.5), there was a signifi­ cant change in lipase concentration with the type of carbon source. Dextrin was the best carbon source (afforded 36.6 � 3.6 U/ml) between other tested sources. However, it could not potentiate any increase in lipase concentration than that in case of starch in control (36.8 � 3.1 U/ml). Other easily utilized sugars and olive oil (as a carbon source) were found to have an inhibitory effect on the production (http://www. ejbiotechnology.info/index.php/ejbiotechnology/article/view/v14n4 -8/1334 Lee et al., 1999). In this context, Bapiraju et al. (2005) obtained similar results with Rhizopus sp. BTNT-2 using potato starch (33.9 U/ml). Also, Espinosa et al. (1990) reported that dextrin and starch were the best carbohydrate for maximum lipase production. However, lower yields were observed by Candida rugosa using starch (Dalmau et al., 2000). On the other hand, Osman et al. (2012) found that the synergistic effect of glucose, sucrose and fructose with oil substrate inhibited the production of lipase. Standard error of the mean ¼ SD / √n Where SD is the standard deviation and n is the sample size. 3. Results and discussion 3.1. Lipolytic activity of Nocardiopsis sp. strain NRC/WN5 in different fermentation media Generally, lipase production in most cases is dependent on the presence of an inducer in the fermentation medium (Lotti et al., 1998). From the previous reports, it was observed that variations in culture media have different effects on the enzyme productivity and that effects is dependent on the type of microorganism (http://www.ejbiotechnolo gy.info/index.php/ejbiotechnology/article/view/v14n4-8/1334 He and Tan, 2006) and the incubation time (Soleymani et al., 2017). To test lipase production, four different media containing olive oil as inducer were used. Fig. 1 showed that the maximum yield (35.9 � 4.0 U/mL) was obtained by applying medium IV and the next favorable one was medium I giving enzyme activity reached 28.3 � 2.1U/ml after 5 days of 3.3. Effect of different inorganic and organic nitrogen sources on lipase production by Nocardiopsis strain NRC/WN5 Although starch and dextrin afforded nearly the same amount of lipase, superiority of starch over dextrin on economic base, availability and ease of extraction from many natural sources clearly justified the choose of starch as the carbon source in subsequent studies aiming at investigating the effect of nitrogen source. In many cases, the combi­ nation of organic and inorganic nitrogenous forms is preferred for some microorganisms (Dong et al., 1999). To investigate the role of nitrogen Table 1 Two-factor ANOVA analysis for lipase production by Nocardiopsis strain NRC/ WN5 in different media at different time courses. ANOVA analysis at 0.05 significance level Fig. 1. Production of lipase by Nocardiopsis strain NRC/WN5 in different fermentation media. Bars in the figure represent the standard error of the mean in replicates. 3 Source of Variation F p-value F crit Media Time course Interaction 47.92509 35.15399 10.88468 0.000000032 0.000000284 0.000027657 3.238872 3.238872 2.537667 M.M. Abdel Aziz et al. Biocatalysis and Agricultural Biotechnology 25 (2020) 101619 Table 2 Codes and levels of the factors studied by Plackett-Burman design. Factor code Name (Units) Low level ( 1) Mean level (0) High level (þ1) Std. Dev. A B C Starch conc. (g/l) Peptone conc. (g/l) Amm. molybdateconc. (g/l) Magnesium sulphate conc. (g/l) Dipotassium hydrogen phosphate conc. (g/l) Sodium chloride conc. (%) Medium pH Oil conc. (%) Tween 80 conc. (g/l) Inoculum size (%) Time course (day) 10.00 4.00 1.00 15.000 12.000 2.400 20.00 20.00 3.80 4.804 7.686 1.345 0.20 0.600 1.00 0.384 1.00 3.000 5.00 1.922 0.000 2.500 5.00 2.402 8.00 1.00 0.000 1.00 4.00 9.000 2.000 1.000 2.000 5.000 10.00 3.00 2.00 3.00 6.00 0.961 0.961 0.961 0.961 0.961 D E F Fig. 2. Effect of different carbon sources on lipase production by Nocardiopsis strain NRC/WN5. Bars in the figure represent the standard error of the mean in replicates. ANOVA analysis of data was indicated inside the frame. G H J K L sources in optimization of lipase production; different inorganic and organic nitrogen sources were added as replacements of ammonium chloride and peptone respectively to other components of medium IV. Fig. 3A and B, with ANOVA analysis data in frames, ascertained an intrinsic change in lipase concentration by variation in type of nitrogen source. The results showed that the best lipase activities (42.4 � 3.3 U/mL and 40.9 � 1.8 U/mL) were observed by ammonium molybdate and peptone as inorganic and organic nitrogen sources respectively. Many previous studies reported that peptone is considered as an inducer for lipase production from different bacteria due to its release of NH4þ ions into the medium which stimulates the microbial growth and consequently enhances the enzyme production (Song et al., 2001). Concerning the inorganic nitrogen source of ammonium molybdate, Bayoumi et al. (2007) reported that it yielded the highest productivity of lipase by G. stearothermophilus B-78. On the other hand, ammonium hydrogen phosphate, casein hydrolysate and soy bean meal showed a negative effect on the enzyme production. Similarly, Bora and Bora (2012) found the same result with Bacillus sp. using soy bean meal. 3.4. Modulating the fermentation parameters of lipase production via two successive statistical steps 3.4.1. Plackett-Burman design Medium IV after being improved with the most suited carbon and nitrogen nutrition was then directed to further optimization through statistical design. Plackett-Burman design was conducted to study the effect of eleven variables on lipase production by Nocardiopsis strain NRC/WN5. The eleven variables were coded and screened at high (þ1) and low ( 1) levels and one central point (0) as indicated in Table 2. The design consisting of 13 runs with corresponding lipase yield was shown in Table 3. Analysis of variance (ANOVA) of the response (lipase pro­ duction) in relation to the tested variables was shown in Table 3 and it revealed very significant model (p ¼ 0.0019) having an F-value of 169416.74 which implies that the model is significant. There is only a 0.19% chance that a “Model F-Value” could occur due to noise. Ac­ cording to outputs shown in Table 4, ten variables (coded as A, B, C, D, E, F, G, H, J, L) are of significant effect (“Prob > F00 was less than 0.05). The effects of the tested variables were depicted in Fig. 4. The highest effect was shown by sodium chloride concentration (standardized effect of 19.1) followed by time course (10.0) and the third highest effector was the medium pH which was of negative effect ( 8.1) inside studied range of pH from 8 to 10. The significant role of sodium chloride concentration and medium pH on lipase production by Nocardiopsis strain NRC/WN5 inferred the inherited characteristics of such strain which had been isolated from haloalkaline environment (Purohit et al., 2014). The percent contribution of the different tested factors in total effect on lipase production (Fig. 5) showed that sodium chloride possessed more than 53% of effect on lipase production, and the three highest factors (sodium chloride, time course and medium pH) had more than 78% of total effect exerted on lipase production by Nocardiopsis sp. As such, the three factors were chosen for second statistical step of Box-Behnken design to realize their effects and interactions between them. 3.4.2. Box-Behnken design and response surface methodology Box-Behnken design is three-level fractional factorial design (Ken­ nedy and Krouse, 1999) and was employed here to improve the effect of most effective variables through modulating the interaction between them (Venkateswarulu et al., 2017). The design was conducted at three levels of each of the studied factors NaCl concentration, medium pH and incubation time (coded by A, B and C respectively) and constituted of 15 runs with three center points. The design with corresponding lipase concentration for each run, as shown in Table 5, was analyzed by ANOVA and very significant quadratic model was obtained (Table 6). Fig. 3. Effect of different inorganic (A) and organic (B) nitrogen sources on lipase production by Nocardiopsis strain NRC/WN5. Bars in the figure represent the standard error of the mean in replicates. ANOVA analysis of data was indicated in frame inside each plot. 4 M.M. Abdel Aziz et al. Biocatalysis and Agricultural Biotechnology 25 (2020) 101619 Table 3 Plackett-Burman experimental design for eleven factors affecting lipase production by Nocardiopsis strain NRC/WN5. Run Levels of different factors A 1 2 3 4 5 6 7 8 9 10 11 12 13 1 1 1 0 1 1 1 B 1 1 1 1 1 1 1 1 1 0 1 1 1 Lipase production (U/ml) C 1 1 1 1 1 1 1 1 1 1 0 1 1 D 1 1 1 1 1 1 1 1 0 1 1 1 1 E 1 1 1 1 1 1 1 1 1 0 1 1 1 F 1 1 1 1 1 1 0 1 1 1 1 1 1 1 1 1 G H 1 1 1 1 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 1 J 1 1 1 1 1 1 1 1 0 1 1 1 1 K 1 1 1 1 1 1 1 1 1 0 1 1 1 L 1 1 1 1 1 1 1 1 0 1 1 1 1 1 1 1 1 1 1 7.45 0.00 14.17 13.76 19.15 47.40 19.59 20.24 24.12 0.56 13.99 1.36 28.28 Table 4 Statistical analysis of Plackett-Burman model. Source Sum of Squares df Mean Square F Value p-value Prob > F Model A-Starch conc. B-Peptone conc. C-Amm. molybdate conc. D-MgSO4 conc. E-K2HPO4 conc. F–NaCl conc. G-Medium pH H-Oil conc. J-Tween 80 conc. L-Time course 2019.36 114.77 13.88 55.48 9.59 79.54 1097.71 197.71 59.90 88.08 302.73 10 1 1 1 1 1 1 1 1 1 1 201.94 114.77 13.88 55.48 9.59 79.54 1097.71 197.71 59.90 88.08 302.73 169400 96284.19 11643.92 46544.17 8045.26 66730.55 9.209Eþ005 1.659Eþ005 50251.39 73892.43 2.540Eþ005 0.0019 0.0021 0.0059 0.0030 0.0071 0.0025 0.0007 0.0016 0.0028 0.0023 0.0013 significant Fig. 4. Effect of different tested factors on lipase production by Nocardiopsis strain NRC/WN5. The model has p-value of 0.0005 and F-value of 36.95 which indicated that the model is significant. There is only a 0.05% chance that a model F-value could occur due to noise. The model showed that the terms A, C, BC and C2were significant (values of “Prob > F00 were less than 0.05). Significant interaction between factors B and C was observed (p ¼ 0.0063). The lack of fit F-value of 6.63 implies that the lack of fit is not significant relative to the pure error. Non-significant lack of fit indicates that the model is valid to navigate the design space. Optimization through response surface methodology (RSM) was then constructed basing on the data of Box-Behnken design. RSM uses the data obtained to develop a mathematical equation describes the model and predicts the response from studied factors (Panda et al., 2007) in a three-dimensional (surface) plot of the response with combination of each two of the studied factors. The final equation describing the effect of the three factors on lipase production is the following quadratic equation: Lipase concentration ¼ 474.01754 þ 0.30561A - 1.87736B - 117.28678C þ 0.35272AB - 0.040715AC - 9.39407BC - 0.28157A2 þ 4.25190B2 þ 12.81652C2 The three-dimensional surface plot for the response (lipase produc­ tion) in relative to the combination of two of the studied factors was depicted in Fig. 6 as shown below. 3.5. Modulating the fermentation parameters of lipase production by Nocardiopsis strain NRC/WN5 using artificial neural network approach Artificial neural networks are aids used to relate data of input vari­ ables (data of parameters assumed to affect certain response) to output 5 M.M. Abdel Aziz et al. Biocatalysis and Agricultural Biotechnology 25 (2020) 101619 Fig. 5. Percent contribution of different tested factors on lipase production by Nocardiopsis strain NRC/WN5. into sets (A, B, C, D and E) as specified in Table 7. The different sets of parameters were then used to conduct the different neural network models. Neural network algorithm was trained on data of the thirteen different runs used in Plackett-Burman design (Table 3) and consisted of three layers (input, output and one hidden layer between them). Fig. 7 showed the relation between actual and predicted values of lipase concentration for neural networks models constructed by the different parameter sets. In each plot in Fig. 7, the straight line inter­ secting the origin point represents the line of zero absolute error, so the distribution of points more close to such line reveals better predictability of the model. It was clearly observed that the models conducted by sets A, D and E had good predictability comparing with those of sets B and C. Change in optimization function from LBFGS in set A to Adam in set B resulted in dramatic decrease in predictability which strongly pointed out to the sensitivity of the model to optimization function and also reflected the special superiority of LBFGS function in prediction models of the current biological system. The mean absolute error between actual and predicted values of the different models presents a measuring aid for accuracy of prediction. Comparison between the mean absolute errors of different models was depicted in Fig. 8. The results in Fig. 8 showed that mean absolute error in set B model (12.23 U/ml) is 233 times greater than that of set A model (0.05 U/ml) which reflected the ability to attain tremendous improve in prediction by changing the optimization function from Adam to LBFGS. All neural networks con­ structed by LBFGS optimization function were of obvious reduced mean absolute errors which have not exceed 0.1 U/ml as in models of sets A, D and E (mean absolute errors were 0.08, 0.06 and 0.01 U/ml respec­ tively). Although sigmoid activation function is used commonly in back propagation algorithm (Rajendran and Thangavelu, 2012), tangent hy­ perbolic (Tanh) function showed better prediction in the current investigation according to the drop in mean absolute error from 0.05 to Table 5 Box-Behnken design for studying the most important factors affecting lipase production by Nocardiopsis strain NRC/WN5. Run Factor A, Sodium chloride conc. (%) Factor B, Medium pH Factor C, Time course (day) Lipase production (U/ ml) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 5 5 5 7.5 5 7.5 7.5 10 7.5 7.5 10 10 7.5 7.5 10 7 8 7.5 7.5 7.5 7.5 8 7.5 8 7 8 7 7.5 7 7.5 7 7 8 7 6 7 6 6 8 8 7 7 7 6 8 22.7 18.2 24.3 18.2 39.4 16.3 45.9 32.2 17.3 25.5 10.9 13.7 16.7 35.2 16.7 data (data of response) through a process mimics the brain in training and learning. While the data of input are arranged in input layer and data of outputs are represented in the output layer, there are several (one or more) hidden layers that exist between the input and output parameters (Nagata and Chu, 2003; Sewsynker-Sukai et al., 2017). The predictive potential of artificial neural networks is profoundly affected by the parameters applied like type of optimization function, number of iterations, type of activation function and number of neurons in hidden layer. As such, neural network was conducted by several variations in the affecting parameters. Variants of different parameters were grouped Table 6 ANOVA for response surface quadratic model of Box-Behnken design. Source Sum of squares df Mean square F value P value Prob > F Model A-NaCl conc. B-Medium pH C-Time course AB AC BC A2 B2 C2 Residual Lack of Fit Pure Error 1442.04 121.29 2.94 593.95 0.78 0.041 88.25 11.43 4.17 606.51 21.68 19.70 1.98 9 1 1 1 1 1 1 1 1 1 5 3 2 160.23 121.29 2.94 593.95 0.78 0.041 88.25 11.43 4.17 606.51 4.34 6.57 0.99 36.95 27.98 0.68 136.99 0.18 0.009558 20.35 2.64 0.96 139.89 0.0005 0.0032 0.4479 <0.0001 0.6895 0.9259 0.0063 0.1653 0.3717 <0.0001 significant 6.63 0.1338 not significant 6 M.M. Abdel Aziz et al. Biocatalysis and Agricultural Biotechnology 25 (2020) 101619 Fig. 6. The three-dimensional surface plot for the response (lipase production) in relative to the combination of two of the studied factors. predictive model conducted by Baskar et al. (2011) which based on 787, 950 iterations. The current prediction model basing on parameters set E, which had the lowest mean absolute error (0.01 U/ml), was coupled with genetic algorithm to predict the parameters of optimum fermen­ tation and the maximum lipase concentration attained with such parameters. Table 7 Specifications of different sets of parameters used in modeling by neural network. Parameter Different sets of parameters Set A Set B Set C Set D Set E Optimization function Number of iterations Activation function LBFGS Adam Adam LBFGS LBFGS 150 150 300 150 150 Sigmoid Sigmoid Sigmoid Sigmoid Number of neurons in hidden layer 50 50 50 Tangent hyperbolic (Tanh) 50 3.6. Prediction and practical validation of optimum fermentation parameters for thermo-alkaline lipase production by Nocardiopsis strain NRC/WN5 After two successive shots of statistical designs (Plackett-Burman and Box-Behnken designs), the optimum fermentation parameters and the predicted yield of lipase were inferred as listed in Table 8. On the other side, the single shot of neural network modeling (basing on parameters set E) coupled with genetic algorithm was employed to find out the optimum fermentation parameters and the predicted lipase yield which were listed as shown in Table 8. Each of the two proposed optimum fermentation parameters were practically verified. It was found that optimum fermentation developed by neural networks coupled with ge­ netic algorithm afforded the highest lipase concentration (62.21 � 1.7 U/ml) comparing with that developed by statistical designs (50.11 � 2.6 U/ml). The medium developed by neural networks pointed out to the ability of Nocardiopsis sp. NRC/WN5 to produce lipase in higher yield in presence of tween-80 as the only inducer for enzyme. In the previous study of Boekema et al. (2007), it was stated that tween-80 contains a fatty acyl ester bond and so could induce (or potentiate) lipase pro­ duction when applied in absence (or presence) of oil through the probable mechanism of inducing lipase gene expression. The ability of neural networks coupled with genetic algorithm to find out the 100 0.04 U/ml by changing activation function from sigmoid to Tanh in models of sets A and D. Increase in number of neurons in hidden layer was also of a significance in getting better predictions and low mean absolute error; number of neurons of 100 realized 5.2 times lower mean absolute error than 50 neurons which was inferred from mean absolute errors of sets A and E models. As such, it was concluded that the most predictive parameters in neural network modeling, in terms of the cur­ rent studied biological system, were LBFGS optimization function, Tanh activation function and hidden layer of 100 neurons. Number of itera­ tions was also found to have an effect on prediction; increasing the number of iterations from 150 to 300 led to drop in mean absolute error from 12.23 U/ml in set B model to 10.46 U/ml in set C model. Inter­ estingly, the current highly predictive model (set E model) was attained using very small number of iterations (150) comparing with the 7 M.M. Abdel Aziz et al. Biocatalysis and Agricultural Biotechnology 25 (2020) 101619 Fig. 7. Models of neural networks conducted by different sets of parameters. Different models were represented by relation between actual and predicted values of lipase concentration. The straight line intersecting the origin point represents the line of zero absolute error. fermentation of highest lipase yield from single shot of practical work consisted from only thirteen runs and covered 11 variables represents the extra valuable advantage. In terms of the current results, it was concluded that neural network (run in parameters set E) improved the microbial fermentation to the highest levels of performance with lowest practical effort. 4. Conclusion The artificial neural networks coupled with genetic algorithm were applied to optimize and predict the optimum variables for highest pro­ ductivity of thermo-alkaline lipase from Nocardiopsis strain NRC/WN5 in comparison with that obtained from two-step statistical designs. The study conducted different ANN models and specified the most predictive one which represented a fabulous aid in improving microbial fermen­ tation to the highest levels of performance with lowest practical effort. Therefore, the current work could help in industrial scale-up of the enzyme production. Fig. 8. Mean absolute errors of neural network models constructed by different sets of parameters. Table 8 Optimum fermentation parameters, predicted lipase concentration and practical validations of fermentations conducted according to statistical design and neural network. Fermentation parameters Starch conc. (g/l) Peptone conc. (g/l) Ammoniummolybdate conc. (g/l) MgSO4 conc. (g/l) K2HPO4 conc. (g/l) Olive oil conc. (%) Tween 80 conc. (g/l) Inoculum size (%) NaCl conc. (%) Medium pH Time course (day) Predicted lipase concentration (U/ml) Statistical design Neural network 20 15.67 1 1 1.06 2.83 2 1 5.08 8 6 15 15 1 1 1 0 4 1 5 8 6 47.15 Practical validation of lipase concentration (U/ml) 50.11 � 2.6 Financial support and sponsorship Nil. Declaration of competing interest The authors declare that there are no conflicts of interest. CRediT authorship contribution statement Mohamed M. Abdel Aziz: Conceptualization, Data curation, Formal analysis, Methodology, Resources, Software, Writing - original draft, Writing - review & editing. Eman W. Elgammal: Conceptualization, Formal analysis, Methodology, Resources, Writing - original draft, Writing - review & editing. Roba G. Ghitas: Conceptualization, Data curation, Software. 66.92 62.21 � 1.7 8 M.M. Abdel Aziz et al. Biocatalysis and Agricultural Biotechnology 25 (2020) 101619 Acknowledgments He, Y.Q., Tan, T.W., 2006. Use of response surface methodology to optimize culture medium for production of lipase with Candida sp. J. Mol. Catal. B Enzym. 43 (1–4), 9–14. https://doi.org/10.1016/j.molcatb.2006.02.018. Kennedy, M., Krouse, D., 1999. Strategies for improving fermentation medium performance: a review. J. Ind. Microbiol. Biotechnol. 23 (6), 456–475. https://doi. org/10.1038/sj.jim.2900755. Lee, D.K., In, J., Lee, S., 2015. Standard deviation and standard error of the mean. Korean J. Anesthesiol. 68 (3), 220–223. Lee, D.W., Koh, Y.S., Kim, K.J., Kim, B.C., Choi, H.J., Ki m, D.S., Suhartono, M.T., Pyun, Y.R., 1999. Isolation and characterization of thermophillic lipase from Bacillus thermoleovorans ID1. FEMS Microbiol. Lett. 179, 393–400. https://doi.org/10.1111/ j.1574-6968.1999.tb08754.x. Lescic, I., Zeh, l.M., Muller, R., Vukelic, B., Abramic, M., Pigac, V., Allmaier, G., Kojicprodic, B., 2004. Structural characterization of extra cellular lipase from Streptomyces rimosus: assignment of disulphide bridge pattern by mass spectrometry. Biol. Chem. 385, 1147–1156. https://doi.org/10.1515/BC.148. Lotti, M., Monticelli, S., Montesinos, J.L., Brocca, S., Valero, F., Lafuente, J., 1998. Physiological control on the expression and secretion of Candida rugosa lipase. Chem. Phys. Lipids 93 (1–2), 143–148. https://doi.org/10.1016/S0009-3084(98)00038-3. Mander, P., Cho, S.S., Simkhada, J.R., Choi, Y.H., Park, D.J., Yoo, J.C., 2012. An organic solvent–tolerant lipase from Streptomyces sp. CS133 for enzymatic transesterification of vegetable oils in organic media. Process Biochem. 47, 635–642. https://doi.org/ 10.1016/j.procbio.2012.01.003. Masomian, M., Rahman, R.N.Z.R.A., Salleh, A.B., Basri, M.A., 2013. A new thermostable and organic solvent tolerant lipase from Aneurinibacillus thermoaerophilus strain HZ. Process Biochem. 48, 169–175. https://doi.org/10.1016/j.procbio.2012.11.002. Nagata, U., Chu, K.H., 2003. Optimization of a fermentation medium using neural networks and genetic algorithms. Biotechnol. Lett. 25, 1837–1842. https://doi.org/ 10.1023/a:1026225526558. Nouroozi, A.S., Rezaei, S., Khoshnevis, N., DoostI, M., HajihoseinI, R., Khoshayand, M.R., Faramarzi, M.A., 2015. Medium based optimization of an organic solvent tolerant extracellular lipase from the isolated halophilic Alkali Bacillus salilacus. Extremophiles 1 (9), 933–947. https://doi.org/10.1007/s00792-015-0769-7. Osman, M.E., Abo El-Nasr, A.A., Abdullah, N.H., 2012. Screening of some fungal isolates for lipase production and optimization of cultural conditions for the most potent isolate. Egypt. J. Microbiol. 47, 79–95. Panda, B.P., Ali, M., Javed, S., 2007. Fermentation process optimization. Res. J. Microbiol. 2 (3), 201–208. Purohit, M.K., Raval, V.H., Singh, S.P., 2014. Haloalkaliphilic bacteria: molecular diversity and biotechnological applications. In: Geomicrobiology and Biogeochemistry. Springer, Berlin, Heidelberg, pp. 61–79. https://doi.org/10.1007/ 978-94-007-2229-3_19. Rajendran, A., Thangavelu, V., 2012. Application of central composite design and artificial neural network for the optimization of fermentation conditions for lipase production by RhizopusarrhizusMTCC 2233. J. Bioprocess. Biotech. 2, 118. https:// doi.org/10.4172/2155-9821.1000118. Rajeshkumar, M.P., Mahendran, V.S., Balakrishnan, V., 2013. Isolation and identification of lipase producing organisms from diverse soil samples of Kolli hills. Int. J. Curr. Microbiol. Appl. Sci. 2 (5), 205–210. https://doi.org/10.4172/2155-9821.1000118. Schmid, R.D., Verger, R., 1998. Lipases: interfacial enzymes with attractive applications. Angew. Chem. Int. Ed. 37 (12), 1608–1633. https://doi.org/10.1002/(SICI)15213773(19980703)37:12<1608::AID-ANIE1608>3.0.CO;2-V. Selvam, K., Vishnupriya, B., 2013. Partial purification of lipase from Streptomyces variabilisngp 3 and its application in bioremediation of waste water. IJPSR 4 (11), 4281–4289. Sewsynker-Sukai, Y., Faloye, F., Kana, E.B.G., 2017. Artificial neural networks: an efficient tool for modeling and optimization of biofuel production (a mini review). Biotechnol. Biotechnol. Equip. 31 (2), 221–235. https://doi.org/10.1080/ 13102818.2016.1269616. Sharma, R., Chisti, Y., Banerjee, U.C., 2001. Production, purification, characterization, and applications of lipases. Biotechnol. Adv. 19 (8), 627–662. https://doi.org/ 10.1016/S0734-9750(01)00086-6. Singh, V., Haque, S., Niwas, R., Srivastava, A., Pasupuleti, M., Tripathi, C.K.M., 2017. Strategies for fermentation medium optimization: an in-depth review. Front. Microbiol. 7, 2087. https://doi.org/10.3389/fmicb.2016.02087. Soleymani, S., Alizadeh, H., Mohammadian, H., Rabbani, E., Moazen, F., Sadeghi, H.M., Shariat, Z.S., Etemadifar, Z., Rabbani, M., 2017. Efficient media for high lipase production: one variable at a time approach. Avicenna J. Med. Biotechnol. (AJMB) 9 (2), 82–86. Song, Q.X., Lin, J.P., Rong, Y.P., Wei, D.Z., 2001. Studies on lipase production from Candida rugosa. Sheng Wu Gong Cheng Xue Bao 17 (1), 101–104. Veerapagu, M., Narayanan, A.S., Ponmurugan, K., Jeya, K.R., 2013. Screening selection identification production and optimization of bacterial lipase from oil spilled soil. Asian J. Pharmaceut. Clin. Res. 6 (3), 62–67. Venkateswarulu, T.C., Prabhakar, K.V., Kumar, R.B., Krupanidhi, S., 2017. Modeling and optimization of fermentation variables for enhanced production of lactase by isolated Bacillus subtilis strain VUVD001 using artificial neural networking and response surface methodology. 3 Biotech 7 (3), 186. https://doi.org/10.1007/ s13205-017-0802-x. The authors thank National Research Centre for supporting this work. References Aly, M.M., Tork, S., Al-Garni, S.M., Nawar, L., 2012. Production of lipase from genetically improved Streptomyces exfoliates LP10 isolated from oil-contaminated soil. Afr. J. Microbiol. Res. 6 (6), 1125–1137. https://doi.org/10.5897/ AJMR11.1123. Arora, M.S., Patel, J.S., Baser, I., Chhasatia, M.R., 2015. Effect of medium constituents on the growth and lipase production in Pseudomonas aeruginosa 2036. Int. J. Adv. Res. Biol. Sci. 2 (7), 171–176. https://ijarbs.com/pdfcopy/july2015/ijarbs23. Atlas, R.M., 1997. Handbook of Microbiological Media. CRC Press, Boca Raton, Fla. Bapiraju, K.V.V.S.N., Sujatha, P., Ellaiah, P., Ramana, T., 2005. Sequential parametric optimization of lipase production by a mutant strain Rhizopus sp. BTNT-2. J. Basic Microbiol. 45 (4), 257–273. https://doi.org/10.1002/jobm.200410548. Baskar, G., Rajasekar, V., Renganathan, S., 2011. Modeling and optimization of Lasparaginase production by Enterobacter aerogenes using artificial neural network linked genetic algorithm. Int. J. Chem. Eng. Appl. 2 (2), 98–100. https://doi.org/ 10.7763/IJCEA.2011.V2.83. Bayoumi, R.A., El-louboudey, S.S., Sidkey, N.M., Abd-El-Rahman, M.A., 2007. Production, purification and characterization of thermo-alkalophilic lipase for application in bio-detergent industry. J. Appl. Sci. Res. 3 (12), 1752–1765. https ://pdfs.semanticscholar.org/fc88/e20c102a779e56f8b30253eaf1e655f5efbc. Bennur, T., Kumar, A.R., Zinjarde, S., Javdekar, V., 2015. Nocardiopsis species: incidence, ecological roles and adaptations. Microbiol. Res. 174, 33–47. https://doi.org/ 10.1016/j.micres.2015.03.010. Bennur, T., Kumar, A., Zinjarde, S., 2014. Nocardiopsis species as potential sources of diverse and novel extracellular enzymes. Appl. Microbiol. Biotechnol. 98, 9173–9185. https://doi.org/10.1007/s00253-014-6111-y. Bhosale, H., Uzma, S., Tukaram, K., 2016. Characterization of a hyperthermostable Alkaline lipase from Bacillus sonorensis 4R. Enzym. Res. 4170684. https://doi.org/ 10.1155/2016/4170684. Boekema, B.K., Beselin, A., Breuer, M., Hauer, B., Koster, M., Rosenau, F., Jaeger, K.E., Tommassen, J., 2007. Hexadecane and Tween 80 stimulate lipase production in Burkholderia glumae by different mechanisms. Appl. Environ. Microbiol. 73 (12), 3838–3844. Bora, L., Bora, M., 2012. Optimization of extracellular thermophilic highly alkaline lipase from thermophilic bacillus sp isolated from hot spring of arunachalpradesh, India. Braz. J. Microbiol. 43 (1), 30–42. https://doi.org/10.1590/S151783822012000100004. Chakraborty, S., Ghosh, M., Chakraborti, S., Jana, S., Sen, K.K., Kokare, C., Zhang, L., 2015. Biosurfactant produced from Actinomycetes nocardiopsis A17: characterization and its biological evaluation. Int. J. Biol. Macromol. 79, 405–412. https://doi.org/10.1016/j.ijbiomac.2015.04.068. Chakraborty, K., Raj, R.P., 2008. An extra-cellular alkaline metallolipase from Bacillus licheniformisMTCC 6824: purification and biochemical characterization. Food Chem. 109 (4), 727–736. Dalmau, E., Montesinos, J.L., Lotti, M., Casas, C., 2000. Effect of different carbon sources on lipase production by Candida rugosa. Enzym. Microb. Technol. 26 (9–10), 657–663. Dong, H., Gao, S., Han, S., Cao, S., 1999. Purification and characterization of a Pseudomonas sp. lipase and its properties in non-aqueous media. Appl. Microbiol. Biotechnol. 30, 251–256. https://doi.org/10.1111/j.1470-8744.1999.tb00778.x. Dutta, J.R., Dutta, P.K., Banerjee, R., 2004. Optimization of culture parameters for extracellular protease production from a newly isolated Pseudomonas sp. using response surface and artificial neural network models. Process Biochem. 39 (12), 2193–2198. Ebrahimpour, A., Rahman, R.N.Z.R.A., Ch’ng, D.H.E., Basri, M., Salleh, A.B., 2008. A modeling study by response surface methodology and artificial neural network on culture parameters optimization for thermostable lipase production from a newly isolated thermophilic Geobacillus sp. strain ARM. BMC Biotechnol. 8 (1), 96. Gandhimathi, R., Kiran, G.S., Hema, T.A., Selvin, J., Raviji, T.R., Shanmughapriya, S., 2009. Production and characterization of lipopeptide biosurfactant by a spongeassociated marine actinomycetes Nocardiopsis alba MSA10. Bioproc. Biosyst. Eng. 32, 825–835. https://doi.org/10.1007/s00449-009-0309-x. Ghanem, E.H., Hashim, A.S., Saleh, M.K., 2000. An alkalophilic thermostable lipase produced by a new isolate of Bacillus alcalophilus. World J. Microbiol. Biotechnol. 16, 459–464. Guerrand, D., 2017. Lipases industrial applications: focus on food and agroindustries. OCL 24 (4), 403. https://doi.org/10.1051/ocl/2017031. Hasan, F., Shah, A.A., Hameed, A., 2006. Industrial applications of microbial lipases. Enzym. Microb. Technol. 39 (2), 235–251. https://doi.org/10.1016/j. enzmictec.2005.10.016. 9