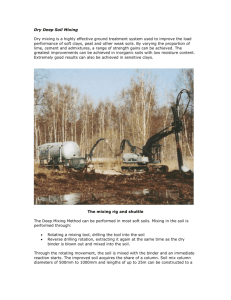

Soil Improvement techniques for Marshy land Following methods are used worldwide• Deep Mixing Method (DMM) /Mass Mixing Method (MMM)/Mass Stabilizing Method (MSM) • Stone columns • Grouting Deep Mixing Method(DMM)/Mass Mixing Method(MMM)/Mass Stabilizing Method (MSM) • The deep mixing method/ mass mixing method involve blending a binder with soil in situ to produce soil-cement that has improved properties, such as increased strength and reduced compressibility, compared to the untreated soil. • Binder materials for the deep mixing method can consist of cement, lime, fly ash, slag, or other binder materials, as well as blends of binder materials. In current United States practice, cement and slag-cement blends are the most common types of binder. When the binder is pre-mixed with water to create a binder-water slurry that is then mixed into the ground, the process is called the :wet mixing method.” When dry binder is delivered pneumatically, the process is called the “dry mixing method.” • Can be used in combination with Stone columns to support heavy structures • Link - https://youtu.be/OqbDSgMJIJw • Codal provision available - prEN 14679, Eurocode EN 1997 Deep Mixing Method(DMM)/Mass Mixing Method(MMM)/Mass Stabilizing Method (MSM) Advantages 1. The plan view arrangement of treatment, the treatment depth, and the degree of improvement to strength and stiffness can be easily adjusted to satisfy design requirements and subsurface conditions. 2. Prevents liquefaction of loose sand deposits by increasing strength of soil. 3. Powerful wet-mixing equipment can penetrate layers of dense and strong material totreat underlying weak, loose, or compressible layers. 4. Economical on large projects. Disadvantages 1. Limit is up-to 40m below ground level 2. The wet method of deep mixing generally uses heavy equipment, which can require timber mats or other techniques to enable equipment to operate on soft ground. Deep Mixing Method(DMM)/Mass Mixing Method(MMM)/Mass Stabilizing Method (MSM) • Used in Japan since 1970 • Live examples where Deep mixing method is implemented- Tokyo's Haneda Airport , expansion of the Hong Kong International Airport. Images taken from Google and book GEO-E2080 Foundation Engineering and Ground Improvement Stone Column • • • • Vibro- Replacement (Wet) - https://youtu.be/F_kI6vQ5_gE Vibro- Displacement - https://youtu.be/XesKo2hHwu4 Rammed Stone Columns - https://youtu.be/5rn1DorMXNA Stone columns can provide a highly cost-effective ground improvement treatment to strengthen, stiffen and improve drainage in loose/soft ground strata. • The process involves formation of compacted columns of clean granular material, typically coarse gravel, penetrating to depth through the soft/loose strata. Advantages • Increased bearing capacity of the ground below shallow foundations and slabs. • Reduced total and differential settlements of structures. Disadvantages • Maximum depth constraint is 165 feet • Effective in granular and cohesion less soil Codal provisions – Is 15284 – 1, ACI, IBC, ICC Stone Column -Continued • Used since 1950 in Europe and sine 1970 in US Vibro- Replacement, Vibro- Displacement and Rammed stone column Images taken from Google Grouting • Grouting comprises a set of geotechnical techniques to introduce materials with pressure, having the objective of waterproofing and/or altering the physical characteristics of the soil or rock formation upon setting. • Soil Grouting 1. Permeation grouting (using particulate, colloidal or solution grouts) – Used in Japan since 1950 Link - https://youtu.be/C42m52LKgX8 2. Soil fracture grouting (including compensation grouting) – Used in US since 1990 Link - https://youtu.be/vKMYJZvUBVc 3. Compaction Grouting - Used in West since 1950 Link- https://youtu.be/mou95Ailfbk 4. Jet Grouting – Used in West since 1970 Link- https://youtu.be/bWnXUCk9Uv0 Advantages • Has nearly unlimited configurations of column geometry. • Can be used in a wide range of soil types and groundwater conditions and minimizes settlement. Disadvantages • Installation may cause ground heave • Can be more difficult in plastic soils Grouting - Continued Codal provisions – IS 13094, IBC Image taken from book GEO-E2080 Foundation Engineering and Ground Improvement