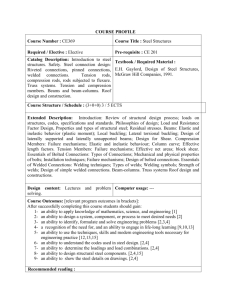

Original Research Behaviour of partly stiffened cold-formed steel built-up beams: Experimental investigation and numerical validation Advances in Structural Engineering 2019, Vol. 22(1) 172–186 Ó The Author(s) 2018 Article reuse guidelines: sagepub.com/journals-permissions DOI: 10.1177/1369433218782767 journals.sagepub.com/home/ase M Adil Dar1 , N Subramanian2, A R Dar3, M Anbarasu4 , James BP Lim5 and Mir Atif3 Abstract To address the various instability problems in cold-formed steel members, many researchers have mainly focused on developing innovative sectional profiles wherein geometry of the section plays a vital role in enhancing the inherent resistance of such sections against premature buckling. However, the process of forming such innovative shapes is not only complex and time-consuming but sometimes such sections fail to mobilize their complete reserve strength. Hence, a stiffening arrangement of weaker zones for mobilizing the untapped reserve strength is suggested. The contribution of this simple, effective and partly stiffening arrangements, aimed at eliminating/delaying the premature local buckling, is studied both experimentally and numerically and also compared with existing codes. Experimental study was carried out on different simply supported cold-formed steel beams with judiciously proposed stiffening arrangements under four-point loading. An equivalent hot-rolled steel beam was also tested to compare the efficiency of the coldformed steel beams. The cold-formed steel beams investigated had different width-to-thickness ratio, different geometries and different stiffening arrangements. The test strengths, failure modes, deformed shapes, load versus mid-span displacements and geometric imperfections were measured and reported. The test strengths of the beam models are also compared with the design strength predicted by North American Standards and Eurocode for cold-formed steel structures. To validate the test results further, a numerical study was carried out on such stiffened cold-formed steel beams using finite element software ABAQUS. All these results show that the proposed strengthening system is efficient and economical and allow cold-formed steel beams to reach greater load carrying capacity. Keywords cold-formed steel, experiment, numerical modelling, stiffening arrangements, structural behaviour Introduction In most of the developing countries, structural designers face the global competition of designing fasttrack and cost-effective structural systems to meet the huge deficit of various infrastructural systems. Such a development is crucial for bringing such countries at par with global standards of living. For this purpose, cold-formed steel (CFS) sections provide the best choice not only for cost-effective structural systems but also an ideal choice for the desired fast-track construction (Anbarasu and Sukumar, 2013, 2014). The main members in any structure need to have an adequate safety to avoid catastrophic or total collapse, thus use of hot-rolled steel sections for such vital members are unavoidable, owing to their superior performance against premature buckling, thus can be justified. However, use of hot-rolled steel sections for moderate to lightly loaded members such as floor beams and purlins generally remains under-utilized (Keerthan et al., 2014; Wang et al., 2014; Wang and 1 Department of Civil Engineering, Indian Institute of Technology Delhi, New Delhi, India 2 Consulting Structural Engineer, Maryland, USA 3 Department of Civil Engineering, National Institute of Technology, Srinagar, Srinagar, India 4 Department of Civil Engineering, Government College of Engineering Salem, Salem, India 5 Department of Civil and Environmental Engineering, The University of Auckland, Auckland, New Zealand Corresponding author: Mohammad Adil Dar, Senior Research Fellow, Department of Civil Engineering, Indian Institute of Technology Delhi, New Delhi 110016, India. Email: dar.adil89@gmail.com Dar et al. Young, 2016). Moreover, optimization techniques in design are not fruitful because of the limited availability of rolled section in the market place (Subramanian and Venugopal (1977). This contributes to the highly conservative use of such a precious construction material with limited reserves. Keeping in view the importance of steel as an ideal construction material in challenging situations, it is of paramount importance to make the most optimum use of such vital construction material (Valsa Ipe et al., 2013). CFS provides an ideal choice to avoid such a wasteful use of steel. Unlike hot rolling, the cold forming process permits an almost infinite variety of shapes to be produced which can serve desired needs efficiently. Generally, the width-to-thickness ratio of individual components of CFS members is high, hence are prone to premature buckling at moderate compressive stress levels (much below the yield stress). This problem can be tackled effectively either by developing innovative sectional profiles with intrinsic resistance against premature buckling and/or by appropriate stiffening arrangement at vulnerable locations. Past research has stressed mainly on the development of innovative sections. In the past decade, due to advances in the manufacturing technology, many attempts were made to make changes in the cross section of the member in order to attain economical and efficient sectional profiles (Hancock, 2016; Schafer, 2011). SudhirSastry et al. (2015) carried out a numerical study to investigate the effect of different flange configurations on the buckling of CFS channel beams. It was observed that the beams with extended open flanges and rounded flanges had enhanced critical buckling moments compared to beams with dropped flanges. Obst et al. (2016) carried out tests to study the behaviour of non-standard channel beams with single- and double-box flanges. Beams with double-box flanges had higher capacities than the ones with single-box flanges. It was also observed that reinforced beams performed better than the unreinforced ones. Ye et al. (2018) conducted a study to optimize the CFS channel beam sections for higher energy dissipation and ductility. It was found that by incorporating intermediate web and flange stiffeners to slender channel beams, there was a significant improvement in their energy dissipating capacity. However, in stockier channel beams, such introduction of stiffeners did not help. Instead, increasing the crosssectional depth and decreasing the flange width helped in attaining higher energy dissipating capacity. Paczos and Wasilewicz (2009) tested anti-symmetrical CFS Ibeam sections fabricated out of a single steel sheet. It was observed that there was quick loss in the stability of beams that were loaded with a concentrated force at the mid-span. Also, the critical loads for lipped beams 173 were higher than that of the non-lipped ones. Trahair and Papangelis (2018) studied the lateral distortional buckling in hollow flanged beams with corrugated web plates. It was observed that the distortion in the hollow flanges resulted in the reduction of their torsional rigidities as well as their lateral buckling resistance. However, corrugation of web plate helped in preventing web distortion and significantly reduced the lateral buckling resistance, which is generally observed in beams with flat webs. Laı́m et al. (2015) conducted a series of tests to study the flexural behaviour of CFS beams with sigma profiles at ambient and elevated temperatures. It was seen that the web stiffeners behave differently under elevated temperatures and that behaviour depends upon the sectional profile. Axially unrestrained beams perform better than the restrained ones. Under ambient temperature, chances of excessive non-uniform compressive stress distribution are very likely compared to that in tension regions. Ye et al. (2016) carried out a numerical study to develop more efficient CFS channel sections under flexure. Just by optimizing the relative dimensions of flat plates and inclination of lips, the bending resistance can increase by nearly 30%. Double folded lips can substantially improve the flexural resistance, whereas intermediate web stiffeners may not necessarily improve flexural performance. Adequately designed CFS channel beam sections have the potential to reach their plastic moment capacity (Kumar and Sahoo, 2016). Siahaan et al. (2016a) studied innovative rectangular hollow flanged channel beams to develop optimum sections which can delay the buckling failure in them. Dar et al. (2015a) investigated various innovative CFS beam sectional profiles under flexure so as to find an ideal replacement for conventional hot-rolled steel sections. Wang and Young (2015) carried out an experimental and numerical investigation to study the local buckling and/or distortional buckling behaviour of the built-up open and closed sections under flexure. All these studies indicate that innovative profiles were successful in postponing the buckling failures in CFS beams; however, the process of forming such innovative sections of complex profiles requires a lot of time and effort, thus making the process very difficult and time-consuming. Appropriate stiffening of vulnerable zones is an effective alternate solution that can eliminate/delay premature buckling (Laı’m et al., 2013; Paczos, 2014; Moen et al., 2013). Hence, there is an urgent need to develop judicious stiffening arrangements that can be effectively used in simple CFS sections to overcome the complex problem of premature buckling failure, thus making CFS construction fast, simple and efficient. The primary objective of this research is to conduct experimental investigation on different simply 174 Advances in Structural Engineering 22(1) Table 1. Model nominal and measured dimensions. Model I II III IV Weight (kg/m) Thickness (mm) Nominal (mm) Measured (mm) a b c d e a b c d e 11.23 14.83 5.62 6.82 2 2 1 1 125 125 125 125 25 25 25 25 150 150 150 150 25 25 25 25 – – – 31.25 122.3 124.4 127.5 123.2 26.4 25.7 22.8 24.7 151.4 153.3 154.1 152.3 23.4 22.8 23.8 24.6 – – – 32.7 supported CFS beams with judiciously proposed stiffening arrangements under four-point loading. The tests would compensate the lack of experimental data on this form of construction and act as a data base for numerical models to be developed. An equivalent hotrolled steel beam was also tested to compare the efficiency and the structural performance of these CFS beams. The CFS beams investigated had different width-to-thickness ratio, different geometries and different stiffening arrangements. The test strengths, failure modes, deformed shapes, load versus mid-span displacements and geometric imperfections were measured and reported in this article. The test strengths of the beam models are compared with the design strength predicted by North American Specifications and Eurocode for CFS structures. In order to validate the test results, a numerical study was also carried out on CFS beams using finite element software ABAQUS. Experimental investigation Test models To achieve the well-defined objective of this study, four CFS beam models have been fabricated with and without appropriate stiffening arrangements. The tested CFS beams comprised two channel sections connected back to back by black bolts of size 5 mm and class 4.6. Two rows of bolts were provided with 100 mm centre to centre spacing along the depth as shown in Figure 1 and 200 mm centre to centre spacing along the length of the beam. To compare the efficiency and effectiveness of the proposed stiffening arrangements, one hotrolled steel section was tested. The dimensional details of all the models are given in Table 1. A digital vernier calliper was used to measure the dimensions of various components of the models. The details of various models fabricated and tested are described below. Model I: unstiffened model. The sectional geometry of this model consisting of I shape using two-lipped channel sections bolted back to back are shown in Figure 2(I). A cold-formed sheet having a thickness of 2 mm only Figure 1. Arrangement of bolts in the cross section. has been used for the fabrication of this model. The nominal and measured dimensions of the various elements of the model are shown Table 1. All the beams had a span of 2.1 m. Model II: angle-stiffened model. During the testing of Model I, localized lip buckling failure on compression side was observed at a low magnitude of loading. Therefore, it was expected that effective stiffening of compression area falling under high bending moment zone would have arrested such localized buckling, thereby considerably improving its structural performance. Accordingly, Model II, which is a modified version of Model I was stiffened by attaching two hotrolled angle stiffeners (25 3 25 3 5) as shown in Figure 2(II). This hot-rolled angle stiffener was placed in the central 1.5 m length of the beam falling under high bending moment zone. The steel angle stiffener was welded to the inside of the compression flange lip by using Shielded Metal Arc Welding process. Rest of the details of Model II were kept strictly identical to Model I so as to investigate the contribution of the proposed variation in Model II towards improved Dar et al. 175 Figure 2. Cross sectional details of the models. Table 2. Dimensions of hot-rolled angle stiffener used in Model II. Designation Size (P 3 Q; mm 3 mm) T (mm) A (mm2) W (kg/m) Cxx = Cyy (mm) exx = eyy (mm) ISA 2525 25 3 25 5 225 1.8 7.9 17.1 Table 3. Dimensions of hot-rolled beam ISMB 150. Designation W (kg/m) A (mm2) D (mm) Wf (mm) tf (mm) tw (mm) Ixx (mm4) Iyy (mm4) rxx (mm) ryy (mm) ISMB 150 14.9 1900 150 80 7.6 4.8 7.26°3106 5.26°3 105 61.8 16.6 structural performance. The dimensions of hot-rolled angle stiffener used in Model II are given in Table 2. Model III: unstiffened lightest model. Keeping in view the importance of achieving steel economy, it was deemed appropriate to fabricate lighter models using thinnest possible steel sheets. Accordingly, Model III with symmetrical I shape (using two-lipped channel sections back to back similar to Model I) involving simple fabrication was fabricated as shown in Figure 2(III). A cold-formed sheet having a thickness of 1 mm only was used for fabrication of this model. Model IV: stiffened lightest model. During the testing of Model III, localized lip buckling failure (similar to Model I) on the compression side was observed in high bending moment zone. It was again expected that strengthening of flange lips in the compression zone could have prevented/delayed such a failure. Accordingly, Model IV which is a modified version of Model III was fabricated by stiffening the compression flange lips using a small-channel section as shown in Figure 2(IV). The small-channel section was bolted to the compression flange of the beam using 5 mm black bolts of class 4.6. For each small-channel stiffener, a single row of bolts were provided with centre to centre spacing of 150 mm along the length. By developing structurally efficient CFS beam sections, steel economy was the main consideration. However, it was equally important to evaluate these proposed CFS sections from structural performance consideration too. Accordingly, Model V, that is, ISMB-150 (hot-rolled steel section), was chosen as the reference model for meaningful comparison with the various CFS beam models. The dimensions of ISMB150 are given in Table 3. Material properties The test specimens were fabricated from locally available structural steel. Tensile coupon tests were used to determine the mechanical properties of the same. Since two categories of steel sheet thicknesses were used to fabricate the models. Three coupons were prepared from the centre of the flange in the longitudinal direction from each sheet. Various standards exist which specify the requirements for testing of tensile specimens. However, the dimensions of the coupons, as conforming to the Indian Standards (IS1608:2005), were used for material testing. A computerized universal testing machine was used to conduct the tensile tests of the coupons. The relevant material properties of the steel obtained from the material testing are given in Table 4. A typical stress–strain curve of CFS used in this study is shown in Figure 3. Since hot-rolled steel angle was used in Model II, three tensile test coupons 176 Advances in Structural Engineering 22(1) Table 4. Material properties of steel used. Test fn (MPa) E (GPa) fy (MPa) fu (MPa) d# (%) 1 (2 mm) 2 (2 mm) 3 (2 mm) 4 (1 mm) 5 (1 mm) 6 (1 mm) Average 350 350 350 350 350 350 350 209 207 208 212 210 209 209 455 468 454 456 456 459 458 510 496 505 510 512 503 506 18 20 19 25 24 26 22 Table 5. Material properties of hot-rolled steel angle used. Test fn (MPa) E (GPa) fy (MPa) fu (MPa) d# (%) 1 2 3 Average 250 250 250 250 214 212 210 212 266 272 275 271 433 457 442 444 26 23 26 25 Figure 4. Directions of measured geometric imperfections. Figure 3. Stress–strain curve of CFS used in this study. were prepared from the flat portion of the angle along the longitudinal portion. The relevant properties of this hot-rolled steel angle are given in Table 5. Table 6. The maximum geometric imperfection measured at the mid-length in d1 and d2 directions was 1/ 2167 mm and 1/2131 mm, respectively, and found in Model III. The minimum geometric imperfection measured at the mid-length in d1 and d2 directions was 1/ 4112 and 1/4346, respectively. As a comparison, the magnitude of the maximum and minimum imperfections measured by Yuan et al. (2015) was 1/100 and 1/ 4856, respectively. Geometric imperfections Prior to testing, the initial overall geometric imperfections were measured. The imperfections were measured at the bottom flange web junctions near the centre both along the longitudinal as well as transverse directions. An optical theodolite and a calibrated vernier calliper were used to obtain the readings at the midlength and near both ends of the models. The imperfections measured at the mid-lengths along the model in two orthogonal directions (Figure 4) are given in Test setup The testing of models was carried out on a loading frame of 500 kN capacity as shown in Figure 5. A hydraulic loading jack of 500 kN capacity was used to transmit load on a rigid spreader beam to ensure fourpoint loading as shown in Figure 6. Dial gauges of least count of 0.01 and 75 mm travel were used to record the vertical displacements. Identical bearing plates of size Dar et al. 177 Table 6. Measured geometric imperfections at mid-length. Model I II III IV d1/L d2/L 1/3221 1/4346 1/4112 1/3549 1/2167 1/2131 1/2654 1/2152 (Dar et al., 2015b, 2017). The supports were restrained laterally at the supports. Test results and discussions Figure 5. Model mounted on the testing rig. 150 mm 3 150 mm 3 15 mm were placed under concentrated loading points to prevent punching failure. To prevent web buckling under concentrated loading points, bearing stiffeners comprising two angles ISA 50 3 50 3 6 (SP 6-1 :2003) back to back were bolted to the web of the models on both sides. Simply supported end conditions with one end hinged and the other end pinned was adopted as shown in Figure 6. The moment span was laterally unrestrained. To assess the contribution of stiffening arrangements towards favourable structural performance, it was important to ensure strict uniformity of various parameters which include span of the beam, support conditions, location of applied point loads and bearing/stiffening arrangement under concentrated applied load/reaction points Figure 6. Loading arrangement. Sometimes, semi-log curves are plotted for better interpretation of results (Dar et al., 2018; Manikandan et al., 2014). Figure 7 shows the log of load versus displacement (at mid-span) curve of various models. The Model I resisted the load until it experienced premature local buckling failure (as seen in Figure 8) in the lip within the central one-third span with the maximum bending moment. The said failure was noticed corresponding to a maximum load of 44.1 kN and mid-span displacement of 11.67 mm. Except a localized lip failure confined to a smalllength segment, rest of the model was in sound condition and still possessed enough reserve strength. To exploit this reserved strength, appropriate stiffening arrangement (as mentioned earlier) was introduced in Model II. The Model II resisted a higher load (68.3 kN) compared to Model I. The extra load carried by Model II was partly due to reserve capacity of the section and partly due to strain hardening. The mode of failure was initiated with local buckling of a compression flange shown in Figure 9 falling within the central one-third length and was under highest compressive stress corresponding to a failure load of 68.3 kN and a maximum deflection of 20.9 mm at mid-span. It is worth highlighting here that the stiffening arrangement adopted over a full length of the vulnerable zone has greatly contributed to a muchimproved load carrying capacity from 44.1 to 68.3 kN 178 Advances in Structural Engineering 22(1) Figure 7. Combined load–displacement curves of various models. Figure 8. Lip buckling of Model I. Figure 10. Lip buckling failure in Model III. Figure 9. Compression flange buckling in Model II. (i.e. an increase of 39%). This encouraging experimental result confirms the important role of judiciously provided stiffening arrangements in CFS construction. The Model III experienced premature local lip buckling failure within the middle third zone of the maximum bending moment as shown in Figure 10. The said failure was observed at a lower load of 12.7 kN and mid-span displacement of 5.0 mm. At this stage, the model suddenly stopped resisting any further load; hence, the model was said to have reached its limit state. Except localized lip failure confined to a small length, the rest of the model seemed in good condition and expected to possess appreciable reserve strength. To exploit this reserved strength, appropriate stiffening (as mentioned earlier) was introduced in Model IV. Dar et al. 179 Figure 11. Lip buckling failure in Model IV. Figure 12. Lateral buckling in ISMB-150. The stiffened model (Model IV) failed at a load of 15 kN against 12.7 kN resisted by the unstiffened model (Model III; i.e. only a meagre increase of 2.3 kN). The mode of failure was again local lip buckling within the middle third zone of high bending moment and is prominently noticeable as seen in Figure 11. It is therefore concluded that using thin sheets with a thickness of 1 mm for the fabrication of CFS beams is highly vulnerable to premature buckling at very low loads even after adopting some stiffening arrangements; hence, such thin cold-formed sheets are not recommended. During testing of specimens, no distortional and lateral torsional buckling was visually observed in any of the selected cross sections. As mentioned earlier, it would be appropriate to have experimental results of a comparable hot-rolled section for meaningful comparison. Accordingly, a hot-rolled beam of ISMB-150 at 15 kg/m, named Model V, was chosen as the only reference beam model, with all other conditions remaining identical. The curve for ISMB-150 shows a linear response till it experienced lateral buckling as seen in Figure 12 corresponding to failure load of 83.65 kN and mid-span displacement of 16 mm. It needs to be highlighted here that the promising results of partly stiffened CFS Model II are comparable with reference hot-rolled section (i.e. Model V), thus confirming the vital role of proper stiffening arrangements in enhancing the structural performance of CFS construction. Hence, judiciously selected stiffening arrangements can be adopted with confidence in new CFS construction as well as in the strengthening of existing CFS structures (which demand upgradation). The flat-width-thickness ratio of the flange had an effect on both strengths as well as stiffness as shown in Figure 13. The stiffness of beams was calculated by the method adopted by Deepak and Shanthi (2018). The effect of stiffening on the strength and initial stiffness of CFS beams is shown in Figure 14. As the flat-widththickness ratio (b/t) of the flange reduced from 62.5 to 31.25 in unstiffened beams and from 31.25 to 18.75 in stiffened beams, the strength increased by 228% and 354%, respectively, as shown in Figure 13(a). For the same reduction in flat-width-thickness ratio (b/t) of the flange, the initial stiffness increased by 35% and 106% for unstiffened and stiffened beams, respectively, as shown in Figure 13(b). Design rules Since one of the objectives of this research was to assess the strengths of the CFS beams against the current design standards. Accordingly, the un-factored design strengths predicted by European code and North American Standards were calculated and are summarized in Table 7. Design rules specified in EC3 The unfactored design strength of flexural members depends on the minimum effective section modulus depending upon the position of the neutral axis. According to EC3 (BS-EN1993-1-3), the unfactored design strength (MEC3) is calculated as follows MEC3 = Weff, y *fyb ð1Þ where fyb is the basic yield strength and Weff,y is the effective section modulus given by Weff, y = min Weff, y, c , Weff, y, t ð2Þ 180 Advances in Structural Engineering 22(1) Figure 13. Effect of flange’s flat-to-width ratio on ultimate load and stiffness: (a) ultimate load variation and (b) stiffness variation. Figure 14. Effect of stiffening on ultimate load and stiffness: (a) ultimate load variation and (b) stiffness variation. Table 7. Summary of all model results. Models lLT PTest (kN) PEC (kN) PNAS (kN) PTest/PEC PTest/PNAS MNAS (kN m) MEC (kN m) Mcr (kN m) My (kN m) I II III IV 0.193 0.18 1.04 0.75 44.1 68.3 12.7 15.0 34.71 54.78 11.98 22.04 35.95 52.86 13.13 19.20 1.27 1.24 1.06 0.68 1.23 1.29 0.97 0.78 12.58 18.50 4.60 6.72 12.15 19.17 4.19 7.71 326.55 591.46 180.88 225.70 28.66 32.04 15.06 15.55 Weff, y = Ieff, y Z ð3Þ where Weff, y,c and Weff, y,t are the section moduli with regard to compression and tension flanges, respectively; Z is the position of neutral axis from respective flange and Ieff,y is the second moment of area of the effective section. The effective section properties are calculated by using a reduction factor for elements in compression heff = r*hc r= lp, h 0:055ð3 + cÞ 2 lp, h ð4Þ ð5Þ lp, h = hp =t pffiffiffiffiffiffiffi 28:4e Ks Ks = 7:81 6:29c + 9:78c2 c= h c hp hc ð6Þ ð7Þ ð8Þ where r is the width reduction factor, lp,h is the relative slenderness, Ks is the buckling factor, c is the stress ratio, hp is the nominal dimension of crosssectional element and hc is the distance of the point of maximum compressive stress in element from neutral axis. Dar et al. 181 Design rules specified in AISI-S100 The unfactored design strength (Mn) of flexural members using the AISI specification (2016) is calculated as follows Mn = Se *Fy Se = Ix ycg ð9Þ ð10Þ where Fy is the nominal yield strength, Se is the elastic section modulus relative to top fibre, ycg is the depth of neutral axis with respect to the compression flange and Ix is the second moment of area of the effective section, determined by using a reduction factor, given by w for l ł 0:673 rw for l.0:673 rffiffiffiffi 1:052 w f l = pffiffiffi E k t beff = r= 1 0:22=l ł1 l ð11Þ ð12Þ ð13Þ where beff is the effective design width, w is the width of compression element, r is the reduction factor, k is the plate buckling co-efficient, t is the thickness of compression element, E is the modulus of elasticity and f is the maximum compressive edge stress in the element. Comparison with design rules Figure 15 shows the comparison between test strengths and design strength predictions of North American Standards and Eurocode. From Table 4 and Figure 15, it can be concluded that North American Standards are conservative for beams with a wall thickness of 2 mm, but un-conservative for the stiffened CFS beam with a wall thickness of 1 mm. A similar behaviour Figure 15. Comparison between test and design strengths for CFS beams. was indicated by Eurocode, except for Model III (where a slight degree of unconservativeness was observed). In all the four models, non-dimensional slenderness for lateral torsional buckling is less than limiting slenderness 0.4; therefore, there is no possibility of occurrence of lateral torsional buckling. Numerical calibration The finite element analysis using ABAQUS (2004) version 6.14 was conducted to simulate an experimental behaviour of CFS lipped channel beams under fourpoint loading as shown in Figure 16. Nominal crosssectional dimensions, material imperfections and initial geometric imperfections of the test specimens were incorporated. S4R5 shell element was selected to develop the finite element model. This element is thin, shear flexible, isometric quadrilateral shell with four nodes and five degrees of freedom per node, utilizing reduced integration and bilinear interpolation scheme (Ammash, 2017; Anbarasu, 2016; Keerthan and Mahendran, 2013). Mesh convergence study was carried out to find the optimum mesh size. The model with 5 mm mesh size provided reasonable accuracy and was hence used in all the finite element models (FEMs). The size of the element adopted was 5 mm 3 5 mm (25) mm2. Elastic perfectly plastic model with a modulus of elasticity of 210 GPa and yield stress of 450 MPa was used in this study. To ensure proper distribution of concentrated forces on to the beams, the load was applied at the centre of the rigid plate attached to the beams as shown in Figure 16. Idealized simply supported end condition was modelled by restraining the displacements in x, y and z directions and rotations in z directions at the pinned support. The displacements were restrained in y and z directions and rotations in z directions at the roller support. To avoid contact problems in-between the Figure 16. Numerical model used in the finite element analysis. 182 Advances in Structural Engineering 22(1) Figure 17. Comparison of test and FEM results. layers, general hard surface contact was adopted. In the assembly, various instances of master–slave surfaces were created between the surfaces. Frictionless hard contact was adopted. One major problem while meshing sections with contact faces is that there are penetrations of layers during analysis. From various trials, it was found that square mesh of size 5 mm 3 5 mm can be adopted for modelling all parts of the assembled sections to avoid any penetrations (Deepak and Shanthi, 2018). Residual stresses have a negligible effect on the strength (Schafer and Pekoz, 1998) and hence were ignored. Local, distortional and global Dar et al. 183 1998). In the nonlinear analysis, RIKS method was used. The comparison of load versus deflection curves for test and FEM studies is shown in Figure 17. The mean value of the (PTest/PFEM) ratio is 0.987 with the corresponding standard deviation of 0.037, as shown in Table 8 and is also presented in Figure 18. Figure 19 shows the comparison of deformed shapes (test vs FEM) in Model II and Model III. Table 5 and Figures 17 to 19 indicate that the FEM-predicted results are in good agreement with test results, thus confirming the accuracy of the experimental results. Conclusion Figure 18. Verification of test results. geometric imperfections were incorporated in the model. The maximum magnitude of local, distortional and global imperfections adopted was 0.34 3 t, 0.94 3 t and L/1000, respectively (Schafer and Pekoz, Based on experimental as well as numerical investigations carried out to study the effectiveness of stiffening arrangements in mobilizing the untapped reserve strength in CFS beams (comprising two channel sections connected back to back by bolts), the following important conclusions are drawn: The judiciously provided steel angle stiffener which was welded to the inside of the compression flange lip only over the vulnerable zone considerably improved the load carrying Figure 19. Comparison of deformed shapes (test vs FEM): (a) Model II and (b) Model III. 184 Advances in Structural Engineering 22(1) Table 8. Summary of all test and FEM results. Models PTest (kN) PFEM (kN) PTest/PFEM dTest (mm) dFEM (mm) MTest (kN m) MFEM (kN m) (P/d)Test (kN/mm) (P/d)FEM (kN/mm) Failure mode I II III IV 44.1 68.3 12.7 15.0 42.92 69.39 13.35 15.28 1.03 0.98 0.96 0.98 11.7 20.9 5.00 6.20 12.1 20.5 5.10 6.10 15.4 23.9 4.44 5.25 14.8 24.2 4.67 5.35 3.51 5.58 2.61 2.71 3.51 5.59 2.62 2.72 LB FB LB LB FEM: finite element model. Average = 0.987. Standard deviation = 0.037. capacity from 43 to 67.8 kN (i.e. increase in strength by 40%) and the initial stiffness from 3.58 to 5.71 kN/mm (i.e. increase by 60%). Hence, instead of using a heavy hot-rolled section or larger CFS section, a suitable smaller CFS section can be partially stiffened in the compression zone to avoid premature local buckling. This type of stiffening can be adopted both in existing structures (which demand stiffening) as well as in the structures to be built to obtain economy. The stiffening of the compression flange lips in sections with flat width-to-thickness ratio of compression flange greater than 62.5 using small-channel section did not perform satisfactorily. It shows that the proposed stiffening arrangement may be suitable only when the flat width-to-thickness ratio of compression flange is not greater than 32.5. The finite element models developed were in good agreement with the experimental results. The ratio of FEM-predicted strengths and test results had an average PTest/PFEM of 0.987 and standard deviation of 0.037. It shows that ABAQUS software can be used to predict the behaviour of such partly stiffened CFS beams. Design strengths computed as per North American Specifications and European Code for CFS structures were found to be conservative, except for the stiffened CFS beam with a wall thickness of 1 mm. Hence, these provisions can be safely used for the design of such CFS beams. Lip buckling and flange buckling in the compression zone were the primary types of observed failures, which can be effectively controlled by the proposed stiffening. The minimum and maximum geometric imperfections observed at mid-lengths in the various models were 1/4346 mm and 1/2131 mm, respectively. It has to be noted that in this study, angles were used to stiffen the compression flange of CFS beams. However, we can optimize the dimensions of the stiffener in order to obtain economy. On this aspect, a parametric study being carried out by the authors is under progress. Acknowledgements The authors would like to thank the Civil Engineering Department of National Institute of Technology Srinagar for their support by permitting the testing of the models in their Structural Engineering Laboratory. Prior to joining IIT Delhi, M. Adil Dar was working as an MTech scholar in Structural Engineering at Kurukshetra University and wishes to thank the University for their support. Declaration of Conflicting Interests The author(s) declared no potential conflicts of interest with respect to the research, authorship and/or publication of this article. Funding The author(s) disclosed receipt of the following financial support for the research, authorship and/or publication of this article: The experimental work described in this paper has been supported by a grant from Consulting Engineers, PVT. LTD (Project No. CES2015/8360). ORCID iDs M Adil Dar M Anbarasu https://orcid.org/0000-0003-2782-9225 https://orcid.org/0000-0002-7144-6195 References ABAQUS (2004) ABAQUS User’s Manual Version 6.14. Providence, RI: Hibbitt, Karlsson and Sorensen, Inc. AISI S-100 (2016) North American Specification for the Design of Cold-formed Steel Structural Members (AISI Standard). Washington, DC: AISI. Dar et al. Ammash HK (2017) Shape optimization of innovation coldformed steel columns under uniaxial compressive loading. Jordan Journal of Civil Engineering 11(3): 473–489. Anbarasu M (2016) Local-distortional buckling interaction on cold-formed steel lipped channel beams. Thin-Walled Structures 98: 351–359. Anbarasu M and Sukumar S (2013) Study on the effect of ties in the intermediate length cold formed steel (CFS) columns. Structural Engineering and Mechanics 46(3): 323–335. Anbarasu M and Sukumar S (2014) Influence of spacers on the ultimate strength of intermediate length thin walled columns. Steel and Composite Structures 16(4): 37–454. Dar MA, Dar AR, Yusuf M, et al. (2015a) Experimental study on innovative sections for cold-formed steel beams. Steel & Composite Structures 19(6): 1599–1610. Dar MA, Subramanian N, Anbarasu M, et al. (2015b) Experimental investigations on the structural behaviour of a distressed bridge. Structural Engineering and Mechanics 56(4): 695–705. Dar MA, Subramanian N, Dar AR, et al. (2017) Rehabilitation of a distressed steel roof truss – a study. Structural Engineering and Mechanics 62(5): 567–576. Dar MA, Subramanian N, Dar AR, et al. (2018) Structural performance of cold-formed steel composite beams. Steel & Composite Structures 27(5): 545–554. Deepak M and Shanthi V (2018) Section bending resistance of new Hybrid Double-I-Box Beams. Advances in Structural Engineering 21(11): 1676–1695. Eurocode3 (EC3) (2006) Eurocode3: Design of Steel Structures. Part1-3: General Rules – Supplementary Rules for Cold-formed Members and Sheeting (BS EN1993-1-3). Brussels: European Committee for Standardization. Hancock GJ (2016) Cold-formed steel structures: research review. Advances in Structural Engineering 19(3): 393–408. IS 1608:2005. Indian Standard– Metallic Materials – Tensile Testing at Ambient Temperature, Bureau of Indian Standards. New Delhi, India: ISI. Keerthan P and Mahendran M (2013) Shear buckling characteristics of cold-formed steel channel beams. International Journal of Steel Structures 13(3): 385–399. Keerthan P, Hughes D and Mahendran M (2014) Experimental studies of hollow flange channel beams subject to combined bending and shear actions. Thin-Walled Structures 77: 129–140. Kumar N and Sahoo DR (2016) Optimization of lip length and aspect ratio of thin channel sections under minor axes bending. Thin-Walled Structures 100: 158–169. Laı́m L, Rodrigues JPC and Craveiro HD (2015) Flexural behaviour of beams made of cold-formed steel sigmashaped sections at ambient and fire conditions. ThinWalled Structures 87: 53–65. Laı́m L, Rodrigues JPC and da Silva LS (2013) Experimental and numerical analysis on the structural behaviour of cold-formed steel beams. Thin-Walled Structures 72: 1–13. Manikandan P, Sukumar S and Balaji TU (2014) Effective shaping of cold-formed thin-walled built-up beams in pure bending. Arabian Journal of Science & Engineering 39: 6043–6054. 185 Moen CD, Schudlich A and von der Hayden A (2013) Experiments on cold-formed steel C-section joists with unstiffened web holes. Journal of Structural Engineering 139(5): 695–704. Obst M, Rodak M and Paczos P (2016) Limit load of cold formed thin-walled nonstandard channel beams. Journal of Theoretical and Applied Mechanics 54(4): 1369–1377. Paczos P (2014) Experimental investigation of C-beams with non-standard flanges. Journal of Constructional Steel Research 93: 77–87. Paczos P and Wasilewicz P (2009) Experimental investigations of buckling of lipped, cold-formed thin-walled beams with I – section. Thin-Walled Structures 47: 1354–1362. Schafer BW (2011) Cold-formed steel structures around the world – a review of recent advances in applications, analysis and design. Steel Construction 4(3): 141–149. Schafer BW and Pekoz T (1998) Computational modelling of cold-formed steel: characterizing geometric imperfections and residual stress. Journal of Constructional Steel Research 47: 193–210. Siahaan R, Keerthan P and Mahendran M (2016a) Finite element modelling of rivet fastened rectangular hollow flange channel beams subject to local buckling. Engineering Structures 126: 311–327. Siahaan R, Mahendran M and Keerthan P (2016b) Section moment capacity tests of rivet fastened rectangular hollow flange channel beams. Journal of Constructional Steel Research 125: 252–262. SP 6-1:2003. Handbook for Structural Engineers – Part-1 and Structural Steel Sections. New Delhi, India: Bureau of Indian Standards. Subramanian N and Venugopal MS (1977) Engineering design using geometric programming. The Bridge and Structural Engineer, Journal of the ING/IABSE 7: 21–35. SudhirSastry YB, Krishna Y and Budarapu PR (2015) Parametric studies on buckling of thin walled channel beams. Computational Materials Science Part B 96: 416–424. Trahair NS and Papangelis JP (2018) Lateral-distortional buckling of beams with hollow flanges and folded plate webs. Engineering Structures 163: 71–76. Valsa Ipe T, Sharada Bai H, Manjulavani K, et al. (2013) Flexural behavior of cold-formed steel concrete composite beams. Steel and Composite Structures 14(2): 105–120. Wang FL and Young B (2016) Behavior of cold-formed steel built-up sections with intermediate stiffeners under bending. II: parametric study and design. Journal of Structural Engineering 142(3): 1–11. Wang FL, Yang J and Lim J (2014) Numerical studies of collapse behaviour of multi-span beams with cold-formed sigma sections. In: 22nd international speciality conference on cold-formed steel design and construction, St Louis, MO, 5–6 November, pp. 345–358. Rolla, MO: Missouri University of Science and Technology. Ye J, Becquea J, Hajirasoulihaa I, et al. (2018) Development of optimum cold-formed steel sections for maximum energy dissipation in uniaxial bending. Engineering Structures 161: 55–67. 186 Advances in Structural Engineering 22(1) Ye J, Hajirasouliha I, Becque J, et al. (2016) Development of more efficient cold-formed steel channel sections in bending. Thin-walled Structures 101: 1–13. Yuan HX, Wang YQ, Gardner L, et al. (2015) Local-overall interactive buckling behaviour of welded stainless steel Isection columns. Journal of Constructional Steel Research 111: 75–87. Appendix 1 Notation a A b beff b/t c CFS Cxx, Cyy d D e exx, eyy E fn fy fyb fu FB hp hc Ieff,y Ixx, Iyy Ix k Ks LB Mcr MFEM width of top compression flange cross-sectional area depth of compression flange lip effective design width ratio of spacing between bolts in the web along the depth to the thickness of the web depth of the section cold-formed steel centroid of the section of hot-rolled angle stiffener in X and Y directions depth of the tension flange lip depth of hot-rolled beam ISMB 150 width of compression flange stiffener distance of extreme fibre in the section of hot-rolled angle stiffener in X and Y directions modulus of elasticity nominal yield strength yield strength basic yield strength ultimate strength flange buckling nominal dimension of cross-sectional element distance of the point of maximum compressive stress in element from neutral axis second moment of area of effective section moment of inertia about major and minor axis second moment of area of the effective section plate buckling co-efficient buckling factor lip buckling elastic critical moment ultimate FEM-predicted moment in the central mid-third portion MEC MNAS MTest PNAS PEC PTest PFEM (P/d)Test (P/ d)FEM P, Q rxx, ryy Se tf tw T W Wf Weff,y Weff, y,c, Weff, y,t ycg Z dTest dFEM d1 d2 d# lp,h lLT r C design moment resistance predicted by EC-1993-3 design moment resistance predicted by AISI-S100 ultimate test moment in the central midthird portion design strength predicted by AISI-S100 design strength predicted by EC-1993-3 ultimate test strength ultimate FEM-predicted strength initial stiffness observed during the test initial stiffness predicted by FEM outstand elements of hot-rolled angle stiffener minimum and maximum radius of gyration elastic section modulus relative to top fibre thickness of flange of hot-rolled beam ISMB 150 thickness of web of flange of hot-rolled beam ISMB 150 wall thickness of hot-rolled angle stiffener weight per metre length width of flange of hot-rolled beam ISMB 150 effective section modulus section moduli with regard to compression and tension flanges, respectively depth of neutral axis with respect to the compression flange position of neutral axis from respective flange maximum deflection at the mid-span in the model tests maximum deflection at the mid-span predicted by FEM maximum imperfection at the mid-span in the transverse direction maximum imperfection at the mid-span in the longitudinal direction elongation (tensile strain) after fracture based on gauge length of 50 mm relative slenderness non-dimensional slenderness for lateral torsional buckling width reduction factor stress ratio