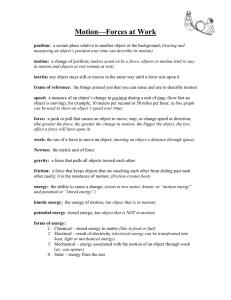

Available online at www.sciencedirect.com ScienceDirect Available online at www.sciencedirect.com Structural Integrity Procedia 00 (2022) 000–000 ScienceDirect www.elsevier.com/locate/procedia Procedia Structural Integrity 41 (2022) 220–231 2nd Mediterranean Conference on Fracture and Structural Integrity Modelling of delamination in rolling and sliding contacts Irina Goryachevaa,b,*, Almira Meshcheryakovaa,b† aa Ishlinsky Ishlinsky Institute for Problems in Mechanics RAS, Prospekt Vernadskogo 101-1, Moscow, 119526, Russia b bSirius University of Science and Technology, 1 Olympic Ave, 354340, Sochi, Russia Abstract The contact fatigue phenomenon in conditions of cyclic sliding or rolling is studied based on the model of contact fatigue damage accumulation in the subsurface layers of the material. It is assumed that the rate of the damage accumulation depends on the principal shear stress amplitudes. The results of numerical modelling show that the contact fatigue fracture process in the conditions of a constant load, acting on the sliding or rolling body, consists of the following stages: the incubation period, the running-in period with the alternating detachment of material’s fragments of certain thickness (the mechanism of delamination) and the surface wear, and then the steady-state stage, characterizing by the surface wear with a constant rate. The influence of the sliding friction coefficient, the relative slippage and the strength properties of contacting bodies on the evolution of the accumulated damage in the surface layers and on the fatigue wear kinetics in sliding and rolling contacts has been analyzed. © 2022 Published by Elsevier B.V. 2022The TheAuthors. Authors. Published by ELSEVIER B.V. © This is an open access article under the CC BY-NC-ND license (https://creativecommons.org/licenses/by-nc-nd/4.0) This is an open access article under the CC BY-NC-ND license (https://creativecommons.org/licenses/by-nc-nd/4.0) Peer-review under responsibility of the MedFract2Guest Editors. Peer-review under responsibility of the MedFract2Guest Editors. Keywords: rolling contact, sliding contact, internal stresses, wear, delamination 1. Introduction Fatigue wear is one of the most common mechanisms of fracture of machine components operating under sliding or rolling friction and cyclic loading and can lead to the breakdown of tribocouplings. In fatigue wear the multiple detachment of material particles from the friction surface occurs, and the corresponding change of contact geometry during each fracture results in the redistribution of contact and internal stresses (Goryacheva, 1998). Modelling of this * Corresponding author. Tel.: +7 495 434 3692. E-mail address: goryache@ipmnet.ru 2452-3216 © 2022 The Authors. Published by ELSEVIER B.V. This is an open access article under the CC BY-NC-ND license (https://creativecommons.org/licenses/by-nc-nd/4.0) Peer-review under responsibility of the MedFract2Guest Editors. 2452-3216 © 2022 The Authors. Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license (https://creativecommons.org/licenses/by-nc-nd/4.0) Peer-review under responsibility of the MedFract2Guest Editors. 10.1016/j.prostr.2022.05.025 2 Irina Goryacheva et al. / Procedia Structural Integrity 41 (2022) 220–231 Author name / Structural Integrity Procedia 00 (2019) 000–000 221 process consists of the following stages: the calculation of contact and internal stresses, analysis of the accumulated damage in the surface layer of the material based on the appropriate dependence of the damage function on the internal stress distribution, the calculation of the thickness of the detached fragment, taking into account the chosen material failure criterion, the calculation of accumulated damage at the next step, etc. (Goryacheva, 1998; Goryacheva and Chekina, 1999). At each step of wear modelling, the history of the process is taken into account, i.e. accumulated damage in previous stages. As the main parameters affecting the wear rate, there are contact conditions, macro and microgeometry of the surfaces of contacting bodies, strength properties of materials, residual stresses, etc. Due to the fact that at the dominant number of cases, the contact fatigue is the main cause of the rail failure, the accumulation of contact fatigue damage in wheel/rail contacts is considered in many studies. The review of rolling contact fatigue defects in wheel/rail systems and the mechanisms of their formation is presented in (Magel, 2011). The experimental studies of the influence of relative slippage on the contact fatigue damage accumulation and wear in rolling contact of wheel and rail are described in (Guo et al., 2016; Pal et al., 2012; Zhang et al., 2022; Zhou et al., 2016). The results of these studies show that the increase of the relative slippage leads to the evolution of the wear mechanism from oxidation wear and local delamination to abrasive wear. In the tests carried out in (Hu et al., 2020), in addition to the relative slippage, the influence of the ratio of the hardnesses of the wheel and rail materials on the damage accumulation and wear was studied. A method of construction of the contact fatigue damage function accumulated in the material for given loading conditions based on the two-disc testing results was developed in (Hiensch and Burgelman, 2019). The rolling contact problem taking into account the relative slippage was solved there using the FASTSIM (Kalker, 1982) and CONTACT (Kalker, 1990) algorithms. The twin disc tests were conducted in (Santa et al., 2019) to study the fatigue wear in rails. As a result, the dependences of the wear rate on the relative slippage for wheel and rail were obtained, and several wear regimes were identified depending on the contact conditions. The method for calculation of the accumulated damage in a rail was developed in (Bernal et al., 2022), taking into account the change in contact characteristics depending on the relative slippage and mechanical properties of the materials of the wheel and rail, measured in the experiments. The results of experiments and field tests, combined with the results of simulation of contact fatigue damage accumulation, can be used for the rail life predictions. The modelling of fatigue damage accumulation in material in rolling with friction of a cylinder over an elastic halfspace (contact problem in a plane formulation) was carried out in (Goryacheva and Torskaya, 2019), where the effect of the relative slippage, the sliding friction coefficient, and residual stresses on the stress state of the subsurface layers of the contacting bodies was studied. The results of the study show that the presence of residual stresses that occur, for example, in the materials of a rail due to heat treatment of the rail surface, leads to an increase of the principal shear stresses and a decrease of their amplitude values. The results of wear modelling in wheel/rail system in rolling with slippage using the Archard model are presented in (Sakalo et al., 2019), where the Dang Wang function (Dang Van et al., 1989), the equivalent Mises stresses and principal shear stresses amplitudes were used in criteria of the material failure. Numerical calculations using the finite element method make it possible to compare the results of wear simulation for different material failure criteria, taking into account the shape of the contact region and the distributions of contact pressure and shear stress. The multiscale finite element model is proposed in (Daves et al., 2016) to predict the initiation of contact fatigue cracks and the formation of wear particles in the wheel/rail contact under sliding and rolling conditions, taking into account the surface roughness. A review of empirical and analytical approaches for modelling the fatigue damage in rolling bearings is given in (Sadeghi et al., 2009). In this study, based on a single mechanism for the fatigue damage accumulation in the subsurface layers of materials of interacting bodies, the surface wear and the detachment of material fragments of finite thickness (delamination) of elastic bodies under the conditions of their cyclic interaction with a sliding or rolling ball are modelled. The influence of the sliding friction coefficient (under conditions of full sliding), as well as the sliding friction coefficient and relative slippage (under rolling conditions) on the stress state of subsurface layers of elastic bodies, the accumulation of fatigue damage there, and the kinetics of surface (wear) and subsurface (delamination) fracture in the materials of contacting bodies are studied. Author name / Structural 00Integrity (2019) 000–000 Irina Goryacheva et al. / Integrity ProcediaProcedia Structural 41 (2022) 220–231 222 3 Nomenclature E V ω P Ω p pH a s τ µ ∆ σ1 σ3 Q Q0 Q* q τmax ∆τmax N c m P a pH Poisson’s ratio Young's modulus linear velocity angular velocity load contact region contact pressure maximum value of contact pressure radius of contact region slip velocity shear stress sliding friction coefficient relative slippage maximum of principal value of stress tensor minimum of principal value of stress tensor accumulated damage initial accumulated damage critical value of accumulated damage rate of damage accumulation principal shear stress principal shear stresses amplitude number of cycles strength parameter (coefficient) strength parameter (exponent) dimensionless load dimensionless radius of contact region dimensionless maximum value of contact pressure 2. Problem formulation The contact of an elastic spherical body (ball) sliding/rolling over an elastic half-space made of the same material in conditions of cyclic interaction is considered. The constant load P is applied to the ball. The movement of the ball with the constant linear velocity V is described as steady relative to the moving coordinate system Oxyz, which origin is located under the center of the ball. The contact scheme is presented in Fig. 1. Fig. 1. Contact scheme of an elastic ball rolling over an elastic half-space Irina Goryacheva et al. / Procedia Structural Integrity 41 (2022) 220–231 Author name / Structural Integrity Procedia 00 (2019) 000–000 4 223 Fixed coordinate system O’x’y’z’ is associated with the moving coordinate system Oxyz by the following relations: x = x + Vt , y = y , z = z (1) In rolling contact the relative slip velocities within the contact region are determined by the formula: s ( x, y= ) (x 2R 2 u ( x, y ) u2 ( x, y ) + y2 ) −V 1 − − , x x (2) where is the angular velocity of the ball rotation in respect to the y -axis (Fig. 1), ui ( x, y ) are the elastic displacements of the contacting bodies (i = 1, 2) in the direction of x -axis due to deformation, R is the radius of the ball, Δ is the relative slippage: V − R . = V (3) In rolling the contact region consists of the slip and stick subregions. In the stick subregion the shear stress ( x, y ) is related to the contact pressure p( x, y ) by the following inequality: ( x, y ) p ( x, y ) . (4) and the slip velocity s ( x, y ) (Eq. 2) is equal to zero: s ( x, y ) = 0 . (5) In the slip subregion in rolling and in sliding contacts the Coulomb-Amonton law is satisfied: ( x, y ) = p ( x, y ) . (6) Outside the contact region, the normal and shear stresses are equal to zero. In cyclic interaction of the system of spherical indenters and the elastic half-space the mutual effect of indenters deforming the elastic half-space is neglected. 3. Method of solution The fatigue wear model is developed here based on a macroscopic approach, in which damage at some point of the material is described by a positive nondecreasing function that depends on the stress state at this point, the number of passed cycles, and parameters describing the strength properties of the material. 3.1. Calculation of contact and internal stresses The stress state of an elastic half-space is determined by its elastic characteristics, contact pressure and shear stresses. Since the materials of the contacting bodies are considered the same, shear stresses do not influence the distribution of a contact pressure. Therefore, the problem of the contact normal and shear stress calculation is solved in two stages: first, the contact pressure is calculated, and then the shear stress is identified under sliding and rolling conditions. 224 Irina Goryacheva et al. / Procedia Structural Integrity 41 (2022) 220–231 Author name / Structural Integrity Procedia 00 (2019) 000–000 5 The contact pressure p( x, y ) is calculated from the Hertz theory: 1 x2 + y 2 2 p(= x, y ) p H 1 − a2 3PE 2 pH = 2 3 R 2 1 − 2 2 ( ) (7) 1 ( 3 3PR 1 − 2 , a= 2E ) 1 3 (8) Here a is the contact radius, E , are the elastic moduli, pH is the maximum value of contact pressure, R is the ball radius. The shear stress ( x, y ) in the contact region is calculated using a numerical-analytical approach based on the variational method (Goldstein et al., 1982; Meshcheryakova and Goryacheva, 2021) which leads to minimization of the following functional: = F , s ( ) ( p ( x, y ) s ( ( x, y ) ) − ( x, y ) s ( ( x, y )) )dxdy , (9) where the slip velocity function is expressed as a function of shear stresses (Goldstein et al., 1982). The internal stresses within the elastic half-space are calculated using the distributions of contact normal and shear stresses and the Boussinesq and Cerruti potentials (Johnson, 1985). 3.2. Modelling of damage accumulation and fatigue wear We assume that the cyclic loading of the elastic half-space is provided by identical rollers located at a sufficiently large distance from each other (which allows us to neglect their mutual influence on the distribution of contact and internal stresses), and the rate q ( z ) of damage accumulation at the depth z depends on the principal shear stress amplitudes max ( z ) and is calculated by the formula (Collins, 1981): m Q ( z, N ) ( z ) = q ( z ) = c max . N pH (10) Here Q ( z , N ) is the damage accumulated over N cycles at the depth z, с and m are the parameters which describe the strength properties of the material, and they are determined experimentally. The following relation is used to calculate the principal shear stress amplitude: 1 max ( z ) = max ( 1 ( x, y, z ) − 3 ( x, y, z ) ) , x, y 2 (11) where 1 ( x, y, z ) and 3 ( x, y, z ) are the maximum and minimum values of the principal stresses at the point with coordinates ( x, y, z ) . Since the rollers are located at a large distance from each other, the principal stresses amplitudes coincide with their maximum values at a fixed depth. Irina Goryacheva et al. / Procedia Structural Integrity 41 (2022) 220–231 Author name / Structural Integrity Procedia 00 (2019) 000–000 6 225 The damage Q ( z , N ) accumulated over the first N cycles at the depth z is calculated by the formula: m ( z ) Q ( z, N ) Nc max = + Q0 ( z ) , pH (12) where Q0 ( z ) is the initial damage at the depth z, which is assumed to depend only on the coordinate z. When the damage function reaches a critical value Q* at some depth z * , the fracture of the material occurs, which involves the separation from the surface layer thickness z * : Q ( z*, N * ) = Q* . (13) Here N * is the number of cycles until the first delamination occurs. The remaining part of the half-space z z * with Q( z , N *) for z z * comes into contact and becomes the initial damage the accumulated damage Q1 ( z − z*) = function for the next stage calculation of the accumulated damage ( ( N − N *) 0 ) following the procedure, described above. Thus, the damage function significantly depends on the principal shear stress distribution under the ball. 4. Analysis of principal shear stress amplitude values in sliding and rolling contacts The stress state of elastic bodies in sliding contact is determined by the following parameters: the elastic characteristics of the material (the elastic modulus E , the Poisson ratio ), the geometry of the contacting surfaces (the radius of the indenter R ) and the acting load P , linear sliding velocity V , as well as the sliding friction coefficient . In addition in rolling contact, an important parameter that affects the stress state of the contacting bodies and the fatigue damage accumulation is the relative slippage (3), which is confirmed by the results of experimental studies (Guo et al., 2016; Pal et al., 2012; Zhang et al., 2022; Zhou et al., 2016). In this study, the elastic constants of materials, the geometry of the contacting bodies and the total load are considered fixed, so the following dimensionless parameters do not change in calculations: = P P = 0.00001 , = 0.3 , ER 2 (14) where P is the dimensionless load. For these parameters the dimensionless radius a of the contact region and the dimensionless maximum value of contact pressure pH have the following values: = a a = 0.024 , p= H R pH = 0.008 . E (15) The dependences of the principal shear stresses amplitudes on depth for a sphere sliding over an elastic half-space with different sliding friction coefficients are presented in Fig. 2. 226 Irina Goryacheva et al. / Procedia Structural Integrity 41 (2022) 220–231 Author name / Structural Integrity Procedia 00 (2019) 000–000 7 Fig. 2. Dependences of the principal shear stress amplitude on depth in sliding contact for different values of sliding friction coefficient The results indicate that the distribution of the principal shear stress amplitudes on the depth in the elastic halfspace under the sliding body has two maxima: at the surface and below the surface. For the selected values of the dimensionless parameters (14) and the sliding friction coefficient not exceeding 0.2, the surface maximum of the principal shear stresses amplitude function is less than the subsurface maximum. With an increase in the sliding friction coefficient (for 0.2 ), the surface maximum of the function ( z ) becomes greater than the subsurface maximum of this function. In rolling contact there are two main parameters which influence essentially on the dependence of the principal shear stress amplitude on the depth: they are the relative slippage and the sliding friction coefficient. Fig. 3 illustrates the influence of the relative slippage and the sliding friction coefficient on the distribution of the principal shear stresses amplitudes. Fig. 3. Dependencies of the principal shear stress amplitude on depth in rolling contact for different values of relative slippage and sliding friction coefficient The results illustrate that in the rolling contact a change in the relative slippage significantly affects the surface maximum value of principal shear stresses amplitudes, while the subsurface maximum value practically does not change. At low values of the relative slippage, the surface maximum of principal shear stress amplitudes is less than the subsurface one. With an increase in the relative slippage up to a value corresponding to the total slip in the contact region ( =0.0045) , the surface and subsurface maxima values become comparable. At the same value of relative slippage, the increase in the sliding friction coefficient corresponds to the increase in the surface and subsurface maxima of principal shear stresses amplitudes, and the surface maximum changes significantly. 8 Irina Goryacheva et al. / Procedia Structural Integrity 41 (2022) 220–231 Author name / Structural Integrity Procedia 00 (2019) 000–000 227 5. Analysis of damage accumulation and wear kinetics The accumulated damage function and its evolution during the process of the fracture of subsurface layers of the material were calculated using the relations (12) and (13). In addition to the parameters that affect the stress state of the contacting bodies under the conditions of sliding and rolling friction mentioned in Section 4, the strength characteristics of the material (coefficient c and exponent m in (10)) influence the fatigue damage accumulation. In calculations the dimensionless damage value Q / Q * , which depends only on the parameter m, is used: m Q ( z, N ) Q( z , N ) N max ( z ) + 0 * = * (16) Q* N max ( z * ) Q So, for N N * the surface or subsurface fracture (delamination) occurs if the value of the right-hand side of Eq. (16) reaches 1. For study of fatigue damage accumulation and wear, a numerical analysis of the damage function (16) was carried out. In Fig. 4 the evolution of the damage function (curves 1-6) in sliding contact is presented, where each curve corresponds to a number of cycles passed until the damage function reaches the critical value at the surface ( z = 0) or under the surface ( z 0 ) of the elastic half-space. Fig. 4. Accumulated damage for sliding contact, sliding friction coefficient μ = 0.2 and m = 4.8 After the first case of subsurface fracture (curve 1), the damage function is a monotonically decreasing function with a maximum on the surface (curves 2 and 3). Then, with an increase in the number of cycles, there is an inflection of the function curve and the next act of subsurface fracture occurs (curve 4). After that, the damage function again takes the form of a monotonically decreasing (with the depth) function corresponding to surface wear (curves 5 and 6). 5.1. Sliding contact In sliding contact the effect of the sliding friction coefficient and the strength properties of the material, describing by the parameter m in Eq. (16), on the damage accumulation in the elastic half-space, i.e. the function Q( z, N ) / Q* (16), is studied. Damage functions for different number of cycles (Fig. 5a) and the kinetics of wear (Fig. 5b) in the sliding contact for sliding friction coefficient µ = 0.2 and different values of parameter m are shown in Fig. 5. 228 Irina Goryacheva et al. / Procedia Structural Integrity 41 (2022) 220–231 Author name / Structural Integrity Procedia 00 (2019) 000–000 9 Fig. 5. Accumulated damage and wear kinetics in sliding contact with sliding friction coefficient μ = 0.2 for different values of strength parameter m The analysis of the results shows that in sliding contact at the sliding friction coefficient µ = 0.2 and parameter m = 3 after several acts of delamination the surface wear with a constant rate occurs. With the increase of the parameter m periods of surface wear alternate with acts of subsurface fracture (delamination). The duration (number of cycles) of the surface wear before each act of subsurface fraction (delamination) grows with increase of the parameter m. The accumulated damage function and the kinetics of wear in sliding contact at the sliding friction coefficient µ = 0.4 and different values of the parameter m are presented in Fig. 6. Fig. 6. Accumulated damage and wear kinetics for sliding contact, sliding friction coefficient μ = 0.4 and different values of strength parameter m The results indicate that in sliding with the sliding friction coefficient µ = 0.4 surface wear is the dominant wear behavior. The results illustrate that after a certain number of cycles, the wear rate reaches a constant value. The number of cycles up to the regime of steady surface wear increases with the growth of the parameter m, while the rate of surface wear decreases. The results presented in Fig. 7, allow us to compare the wear kinetics for different values of the parameter m and the sliding friction coefficient µ under conditions of sliding friction. Irina Goryacheva et al.Integrity / Procedia Structural 41 (2022) 220–231 Author name / Structural Procedia 00 Integrity (2019) 000–000 10 229 Fig. 7. Wear kinetics for sliding contact and different values of sliding friction coefficient μ and strength parameter m The analysis of the wear kinetics for different values of the sliding friction coefficient and the strength properties of the material shows that at a large value of the sliding friction coefficient ( = 0.4 ) , surface wear prevails. The surface wear rate for a constant sliding friction coefficient depends on the strength properties of the material, given by the parameter m. At low values of the sliding friction coefficient, the wear is accompanied by periodic separation of fragments of the base material of finite thickness; the duration of the regime before the only surface wear takes place, increases with the growth of the parameter m . 5.2. Rolling contact Under conditions of rolling friction, the analysis of the relative slippage effect is of great interest. The study of the principal shear stress distribution developed in Section 4 shows that a change in the relative slippage affects the values of the surface and subsurface maxima of principal shear stress amplitudes and, accordingly, affects the fatigue damage accumulation features within the contacting bodies. Damage functions and the kinetics of wear in rolling contact for sliding friction coefficient = 0.3 and different values of the relative slippage are presented in Fig. 8. Fig. 8. Accumulated damage and wear kinetics in rolling contact with sliding friction coefficient μ = 0.3, strength parameter m = 4 and different relative slippages The obtained results illustrate that in rolling contact two types of fatigue wear occur: the subsurface fracture (delamination) and the surface wear. The rate and the duration of surface wear and the number of delamination acts, as well as the thickness of separated fragments of the material depend on the relative slippage. Irina Goryacheva et al. / Procedia Structural Integrity 41 (2022) 220–231 Author name / Structural Integrity Procedia 00 (2019) 000–000 230 11 The curves of the wear kinetics in conditions of rolling friction for different values of relative slippage are presented in Fig. 9. Fig. 9. Wear kinetics for rolling contact with μ = 0.3, m = 4 and different values of relative slippage The results indicate that in rolling contact the surface wear alternates with acts of subsurface fracture (delamination), and the rate of surface wear is constant and depends on the relative slippage. For sliding friction coefficient equals to 0.3 and large value of relative slippage (Δ = 0.0045), which corresponds to the complete slip in the contact region a single act of delamination occurs, after which, with an increase in the number of cycles, a regime of surface wear with a constant rate is established. 6. Conclusion The paper presents a model, developed to describe the fatigue damage accumulation and surface and subsurface (delamination) wear under conditions of frictional interaction of elastic bodies. The sliding and rolling contacts of elastic bodies were considered, and the sliding friction coefficient, the relative slippage and the strength properties of the material of elastic bodies were used as variable parameters. The obtained results illustrate the evolution of the accumulated damage function with an increasing number of cycles, as well as the change of the wear behavior from acts of subsurface fracture (delamination) to continuous surface wear with a constant rate. It is shown that the surface wear dominates in sliding contact for the sliding friction coefficient equals to 0.4. At low values of the sliding friction coefficient, there is an alternation of subsurface fracture (delamination) and surface wear. In rolling contact of elastic bodies, the wear rate increases with the growth of the relative slippage, which is accompanied by a change of wear behavior from subsurface to surface. The results of the study are used to analyze the influence of the mechanical and strength characteristics of materials of interacting bodies, as well as the sliding friction coefficient under conditions of sliding friction and additionally relative slippage in rolling contact on fatigue wear features. Acknowledgements The reported study was funded by RFBR, Sirius University of Science and Technology, JSC Russian Railways and Educational Fund “Talent and success”, project number 20-38-51005. References Bernal, E., Spiryagin, M., Vollebregt, E., Oldknow, K., Stichel, S., Shrestha, S., Ahmad, S., et al. (2022), “Prediction of rail surface damage in locomotive traction operations using laboratory-field measured and calibrated data”, Engineering Failure Analysis, Vol. 135, p. 106165. Collins, J.A. (1981), Failure of Materials in Mechanical Design, A Wiley-In., New York. Dang Van, K., Cailletaud, G., Flavenot, J.F., Douaron, A. Le and Lieurade, H.P. (1989), “Criterion for High Cycle Fatigue Failure Under 12 Irina Goryacheva et al. / Procedia Structural Integrity 41 (2022) 220–231 Author name / Structural Integrity Procedia 00 (2019) 000–000 231 Multuiaxial Loading”, Biaxial and Multiaxial Fatigue. Daves, W., Kubin, W., Scheriau, S. and Pletz, M. (2016), “A finite element model to simulate the physical mechanisms of wear and crack initiation in wheel/rail contact”, Wear, Vol. 366–367, pp. 78–83. Goldstein, R.V., Zazovsky, A.F., Spector, A.A. and Fedorenko, R.P. (1982), “Solutions of three-dimensional rolling problems with slip and adhesion by variational methods”, Advances in Mechanics, Vol. 5 No. 3/4, pp. 61–102. Goryacheva, I.G. (1998), Contact Mechanics in Tribology, Kluwer Aca. Goryacheva, I.G. and Chekina, O.G. (1999), “Surface Wear: From Microfracture Modeling to Form Change Analysis”, Mechanics of Solids, Vol. 5, pp. 131–147. Goryacheva, I.G. and Torskaya, E.V. (2019), “Modeling the Accumulation of Contact Fatigue Damage in Materials with Residual Stresses under Rolling Friction”, Journal of Friction and Wear, Vol. 40 No. 1, pp. 33–38. Guo, J., Wang, W.J., He, C.G., Jin, X.S., Liu, Q.Y., Zhu, Y., Ma, L., et al. (2016), “Study on wear and rolling contact fatigue behaviors of wheel/rail materials under different slip ratio conditions”, Wear, Vol. 366–367, pp. 13–26. Hiensch, M. and Burgelman, N. (2019), “Rolling contact fatigue: Damage function development from two-disc test data”, Wear, Elsevier B.V., Vol. 430–431 No. May, pp. 376–382. Hu, Y., Zhou, L., Ding, H.H., Tan, G.X., Lewis, R., Liu, Q.Y., Guo, J., et al. (2020), “Investigation on wear and rolling contact fatigue of wheelrail materials under various wheel/rail hardness ratio and creepage conditions”, Tribology International, Vol. 143 No. November 2019, p. 106091. Johnson, K.L. (1985), Contact Mechanics, Cambridge University Press, available at:https://doi.org/10.1017/CBO9781139171731. Kalker, J.J. (1982), “A Fast Algorithm for the Simplified Theory of Rolling Contact”, Vehicle System Dynamics, Vol. 11 No. 1, pp. 1–13. Kalker, J.J. (1990), Three-Dimensional Elastic Bodies in Rolling Contact, Book, Vol. 66, Springer, available at:https://doi.org/10.1007/978-94015-7889-9. Magel, E.E. (2011), “Rolling Contact Fatigue: A Comprehensive Review”, Federal Railroad Administration, No. November, p. 132. Meshcheryakova, A.R. and Goryacheva, I.G. (2021), “Stress State of Elastic Bodies with an Intermediate Layer in Rolling Contact with Slip”, Physical Mesomechanics, Vol. 24 No. 4, pp. 441–450. Pal, S., Daniel, W.J.T., Valente, C.H.G., Wilson, A. and Atrens, A. (2012), “Surface damage on new AS60 rail caused by wheel slip”, Engineering Failure Analysis, Elsevier Ltd, Vol. 22, pp. 152–165. Sadeghi, F., Jalalahmadi, B., Slack, T.S., Raje, N. and Arakere, N.K. (2009), “A review of rolling contact fatigue”, Journal of Tribology, Vol. 131 No. 4, pp. 1–15. Sakalo, V., Sakalo, A., Rodikov, A. and Tomashevskiy, S. (2019), “Computer modeling of processes of wear and accumulation of rolling contact fatigue damage in railway wheels using combined criterion”, Wear, Elsevier Ltd, Vol. 432–433, available at:https://doi.org/10.1016/j.wear.2019.05.015. Santa, J.F., Cuervo, P., Christoforou, P., Harmon, M., Beagles, A., Toro, A. and Lewis, R. (2019), “Twin disc assessment of wear regime transitions and rolling contact fatigue in R400HT – E8 pairs”, Wear, Elsevier B.V., Vol. 432–433 No. May, p. 102916. Zhang, S., Spiryagin, M., Lina, Q., Ding, H., Wu, Q., Guo, J., Liu, Q., et al. (2022), “Study on wear and rolling contact fatigue behaviours of defective rail under different slip ratio and contact stress conditions”, Tribology International, Elsevier Ltd, Vol. 169 No. December 2021, p. 107491. Zhou, Y., Peng, J.F., Wang, W.J., Jin, X.S. and Zhu, M.H. (2016), “Slippage effect on rolling contact wear and damage behavior of pearlitic steels”, Wear, Elsevier, Vol. 362–363, pp. 78–86.