Cooperative game-based anchor process allocation within sustainable palm oil based complex for environment-food-energy-water nexus evaluation

advertisement

Journal of Cleaner Production 314 (2021) 127927

Contents lists available at ScienceDirect

Journal of Cleaner Production

journal homepage: www.elsevier.com/locate/jclepro

Cooperative game-based anchor process allocation within sustainable palm

oil based complex for environment-food-energy-water nexus evaluation

Yue Dian Tan a, b, Jeng Shiun Lim a, b, *, Viknesh Andiappan c, Sharifah Rafidah Wan Alwi a, b

a

Process Systems Engineering Centre (PROSPECT), Research Institute of Sustainable Environment (RISE), Universiti Teknologi Malaysia, 81310, Johor Bahru, Johor,

Malaysia

b

School of Chemical and Energy Engineering, Faculty of Engineering, Universiti Teknologi Malaysia, 81310, UTM Johor Bahru, Malaysia

c

School of Engineering and Physical Sciences, Heriot-Watt University Malaysia, 1, Jalan Venna P5/2, Precinct 5, 62200, Putrajaya, Wilayah Persekutuan, Malaysia

A R T I C L E I N F O

A B S T R A C T

Handling editor: Cecilia Maria Villas Bôas de

Almeida

The challenge in clean palm oil production falls on the management of palm oil mill effluent which is a notable

source of greenhouse gas emissions and water pollution. To address these critics against edible palm oil, an

integrated palm oil-based complex (POBC) considering effluent elimination and refinery integration is suitable

for environmental-food-energy-water (EFEW) nexus development. Optimal retrofit of palm oil mill into EFEW

nexus-integrated POBC requires multi-objective considerations to balance the trade-offs between profitability,

energy contribution, greenhouse gas, water and land footprints via fuzzy optimisation. With limited practical

knowledge, potential flowsheet modifications should be investigated for flexible POBC design. In a cooperative

game context, interconnecting processes act as multiple players cooperating to achieve the goal of the game, i.e.,

POBC performance, where each player has a distinctive impact on the outcome. In this work, such process

performance was suggested to be distributed using cooperative game model, to target the EFEW-based anchor

process, i.e., the process stage of greatest contribution in the weighted EFEW nexus, for desired flowsheet

advancement. Considering these aspects, an integrated fuzzy and cooperative game optimisation framework was

developed to identify the anchor process of an EFEW nexus-integrated POBC. EFEW objective-based process

performance allocation in the fuzzy optimal POBC was weighted by the decision-maker to allocate the anchor

process using developed models and Excel tools. Nut/kernel separation and cogeneration stage is the EFEWbased anchor process in the fuzzy optimal POBC with EFEW nexus score of 41% in this work. A comparative

analysis between the proposed method with other approach was done. The favourability of EFEW contributions

by POBC in terms of benefit-drawback ratio increased with the percentage of boiler efficiency increment within

the targeted anchor process. Targeting anchor process aids planning for process maintenance and advancement

to avoid resource wastage on sub-critical processes.

Keywords:

Cooperative game

Waste elimination

Environment-food-energy-water nexus

Optimisation

Sustainable development

Multi-objective

1. Introduction

There is no doubt that palm oil industry secures a major role in global

food production by supplying 34% of the international vegetable oil

demand (The American Soybean Association, 2018). To major palm oil

exporters such as Malaysia, the plus from palm oil industry in gross

domestic product growth comes with the minus in terms of environ­

mental threats such as water pollution and climate change (Andiappan

et al., 2018). Despite the need to satisfy increasing global oilseed-based

food demand (Abdul-Hamid et al., 2020), the sustainability critics

hinder Malaysia from achieving palm oil production targets via oil

extraction rate improvement in Malaysian palm oil mills for projected

biodiesel consumption (Dompok, 2013) and palm oil economic potential

exploitation (Ministry of Economic Affairs, 2019). In palm oil mill,

increased palm oil production associates with greater energy and water

consumption, indirectly contributes to greenhouse gas (GHG) emissions

and water scarcity (Subramaniam et al., 2011) due to steam-intensive

and water-consuming milling processes. Additionally, greater palm oil

mill effluent (POME) generation is unfavourable towards water security

and GHG mitigation due to its polluting nature and GHG-emitting

anaerobic treatment (International Energy Agency (IEA), 2014).

To address the regarded concerns and comply with the mandatory

Malaysian Sustainable Palm Oil certification scheme (Shahida et al.,

* Corresponding author. Process Systems Engineering Centre (PROSPECT), Research Institute of Sustainable Environment (RISE), Universiti Teknologi Malaysia,

81310, Johor Bahru, Johor, Malaysia.

E-mail address: jslim@utm.my (J.S. Lim).

https://doi.org/10.1016/j.jclepro.2021.127927

Received 14 December 2020; Received in revised form 4 June 2021; Accepted 12 June 2021

Available online 17 June 2021

0959-6526/© 2021 Elsevier Ltd. All rights reserved.

Y.D. Tan et al.

Journal of Cleaner Production 314 (2021) 127927

List of symbols and abbreviations

Binary indicator for unprocessed product i for external

RindEXPRO

i

processing or treatment

Abbreviations

AHP

Analytic Hierarchy Process

B/D

Benefit-drawback

BOD

Biological Oxygen Demand

CHP

Combined Heat and Power

CN

Cracked Nut

CO2

Carbon Dioxide

CPLEX

IBM ILOG CPLEX Optimizer

CPO

Crude Palm Oil

DF

Digested Fruitlet

EFB

Empty Fruit Bunches

EFEW

Environment, Food, Energy and Water

FFB

Fresh Fruit Bunches

GAMS

General Algebraic Modelling System

GHG

Greenhouse Gas

GP

Gross Profit

HPS

High-Pressure Steam

LPS

Low-pressure Steam

MPS

Medium-pressure Steam

PFAD

Palm Fatty Acid Distillate

PFN

Palm Fruit Nut

PK

Palm Kernel

PKS

Palm Kernel Shell

PL

Pressed Liquid

PMF

Palm Mesocarp Fibre

POBC

Integrated Palm Oil-Based Complex

POME

Palm Oil Mill Effluent

PORE

Palm Oil Refinery Effluent

PS

Pressed Solid

RBDPOL Refined, Bleached, Deodorised Palm Olein

RBDPS Refined, Bleached, Deodorised Palm Stearin

SBR

Sequential Batch Reactor

SF

Sterilised Fruitlet

SFB

Sterilised Fruit Bunch

SSI

Shapley-Shubik Power Index

WFP

Water Footprint

Sets

f

i

p

u

z

Objective function variables

NE

Net amount of electrical energy converted from biogas or

biomass (MWh)

GP

Annual gross profit generated by POBC (USD/y)

EP

Annualised economic potential of POBC (USD/y)

GHGBAL Overall GHG impacts at the POBC (kgCO2eq/h)

LFP

Human infrastructure based land footprint (hectare)

TWFP

POBC’s WFP which accounts grey WFP and blue WFP (t/h)

λ

Fuzzy aggregate membership degree between multiple

objective functions

Parameters

AOT

Number of operation hours for POBC in a year (h/y)

AVRESLOCAL

Basis amount of available resource for import (t/h)

i

Additional

amount of intermediate resource i made

AVRESPEXT

i,p

available during failure of process p (t/h)

Cact

Pollutant concentration in actual water supply (mg/L)

Pollutant concentration of treated effluent (mg/L)

Ceff

Cmax

Maximum BOD value at waterways (mg/L)

BOD value of natural water supply (mg/L)

Cnat

EPL ,EPU Fuzzy lower and upper limits for economic potential (USD/

y)

EFEWwOBJ Defined weightages for EFEW objectives (GP, NE,

GHGBAL and TWFP) to calculate EFEW nexus score and B/

D ratio

GHGBALFuzzy Fuzzy optimal GHG balance in POBC multi-objective

optimisation (kgCO2eq/h)

GHGBALL GHGBALU Fuzzy lower and upper limits for GHG

balance (kgCO2eq/h)

LFPL ,LFPU Fuzzy lower and upper limits for land footprint (hectare)

MCMi,p Material i consumption factor in process p

Non-consumed material i for the failure of process p

MCMBY

i,p

NEL , NEU Fuzzy lower and upper limits for net energy (MWh)

PRICEi Market price for selling one unit of system-generated

product i (USD/t)

PRCMi,p Resource i conversion factor in process p

PRCMBY

Non-generated material i for the failure of process p

i,p

Set of process stages defining groups of processes based on

their specific function in POBC

Set of resources including material and product involved in

POBC

Set of processes or technology considered in POBC process

route design

Set of stand-alone process stages as basis for objective

improvement calculation

Set of process failure scenarios defining various working

combinations of process stages for different process failure

possibilities

PWOBJ

f

process stage f for EFEW objectives (GP, NE, GHGBAL and

TWFP) in cooperative game model

Ref GHG

Parameter addressing GHG emission from one unit of

i,p

material i in process p (kgCO2eq/t)

RindGHGPRO

GHG-emitting indicator for unconsumed product

i

(kgCO2eq/t)

RindGHGRES

GHG-emitting indicator for external resource import

i

(kgCO2eq/t)

TWFPFuzzy Fuzzy optimal WFP in POBC multi-objective optimisation

(t/h)

TWFPL , TWFPU Fuzzy lower and upper limits for WFP (t/h)

UCAPEXp Capital expenditure for installing required units of

process p (USD/unit)

UOPEXp Unit cost for operation of process p (USD/unit)

URCOSTi Unit import price of external material i (USD/t)

URCOSTEXT

Unit external processing cost of resource i (USD/t)

i

Binary parameters

BYindADD

Binary indicator for additional available intermediate

i

product i

Binary indicator for intermediate material i in core process

MindEXT

i,p

p to be processed externally

PindBYPASS

Binary indicator for failing process p

p

PindEXIST

Binary indicator for functioning process p

p

PindINT

p

PindREL

p

PRindREL

i,p

Marginal contributions or performance weightage for

Binary indicator for integrated milling process p

Variables

ALLOBJ

Distributed EFEW objective-based performance to process

f

Binary indicator for correlated process p

Binary indicator for intermediate resource i to be

considered in correlated process p

RindEXGEN

Binary indicator for externally generated resource i

i

AVRESi

2

stage f (GP, NE, GHGBAL and TWFP)

Overall amount of resource i available for purchase from

Y.D. Tan et al.

Journal of Cleaner Production 314 (2021) 127927

external sources (t/h)

capp

Total units of equipment operating for process p (unit)

EFF

Hourly flowrate of treated effluent (t/h)

ELECCOST Expense for grid electricity import (USD/h)

ELECREV Income from exporting self-generated electricity (USD/h)

ELECEX Required amount of grid electricity for import (MWh)

ELECEXCESS Surplus electricity generated to be sold (MWh)

EXRESi Hourly flowrate of imported material i (t/h)

n

NSEFEW

f

Number of process stage f defined

Percentage weighted-sum EFEW nexus score (%)

PALLOBJ

Percentage EFEW objective-based performance allocation

f

PRESp

PROi

SGRESi,p

imp

GPimp

Characteristic functions for GP and net energy

z , NEz

distribution defined as GP and NE improvements in

scenario z compared to basis scenario u

GPNew , NENew , TWFPNew , GHGBALNew Optimal values for EFEW

objectives (GP, NE, GHGBAL and TWFP) in GP-maximised

scenario for modified POBC

IMPOBJ

Percentage EFEW objective (for GP, NE, GHGBAL and

TWFP) improvements in new POBC flowsheet with anchor

process parameter changes (%)

MATi,p

Hourly flowrate of feed resource i to process p (t/h)

TIS

v(z)OBJ

v(ℵ)OBJ

(GP, NE, GHGBAL and TWFP) for process stage f (%)

Total amount of resource i to be processed in process p (t/

h)

Generated material i sold directly as product (t/h)

Hourly flowrate of system-generated resource i from

process p (t/h)

Percentage total improvement score for the modified POBC

based on anchor process parameter changes (%)

Characteristic function for EFEW objectives (GP, NE,

GHGBAL and TWFP)

Characteristic function value of the full operation scenario

with no failure of process stages included for EFEW

objectives (GP, NE, GHGBAL and TWFP)

food-energy-water nexus are investigated. The work of Jaroenkietkajorn

and Gheewala (2020) has compared two food-energy-water nexus as­

sessments in studying different regions of oil palm plantation in

Thailand. Multi-objective optimisation studies with nexus consider­

ations are still limited to food-energy-water objectives. For hypothetical

food-energy-water system evaluations, Zhang and Vesselinov (2017)

have presented a multi-period modelling approach to perform trade-off

analysis for the economic advantage, food supply, energy supply and

water consumption. In the optimisation of biofuel production system,

López-Díaz et al. (2018) developed a mixed-integer linear programming

optimisation model to integrate with food-energy-water nexus. Tan et al.

(2020b) have attempted food-energy-water nexus evaluations to address

trade-offs between biogas recovery and POME elimination pathways by

maximising food revenue and energy balance while minimising the

water footprint (WFP) of optimal POBC design. To consider GHG impact

and land use, Tan et al. (2020c) further the study by including GHG

emissions and land footprint minimisation in the multi-objective opti­

misation of POBC. It is desired to further evaluate the flexibility of fuzzy

optimal POBC design for practical application and EFEW nexus devel­

opment. The flexibility of optimal palm oil mill design with maximum

economic performance was studied in the optimisation work of Foong

et al. (2019a). However, their work only focused on the mill side without

considering POME management and EFEW performance. There is still a

lack of EFEW nexus elaboration within the integrated palm oil produc­

tion system, especially on the process level impact, which is crucial to

provide insights for palm oil mill flexibility.

To integrate EFEW elements in the optimal planning of a new system

such as POBC, multi-objective optimisation alone could not exhibit the

flexibility of designed POBC flowsheet. Flowsheet modification should

be targeted to achieve desired performance improvements in consider­

ation of relative impacts to EFEW nexus. The challenge is to identify the

anchor process, i.e., the process which provides the greatest contribu­

tion to the plant’s performance concerning all aspects in the EFEW

nexus, to discover opportunities for process advancement in the

designed system. Failing to target the anchor process before flowsheet

modification could result in wasting of financial, material and human

resources as well as unbalanced EFEW performance trade-offs due to

investment in sub-critical processes which provides limited or negative

contribution to the EFEW nexus-integrated POBC. The key strategy in

anchor process determination is to demonstrate individual contribution

of each process towards multiple EFEW objectives achieved by the

optimal POBC flowsheet. The concept of anchor process was proposed

by Tan et al. (2020d) in their work to determine internal process in­

fluence on POBC’s economic performance. A cooperative game-based

2019), palm oil holders need a guideline to link the planning of palm oil

mill with the environment-food-energy-water (EFEW) nexus to consider

trade-offs between sustainability drivers. Efforts such as POME-based

biogas recovery, bio-fuel commercialisation and palm oil value addi­

tion has been initiated under the Palm Oil National Key Economic Area

for positive impacts on the EFEW nexus (Wan Ab Karim Ghani et al.,

2019). However, unfavourable economics have impeded the adoption

rate of these projects especially biogas facility among Malaysian palm oil

mills (Loh et al., 2017). Tan et al. (2020c) have suggested an alternative

palm oil production structure based on POME elimination technologies

and food, energy, water, effluent integrations between palm oil mill and

refinery. For cleaner palm oil production, the proposed structure known

as integrated palm oil-based complex (POBC) considers alternative

POME elimination pathway which applies undiluted clarification to

reduce POME load for further evaporation to recover trapped oil, avoid

methane emissions and convert effluent to marketable solid (Kandiah

and Batumalai, 2013). Nevertheless, potential linkages exist in the

energy-intensive evaporation process and elimination of renewable en­

ergy feedstock (i.e., biogas) which contribute distinctively to the EFEW

nexus. EFEW nexus integration is desired to evaluate the synergies be­

tween GHG impact, food, energy, and water resources in local produc­

tion systems such as POBC for sustainability enhancement (Leung Pah

Hang et al., 2016).

The concept of EFEW nexus was broadened from the food-energywater nexus applied to address the United Nation Sustainable Devel­

opment Goals by considering the environmental element (Zhang et al.,

2018). According to Hamidov and Helming (2020), the concept of

food-energy-water nexus has been proven critical to natural resource

management studies especially on irrigated agriculture systems to

investigate the coupled relationships between food production and

competing water use for agriculture and energy generation. The

assessment of food-energy-water nexus could highlight the impacts of

water governance principles on transboundary water use such as the

Indus Water Treaty (Kalair et al., 2019). Sun et al. (2020) have per­

formed quantification of potential synergies within the water, energy

and environmental pollutant nexus of the petrochemical production

system via an integrated approach. EFEW nexus evaluation has been

gaining attention in palm oil case studies. Recently, the elaboration in

EFEW nexus has been done on empty fruit bunches (EFB) value chain

optimisation in Peninsular Malaysia (James Rubinsin et al., 2020). Wan

Ab Karim Ghani et al. (2019) have discussed the impacts of EFEW nexus

on the biomass value chain planning in Malaysia using palm-based

biomass as case study. In the experimental-based study of Loh et al.

(2019), the impacts of POME-based organic fertiliser on the

3

Y.D. Tan et al.

Journal of Cleaner Production 314 (2021) 127927

optimisation approach has been suggested to assist the aforementioned

task (Tan et al., 2020d).

The cooperative game theory model developed by Maali (2009)

based on linear programming has been applied by previous researchers

in formulating profit allocation among collaborating plants. The coop­

erative game approach is desired when the players in a “game” are

willing to compromise and collaborate, thus is suitable for describing

interdepending processes within a system. In this context, the internal

processes within the POBC serve as multiple “players” responsible for

the overall performance of the “game”, allowing pooled benefits or

impacts with respect to each targeted objective to be rationally

distributed among the processes using adapted cooperative game model.

Researchers have been utilising cooperative game-based framework to

perform rational savings allocation between participating parties within

eco-industrial parks (EIP) (Tan et al., 2016). Andiappan et al. (2015) has

adapted Maali’s model to perform cost savings distribution among

collaborating facilities within a palm-based EIP. Tan et al. (2016)

demonstrated interplant profit allocation in a palm oil EIP using a linear

programming model according to game theory. Andiappan et al. (2016)

extended their previous model to evaluate the economic viability of a

palm-based EIP based on cooperative game theory to include stability as

one of the criteria in achieving industrial integration between palm oil

mill, biomass trigeneration system and palm biomass biorefinery of

different ownerships. Andiappan et al. (2018) adapted his published

results to perform cooperative game-based allocation of incremental

benefits among stakeholders in the palm-based EIP, concerning their

respective contributions.

Besides the cooperative game optimisation model, another potential

approach to provide rational basis for benefit distribution using coop­

erative game theory is the application of Shapley-Shubik Power Index

(SSI). SSI was originally proposed for evaluating the power of each voter

in affecting the result of a voting system (Wilms, 2020). The quantifi­

cation of SSI involves the generation of sequential coalitions by

considering each vote to be added one-by-one in different sequences to

the coalition until the number of positive votes meets the winning quota.

In a sequential coalition, the vital voter that secures the winning status

of the coalition when his/her vote enters the coalition in the defined

sequence is known as the pivotal voter. According to Shapley and Shubik

(1954), the frequency of each participated voter being determined as the

pivotal voter among all possible sequential coalitions could be used to

define the power of each voter in influencing the voting outcome. By

applying this concept, SSI has been considered to validate the

cost-benefit distribution for an energy supply network by Wu et al.

(2017). Mizuno et al. (2020) have explored the use of SSI in quantifying

corporate control among stakeholders. Recently, the utility of SSI has

been extended for process impact evaluation within a palm oil-based

complex to target the potential system bottleneck (Tan et al., 2021).

Previous literature has shown limited work in process level benefit

allocation within an EFEW nexus-integrated plant such as POBC. As

mentioned previously, Tan et al. (2020d) attempted economic perfor­

mance distribution among internal processes in the POBC using coop­

erative game model. Their recent work proposed a debottlenecking

framework to identify the profit and energy driving system bottleneck in

the multi-objective optimal POBC based on SSI allocation for flowsheet

debottlenecking (Tan et al., 2021). However, both works lack simulta­

neous consideration of economic, energy and environmental perfor­

mance allocation for designed POBC to investigate all aspects from the

EFEW nexus. In this regard, this study aims to address the gaps in pre­

vious studies to propose a systematic cooperative game-based optimi­

sation framework for targeting the anchor process based on

multi-objective process impact allocation in an optimal EFEW

nexus-integrated POBC. The proposed approach and mathematical

models could be applied consecutively to aid palm oil holders in sus­

tainable planning of palm oil mill retrofit to comply with sustainability

standards and provide insights on optimal budget allocation for POBC

investment.

In this study, the problem statement could be addressed as below:

• Given a set of technologies p (POME elimination, palm oil milling,

biogas recovery, physical refining) and resources i, an optimal POBC

flowsheet is aimed to be designed with simultaneous consideration of

multiple objectives (GHG, land and water footprints, economic po­

tential, net energy) via fuzzy optimisation method based on essential

process, economic, and environmental data.

• Groups of processes p carrying specific function in the given fuzzy

optimal POBC flowsheet are defined as the set of process stages f. By

considering different possibilities of process stage failures, all

working combinations of process stage f are defined under the set of

process failure scenario z.

• The characteristic function v(z) is defined as the pooled economic

and energy benefits or environmental impacts contributed by all

process stages f working together in scenario z. The values of v(z) are

obtained according to the description in Section 2.2.1.2.

• Based on the optimal values of characteristic function, allocation of

EFEW contributions among process stages f is performed via the

adapted cooperative game model proposed by Maali (2009) and

subsequently determine the specific anchor process for each EFEW

objective.

• Given the heuristic weights for EFEW objectives (gross profit, net

energy, GHG impacts and WFP) from decision-maker, the final aim is

to identify the overall anchor process in the fuzzy optimal POBC,

which is the process stage f of highest weighted-sum performance

allocation, (i.e., EFEW nexus score), in defined objectives. Benefitdrawback ratio analysis is conducted to verify the feasibility of an­

chor process advancement in POBC flowsheet modification.

Assumptions and limitations:

1) Extra cost is incurred to purchase resources processed externally to

allow operation of stand-alone process stages within the palm oil

mill.

2) To perform palm oil mill retrofit with compliance to current policies

and standards, the evaluation scope of environmental POBC foot­

prints is assumed within the system boundaries of a palm oil mill.

3) Only electricity converted from biomass in excess on-site or exported

to grid is added to the net energy of POBC.

4) To eliminate waste, all by-products and waste are assumed to be

consumed completely at the POBC thus GHG emissions from trans­

porting resource and logistic constraints are beyond the scope of the

work.

The content of this paper is outlined below. The problem is first

stated to include EFEW-based anchor process targeting in the optimal

design of a POBC with EFEW nexus integrations. The development of the

suggested integrated approach and mathematical models will be elab­

orated in Section 2 before applying them consecutively in Section 3 to

solve the given case study. Cooperative game-based performance allo­

cation will be conducted to target the POBC anchor process for concerns

in the EFEW nexus followed by the comparative analysis with SSI

method and anchor process validation via benefit-drawback analysis in

Section 4.

2. Methodology

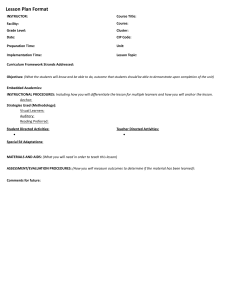

The proposed systematic framework to identify the anchor process

for an optimal POBC design concerning multiple EFEW objectives is

illustrated in Fig. 1 consisting of fuzzy optimisation and cooperative

game-based process impact distribution approaches. The fuzzy multiobjective optimisation approach as shown in Fig. 1 is adopted from

the published work by Tan et al. (2020c) to introduce the beginning step

for the new cooperative game-based anchor process targeting frame­

work. Using the fuzzy optimal POBC flowsheet produced from Stage 1,

4

Journal of Cleaner Production 314 (2021) 127927

Y.D. Tan et al.

Fig. 1. Fuzzy optimisation and cooperative game-based anchor process targeting framework proposed for optimal design of EFEW nexus-integrated POBC.

different optimal scenarios are generated for all possibilities of process

stage failure via the scenario optimisation model in the initial phase of

Stage 2. Based on the optimal results, the developed cooperative

game-based performance allocation method is applied to quantify the

impacts of POBC process stages on multiple EFEW objectives. The

EFEW-based anchor process is then targeted based on the heuristic

EFEW objective priority weights obtained from the decision-maker. The

benefit-drawback (B/D) ratio analysis is included in the developed

framework to validate the determination of anchor process by evalu­

ating the impacts of selected process parameter change on the

EFEW-based performances of the POBC with maximum profit. The detail

description of each methodological approach in Fig. 1 is given in the

subsections.

5

Y.D. Tan et al.

Journal of Cleaner Production 314 (2021) 127927

2.1. Formulation of fuzzy multi-objective optimisation model

2.2.1.1. Formulations of EFEW objective functions. The target objective

functions for EFEW nexus evaluations are gross profit (GP), net energy,

GHG impacts and total WFP of the POBC. GP of a food production system

(i.e., POBC which gains main revenue from selling refined palm oil

products), could reflect its degree of contribution to the food market

thus should be evaluated in the EFEW nexus for global food security and

economic feasibility. GP is evaluated as the variable economic perfor­

mance of the POBC to exclude the capital expenses of selected and

installed processes in the fuzzy optimal POBC while distributing the

process impacts on long-term POBC profitability. The GP of POBC is

calculated via Eq. (8) by deducting the annual costs for operating

working units of technology p (capp ), purchasing material i externally at

required amount (EXRESi ) and importing electricity from grid

(ELECCOST) given the unit processing cost (UOPEXp ) and material

purchase cost (URCOSTi ) from the overall product revenue of selfgenerated product i at optimal output flowrates (PROi ) and excess

electricity (ELECREV) sold at unit selling prices (PRICEi ). To evaluate

the energy synergies of POBC in the EFEW nexus using Eq. (9), the POBC

net energy contribution (NE) accounts the amount of on-grid electricity

supply from biogas-based power plant (PROi=32 ) and excess on-site

electricity generated from biogas or biomass (ELECEXCESS ) after deduct­

ing the external electricity requirements (ELECEX ). In this study, the

environmental aspects in the EFEW nexus to be evaluated is the GHG

impacts of the POBC defined as the net GHG balance (GHGBAL) and the

total WFP. Based on Eq. (10), GHGBAL sums up the GHG emissions from

external resources and process materials. The process GHG emissions are

contributed by resources defined via the GHG process material reference

parameter (Ref GHG

i,p ) at optimal amounts of system-generated resource i

(SGRESi,p ) and process feed material i (MATi,p ). Some unconsumed

products and imported resources with positive GHG indicators for

external resource (RindGHGRES

) and product (RindGHGPRO

) will increase

i

i

GHG balance. This applies when raw POME emits methane and grid

electricity import increases national demand of fossil-based energy. For

water scarcity and security concerns, both blue WFP and grey WFP for

freshwater consumption and effluent generation are considered for the

overall WFP of POBC (TWFP) for EFEW nexus study. TWFP in Eq. (11) is

calculated as the sum of blue WFP, i.e., freshwater requirements per

hour (EXRESi=24 ), and grey WFP defined as the water demand estimated

to assimilate the effluent discharged at certain amount (EFF) given the

pollutant concentrations in the actual water supply (Cact ) and discharged

effluent (Ceff ), natural water quality (Cnat ) and maximum pollutant

concentration (Cmax ) (Subramaniam et al., 2014). The formulations for

the four objective functions, Eqs. (8)-(11), are based on the paper of Tan

et al. (2020d).

[

(

∑

∑

GP = AOT ×

PROi × PRICEi −

EXRESi × URCOSTi

To obtain optimal process route selection and flowsheet design

considering multiple objectives for sustainable POBC planning, fuzzy

optimisation approach is applied to study the trade-offs between five

objective functions, namely economic potential (EP), net energy (NE),

GHG emissions in balance (GHGBAL), overall WFP (TWFP) and opera­

tional land footprint (LFP). The fuzzy optimisation of POBC serves as the

beginning stage in the new anchor process targeting framework via the

fuzzy approach and optimisation models developed by Tan et al. (2020c)

to generate the multi-objective optimal POBC flowsheet. To determine

the fuzzy lower limits (e.g. EPL ) and upper limits (e.g. EPU ) for all ob­

jectives, the generic POBC optimisation model is solved individually

subjected to each objective function. The fuzzy limits are incorporated

into the fuzzy constraints, Eqs. (2)–(6), in the multi-objective optimi­

sation model. The fuzzy model is then solved by an integrated objective

function defined as λ, which indicates the aggregate degree of mem­

bership in the optimal fuzzy set (i.e., overall fuzzy level of satisfaction of

the fuzzy goals). Solving the model with the objective function in Eq. (1)

generates the fuzzy optimal POBC flowsheet.

Maximise λ

(1)

EP − EPL

≥λ

EPU − EPL

(2)

NE − NEL

≥λ

NEU − NEL

(3)

GHGBALU − GHGBAL

≥λ

GHGBALU − GHGBALL

(4)

TWFPU − TWFP

≥λ

TWFPU − TWFPL

(5)

LFPU − LFP

≥λ

LFPU − LFPL

(6)

0≤λ ≤ 1

(7)

2.2. Cooperative game-based anchor process targeting approach for

environment-food-energy-water (EFEW) nexus

As shown in Fig. 1, the following stage aims to determine the anchor

process for critical enhancement of the fuzzy optimal POBC flowsheet

concerning EFEW nexus contributions. In this stage, anchor process is

defined as the process stage with the greatest contribution to POBC

performance considering all aspects of the EFEW nexus. The proposed

anchor process determination approach adopts Maali’s cooperative

game linear programming model to rationally distribute the overall

plant performance among internal process stages f in the fuzzy optimal

POBC flowsheet with respect to each EFEW objective. The procedure for

EFEW-based anchor process targeting will be elaborated in the

subsections.

i

)]

+ ELECREV − ELECCOST

i

∑

−

capp × UOPEXp

(8)

p

(9)

NE = PROi=32 + ELECEXCESS − ELECEX

2.2.1. Multi-objective process impact distribution

The objective of targeting anchor process is to identify which process

stage provides the best trade-offs on the EFEW nexus improvements if

being invested for POBC flowsheet enhancement. This step is essential to

avoid incurring unnecessary capital for sub-optimal process investments

and time wastage for simulating all potential process variations in a

complex production system. To determine the EFEW-based anchor

process, allocation of process stage impacts for multiple POBC perfor­

mances is proposed to be done via a systematic cooperative game

optimisation approach. The detailed methodology will be elaborated as

follows.

GHGBAL =

(

)

∑ ∑

∑

GHG

Ref GHG

×

MAT

+

Ref

×

SGRES

i,p

i,p

i,p

i,p

p

i

i

(

)

+ RindGHGRES

× ELECEX

i=31

+

+

i

∑

RindGHGPRO

× PROi

i

i

(10)

(

TWFP = EXRESi=24 + EFF

∑

RindGHGRES

× EXRESi

i

Ceff − Cact

Cmax − Cnat

)

(11)

2.2.1.2. Scenario generation and characteristic function formulation. The

6

Y.D. Tan et al.

Journal of Cleaner Production 314 (2021) 127927

cooperative game model developed by Maali (2009) is adapted to pro­

vide optimal benefit or impact distribution among POBC processes.

According to Maali (2009), characteristic function addresses the defined

benefits for distribution and should be determined for all potential co­

alitions with different combinations of cooperative players, in this case,

interconnecting processes, to perform rational benefit allocation via the

linear programming model. The challenge is to obtain the optimal

characteristic function values for different process coalitions. Using the

fuzzy optimal POBC flowsheet obtained via the optimisation approach in

Section 2.1, the members of set f are defined as the vital process stages

by grouping selected processes p in the flowsheet according to the spe­

cific function of process stages and process interdependencies. To

evaluate different coalitions, it is assumed that one or more process

stages f exit from the coalition when they fail to operate, a set of process

stage failure scenarios z is thus determined to consider all working

combinations of process stage f based on failures of process stage using

an Excel Spreadsheet. For instance, process stages of {1,2,3,4,5} are

defined under set f. When process stage f = 1 fails in the process failure

scenario z = 1, f = 1 will not be included as a member in this scenario,

resulting in z1 = {2,3,4,5} only. Generally, every subset of f is the

element of set z except the empty set in mathematical means. Given n

number of process stages f defined, the combination formula, Eq. (12),

can be used to calculate the total number of potential scenario z (Vel­

leman and Call, 1995).

∑

Number of z = |z| =

r

n!

, r ∈ f , n = |f |

r!(n − r)!

emissions-minimised and WFP-minimised scenario z, GHGBALz and

TWFPz according to Eqs. (15)-(16).

v(z)GP = GPimp

= GPz − GPu

z

∀z u∈z

(13)

v(z)NE = NEzimp = NEz − NEu

∀z u∈z

(14)

v(z)GHGBAL = GHGBALz

v(z)TWFP = TWFPz

∀z

∀z

(15)

(16)

2.2.1.3. Integrated formulations for scenario optimisation model. To

obtain the optimal values of GPz , NEz , GPu , NEu , GHGBALz and TWFPz

for characteristic function calculation, each scenario z should be opti­

mised individually for every objective function. Conventionally,

different superstructures should be developed for every process failure

scenario z to formulate the respective mathematical models, which is

undesirable in terms of efficiency and conveniency. By including

scenario-specific parameters and formulations in Eqs. (17)-(20), a

mixed-integer linear programming optimisation model is formulated

and solved with subject to each objective function to produce optimal

objective values for calculating the characteristic functions of all sce­

narios z. Additional formulations of Eqs. (17)-(20) based on the work of

Tan et al. (2020d) need to be integrated with the POBC optimisation

model to simultaneously generate specific optimal results for each

process failure scenario z.

To identify the correlated, integrated, by-passing, existing processes

p based on working process stages f in each scenario z, binary parameters

INT

BYPASS

PindREL

and PindEXIST

are assigned with binary

p , Pindp , Pindp

p

values. When mill and refinery process integration is considered

(PindINT

= 1) in scenario z, intermediate resource i that requires

p

external processing due to failure of core process p, is given value 1 for

binary external intermediate material indicator (MindEXT

i,p ), whereas

externally generated resources such as crude palm oil (CPO) to be pur­

chased at market price to substitute lost self-generated resources, is

given value 1 for binary external generated resource indicator

(RindEXGEN

). Absent core process p between two working units is defined

i

as correlated process p (PindREL

= 1) to estimate the required amount of

p

intermediate resource. Polluting waste or unprocessed product

(RindEXPRO

) retained due to process p failure, i.e., POME, requires

i

external treatment or processing. Considering the defined binary pa­

rameters, Eq. (17) summed up the external processing costs for unpro­

cessed and intermediate resources during specific process failures with

fixed unit external resource processing costs (URCOSTEXT

). The overall

i

availability of external resource (AVRESi ) includes the basic available

quantity of resource without process failures (AVRESLOCAL

) and the

i

extra available quantity of intermediate resource during specific process

) as in Eq. (18). To eliminate by-product generation

failures (AVRESPEXT

i,p

and utility consumption during process p failures, the original process

resource conversion matrices, MCMi,p and PRCMi,p , require corrections

BY

by incorporating MCMBY

i,p and PRCMi,p into Eqs. (19)-(20) to estimate an

accurate amount of total processing resource in technology p (PRESp ).

Scenario-specific PRCMBY

i,p is used to correct the general PRCMi,p in Eq.

(20) as well. In Eq. (20), the quantity of intermediate process material

that requires external processing is predicted by multiplying PRCMi,p

with the binary process resource material indicator PRindREL

i,p to allow

(12)

For multi-objective performance allocation, distinctive characteristic

functions, v(z), need to be defined for each EFEW objective to evaluate

the pooled benefit or impact in each process stage failure scenario z

(Maali, 2009). The four objective functions formulated in Section

2.2.1.1 are used to calculate the characteristic functions for developed

cooperative game models. To allocate process impacts to each EFEW

objective using the cooperative game model, different objective-based

characteristic functions, v(z)OBJ as in Eqs. (13)-(16), are calculated

using an Excel Spreadsheet based on single-objective optimisation re­

sults of scenario z. For process impact distribution towards GP and net

energy of POBC, the characteristic functions are addressed as overall

benefits received from the process stage coalition, given as GP im­

imp

provements (GPimp

z ) and net energy improvements (NEz ). GPz is ob­

tained as the optimal GP when performing scenario z optimisation with

the objective function of maximising GP. To calculate the objective

improvements for each scenario z, the optimal objective function values

of each scenario z need to be compared to the performance of

stand-alone process stage operation. Therefore, a set of basis process

stage u is selected from the operating process stage f in each scenario z as

the basis stand-alone scenario used to allocate overall performance

improvements during process stage coalition. In this context, GPu and

NEu represent the optimal GP and net energy during sole operation of

basis process stage u according to the case study. In Eq. (13), GPimp

is

z

calculated by deducting GPu obtained in stand-alone process stage u

operation scenario from GPz which is the optimal GP generated for

scenario z including operation of basis process stage u (Tan et al., 2016).

Similarly, the relative net energy increment in the process stage failure

scenarios, NEimp

is calculated via Eq. (14). For the environmental foot­

z

print distribution in terms of GHG emissions and total WFP, the char­

acteristic functions are defined as the overall footprint accounted in each

scenario z to demonstrate the environmental impacts contributed by

resource conversion in the correlated processes (PindREL

= 1) for in­

p

termediate material flowrate prediction as part of the system-generated

each process stage f in all scenarios z. Hence, v(z)GHGBAL and v(z)TWFP are

defined as the optimal objective function values for GHG

7

Y.D. Tan et al.

Journal of Cleaner Production 314 (2021) 127927

process output resource (SGRESi,p ).

∑

×

SGRESi,p × RindEXPRO

+ URCOSTEXT

COSTiEXT = URCOSTEXT

i

i

i

p

∑

BYPASS

×

SGRESi,p × MindEXT

× PindINT

+

i,p × Pindp

p

p

× RindEXGEN

×

i

∑

SGRESi,p

ALLfOBJ ≥ v(z = {f } )OBJ ∀f

OBJ = GP, NE, GHGBAL, TWFP

∑

(

f

PRICEi

OBJ = GP, NE, GHGBAL, TWFP

)

PALLfOBJ = v(ℵ)fOBJ ∀f

OBJ = GP, NE, GHGBAL, TWFP

(17)

)

(

∑

∀i

AVRESPEXT

× PindBYPASS

p

i,p

)]

[

(

BYPASS

× PRESp

= MCMi,p − MCMBY

i,p × Pindp

∀i ∀p

[

(

REL

SGRESi,p = PRESp × PRindREL

× PRCMi,p − PRCMBY

i,p × Pindp

i,p

)]

BYPASS

∀i ∀p

× Pindp

(19)

(20)

2.2.1.4. Cooperative game process performance allocation model. The

optimal values of characteristic functions for EFEW objectives in Section

2.2.1.2 are essential inputs to the adapted Maali’s (2009) cooperative

game model. The linear programming model is solved by maximising

the aggregate degree of λ as described in Eq. (21) based on max-min

aggregation method (Maali, 2009). To ensure the Pareto optimality of

solution from the optimisation model, scenario-specific values of

objective-based characteristic functions are used to calculate the mar­

ginal contributions or performance weightage denoted as PWOBJ

in Eq.

f

formula of weighted sum score reviewed by Kolios et al. (2016). The

respective weights for each EFEW objective, named as the EFEW

weightage (EFEWwOBJ ), represent the subjective priorities of POBC

objectives in EFEW nexus contributions based on the decision-maker’s

interest. Heuristic values of EFEWwOBJ are considered sufficient in this

work as the proposed anchor process determination approach aims to

suggest possible process advancements for the unbiased fuzzy optimal

POBC flowsheet according to the decision-maker’s specific focus in

EFEW nexus. In the future direction, priority quantification methods, i.

e., analytic hierarchy process (AHP) method, could be considered for

targeting anchor process in non-subjective means, by performing

pair-wise comparison on collected priorities of respondents between

defined objectives to calculate the rational weightage (Ren et al., 2019).

The final anchor process for POBC is determined as the process stage

f with the highest score of NSEFEW

, indicating that this process stage

f

(22) for each process stage f using Excel Spreadsheet, to formulate the

constraint in Eq. (23) concerning the EFEW objectives (Tan et al., 2016).

Based on Eq. (22), PWOBJ

for process stage f is calculated as the sum of

f

average deviation values between the characteristic function of every

scenario z including operating process stage f, v(z)OBJ , and the charac­

teristic function of the scenario z − {f}, which includes all existing

process stages in scenario z except process stage f, v(z − {f})OBJ , divided

by the characteristic function of the zero failure scenario where all POBC

OBJ

process stages operate, v(ℵ)OBJ . As an example, to determine PWf=1

when

set f =

{1, 2, 3}, the

calculation

[(v(z = {1, 2, 3})OBJ − v(z = {2, 3})OBJ )

+(v(z = {1, 2})OBJ − v(z = {2})OBJ )

OBJ

OBJ

will

be

as follows:

+(v(z = {1, 3})OBJ − v(z = {3})OBJ )

+v(z = {1}) ] /v(z = {1, 2, 3}) . Constraints in Eqs. (23)-(26) are

formulated based on the cooperative game optimisation model (Maali,

2009) to provide optimal values of distributed EFEW objective-based

performance (ALLOBJ

) among process stages f within the fuzzy optimal

f

provides the greatest contribution to the weighted EFEW performance of

POBC thus attains the highest priority in process advancement and

maintenance for long-term POBC flexibility.

)

∑(

NSfEFEW =

PALLOBJ

× EFEWwOBJ ∀f

f

OBJ

(27)

OBJ = GP, NE, GHGBAL, TWFP

POBC. The respective percentage allocation score is denoted as PALLOBJ

f

as in Eq. (26) which reflects the process stage’s degree of contribution

towards the POBC performance in the EFEW nexus. The calculated

values of PWOBJ

obtained from the Excel Spreadsheet based on Eqs.

f

(22)-(23) are inputted to the formulated cooperative game models and

solved using the objective function λ in Eq. (21) to obtain optimum re­

sults of PALLOBJ

concerning EFEW objectives for the following anchor

f

2.2.3. EFEW-based benefit-drawback (B/D) ratio analysis

Results validation is an essential step to demonstrate the feasibility of

a new innovative concept (Kuznetsova et al., 2016). In this study, the

concept of anchor process is introduced to target the process stage

within a food production system such as POBC which requires major

focus in process maintenance and advancement for sustainable EFEW

nexus development. To validate the anchor process obtained from the

proposed cooperative game optimisation framework, B/D ratio assess­

ment is suggested to perform advantage versus disadvantage analysis in

terms of EFEW nexus contributions from the anchor process advance­

ment. Firstly, a suitable process parameter is selected within the tar­

geted anchor process concerning available technology advancements.

The impacts of anchor process parameter variation on the multiple

process determination (Andiappan et al., 2015).

(21)

Maximise λ

PWOBJ

=

f

∑v(z)OBJ −

z∋f

v(z− {f } )OBJ

v(ℵ)OBJ

∀f

OBJ = GP, NE, GHGBAL, TWFP

1

PWOBJ

f

ALLOBJ

≥ λ ∀f

f

OBJ = GP, NE, GHGBAL, TWFP

(26)

2.2.2. EFEW-based anchor process determination

For this work, anchor process is defined as the process stage which

allocates the highest weighted-sum of POBC performance contribution

to all EFEW objectives based on cooperative game distribution. Due to

the significant contributions by the anchor process, the highest budget

allocation should be considered for its maintenance and advancement to

ensure the flexibility of POBC in the EFEW nexus. In terms of definition,

anchor process is different from bottleneck which is the potential root

cause threatening future system performance (How and Lam, 2019).

Nevertheless, targeting anchor process for advancement could achieve

similar aim for system enhancement and discover possible bottleneck

within the process. To consider multiple EFEW objectives simulta­

neously in targeting the anchor process for optimal POBC flowsheet

improvement, the weighted-sum method could be applied to solve such

multi-objective decision-making problem via obtaining a summation

score for all weighted objectives (Kolios et al., 2016).

For this work, the weighted-sum score for EFEW objective-based

impact allocation in each process stage f is defined as the percentage

EFEW nexus score (NSEFEW

) obtained via Eq. (27) adapted from the

f

(18)

p

MATi,p

(25)

ALLOBJ

∀i

p

AVRESi = AVRESLOCAL

+

i

ALLOBJ

= v(ℵ)OBJ ∀f

f

(24)

(22)

(23)

8

Y.D. Tan et al.

Journal of Cleaner Production 314 (2021) 127927

EFEW performances of POBC will then be evaluated in terms of B/D

ratio to reflect the feasibility of anchor process investment in enhancing

the EFEW aspects for the designed POBC. To investigate the effects of

anchor process parameter changes on the POBC objectives, the fuzzy

optimal POBC case study obtained in Section 2.1 is revised according to

percentage improvements on the selected process parameter to be

solved by the mixed-integer linear programming optimisation model

adapted from Section 2.2.1.3 to generate GP-maximised results with

subject to the environmental constraints formulated from fuzzy optimal

values of GHG emissions and total WFP in Eqs. (28)-(30). The

GP-optimal results for the baseline fuzzy POBC case study and the new

results generated from process parameter variation are compared to

obtain the respective percentage improvements in terms of EFEW ob­

jectives. The percentage of EFEW objective improvements (IMPOBJ ) in

terms of net energy, GP, GHG emissions and total WFP in the new POBC

results are essential to calculate the total weighted improvement score,

TIS (Kolios et al., 2016) and B/D ratio for each anchor process parameter

improvement using Eqs. (31)-(32). Using Eq. (32), the B/D ratio ob­

tained could represent the overall percentage improvements of EFEW

objectives with respective anchor process parameter changes over the

percentage deterioration in the performance of POBC (Wouters et al.,

2014). EFEW nexus weightage is used in the weighted B/D ratio and

total improvement score calculation to consider the heuristic priorities

for each EFEW-related objective. Positive value of TIS suggests favour­

able net improvements in weighted EFEW performances from varied

POBC process parameter whereas B/D ratio greater than 1 implies

feasible process parameter changes such that the POBC benefits gained

via anchor process parameter improvement outweigh the associated

drawbacks considering EFEW nexus development.

GHGBAL ≤ GHGBALFuzzy

(28)

TWFP ≤ TWFPFuzzy

(29)

Maximise GP

(30)

TIS =

∑

IMPOBJ × EFEWwOBJ ,

∑

/

Positive IMPOBJ × EFEWwOBJ

⃒

D ratio = ∑ OBJ⃒⃒

,

OBJ ⃒ × EFEWwOBJ

OBJ Negative IMP

= GP, NE, GHGBAL, TWFP

4. Results and discussion

The palm oil mill retrofit case study described in Section 3 is solved

by the mathematical models and Excel Spreadsheet developed in Section

2 consecutively according to the systematic framework proposed in

Fig. 1 to be discussed in the subsections.

(31)

OBJ

OBJ = GP, NE, GHGBAL, TWFP

B

portfolio and process pathway design of the retrofitted POBC should

consider economic potential and net energy maximisation along with

minimisation of GHG, water, and land footprints. Additionally, the

company owner aims to target an anchor process within the fuzzy

optimal POBC flowsheet for investment in process advancement to

further improve the POBC design towards desired EFEW nexus contri­

butions and evaluate the individual POBC process impacts on the syn­

ergies between EFEW resources.

Fig. 2 illustrates all alternative technologies and process routes

proposed for POBC retrofit adapted from the fuzzy POBC optimisation

problem in the work of Tan et al. (2020c) to demonstrate the subsequent

anchor process targeting approach. Their work has successfully

considered two POME management pathways: a) biogas recovery and b)

POME elimination, in the process route selection to generate a

methane-eliminated POBC. In the adaptation of the cited work, this

study considers updated process-utility flows and process units based on

the latest technology advancement from suppliers. Besides, the process

selections for biogas recovery are coloured in orange whereas the

distinctive process alternatives for POME elimination are coloured in

blue in the modified Fig. 2. The related process, economic, and envi­

ronmental data applied in the case study are retrieved from the work of

Tan et al. (2020c). Under Appendix, Table A.1 compiled all resources i

involved including their corresponding unit prices for external pro­

cessing, purchasing, and selling. The environmental factors for GHG

emission from unconsumed products and external resources are sum­

marised in Table A.2. The set of available technology p for constructing

the optimum process pathway of POBC is given with the process

resource input and out data in Table A.3 whereas their respective

operating and capital costs are summarised in Table A.4. It is worth

noting that no capital cost will be incurred for the pre-existing process

units in Table A.4 with the label “Existing”.

4.1. Fuzzy multi-objective POBC optimisation results

OBJ

Based on the fuzzy approach in Section 2.1 proposed by Tan et al.

(2020c), the developed mixed-integer linear programming optimisation

model is used to solve the case study in Section 3 via CPLEX solver

(12.6.3.0) in the General Algebraic Modelling System (GAMS) software

(version 24.7.4) to obtain the fuzzy optimal POBC flowsheet as illus­

trated in Fig. 3 considering trade-offs between economic potential, net

energy, water, land and GHG footprints. According to Fig. 3, POME

elimination pathway is chosen for methane avoidance where undiluted

clarification and multi-effect evaporation process units are installed to

convert POME and PORE into process condensate and concentrate for

minimal GHG impacts and WFP. The process condensate is recycled as

process water while solvent extraction is invested for additional oil and

decanter solid recovery from process concentrate. It is proven that

POME elimination offers better trade-offs between conflicting objectives

of profit, energy efficiency and environmental in addressing POBC sus­

tainability. The fuzzy multi-objective optimal results are summarised in

Table 1 which are essential inputs for the following anchor process

determination.

(32)

3. Case study application

The proposed multi-objective optimisation and anchor process tar­

geting framework is used to solve the case study adapted from the work

of Tan et al. (2020c) to demonstrate the applicability of the framework.

As an effort to receive the Malaysian Sustainable Palm Oil certification

scheme, a palm oil company owning a mill in Peninsular Malaysia plans

to retrofit the palm oil mill into a methane-mitigated POBC, via

investing biogas recovery technologies or POME elimination strategies

and form a mill-refinery production complex with a self-owned refinery

within 1 km distance to share the resources and directly convert the CPO

extracted from 60 t/h free fresh fruit bunches (FFB) into refined palm oil

products such as refined, bleached, deodorised palm stearin (RBDPS)

and palm olein (RBDPOL), fatty acid distillate (PFAD). The mill operates

4,350 h/y to extract CPO from FFB pre-treated with steam via conven­

tional diluted clarification processes. Palm-based biomass in the form of

shell and fibre are utilised as biomass boiler fuel to supply the steam and

electricity demand in the mill. Open anaerobic pond is the current POME

treatment method which does not comply with the methane avoidance

policy whereas palm oil refinery effluent (PORE) is treated at the

wastewater treatment plant.

With rising concerns in palm oil sustainability, the optimal product

4.2. Scenario specific optimisation results and objective-based

characteristic functions

The fuzzy optimal POBC flowsheet serves as the case study for tar­

geting the EFEW-based anchor process via the proposed cooperative

game-based framework presented in Section 2.2 with the consecutive

9

Y.D. Tan et al.

Journal of Cleaner Production 314 (2021) 127927

Fig. 2. Potential technologies and process routes for POBC (modified from Tan et al. (2020c)).

application of developed optimisation models and Excel tools. To

determine optimal values in different process stage coalitions for char­

acteristic function calculation, the selected processes p in Fig. 3 are first

classified into five process stages under set f based on their specific

function in supporting refined palm oil production. Table 2 shows the

selected processes p grouped in every process stage f.

Total 31 process failure scenarios z are expected via Eq. (12) to

include all working combinations of five process stages f via Excel tool.

The fuzzy optimal POBC serves as the case study to generate the input

data for 31 process failure scenarios as tabulated in Tables A.5–A.10.

The input values of binary parameters defined in Section 2.2.1.3 for

differentiating the existing, correlated, integrated and by-passing pro­

cesses in every scenario z are compiled in Tables A.5–A.8. Binary and

cost parameters related to import and external processing of interme­

diate resources and unconsumed products due to respective process

failures in scenarios z are summarised in Tables A.9–A.10. The input

data is then solved with the mixed-integer linear programming optimi­

sation model developed in Section 2.2.1.3 to generate optimal results for

different individual optimisation scenarios (maximum net energy sce­

nario, maximum GP scenario, minimum GHG balance scenario and

minimum WFP scenario) by assigning different objective functions. The

optimal values of the objective function (net energy, GP, GHG balance

and WFP) for each individual optimisation scenario are simultaneously

generated for 31 process failure scenarios using the integrated scenario

optimisation model in Section 2.2.1.3. For instance, when solving the

scenario optimisation model with the objective function of maximising

GP, 31 optimal values of GP are generated for the 31 process failure

scenarios. Subsequently, these optimal values of objective function are

used to calculate the objective-based characteristic functions, v(z)OBJ ,

based on Eqs. (13)-(16) described in Section 2.2.1.2. The values of

v(z)OBJ with respect to four EFEW objectives defined as GP improve­

ment, net energy improvement, GHG emissions and overall WFP are

calculated in an Excel Spreadsheet based on the optimal and basis

objective values compiled in Table 3. The GAMS coding for the process

failure scenario optimisation modelling and solving could be found at

GitHub repository (Tan et al., 2020a).

4.3. Cooperative game-based allocation of process stage impacts to EFEW

objectives

The results in Table 3 are integrated into the cooperative game dis­

tribution models developed in Section 2.2.1.4 to perform optimal per­

formance allocation among the fuzzy optimal POBC process stages for

the economic performance, energy efficiency, GHG impacts and WFP of

the POBC. To generate the essential inputs for the cooperative game

allocation model, the objective-specific performance weightage, PWOBJ

f

for each process stage f as shown in Table 4 are calculated based on the

imp

values of defined v(z)OBJ in Table 3 (GPimp

z , NEz , GHGBALz , TWFPz )

with respect to each EFEW objective using Eq. (22). The breakdown of

v(z)OBJ and v(z − {f})OBJ values used for PWOBJ

calculation for five

f

process stages f via Eq. (22) and description in Section 2.2.1.4 is shown

in Tables A.11–A.15. Note that the value of v(z − {f})OBJ is obtained as

the value of v(z)OBJ with process stage f being removed in all process

10

Y.D. Tan et al.

Journal of Cleaner Production 314 (2021) 127927

Fig. 3. Fuzzy optimal flowsheet for multi-objective POBC.

{2}). With reference to Fig. 1, the linear programming optimisation

models for EFEW objective distribution including Eqs. (23)-(26) are

solved with the objective function of maximising variable λ in GAMS

using CPLEX solver to generate Pareto optimal results for rational dis­

tribution of process impact towards defined EFEW objectives as sum­

marised in Table 4.

Based on Table 4, the nut/kernel separation and combined heat and

power (CHP) process stage attains the highest allocation of GP and net

energy improvements with percentage scores of 41% and 75% in the

fuzzy optimal POBC. This implies that this process stage provides major

contributions to the POBC’s profitability and energy efficiency. The CHP

system fuelled by recovered palm mesocarp fibres (PMF) and palm

kernel shell (PKS) is responsible for fulfilling the demand of energyextensive milling, evaporating and refining processes in the POBC to

reduce import requirements on steam and grid electricity associated

Table 1

Fuzzy optimal results from POBC multi-objective optimisation.

Objective function

Fuzzy optimal value

Max λ

0.457

Max EP (M USD/y)

41.140

Max NE (MWh)

0.919

Min GHGBAL (kgCO2eq/h)

21.420

Min TWFP (t/h)

22.800

Min LFP (hectare)

0.103

failure scenario z considering process stage f operating. For example, to

for f = 1 using Table A.11, the value of v(z − {1})OBJ for

calculate PWOBJ

f

z = 6 (z = {1,2}) is obtained as the value of v(z)OBJ at scenario z = 2 (z =

Table 2

Identification of technologies p considered in each defined process stage f

f

Process stage

1

2

3

4

5

FFB pre-treatment

Undiluted CPO extraction

POME elimination

Nut/kernel separation and CHP

Palm oil refinery

Process p

1

2

3

√

√

√

4

5

√

√

9

10

11

12

13

14

15

√

√

16

17

18

19

√

√

√

√

22

23

√

√

√

√

√

√

11

√

Y.D. Tan et al.

Journal of Cleaner Production 314 (2021) 127927

Table 3

Optimal characteristic function values for GP, NE, GHGBAL and TWFP objectives in all scenarios z.

Process failure scenario z

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

v(z)NE

v(z)GP

v(z)GHGBAL

v(z)TWFP

GPz (M USD/y)

GPu (M USD/y)

GPimp

z (M USD/y)

NEz (MWh)

NEu (MWh)

NEimp

(MWh)

z

GHGBALz (kgCO2eq/h)

TWFPz (t/h)

27.57

30.32

0.00

7.33

2.46

29.25

27.71

36.11

30.03

30.40

37.71

32.78

7.33

2.38

10.14

29.60

37.81

31.71

36.43

30.25

38.92

37.95

32.93

40.46

10.12

38.44

32.15

40.62

39.33

40.81

41.35

27.57

30.32

0.00

7.33

2.46

27.57

27.57

27.57

27.57

30.32

30.32

30.32

7.33

2.46

7.33

27.57

27.57

27.57

27.57

27.57

27.57

30.32

30.32

30.32

7.33

27.57

27.57

27.57

27.57

30.32

27.57

0.00

0.00

0.00

0.00

0.00

1.69

0.14

8.55

2.46

0.08

7.39

2.46

0.00

-0.08

2.81

2.03

10.25

4.14

8.86

2.68

11.35

7.63

2.62

10.15

2.79

10.87

4.58

13.05

11.76

10.49

13.78

-0.336

-0.245

0.000

3.203

-1.500

-0.581

-0.522

2.867

-1.836

-0.430

2.941

-1.745

3.203

-1.686

1.700

-0.767

2.605

-2.081

2.681

-2.022

1.367

2.755

-1.930

1.441

1.515

2.419

-2.267

1.105

1.181

1.255

0.919

-0.336

-0.245

0.000

3.203

-1.500

-0.336

-0.336

-0.336

-0.336

-0.245

-0.245

-0.245

-1.500

3.203

3.203

-0.336

-0.336

-0.336

-0.336

-0.336

-0.336

-0.245

-0.245

-0.245

3.203

-0.336

-0.336

-0.336

-0.336

-0.245

-0.336

0.000

0.000

0.000

0.000

0.000

-0.245

-0.186

3.203

-1.500

-0.185

3.186

-1.500

4.703

-4.889

-1.503

-0.431

2.941

-1.745

3.018

-1.686

1.703

3.000

-1.685

1.686

-1.688

2.755

-1.931

1.441

1.518

1.500

1.255

6538.78

284.39

0.00

0.00

975.94

6823.17

7184.10

214.62

7514.72

803.33

154.24

1260.33

0.00

1196.00

55.54

7886.71

365.98

7799.11

17.63

8279.92

259.12

2.37

1898.93

209.07

13.23

17.72

8983.20

410.49

18.87

13.70

18.97

1.109

0.852

0.000

0.000

2.724

1.961

0.000

24.124

3.834

0.000

0.852

3.576

0.000

1.041

2.724

0.000

24.976

4.685

19.357

0.000

27.307

0.000

0.000

3.576

1.081

16.549

0.000

28.158

21.501

0.000

18.698

Table 4

Percentage allocation score of EFEW-based performance for five process stages in the fuzzy optimal POBC.

f

1

2

3

4

5

Process stage

FFB pre-treatment

Undiluted CPO extraction

POME elimination

Nut/kernel separation and CHP

Palm oil refinery

GP impact allocation

NE impact allocation

GHGBAL impact allocation

TWFP impact allocation

PWGP

f

PALLGP

(%)

f

PWNE

f

PALLNE

(%)

f

PWGHGBAL

f

PALLGHGBAL

(%)

f

PWTWFP

f

PALLTWFP

(%)

f

4.34

3.62

0.29

7.76

2.72

23.18

19.32

1.53

41.42

14.54

5.96

5.85

-2.06

35.61

-24.52

12.58

12.35

0

75.08

0

2579.7

230.9

182.9

-3461.8

402.7

75.96

6.80

5.39

0

11.86

9.34

-1.41

-41.61

134.72

21.03

5.66

0

0

81.6

12.74

with expensive tariffs. The contribution of nut/kernel separation and

CHP process stage is vital in assisting the operation of all POBC process

stages in terms of thermal and electrical energy to achieve refined palm

oil production target. Excess PMF and PKS could either enhance the

renewable energy contribution or create additional income by direct

trading. Attractive revenue from selling separated palm kernel (PK) as

high quality fuel also supports the POBC profitability (Husain et al.,

2002). Maintenance focus in the nut/kernel separation and CHP process

stage is essential to secure the energy and economic performance of the

fuzzy optimal POBC. However, nut/kernel separation and CHP system is

also the dominant process stage which makes up 82% of WFP accounted

in the fuzzy optimal POBC. In other words, the operation of this process

stage provides the greatest negative impact on water scarcity issue

within the EFEW nexus-integrated POBC. This is due to the water con­

sumption for steam generation in the biomass-fuelled CHP system to

satisfy POBC energy demand. Thus, the CHP system could be targeted

for process advancement to achieve critical improvements in water use

of POBC.

For GHG impacts evaluation, the process stage which releases the

highest amount of GHG emissions is the FFB pre-treatment, accounting

for 76% of POBC’s GHG footprint. This is due to the steam pre-treatment

technology selected in the fuzzy optimal POBC which consumes large

amount of steam to sterilise and digest FFB. If insufficient biomass is

available for energy conversion, the dependency of the process stage on

fossil fuel-based energy will increase the GHG emission of POBC. Be­

sides, FFB pre-treatment contributes the most to POME generation in the

fuzzy optimal POBC which releases high global warming potential

methane if not evaporated. Nevertheless, to target the final anchor

process in the fuzzy optimal POBC for EFEW nexus evaluations, per­

formance allocation for all objectives needs to be considered simulta­

neously with assigned priorities.

4.4. Targeted EFEW-Based anchor process

The weighted-sum EFEW nexus scores for all process stages (NSEFEW

)

f

are tabulated in Table 5 with reference to Eq. (27) using heuristic values

of EFEW weightage describing the relative importance of GP, net energy,

GHG impacts and WFP objectives in the desired EFEW nexus. Based on

Table 5, the EFEW-based anchor process for the fuzzy optimal POBC is

targeted as the nut/kernel separation and CHP process stage (f = 4) with

the highest score of NSEFEW

at 41% followed by FFB pre-treatment and

f

undiluted CPO extraction. According to the weighted focus on economic

performance, energy contribution, GHG emissions and WFP, the nut/

12

Y.D. Tan et al.

Journal of Cleaner Production 314 (2021) 127927

Table 5

Percentage EFEW nexus score of the process stages and EFEW-based anchor process in the fuzzy optimal POBC.

f

1

2

3

4

5

Process stage

FFB pre-treatment

Undiluted CPO extraction

POME elimination

Nut/kernel separation and CHP

Palm oil refinery

EFEW weightage, EFEWwOBJ

PALLGP

(%)

f

(%)

PALLNE

f

PALLGHGBAL

(%)

f

(%)

PALLTWFP

f

EFEW nexus score, NSEFEW

(%)

f

23.18

19.32

1.53

41.42

14.54

0.6

12.58

12.35

0

75.08

0

0.1

75.96

6.80

5.39

0

11.86

0.2

5.66

0

0

81.60

12.74

0.1

30.93

14.19

2.00

40.52

12.37

kernel separation and CHP stage in the fuzzy optimal POBC is the pro­

cess stage that creates the greatest impact on the EFEW nexus.

Fig. 4a and b illustrate the non-weighted and weighted EFEW-based

performance allocation for the five POBC process stages based on given

EFEW weightage. In both diagrams, the identified anchor process (i.e.,

nut/kernel separation and CHP) achieves the largest coverage on the

four EFEW objectives due to its superior contributions in profit,

renewable energy balance and WFP. By considering defined priorities in

the EFEW nexus, the difference in the EFEW nexus coverage between the

anchor process and FFB pre-treatment which rates second in terms of

EFEW nexus score, is smaller in Fig. 4b due to the greater focus on GHG

impacts compared to energy contribution and WFP for sustainable

POBC. The importance of the identified anchor process to the EFEW

nexus could be exemplified by the water-energy synergies in steam and

electricity generation from water-consuming boilers within the CHP