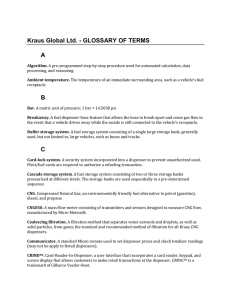

Compressed Natural Gas Supplement Service Manual for Mixer Vehicles 1565578 © 2016 McNeilus Truck and Manufacturing, Inc. Rev. 0218 Disclaimer: This manual must not be used to repair your vehicle. Repair information is available by calling McNeilus Customer Service at (888) 686-7278. The information in this Manual will be your guide to operation, service, and basic maintenance for this equipment. All information, illustrations, and specifications in this manual are based on the information available at the time this manual was published. The illustrations used in this manual are intended as representative reference views only. Because of our continuous product improvement policy, we may modify information, illustrations, and/or specifications to explain and/or exemplify a product, service, or maintenance improvement. We reserve the right to make any change at any time without notice. Go to www.streetsmartparts.com for current information. No part of this publication may be reproduced by any means - graphic, electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval systems for any use or purpose - without the written permission of McNeilus Truck and Manufacturing, Inc. For assistance in ordering OSHA Publications, contact: U.S. Department of Labor/OSHA OSHA Publications P.O. Box 37535 Washington, D.C. 20210 Telephone: 202-693-1888 • Fax: 202-693-2498 Table of Contents Section 1: General Information Section 2: Safety Section 3: General CNG Components Section 4: CNG Fueling and Defueling Section 5: Preventive Maintenance Section 6: Component Remove and Replace Section 7: Troubleshooting Section 8: Index THIS PAGE INTENTIONALLY LEFT BLANK General Information 1 Thank You Thank you for placing your confidence in our product. With proper maintenance, you will have a product that will serve your company for a number of years. This manual is your guide for general and maintenance information of the CNG system. For service and maintenance of the vehicle, please refer to the service manual for that vehicle. For parts information, manuals can be purchased through your McNeilus Parts and Service branch location. Please keep this manual in a safe place. Protect your investment in McNeilus equipment. Do not jeopardize your warranty. Use only genuine McNeilus replacement parts. Original McNeilus Parts ensure the finest quality, the longest life and proper, reliable operation. We encourage you to call anytime you have questions or require assistance with our product. We also welcome your suggestions and ideas. Always have your model and serial number, if applicable, ready when calling for information and parts. © 2016 McNeilus Truck and Manufacturing, Inc. 1-1 CNG — Service Manual General Information Table of Contents 1.0 PURPOSE OF THIS MANUAL........................................................................................................................................... 1-3 1 2.0 PARTS AND SERVICE....................................................................................................................................................... 1-3 3.0 CORPORATE HEADQUARTERS...................................................................................................................................... 1-3 4.0 GLOSSARY........................................................................................................................................................................ 1-4 CNG — Service Manual 1-2 © 2016 McNeilus Truck and Manufacturing, Inc. General Information 1.0 Purpose of this Manual 2.0 Parts and Service 1.1 Introduction Contact your McNeilus Parts and Service branch locations to order parts, receive service information, or for other assistance. Your Mixer system may be equipped with Compressed Natural Gas (CNG) fuel tanks. Vehicles with CNG are designated as dedicated CNG vehicles which means the vehicles are equipped with one fuel system and are designed to operate on CNG. Use these instructions for the safe operation, inspection, and maintenance of all CNG tanks. Contact by phone or visit www.streetsmartparts.com. We have factory owned parts and service centers near you. 888-686-7278 Phone Number State CA CT FL GA IL IN MN NY OH OH PA TX TX UT WI NOTE: Reference the chassis CNG manual and all other available resources for additional information. City Colton East Granby Tampa Villa Rica Sugar Grove Fort Wayne Dodge Center Bronx Cincinnati Columbus Morgantown Houston Hutchins West Valley City Oshkosh Canada Ontario and Western Provinces Quebec and Maritime Provinces 800-265-1089 800-996-4937 3.0 Corporate Headquarters Contact McNeilus Truck and Manufacturing, Inc. directly at our corporate headquarters at the following address, phone number, and website. McNeilus Truck and Manufacturing, Inc. 524 County Road 34 East Dodge Center, MN 55927 Telephone: 507-374-6321 Corporate Website: www.mcneiluscompanies.com Parts and Service Website: www.streetsmartparts.com © 2016 McNeilus Truck and Manufacturing, Inc. 1-3 CNG — Service Manual 1 General Information 4.0 Glossary MAWP - Maximum Allowable Working Pressure that the CNG system may be pressurized to. Defueling - Depletion of fuel from the CNG tank(s). 1 NGV - Natural gas vehicle. Any vehicle whose primary fuel source is natural gas. Diesel Gallon Equivalent (DGE) - The amount of natural gas whose energy equals that of a single gallon of automotive grade diesel fuel. Approximately 6.6 lbs. natural gas or 140 standard cubic feet contains energy equivalent to one gallon of standard automotive-grade diesel fuel. Pressure Relief Device (PRD) - A thermally activated device installed in direct contact with internal pressure in each tank that will release the contained gas in excess temperature (219°F). Fuel Control Module - (Also known as Fuel Management Module or FMM.) Displays the storage tank pressure and output pressure. Controls the manual shut off valve, and the fill receptacle and defueling receptacle. Fuel pressure regulation occurs in the Fuel Control Module. Remote Fueling Receptacle - Some vehicles may be equipped with additional remote fill receptacles located at the front bumper, on the passenger side of the vehicle, or as a rear fill port (located rearward on the vehicle). Safety Decals - Decals found on the fuel control module and the vehicle that warn of hazards related to the use of this equipment. Fuel Storage Pod - Houses and protects the fuel tanks and their associated hardware. Fueling Receptacle - Is used for adding fuel to the vehicle’s fuel tanks. The receptacle is located on the front panel of the fuel control module. There are two standard fueling receptacles: NGV1 and Transit Fill (“Fast Fill”). Service Pressure - Nominal tank pressure determined when system is considered full, at 70°F gas temperature. High Pressure Gauge - Indicates fuel pressure being supplied to the regulator. This gauge is located on the front panel of the fuel control module. Low Pressure Gauge - Indicates the fuel pressure exiting the regulator and being supplied to the vehicle’s engine. This gauge is located in the front panel of the fuel control module. Manual Shut-Off Valve - When activated in the shut-off position (vertical with the arrow pointing down), fuel is prohibited from flowing from the fuel tanks to the vehicle’s engine. The valve is located on the front of the fuel control module. CNG — Service Manual 1-4 © 2016 McNeilus Truck and Manufacturing, Inc. 2 Safety Table of Contents 1.0 IMPORTANT SAFETY INFORMATION.............................................................................................................................. 2-3 1.1 Safety Notices........................................................................................................................................................... 2-3 1.2 Safety Decals............................................................................................................................................................ 2-5 1.2.1 McNeilus Mixer CNG System........................................................................................................................ 2-5 1.2.1 McNeilus Mixer Cross Mount CNG System.................................................................................................. 2-6 1.2.3 Twin Vertical CNG System............................................................................................................................ 2-7 1.3 PRD Vent Locations and Directions.......................................................................................................................... 2-8 1.4 Fire and Explosion Hazards...................................................................................................................................... 2-9 1.4.1 Fire and Explosion......................................................................................................................................... 2-9 1.4.2 Extinguish Media........................................................................................................................................... 2-9 1.4.3 Fire Fighting Instructions............................................................................................................................... 2-9 1.5 Methane Detection/Alarm System (Optional).......................................................................................................... 2-10 © 2016 McNeilus Truck and Manufacturing, Inc. 2-1 CNG — Service Manual THIS PAGE INTENTIONALLY LEFT BLANK Safety 1.0 Important Safety Information Take the safety warnings seriously. If you do not understand them or have questions about them, call McNeilus Truck and Manufacturing, Inc. at 888-686-7278. READ AND UNDERSTAND THIS ENTIRE DOCUMENT BEFORE OPERATING, REPAIRING, OR ADJUSTING YOUR EQUIPMENT. DANGER THOSE WHO USE AND MAINTAIN THIS EQUIPMENT MUST BE THOROUGHLY TRAINED AND FAMILIAR WITH THE PRODUCT. Danger indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Danger is used in the most extreme situations. IF INCORRECTLY USED OR MAINTAINED, THIS EQUIPMENT CAN CAUSE SEVERE INJURY. Always keep this manual in a location where it is readily available for persons who operate or maintain the product. Additional copies of this manual are available from McNeilus Truck and Manufacturing, Inc. Please contact McNeilus Truck and Manufacturing, Inc. at 888-686-7278 if you require additional manuals or if you have any questions about the information in this manual, this product, or safe operating procedures. WARNING Warning indicates a potentially hazardous situation which, if not avoided, could result in serious injury or death. CAUTION THESE SAFETY PROCEDURES ARE FOR YOUR OWN PROTECTION. Caution indicates a situation that might result in property damage. Do not operate this equipment until you have read its contents thoroughly. Please contact McNeilus Truck and Manufacturing, Inc. if you require assistance. SAFETY NOTICE Should operators of this equipment have a reading or learning disability, dyslexia, or other such condition, they must be assigned a mentor/trainer to read and explain to them the entire contents of this manual as well as the safety guidelines, danger, caution, and warning decals on this unit. Such individuals should not be allowed to operate this equipment until they thoroughly understand all of these materials. Failure to do so can result in serious injury or death. WARNING The CNG fuel storage system should be serviced only in well ventilated areas that comply with all federal, state, and local regulations. Serious personal injury or death may occur. Safety and safe working procedures must be followed at all times. SAFETY NOTICE Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 and 1910.146 Confined Space as appropriate. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 and 1910.146 Confined Space as appropriate. 1.1 Safety Notices Safety notices are one of the primary ways to call your attention to potential hazards. WARNING The operator of this vehicle must be properly licensed and trained to operate this vehicle. THIS SAFETY SYMBOL INDICATES IMPORTANT SAFETY MESSAGES IN THIS MANUAL. If you do not have the proper training and licensing to operate this vehicle, you are putting yourself and others at risk of serious injury or death. WHEN YOU SEE THIS SYMBOL, CAREFULLY READ THE MESSAGE THAT FOLLOWS. BE ALERT TO THE POSSIBILITY OF PERSONAL INJURY OR DEATH. If you are uncertain how to operate this vehicle, inform your supervisor or contact McNeilus Truck and Manufacturing, Inc. at 888-686-7278. The following safety notices are used throughout this manual. The “signal words” of DANGER, WARNING, and CAUTION have specific meanings to alert you to the relative level of hazard. © 2016 McNeilus Truck and Manufacturing, Inc. 2-3 CNG — Service Manual 2 Safety WARNING DANGER 2 KEEP THE EQUIPMENT AREA WELL VENTILATED. CNG is considered to be non-toxic by inhalation. The effects of inhalation of high concentrations may cause the same effects as asphyxiation. This includes central nervous system depression such as dizziness, drowsiness, headache, and similar narcotic symptoms, but no long-term effects if removed from the exposure area. Numbness, a “chilly” feeling, and vomiting have been reported from accidental exposures to high concentrations. Wear proper Personal Protective Equipment (PPE) such as hard hats, safety glasses or goggles, sturdy gloves, hearing protection, steel toed boots, and snug fitting sturdy long-sleeve shirt and long pants when operating, fueling, defueling, or maintaining the truck. Reflective clothing is recommended for drivers and employees. Serious personal injury or death can result without proper PPE. Failure to follow will cause serious personal injury or death. WARNING Use the three-point contact method (either two hands and one foot, or two feet and one hand on the ladder at all times) when climbing the ladder. Always face the ladder when climbing up or down. Serious personal injury may result due to a fall. DANGER KEEP THE EQUIPMENT AREA WELL VENTILATED. Carbon Monoxide poisoning can occur as a result of poor installation, poor maintenance or failure or damage to a gas component in service, gas is not burned properly, or when cabs are poorly ventilated and carbon monoxide is unable to escape. WARNING Do not climb on ladders or ride on platforms (if equipped with either) while the truck is in motion or when ladders or platforms are wet and slippery. Serious personal injury may result due to a fall. Failure to follow will cause serious personal injury or death. WARNING WARNING Natural gas is flammable and explosive. Never use any type of open flame (match, lighter, or other) as a source of light around the CNG fuel storage system. Use proper fall protection equipment and training when inspecting or maintaining the CNG cylinder on the truck. Serious personal injury or death may occur. Failure to use proper fall protection equipment may result in serious personal injury or death. WARNING This product may contain materials with chemicals or byproducts of chemical processes known in the State of California to cause cancer or birth defects or other reproductive harm (California Proposition 65). WARNING Safety decals must be replaced anytime they are damaged, missing, or cannot be read clearly. Failure to have proper decals in place can result in serious injury or death. If you require safety decals, please contact McNeilus Truck and Manufacturing, Inc. at 888-686-7278. WARNING The CNG fuel system must not be modified from its original configuration. Modifications may not comply with safety standards. Failure to comply may result in serious personal injury or death. CNG — Service Manual 2-4 © 2016 McNeilus Truck and Manufacturing, Inc. Safety 1.2 Safety Decals The following safety decals are found on the Fuel Control Module and on the vehicle and warn of hazards related to the use of this equipment. Read and understand all safety decals before operating this equipment. If any safety decals on the equipment are not clearly readable, contact McNeilus Truck and Manufacturing, Inc. at 888-686-7278 or www.streetsmartparts.com to order replacements. Use only McNeilus replacement decals. 2 The locations for the following decals are illustrated on charts and drawings of the vehicles on the following pages. 1.2.1 McNeilus Mixer CNG System Ref No. Part Number Qty. Comments 1 1532985 2 2 1479924 2 One decal is placed on the air intake under the front hood. 3 1479921 2 One decal on each CNG tank and one on rear of vehicle. 4 1479922 1 5 1534429 1 6 1479911 2 7 1479915 1 One decal on each side. NOTE: Only one side of the truck is shown for illustrative purposes. McNeilus Mixer CNG Mount 5 2 3 4 1 6 3 7 1 2 © 2016 McNeilus Truck and Manufacturing, Inc. 2-5 CNG — Service Manual Safety 1.2.1 McNeilus Mixer Cross Mount CNG System 2 Ref No. Part Number Qty. Comments 1 1532985 4 One decal on each CNG tank and one on the fuel management module box.* 2 1479924 2 One decal is placed on the air intake under the front hood and one on the fuel management module box. 3 1479921 4 One decal on each CNG tank and one on rear of vehicle.* 4 1479922 1 5 1534429 1 6 1479911 2 7 1479915 1 One decal on each side. * The highest CNG capacity systems will have a frame mounted tank on either side of the truck and a single tank cross mounted on the back of the frame behind the cab. The number of necessary decals is dependent upon system configuration. NOTE: Only one side of the truck is shown for illustrative purposes. McNeilus Mixer Cross Mount CNG System 5 1 2 3 1 3 6 4 3 7 1 2 CNG — Service Manual 2-6 © 2016 McNeilus Truck and Manufacturing, Inc. Safety 1.2.3 Twin Vertical CNG System Ref No. Part Number Qty. Comments 1 1532985 3 One decal on each CNG tank and one on the fuel management module box. 2 1479924 2 One decal placed on the air intake under the front hood (not shown) and one on the fuel management module box. 3 1479921 3 One decal on each CNG tank and one on rear of vehicle. 4 1479922 1 7 1479915 1 2 3 Twin Vertical Mixer CNG Mount 3 4 1 1 3 7 1 2 © 2016 McNeilus Truck and Manufacturing, Inc. 2-7 CNG — Service Manual Safety 1.3 PRD Vent Locations and Directions NOTE: Arrows indicate the direction the natural gas vents from the PRDs. Twin Vertical Mount Frame and Cross Mount 2 CNG — Service Manual 2-8 © 2016 McNeilus Truck and Manufacturing, Inc. Safety 1.4 Fire and Explosion Hazards 1.4.3 Fire Fighting Instructions Auto Ignition Point: 900 - 1170°F (482 - 632°C) Natural gas fires should not be extinguished unless flow of gas can be immediately stopped. Shut off gas source and allow gas to burn out. If spill or leak has not ignited, determine if water spray will assist in dispersing gas or vapor to protect personnel attempting to stop the leak. Lower Explosive Limit (%): 5 Upper Explosive Limit (%): 15 Use water to cool equipment, surfaces, and containers exposed to fire and excessive heat. For large fires, the use of unmanned hose holders or monitor nozzles may be advantageous to further minimize personnel exposure. WARNING Natural gas is flammable and explosive. Never use any type of open flame (match, lighter, or other) as a source of light around the CNG fuel storage system. If there is a fire, isolate the area. Let the tank burn unless leak can be stopped. Withdraw immediately in the event of a rising sound from a venting safety device. Large fires typically require specially trained personnel and equipment to isolate and extinguish. Serious personal injury or death may occur. WARNING Fire fighting activities that may result in potential exposure to high heat, smoke or toxic by-products of combustion should require NIOSH/MSHA- approved pressure-demand, self-contained breathing apparatus with full face piece and full protective clothing. KEEP THE EQUIPMENT AREA WELL VENTILATED. Although CNG is non-toxic, it can cause asphyxiation in a confined area without ventilation. Any atmosphere that does not contain enough oxygen for breathing can cause dizziness, unconsciousness, or even death. Even though CNG is sulfurized, the smell may go unnoticed on some vehicles, such as a refuse truck. Without adequate ventilation, natural gas will displace the oxygen and give no warning that a non-life supporting atmosphere is present. Store CNG in a well ventilated area. Refer to the CNG Material Safety Data Sheet (MSDS) for more information on natural gas fire and explosion hazards. Serious personal injury or death may occur. 1.4.1 Fire and Explosion There is a dangerous fire and explosion hazard when natural gas is exposed to heat, sparks, or flame. Natural gas is lighter than air and may travel long distances to a point of ignition and flash back. Containers containing or which have contained natural gas may explode in heat or fire. 1.4.2 Extinguish Media To extinguish a natural gas fire, stop the flow of natural gas, use dry chemical, carbon dioxide, halon, or water. Fire should not be extinguished unless flow of gas can be immediately stopped. © 2016 McNeilus Truck and Manufacturing, Inc. 2-9 CNG — Service Manual 2 Safety 1.5 Methane Detection/Alarm System (Optional) 2 NOTE If methane detector/alarm is used, note the information below. The methane vapor detection system utilizes two sensors to identify methane vapors: one located in the cab compartment and one located in the engine compartment of the vehicle. The system operates with both a visual and an audible alarm to warn the operator of potential danger. The alarms are triggered at trace levels (20% LEL [Lower Explosive Limit]) and at significant levels (50% LEL) of vapor concentration. An internal relay controls two indicator lights (one green and one red) that can be seen through the windshield. The lights should always be checked before entering the vehicle. The green light will go out and the red light will illuminate 15 seconds after a significant level of methane has been detected. The methane detector also has a press-to-test button that can be used to test the indicator lights and the audible alarm. When the vehicle battery is disconnected, the methane detector/alarm system will not operate therefore the green light will not be on. The methane detector/system is powered by the vehicle battery and is active at all times unless the vehicle battery is disconnected or the fuse is blown. Hand-held methane detector/ alarm devices should be used when working on natural gas vehicles with a nonfunctional or disconnected methane detector/alarm system and where no auxiliary methane detector/alarm system is installed. WARNING If the optional methane detection system is used, when approaching the vehicle to enter, do not open the vehicle if the RED LIGHT IS ON! Do not open the vehicle doors if the ALARM IS SOUNDING! Do not open the vehicle doors if the GREEN LIGHT is NOT ON! If the indicator light is red, if the alarm is sounding or if the green light is NOT ON, it is unsafe to open the vehicle doors because even static electricity can ignite concentrated methane fumes in an enclosed area. Immediately implement the following procedure: Remove all personnel from the area. Turn off electrical circuits and sources of ignition in the immediate area. Manually turn off the Fuel Shut-Off Valve on each fuel tank to prevent further gas leakage. Wait until the gas has dissipated and the alarm situation has been cleared. It is now safe to open the vehicle doors and windows to vent the vehicle. Do not operate the vehicle until the source of the leak has been repaired. WARNING In the event of an alarm while operating the vehicle, immediately open the cab windows, safely stop the vehicle, shut down the engine, and turn off the ignition. Exit the cab and leave the doors and windows open to vent the vehicle. Manually turn off the Fuel Shut-Off Valve on each fuel tank to prevent further gas leakage. Wait until the gas has dissipated and the alarm situation has cleared. Do not operate the vehicle until the source of the leak has been repaired. Methane is extremely flammable. Inhalation may cause dizziness, drowsiness, headache, but no long-term effects if removed from the exposure area. Serious personal injury or death may occur. 1 Methane is extremely flammable. Serious personal injury or death may occur. 2 4 Gas Detection System AMGaDS III PLUS 3 POWER Push To Silence Silence Engaged Shutdown Reset Relay Engaged Gas Concentration SIGNIFICANT 5 6 Trace 1 2 NE NE ZO ZO SENSOR FAULT AMGaDS III 9 Push to Test 8 CNG — Service Manual 2-10 © 2016 McNeilus Truck and Manufacturing, Inc. 7 Safety Methane Detection System Number Description Function Power On Indicator (Green) The green LED should always be on when there is no methane detection. No power on/off switch is provided for this unit as it should be on at all times. Significant Alarm Indicators (Red) Illumination of the red LED for “Zone 1” (cab compartment) or “Zone 2” (engine compartment) indicates the system has detected gas fumes in concentrations above 50% of the Lower Explosive Limit (LEL) and an audible horn will sound. 3 Trace Sensor Alarm Indicators (Amber) Illumination of the amber LED for “Zone 1” (cab compartment) or “Zone 2” (engine compartment) indicates the system has detected a gas concentration above 20% of the LEL. This is a cautionary situation. Corrective measures should be taken as soon as possible — including opening the vehicle windows and returning the vehicle for service — to identify and correct the source of the methane leak. 4 Audible Alarm Silence Button Press to silence the audible alarm. 5 Alarm Silenced Indicator Illuminates to indicate the audible alarm has been silenced. 6 Relay On/Off Indicator If there is a SIGNIFICANT alarm detected for 15 seconds, the “Relay Engaged” LED will go on. The windshield-visible green light will go out and the windshield-visible red light will illuminate. 7 Relay Reset Button Only after the methane gas has cleared and the alarms are off, the internal relay can be reset by pressing the “Shutdown Reset” button. After pressing this button, the “Relay Engaged” LED will go off. 8 System Test Button Press this button to perform a self-test of all electrical and sensor functions and simulate an alarm condition. The system returns to normal when the test button is released. Sensor Fault Indicators If either Sensor Fault Light remains illuminated or go on intermittently, a disconnected or faulty sensor is indicated in the corresponding zone. Zone 1 is the cab compartment sensor and Zone 2 is the engine compartment sensor. Do not operate the vehicle until a qualified person corrects this condition 1 2 9 © 2016 McNeilus Truck and Manufacturing, Inc. 2-11 CNG — Service Manual 2 THIS PAGE INTENTIONALLY LEFT BLANK CNG System 3 Table of Contents 1.0 CNG SYSTEM.................................................................................................................................................................... 3-3 1.1 Fuel Control Module Components............................................................................................................................. 3-3 1.1.1 High Pressure Gauge.................................................................................................................................... 3-3 1.1.1.1 High Pressure Line Identification Tags........................................................................................... 3-3 1.1.2 Low Pressure Gauge..................................................................................................................................... 3-3 1.1.3 Manual Shut-Off Valve................................................................................................................................... 3-3 1.1.4 Purge Valve................................................................................................................................................... 3-4 1.1.5 Coalescing Filter............................................................................................................................................ 3-4 1.1.6 Pressure Regulator....................................................................................................................................... 3-4 1.1.7 Pressure Sensor............................................................................................................................................ 3-4 1.1.8 Fueling Receptacle........................................................................................................................................ 3-4 1.1.9 Remote Fueling Receptacle.......................................................................................................................... 3-5 1.2 Fuel Storage Pod...................................................................................................................................................... 3-5 1.2.1 Pressure Relief Devices (PRD)..................................................................................................................... 3-5 1.2.2 Tank Manual Fuel Shut-Off Valves................................................................................................................ 3-5 1.3 Vehicle Fueling.......................................................................................................................................................... 3-5 1.3.1 Vehicle Fueling.............................................................................................................................................. 3-6 1.3.2 Vehicle Fueling Through Remote Receptacles............................................................................................. 3-6 1.3.3 Filling Standards............................................................................................................................................ 3-7 1.3.4 Overpressuring Standards............................................................................................................................ 3-7 © 2016 McNeilus Truck and Manufacturing, Inc. 3-1 CNG — Service Manual THIS PAGE INTENTIONALLY LEFT BLANK CNG System 1.0 CNG System 1.1.2 Low Pressure Gauge • Fuel Control Module The low pressure gauge, located in the front panel of the fuel control module, indicates the fuel pressure exiting the regulator and being supplied to the vehicle’s engine. A typical reading for this gauge is between 100 psi and 120 psi. • Fuel Storage Pods 1.1.3 Manual Shut-Off Valve • Plumbing The manual shut-off valve is located on the front of the fuel control module. When the valve is in the vertical position (arrow pointing down), fuel is prohibited from flowing from the fuel tanks to the vehicle’s engine. The service pressure of this CNG system is 3,600 psig (250 bar). The CNG fuel system has several components 1.1 Fuel Control Module Components The fuel control module has several functions (these functions are described in sections 1.1.1-1.1.9): MA10 CNG Control Module Manual Shut-Off Valve • Local and remote storage tank pressure measurement • Manual and ignition controlled shut-off • Pressure reduction from storage tank pressure to engine supply pressure 2000 1000 • Filtration of fuel stream 3000 4000 5000 6000 • Liquid removal from fuel stream 1.1.1 High Pressure Gauge The high pressure gauge, located in the front panel of the fuel control module, indicates the fuel pressure being supplied to the regulator. This gauge will indicate fuel tank pressure if the manual shut-off valve is open and all other valves between the fuel module and the fuel tanks are also open. 1.1.1.1 High Pressure Line Identification Tags High pressure lines have high pressure line identification tags placed every 24 inches on lines that are longer than 30 inches. Look for the tags before performing maintenance on or near high pressure lines. © 2016 McNeilus Truck and Manufacturing, Inc. MA20 CNG Control Module with Defueling Manual Shut-Off Valve 3-3 CNG — Service Manual 3 CNG System 1.1.4 Purge Valve 1.1.8 Fueling Receptacle The purge valve, located inside the service access door, safely purges all CNG fuel from the fuel control module in order to safely access the filter housing. The fueling receptacle, located on the front panel of the fuel control module, is used for adding fuel to the vehicle’s fuel tanks. Standard equipment is a buzzer in the cab that signals when the fuel control module is open. An optional part is a door interlock that requires the door be closed for the vehicle’s ignition circuit to start the engine. 1.1.5 Coalescing Filter The coalescing filter, located inside the service access door, removes solid particles as well as liquids (such as water or oil in aerosol form). The filter requires periodic maintenance to remove accumulated liquids. Purge Valve MA10 CNG Control Module Fuel Receptacle Coalescing Filter 2000 1000 3000 4000 5000 NGV 1 Standard Fueling Port 6000 3 MA11 CNG Control Module with Defueling Receptacle 1.1.6 Pressure Regulator Defueling Port The pressure regulator, located inside the service access door, converts high pressure fuel supplied from fuel tanks to a low pressure that is needed for proper operation of the vehicle’s engine. The regulator also contains a shut-off valve that, through the ignition circuit, can allow or prohibit the flow of fuel to the engine. NGV 1 Port 1.1.7 Pressure Sensor The pressure sensor, mounted in the regulator’s sensor port inside the service access door, generates an electrical signal that is proportional to the pressure being supplied to the regulator from the fuel tanks. The signal indicates the fuel level on the fuel gauge. CNG — Service Manual Transit Fill 3-4 © 2016 McNeilus Truck and Manufacturing, Inc. CNG System 1.2 Fuel Storage Pod MA20 CNG Control Module with Defueling Receptacle The fuel storage pod houses and protects the fuel tanks and their associated hardware. Defueling Port 1.2.1 Pressure Relief Devices (PRD) A thermally activated device installed in direct contact with internal pressure in each tank that will release the contained gas in excess temperature (219° F). NGV 1 Port 1.2.2 Tank Manual Fuel Shut-Off Valves The quantity per fuel pod will be dependent upon total capacity per system. There will be one manual shut-off per tank. The shut-off valves turn off fuel flow from the tank to the fuel control module for plumbing or component maintenance and service. They do not isolate the tank from the PRD plumbing. Transit Fill MA20 CNG Control Module with Defueling Receptacle (no Transit Fill Port) Defueling Port NGV 1 Port 1.1.9 Remote Fueling Receptacle Some vehicles may be equipped with additional remote fill receptacles located at the front bumper or on the passenger side of the vehicle. © 2016 McNeilus Truck and Manufacturing, Inc. 3-5 CNG — Service Manual 3 CNG System 1.3 Vehicle Fueling 1.3.1 Vehicle Fueling A vehicle fueled through the fuel receptacle on the front panel of the fuel control module has two (2) check valves to protect against uncontrolled flow of fuel out of the storage tanks. The first check valve is within the fuel receptacle, and the second check valve is inside the fuel control module and is used in the event the fuel receptacle is damaged. 1.3.2 Vehicle Fueling Through Remote Receptacles UNIVERSAL FILL TABLE FOR NGV FUEL CONTAINERS CNG TEMPERATURE, °F 3 Fuel flows from remote fill receptacles through the fuel control module to storage tanks. A double check valve arrangement is also used in this process. 200 190 180 170 160 150 140 130 120 110 100 90 80 70 60 50 40 30 20 10 0 -10 -20 -30 -40 -50 OverFill 120% 110% 100% 90% 80% 70% 4500psig, 84°F 60% 50% 40% 30% 20% 15% 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 CONTAINER PRESSURE, PSIG Gas Data Source: A.G.A. Report No. 8, Catalog No. XQ 9212) and a typical natural gas composition (93.6% methane, 3.1% ethane, 1.4% nitrogen, 0.8% carbon dioxide, plus other heavier hydrocarbons. 1 Table 1 CNG — Service Manual 3-6 © 2016 McNeilus Truck and Manufacturing, Inc. CNG System 1.3.3 Filling Standards According to ANSI NGV 2-2007 standards, CNG tanks are designed to be filled to a pressure that does not exceed any of the following conditions: a. A pressure that would settle to 1.0 times the service pressure at a settled temperature of 70°F (21°C). b. A settled pressure of 1.25 times the service pressure at 135°F (47°C); or c. 1.25 times the service pressure immediately after filling, regardless of temperature. The designed service pressure and temperature of your CNG tank is 3,600 psig at 70°F, with a maximum working condition of 4,500 psig at or below 135°F. 3 1.3.4 Overpressuring Standards According to ANSI NVG 2-2007 standards, any tank that has exceeded the limits of the constraints listed above shall be handled accordingly. Any tank that is believed to have a pressure greater than 1.25 times service pressure shall be defueled, depressurized, and removed from service. The tank shall then be inspected by an agency authorized by the manufacturer..., the tank may be returned to service if it is determined that the tank has not suffered any damage that may reduce its service life. A record of such incident shall be sent to and retained by the manufacturer. If you feel the tank has been over pressurized, i.e. above 4,500 psig, contact McNeilus Truck and Manufacturing, Inc. at 888-686-7278 for approved authorized agencies to inspect the tank. Should you find an overpressure situation and a need to defuel, reference the Fueling and Defueling section of this manual for proper defueling procedures. If the tank is found to be damaged beyond use, contact McNeilus Truck and Manufacturing, Inc. at 888-6867278 for proper disposal procedures. See the Preventive Maintenance section of this manual for end of service life procedures if tank has been over pressurized. © 2016 McNeilus Truck and Manufacturing, Inc. 3-7 CNG — Service Manual THIS PAGE INTENTIONALLY LEFT BLANK CNG Fueling and Defueling Table of Contents 1.0 OPERATION....................................................................................................................................................................... 4-3 1.1 Warm Up Procedure.................................................................................................................................................. 4-3 2.0 FUELING PROCEDURE.................................................................................................................................................... 4-3 3.0 DEFUELING THE CNG TANKS PROCEDURE................................................................................................................. 4-3 3.1 Defueling Requirements............................................................................................................................................ 4-3 3.2 Grounding Information............................................................................................................................................... 4-4 3.3 Identify Your Fuel Management Module Box............................................................................................................. 4-4 3.3.1 Install a Defueling Three-Way Valve to the Fuel Box (MA10 Only)............................................................... 4-5 3.4 Receptacle Defueling Procedure Set-Up.................................................................................................................. 4-5 3.4.1.1 Option 1: Defueling with a Defueling Panel (Atmospheric Venting)............................................... 4-5 3.4.1.2 Option 2: Defueling with a Defueling Panel (Compressor Inlet Method)....................................... 4-5 3.4.1.3 Option 3: Defueling with a Defueling Panel (Vent Back to Gas Main Method).............................. 4-5 3.5 Vehicle to Vehicle Defueling Procedure Set-Up........................................................................................................ 4-5 © 2016 McNeilus Truck and Manufacturing, Inc. 4-1 CNG — Service Manual 4 THIS PAGE INTENTIONALLY LEFT BLANK Fueling and Defueling 1.0 Operation 8. Return dispensing nozzle to appropriate location on dispenser. 1.1 Warm Up Procedure 9. Return dust cap to vehicle fuel receptacle. Run the vehicle for 15 minutes at low throttle before starting the day’s route or until coolant reaches minimum chassis operating temperature and adequately warm the CNG regulator to prevent freeze up. 10. Disengage the parking brake. 2.0 Fueling Procedure All CNG tanks in the CNG system must be depleted of all fuel before replacing the PRD valve(s). 1. Make sure the vehicle’s engine is turned off. 2. Set the parking brake. 3. Access the fuel receptacle and remove dust cap. 4. Retrieve fueling nozzle from dispenser. 5. Turn the control handle 1/4 turn counterclockwise and attach CNG dispensing nozzle to vehicle receptacle. 3.0 Defueling the CNG Tanks Procedure WARNING The defueling process must occur outside, away from flammable materials. Failure to comply could result in an explosion and serious personal injury or death. There are multiple methods to defuel the CNG tanks in the CNG system. Choose the method that is appropriate for the equipment you have. Read the entire Procedure before beginning. 3.1 Defueling Requirements The most important information with defueling is ensuring the technician’s safety which requires training and careful attention to using proper procedures. Defueling is not something technicians should “figure out” when it is time to perform it, but requires significant preparation. Every facility that services CNG vehicles should prepare for defueling ahead of time, especially in case emergency defueling becomes necessary. Figure 1: Attach dispensing nozzle to vehicle. 6. Turn the control handle 1/2 rotation clockwise to lock the nozzle to the vehicle receptacle. The vehicle is ready for fueling. WARNING Basic Rules for Defueling • Deplete as much fuel as possible prior to defueling • Notify appropriate nearby personnel prior to defueling • Always ground (earth ground) the vehicle and the fuel system being defueled Figure 2: Turn control handle to lock the nozzle to the vehicle receptacle. 7. After dispensing is complete, turn control handle on nozzle 1/2 turn counterclockwise and remove CNG dispensing nozzle from vehicle receptacle. • Never defuel indoors • Always defuel in a well-ventilated area (outside) • Always wear personal protective equipment such as safety glasses, gloves, safety shoes, hard hats • Be familiar with evacuation routes Failure to comply could result in serious personal injury or death. Figure 3: Remove the dispensing nozzle from the vehicle receptacle. © 2016 McNeilus Truck and Manufacturing, Inc. 4-3 CNG — Service Manual 4 Fueling and Defueling 3.3 Identify Your Fuel Management Module Box WARNING Even if the truck has stalled after running it out of fuel, and you think all fuel has been depleted, check the high pressure gauge to make sure it is at zero. If the gauge is not at zero, continue to deplete the fuel until the gauge reads zero. Failure to comply may result in serious personal injury or death. 1. 4 There are three types of CNG fuel management module boxes. Identify which type you have and follow the appropriate procedures for defueling. If you have MA10, install the three-way valve before beginning to defuel. See 3.3.1 Install a Defueling ThreeWay Valve to the Fuel Box (MA10 Only). If you have MA11 or MA20, go to 3.4 Receptacle Defueling Procedure SetUp. Close the manual shut-off valve on each storage vessel or close the electronically activated solenoid valves (if available) on the fuel delivery and storage system. On vehicles with electronically activated valves, use the manual lock-down screw or remove the relay or fuse/ circuit breaker in the circuit. 2. Run the vehicle on CNG until it stalls. 3. Attempt to start the vehicle again. If it starts, let it run until it stalls again. Repeat the step until the vehicle no longer starts. 2000 1000 3000 4000 5000 6000 Fueling Receptacle 3.2 Grounding Information Before choosing one of the following options, ground the truck. WARNING MA10 The tank must be grounded before venting. The venting orifice must be grounded with a 3-gauge wire minimum to an appropriate ground source at least eight (8) feet (2.44 meters) in the ground. Failure to comply may result in serious personal injury or death. Defueling Valve Fueling Receptacle MA11 or MA20 Figure 4: Illustration of a grounding rod in the ground. CNG — Service Manual 4-4 © 2016 McNeilus Truck and Manufacturing, Inc. Fueling and Defueling 3.3.1 Install a Defueling Three-Way Valve to the Fuel Box (MA10 Only) 1. Close the manual shut-off valve on each storage vessel or close the electronically activated solenoid valves (if available) on the fuel delivery and storage system. On vehicles with electronically activated valves, use the manual lock-down screw or remove the relay or fuse/ circuit breaker in the circuit. 2. Run the vehicle on CNG until it stalls. 3. Attempt to start the vehicle again. If it starts, let it run until it stalls again. Repeat the step until the vehicle no longer starts. 4. Check the high pressure gauge to make sure it reads zero. If it does not read zero, repeat Step 3 (above) until both the high pressure gauge reads zero and the truck no longer starts. 5. Once pressure is removed from lines, install the 3-way valve at the back of the fuel module or in-line wherever accessible. 6. Once installed, ensure the 3-way valve is in the OFF position, then slowly open the tank manual valves. 7. Continue to Defueling Options (below). 3.4.1.2 Option 2: Defueling with a Defueling Panel (Compressor Inlet Method) By far the easiest method, this procedure requires preplanning and special equipment installed at the CNG fueling station. If there is not a fueling station at the site where the technician is working on the vehicle, it is required to tow the vehicle to the facility to repair after defueling. In this method, the vehicle is connected through the defueling nozzle to the defueling panel and the compressor at the fueling station extracts the gas from the vehicle. The vehicle and its fuel system must be grounded. If you have a MA10 Fuel Box system, remove the defueling 3-way valve. 3.4.1.3 Option 3: Defueling with a Defueling Panel (Vent Back to Gas Main Method) The least common method, venting back to gas main, requires pre-planning and specialized equipment. The local gas utility would install special valving, regulation, and piping that allows the gas to be put back into the distribution system. This process works on the basis of pressure equalization between the vehicle and the utility system, so it is possible that there will still be pressure in the vehicle’s onboard fuel system. As in the other defueling methods, both the vehicle and the fuel system must be grounded during the process. Choose one of the following options: If you have a MA10 Fuel Box system, remove the defueling 3-way valve. Option 1: Run truck as low on fuel as possible. Once the fuel level has been depleted as much as possible, remaining fuel shall be depleted during defueling. Defueling ThreeWay Valve OR Option 2: Use vehicle to vehicle defueling to reduce pressure as far as possible (see Vehicle to Vehicle Defueling Procedure Set-Up). Defueling Connection CNG Fuel Fill Connection 3.4 Receptacle Defueling Procedure SetUp Once the vehicle is equipped with the defueling receptacle, there must be an approved place to put the natural gas fuel removed from the vehicle. The following are the three most common defueling options. 3.5 Vehicle to Vehicle Defueling Procedure Set-Up 3.4.1.1 Option 1: Defueling with a Defueling Panel (Atmospheric Venting) Defueling Hose for Vehicle to Vehicle Defueling The first thing to check when using this method is your local air quality regulations. There may be local air quality regulations regarding the release of methane into the atmosphere. If atmospheric venting is acceptable in the area, then a vent stack apparatus that meets the requirements established in either the Uniform Building Code or the International Building Code must be followed. The local authority having jurisdiction—typically the Fire Marshal—should be consulted. Both the vehicle and the fuel system must be grounded (see Grounding Information). If you use this method, you must fill out the CNG Fuel Release Tracking Sheet attached to this bulletin and return it to the e-mail address listed on it. A defueling hose is used to transfer CNG fuel from a supplying (defueling) vehicle to a receiving (fueling) vehicle. There are two different length defueling hoses available from McNeilus Truck and Manufacturing, Inc. 20 foot defueling hose is part number 1462077 50 foot defueling hose is part number 1464662 If you have a MA10 Fuel Box system, remove the defueling 3-way valve. © 2016 McNeilus Truck and Manufacturing, Inc. 4-5 1. A defueling hose can be used only if one of the vehicles is equipped with a defueling receptacle. The supplying vehicle must have the defueling valve. 2. In order for the CNG fuel to flow, the tank pressure in the supplying vehicle must be higher than the tank pressure in the receiving vehicle. CNG — Service Manual 4 Fueling and Defueling 3. Open access doors on the fuel control module on both vehicles. 4. Before connecting the defueling hose to either vehicle, open the purge valve on the defueling hose to release any pressure that may be in the hose. Close the purge valve after pressure is released. 5. Turn the defueling control valve to the Normal Operation position to release pressure in the defueling circuit. This also allows the hose’s defueling nozzle to be connected to the defueling receptacle. It is not possible to make the connection if the valve is not in the Normal Operation position. 6. Connect the hose’s defueling nozzle to the defueling receptacle of the supplying vehicle (Figure 7) by pulling back on the quick connect collar on the hose and pushing it onto the vehicle’s coupler. 4 Defueling Hose Defueling Receptacle Figure 5Figure 7: Defueling hose attached to defueling receptacle on supplying vehicle. 7. Connect the hose’s fueling nozzle to the fueling (NGV1) receptacle on the receiving vehicle. 8. Slowly turn the defueling control valve on the supplying vehicle to Defueling Enabled to initiate the flow of CNG fuel from the supplying vehicle to the receiving vehicle. 9. Adjust this flow to a steady flow rate. Too fast of a flow rate will cause the system to freeze up. 10. When fuel stops flowing, check the gas pressure by reading the high pressure gauges of both vehicles. Both CNG tank pressure gauges should equalize. 11. Stop the flow of CNG fuel by turning the defueling control valve to the Normal Operation position. NOTE: Pressure in the defueling hose is vented so that the hose can be disconnected. 12. Disconnect the fuel hose from the supplying vehicle by pulling back on the quick connect collar on the hose and pulling the hose away from the vehicle’s coupler. CNG — Service Manual 4-6 © 2016 McNeilus Truck and Manufacturing, Inc. Preventive Maintenance Table of Contents 1.0 CNG INSPECTION............................................................................................................................................................ 5-3 1.1 CNG System Inspection............................................................................................................................................ 5-3 1.2 General Visual Inspection.......................................................................................................................................... 5-3 1.3 Detailed Visual Inspection......................................................................................................................................... 5-3 1.4 Fitting Leak Inspection.............................................................................................................................................. 5-3 1.5 Mounting Bracket Inspection..................................................................................................................................... 5-3 1.6 End of Service Life of a Tank..................................................................................................................................... 5-3 1.6.1 Condemned Tank Tool List............................................................................................................................ 5-4 2.0 PREVENTIVE MAINTENANCE......................................................................................................................................... 5-4 2.1 Before Performing Maintenance................................................................................................................................ 5-4 2.1.1 Depressurize Before Working on the Engine Fuel System........................................................................... 5-4 2.1.2 Depressurize Before Working on the Tanks or PRD Plumbing..................................................................... 5-4 2.2 Maintenance Schedule.............................................................................................................................................. 5-5 2.2.1 Daily CNG Fuel System Checks................................................................................................................... 5-5 2.2.1.1 Check for CNG Leaks.................................................................................................................... 5-5 2.2.2 Maintenance Chart........................................................................................................................................ 5-5 © 2016 McNeilus Truck and Manufacturing, Inc. 5-1 CNG — Service Manual 5 THIS PAGE INTENTIONALLY LEFT BLANK Preventive Maintenance 1.0 CNG Inspection 1.3 Detailed Visual Inspection A detailed visual inspection is conducted by trained personnel holding the proper certifications and thoroughly inspects and evaluates the tank and bracket assembly. McNeilus Truck and Manufacturing, Inc. employs CNG inspectors who are certified by CSA International to recertify tanks. Contact McNeilus Truck and Manufacturing, Inc. at 888-686-7278. All covers and shields must be removed to enable the inspector to see the tanks. 1.1 CNG System Inspection The CNG system shall have a detailed visual inspection after a fire or motor vehicle accident or when the vehicle has been in a collision operating at over five (5) mph and at least every 36 months or 36,000 miles, whichever comes first, for damage and deterioration. The CNG system must be recertified by a CNG inspector who is certified by CSA International before the unit is placed back into operation. McNeilus Truck and Manufacturing, Inc. employs CNG inspectors who are certified by CSA International to recertify tanks. Contact McNeilus Truck and Manufacturing, Inc. at 888-686-7278. The system shall be inspected: • Prior to installation • Prior to being filled if there is reason for concern (i.e., if the vehicle was involved in a collision or fire regardless if there was contact with the CNG system) The CNG tanks and fittings must be cleaned before inspection. 1. Use warm, soapy water, a mop, and a soft bristle brush to clean the tanks, tubes, and fittings. 2. Rinse the components well with clean water. • Periodically, as required by law, regulation, and/or the tank design specifications • When known or suspected to have been abused in service, such as involvement in fire, impact, exposed to excessive heat or any other potential damage causing situation NOTE: A garden hose works well to wet and rinse off the area. • If any unusual behavior is observed, such as emission of natural gas odor, unexpected loss of gas pressure, rattling or other indications of looseness, or unusual snapping or hissing sounds SAFETY NOTICE Cylinders that have been involved in an accident which may have the potential of Level 2 or Level 3 damage should be depressurized prior to inspection. See cylinder manufacturer guidelines for damage disposition and level descriptions. 1.4 Fitting Leak Inspection Fittings and connections should be checked for leaks periodically. Servicing and inspecting for leaks is to be conducted by individuals with the proper certifications and training. 1.5 Mounting Bracket Inspection WARNING • The tank must be mounted in a manner that adequately restrains it, but does not induce damage. Because the tank expands and contracts as the internal pressure increases or decreases, the tank’s diameter and length will vary Use proper fall protection equipment and training when inspecting or maintaining the CNG cylinder on the truck. Failure to use proper fall protection equipment may result in serious personal injury or death. • Verify the tanks are firmly restrained. If a tank is loose within the brackets, the tank must be vented and removed from the vehicle, and a visual inspection of the tank and brackets must be initiated and recorded 1.2 General Visual Inspection • Verify the bolts, which secure the brackets to the vehicle, are present and tight General visual inspection is a general inspection and evaluation of the visible areas of the system for signs of gross external damage or abuse. This type of inspection can be conducted by operators or maintenance personnel. A general visual inspection is looking for cuts, gouges, abrasions, discoloration, broken fibers, loose brackets, damaged gaskets or o-rings, and heat damage. In addition, verify that all safety signs are still present, readable, and in good condition. If the truck requires new safety signs, contact McNeilus Truck and Manufacturing, Inc. at 888-6867278. • Verify the brackets are in good condition and suitable for continued service 1.6 End of Service Life of a Tank Refer to the label marking the end of the manufacturer’s recommended service life for the tank. 1. • It is inspected • Removed from service This inspection should be a part of normal maintenance or a scheduled maintenance activity. It should be performed any time the vehicle is on a service lift or scheduled into the maintenance shop. © 2016 McNeilus Truck and Manufacturing, Inc. When the tank reaches the manufacturer’s recommended service life, • Condemned and clearly labeled “CONDEMNED” at the time of inspection. The marking shall be affixed to the manufacturer’s label and the duplicate manufacturer’s label, if used. 5-3 CNG — Service Manual 5 Preventive Maintenance 2. The tank must be depressurized. Follow all depressurizing instructions. 2.0 Preventive Maintenance 3. The tank must be defueled according to proper defueling procedures. 2.1 Before Performing Maintenance 4. Flush residual fumes with compressed nitrogen. If compressed nitrogen is not available, flushing the tank with water is acceptable. Wait eight (8) hours before proceeding to the next step. 5. 2.1.1 Depressurize Before Working on the Engine Fuel System Before servicing the CNG engine fuel system, remove pressure from the fuel lines by turning the valves on each tank to the OFF position. This will stop more fuel from entering the lines to the engine. Run the engine until it “dies.” Attempt to start the vehicle again. If it starts, let it run until it stalls again. Repeat the step until the vehicle no longer starts. See Depressurizing the CNG Fuel System in this manual for more information. The tank must be destroyed by drilling two or more holes one-half inch or greater in diameter completely through the tank wall and internal liner in order to prevent unauthorized pressurization. 1.6.1 Condemned Tank Tool List • Compressed nitrogen supply to remove as much natural gas as possible. If nitrogen is not available, then flush the tank with water 2.1.2 Depressurize Before Working on the Tanks or PRD Plumbing Fuel tanks and the lines that connect them must be depressurized and all fuel removed before any maintenance on these items is performed. Never bleed the tanks in an enclosed area. See Depressurizing the CNG Fuel System in this manual for more information. • Drill with 1/2 inch (13 mm) bit CAUTION 5 Residual natural gas and/or air can be trapped between the liner and the composite after venting. Allow the vented tank (open to atmosphere) to sit for 8 hours to allow the trapped gas to escape before drilling the condemned tank. Failure to vent may cause personal injury or equipment damage. WARNING Never purge the tanks in an enclosed area. Be sure there are no sources of ignition in the area. Failure to comply may result in serious personal injury or death. NOTE WARNING The tank will contain residual gas fumes after depressurization. Precautions should be taken to ensure that residual fumes are not ignited during destruction. Vent all pressure from the tank and displace residual fumes with compressed nitrogen. If compressed nitrogen is not available, flushing the tank with water will also displace residual fumes. CNG — Service Manual PRD lines are always pressurized. The tanks the lines are connected to must be completely depressurized prior to working on this plumbing. Failure to completely depressurize the lines may result in serious personal injury or death. 5-4 © 2016 McNeilus Truck and Manufacturing, Inc. Preventive Maintenance 2.2 Maintenance Schedule 2.2.1 Daily CNG Fuel System Checks 2.2.1.1 Check for CNG Leaks The CNG system is pressurized. During daily inspection, check for any leaks or damage to the fuel system. The appearance of frost around a fitting, hose, or tube, a sulfur smell, or any audible hissing noise may indicate a CNG leak. WARNING Do not operate a vehicle that has a CNG leak. Failure to comply may result in serious personal injury or death. 2.2.2 Maintenance Chart Part Maintenance Fuel Filter Housing Drain filter housing weekly at initial install. If no oil is detected for 2 consecutive weeks, extend draining process to monthly. Fuel Filter Element Replace every six (6) months or when oil is detected in four (4) drains in a row, whichever comes first. Fuel Fittings and Connections Fittings and connections should be checked for leaks periodically. Servicing and inspecting for leaks must be conducted by individuals with the proper certifications and training. Fuel Tank Inspection Tanks must to be inspected by trained individuals holding the proper certifications. Tanks must to be inspected: • Every 36 months or 36,000 miles, whichever comes first • Prior to installation • Prior to being filled if there is reason to believe they may have been damaged (i.e., if the vehicle was involved in an accident, fire) • Periodically, as required by law, regulation, and/or the tank design specifications • When known or suspected to have been abused in service, such as involvement in fire, impact, exposed to excessive heat or any other potential damage causing situation • If any unusual behavior is observed, such as emission of natural gas odor, unexpected loss of gas pressure, unusual noises (i.e., rattling, snapping, hissing) © 2016 McNeilus Truck and Manufacturing, Inc. 5-5 CNG — Service Manual 5 THIS PAGE INTENTIONALLY LEFT BLANK CNG Component Remove and Replace Table of Contents 1.0 OVERVIEW.................................................................................................................................................... 6-3 2.0 TORQUE STANDARDS................................................................................................................................. 6-3 3.0 DEPRESSURIZING THE CNG FUEL SYSTEM............................................................................................ 6-3 4.0 REMOVE AND REPLACE FUEL MODULE................................................................................................... 6-4 4.1 CNG Depressurization.............................................................................................................................................. 6-4 4.2 Fuel Module Removal............................................................................................................................................... 6-5 4.3 Fuel Module Upper and Lower Covers...................................................................................................................... 6-7 4.3.1 Upper Cover Removal and Installation.......................................................................................................... 6-7 4.3.2 Lower Cover Removal and Installation.......................................................................................................... 6-7 4.4 Fuel Module Installation............................................................................................................................................ 6-8 4.5 Leak Detection.......................................................................................................................................................... 6-8 5.0 CONNECTING THE FUEL MODULE DOOR INTERLOCK........................................................................... 6-9 5.1 Vehicle Preparation................................................................................................................................................... 6-9 5.2 Door Interlock Installation.......................................................................................................................................... 6-9 6.0 REMOVE AND REPLACE FILL RECEPTACLES........................................................................................ 6-10 6.1 CNG Depressurization............................................................................................................................................ 6-10 6.2 Receptacle Removal and Replacement...................................................................................................................6-11 7.0 REMOVE AND REPLACE LOW PRESSURE SOLENOID ASSEMBLY.......................................................6-11 7.1 CNG Depressurization............................................................................................................................................ 6-12 7.2 Low Pressure Solenoid Assembly Removal and Replacement............................................................................... 6-12 8.0 REMOVE AND REPLACE SOLENOID COIL............................................................................................... 6-14 8.1 Vehicle Preparation................................................................................................................................................. 6-14 8.2 Solenoid Coil Removal and Replacement............................................................................................................... 6-14 9.0 REMOVE AND REPLACE TRANSDUCER.................................................................................................. 6-15 9.1 CNG Depressurization............................................................................................................................................ 6-15 9.2 Transducer Removal and Replacement.................................................................................................................. 6-15 10.0 REMOVE AND REPLACE SIGNAL CONDITIONER................................................................................. 6-16 10.1 Vehicle Preparation............................................................................................................................................... 6-16 10.2 Signal Conditioner Removal and Replacement..................................................................................................... 6-16 © 2016 McNeilus Truck and Manufacturing, Inc. 6-1 CNG — Service Manual 6 Component Remove and Replace 11.0 REMOVE AND REPLACE FUEL REGULATOR......................................................................................... 6-18 11.1 CNG Depressurization........................................................................................................................................... 6-18 11.2 Fuel Regulator Removal and Replacement........................................................................................................... 6-18 12.0 REMOVE AND REPLACE FUEL FILTER.................................................................................................. 6-24 12.1 Fuel Filter Access Procedure................................................................................................................................ 6-24 12.2 Fuel Filter Drain Procedure................................................................................................................................... 6-24 12.3 Fuel Filter Element Replacement Procedure........................................................................................................ 6-24 13.0 REMOVE AND REPLACE LOW AND HIGH PRESSURE LINES.............................................................. 6-25 13.1 High Pressure Line Identification Tags.................................................................................................................. 6-25 6 CNG — Service Manual 6-2 © 2016 McNeilus Truck and Manufacturing, Inc 1.0 Overview Component Remove and Replace 1. Turn OFF each tank valve (Figure 1), main tanks and side saddle tank(s) if installed. Location of the tank valves varies by vehicle. As already stated, the tanks will remain pressurized. The content of this manual was provided by Mainstay Fuel Technologies for the MA20 fuel management module system. If you have questions regarding any of the tasks provided in this section, contact Mainstay. Mainstay Fuel Technologies 100 Hurricane Creek Road, Piedmont, SC 29673 Telephone: 864-655-6905 Service number: 1-844-332-3775 This section describes how to remove, replace, or install the CNG fuel module and its major serviceable components. • Depressurizing the CNG System Figure 1 • Fuel Module 2. Start the vehicle and allow it to run until it stalls. -- Upper Covers 3. Attempt to start the vehicle again. If it starts, let it run until it stalls again. Repeat this step until the vehicle no longer starts. This ensures that all CNG in the system downstream of the tanks is consumed. -- Lower Covers • Door Interlock (Vehicle Starter Interrupt) • Fill Receptacles WARNING -- Defueling Even if the truck has stalled after running it out of fuel, and you think all fuel has been depleted, check the high pressure gauge to make sure it is at zero. If the gauge is not at zero, continue to deplete the fuel until the gauge reads zero. Failure to comply may result in serious personal injury or death. -- NGV1 -- CL-50 • Low Pressure Solenoid Assembly • Solenoid Coil • Transducer • Signal Conditioner • Fuel Regulator 4. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. 2.0 Torque Standards Always torque fasteners, clamps, hydraulic line fittings and nuts per specifications. Failure to do so can cause a part to fail, which may result in serious injury or death. Do not under or over-torque fasteners, clamps, hydraulic fittings and nuts to compensate for not having a torque wrench. Unless otherwise stated, see torque standards in the Preventive Maintenance Section of this manual. 5. Turn off battery disconnect switch (if equipped) or disconnect all battery cables. WARNING For trucks without a battery disconnect switch, to prevent accidental vehicle start-up, which could cause death or serious injury, disconnect battery cables (negative cable first) before proceeding. 3.0 Depressurizing the CNG Fuel System Disconnect negative (-) battery cable first. If positive (+) cable should contact ground with negative (-) cable connected, the resulting sparks can cause a battery explosion, which could result in death or serious injury. When performing any maintenance that requires removing or replacing components, including removing and reinstalling the fuel module, completely depressurize the CNG system. The CNG tanks do NOT need to be depressurized. Perform ALL of these steps to ensure that there is NO system pressure (except the tanks). Do not skip this process or any steps in this process. Failure to do so can cause a part to fail, which may result in serious injury or death. © 2016 McNeilus Truck and Manufacturing, Inc. 6-3 CNG — Service Manual 6 Component Remove and Replace 8. Ensure that the Tank Pressure gauge (high pressure)on the fuel control module (Figure 4, Item 1) reads 0 PSI. The Output Pressure gauge (Figure 4, Item 2) should also read 0 PSI. If they do not read 0 PSI, ensure that all tank valves are fully closed and the purge valve is completely open. 6. Leave the Manual Shut-Off Valve on the fuel module in the ‘ON’ position (Figure 2, Item 1). 1 1 Figure 2 7. The system purge valve is located inside the fuel module side access maintenance door (Figure 3, Item 1) on the side of the fuel module. Open the access door, locate the purge valve (Figure 3, Item 2), and use a wrench to open the valve to relieve any remaining pressure in the tank line, the fuel module, and the remote fill line. Leave the purge valve open. 2 Figure 4 6 9. Continue with removal and replacement of fuel module or system component as required. 1 4.0 Remove and Replace Fuel Module Along with inspections, some time during the normal life span of the vehicle, the CNG system will require repair and maintenance. To more easily and effectively perform maintenance and replace various system components, the fuel module will have to be removed and reinstalled. 2 This section describes how to remove and reinstall the fuel module. Tools required: • 1/2” wrench • 1/2” socket Figure 3 • 15/16” wrench • Torque wrench • Pliers • Service clamps 4.1 CNG Depressurization Prepare the vehicle for fuel module removal. Depressurize the CNG system as shown in Section 3.0 Depressurizing the CNG Fuel System. CNG — Service Manual 6-4 © 2016 McNeilus Truck and Manufacturing, Inc Component Remove and Replace 4.2 Fuel Module Removal 4. Use nut driver, screw driver, or pliers as needed to loosen radiator hose clamps and disconnect upper and lower coolant lines (Figure 5, Items 1 and 2). Mark the coolant lines (upper and lower) for proper installation later on. After preparing the vehicle and the CNG system is completely depressurized (except the tanks), review Figure 5, and then perform the steps in this section to remove and reinstall the fuel module. 5. Gently move all coolant lines and harnesses safely out of the way (Figure 7). Figure 5 shows the hoses, lines, and connector on the rear of the fuel module that will be loosened and removed. • Item 1 - Upper coolant line • Item 2 - Lower coolant line • Item 3 - Deutsch connector • Item 4 - Low pressure CNG line • Item 5 - High pressure (tank) CNG line • Item 6 - Remote fill CNG line (not visible) 1 2 3 Figure 7 6. Disconnect the low pressure CNG line (Figure 8). Use a backing wrench to hold the fitting to prevent damage to the module. Move the line safely out of the way. 4 6 5 6 Figure 5 1. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. 2. Disconnect the Deutsch connector (Figure 5, Item 3). 3. Properly install service clamps on both coolant lines (Figure 6) to prevent a coolant spill. If a spill occurs, properly clean the spill per all applicable laws. Figure 8 Figure 6 © 2016 McNeilus Truck and Manufacturing, Inc. 6-5 CNG — Service Manual Component Remove and Replace 7. Disconnect the remote fill port supply line (Figure 9, Item 1). Use a backing wrench to hold the fitting to prevent damage to the module. Move the line safely out of the way. 10. Loosen, remove, and retain the left side mounting bolts (Figure 11, Item 1). 1 1 Front Figure 11 11. Loosen, remove, and retain the right side mounting bolts (Figure 12, Item 1). Figure 9 8. Disconnect the high pressure CNG line coming from the tank (Figure 10). Use a backing wrench to hold the fitting to prevent damage to the module. Move the line safely out of the way. Front 1 6 Figure 10 Figure 12 9. Before loosening and removing the fuel module mounting bolts, safely and completely support the fuel module with an adequate floor jack and or strapping. 12. Safely and completely support the fuel module with an adequate floor jack and or strapping and slowly lower the fuel module away from the vehicle mount bracket. 13. Continue with removing the upper, lower, or both fuel module housing covers as needed. CNG — Service Manual 6-6 © 2016 McNeilus Truck and Manufacturing, Inc Component Remove and Replace 4.3 Fuel Module Upper and Lower Covers 4.3.2 Lower Cover Removal and Installation To remove the lower cover, it is not always required to remove the fuel module from the vehicle mounting bracket. However, if removing the fuel module is required, perform the steps as show in Section 4.2 Fuel Module Removal. After removing the fuel module, to gain access to the serviceable components, remove the upper, lower, or both fuel module housing covers as needed. 1. Remove the fuel module from the vehicle if needed. 4.3.1 Upper Cover Removal and Installation 2. Remove and retain the left side lower cover bolts. 1. Remove the fuel module from the vehicle as shown in Section 4.2 Fuel Module Removal. 2. Remove and retain the left side upper cover bolts. 1 1 Front Front Figure 15 3. Remove and retain the right side lower cover bolts. Figure 13 3. Remove and retain the right side upper cover bolts. Front 1 Front Figure 16 1 4. Set the lower cover aside and perform the necessary maintenance to the fuel module. Figure 14 5. To reinstall the lower cover, align and install the left side lower cover bolts. 4. Set the upper cover aside and perform the necessary maintenance to the fuel module. 6. Align and install the right side lower cover bolts. 5. To reinstall the upper cover, align and install the left side upper cover bolts. 7. Either continue with component removal and replacement or reinstall the Fuel Module (if removed) as shown in Section 4.4 Fuel Module Installation. 6. Align and install the right side upper cover bolts. 7. Either continue with component removal and replacement or reinstall the fuel module as shown in Section 4.4 Fuel Module Installation. © 2016 McNeilus Truck and Manufacturing, Inc. 6-7 CNG — Service Manual 6 Component Remove and Replace 4.4 Fuel Module Installation 4.5 Leak Detection To reinstall the fuel module, perform the following tasks. 1. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. 1. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. 2. Once the system has been repaired, all components properly re-installed, and the system is pressurized, use a liquid leak detector and carefully check all fittings for leaks. 2. Safely and completely support the fuel module with an adequate floor jack and or strapping and slowly lift the fuel module in place under the vehicle mount bracket. 3. On the regulator, pay special attention to and observe the reducing tee-connection located on the low pressure tube (Figure 17, Item 1). 3. Ensure upper and lower covers are installed. See Section 4.3 Fuel Module Upper and Lower Covers. 4. Align the fuel module mounting holes with the vehicle bracket mounting holes. Reinstall and tighten the four fuel module mounting bolts (Figure 11, Item 1 and Figure 12, Item 1). 5. Move all the coolant lines, CNG lines, and the harness into place. (Figure 6). 6. Reconnect and tighten the high pressure CNG line coming from the tank (Figure 10). Use a backing wrench to hold the fitting to prevent damage to the module and use a torque wrench to tighten the fitting to 40 ft.-lbs. 7. Reconnect and tighten the remote fill CNG line (Figure 9). Use a backing wrench to hold the fitting to prevent damage to the module and use a torque wrench to tighten the fitting to 40 ft.-lbs. 6 1 Figure 17 8. Reconnect and tighten the low pressure CNG line (Figure 8). Use a backing wrench to hold the fitting to prevent damage to the module and use a torque wrench to tighten the fitting to 40 ft.-lbs. a. If a leak is detected at the reducing tee, use a backing wrench to hold the fittings, and tighten the compression fittings one (1) flat at a time and check for leaks again between each turn until the line no longer leaks. b. Use caution if one of these compression fittings is leaking. Do not over-tighten and damage the connection. 4. After checking and repairing leaks in the reducing tee area, check for leaks on the rest of the fuel module fittings. If a leak is detected (Figure 18), depressurize the system again as shown in Section 3.0 Depressurizing the CNG Fuel System. 9. Properly reconnect upper and lower coolant lines (Figure 5, Items 1 and 2). 10. Remove service clamps from coolant lines (Figure 6). 11. Connect the Deutsch connector (Figure 5, Item 3) and listen for the audible click to ensure the connector is fully seated. 12. Turn on battery disconnect switch (if equipped) or connect all battery cables. 13. Close the purge valve (Figure 3, Item 1). 14. Ensure that the manual shutoff valve (Figure 1, Item 1) is still open. 15. Slowly open the tank valves. 16. Check the tank pressure gauge (high pressure) (Figure 4, Item 1) to confirm a rise in fuel pressure. The output pressure gauge (low pressure) (Figure 4, Item 2) may not register pressure until the vehicle ignition is turned to the On position. 17. Check for leaks as shown in Section 4.5 Leak Detection. 18. Remove Lockout/Tagout from the refuse vehicle. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. Figure 18 5. Check the leaky connection for a damaged O-Ring, line or fitting damage, cracks, debris, etc. 19. Return vehicle to service. CNG — Service Manual 6. Repair, reconnect, torque to specifications, and repressurize the system. 6-8 © 2016 McNeilus Truck and Manufacturing, Inc Component Remove and Replace 5.2 Door Interlock Installation 7. Use a liquid leak detector and check all fittings again for leaks. 1. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. 8. Repeat Steps 1 through 5 until all leaks are repaired. 9. If no leaks are detected, remove Lockout/Tagout from the refuse vehicle. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. 2. Turn off battery disconnect switch (if equipped) or disconnect all battery cables. WARNING 10. Return the vehicle to service. For trucks without a battery disconnect switch, to prevent accidental vehicle start-up, which could cause death or serious injury, disconnect battery cables (negative cable first) before proceeding. 5.0 Connecting the Fuel Module Door Interlock Disconnect negative (-) battery cable first. If positive (+) cable should contact ground with negative (-) cable connected, the resulting sparks can cause a battery explosion, which could result in death or serious injury. When connected properly, the fuel module door interlock (Figure 19, Item 1) interrupts the vehicle starter control circuit if the fuel module door is open. When the fuel module door is closed, the door interlock allows the vehicle to start. Door Interlock McNeilus part number 1549767. 3. Locate the vehicle starter. Starter location, cable size and type varies by vehicle. Tools required: • Wire cutters 4. Ensure there is no battery voltage at the starter. • Appropriate sized splice or wire connector 5. Disconnect and remove the starter GROUND wire (Figure 20, Item 1) from the vehicle starter circuit. Disconnect and remove only the ground wire and ensure all other wires stay in place and properly connected. Starter circuit type, ground wire location, wire size, and connections vary by vehicle. • Wrench (for starter ground wire nut, size varies) • Heat shrink and or electrical tape • Proper sized splice or split nut connector 1 1 Figure 19 5.1 Vehicle Preparation It is not necessary to depressurize the CNG system to install the fuel module door interlock. However, the vehicle electrical system must be completely disabled. Figure 20 © 2016 McNeilus Truck and Manufacturing, Inc. 6-9 CNG — Service Manual 6 Component Remove and Replace 6.0 Remove and Replace Fill Receptacles 6. Properly splice/connect the GROUND wire disconnected from the starter circuit in Figure 20, to the door interlock wire of the fuel module door interlock circuit as shown in Figure 21, Item 1. During the course of normal operation and use, the three fill receptacles (Figure 22, Item 1) and their O-rings installed in the main panel (Figure 22, Item 2) can be damaged or worn and require replacement. This section describes how to remove and replace all three fill receptacles. 1 1 Figure 21 7. Properly wrap and/or heat shrink the spliced connection. 2 8. Ensure all wires are safely wrapped, routed, and secured. 6 9. Turn on battery disconnect switch (if equipped) or connect all battery cables. Figure 22 When replacing any of the fill receptacles, ensure the system (except the tanks) is completely depressurized before disconnecting any lines. 10. Remove Lockout/Tagout from the refuse vehicle. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. It is not necessary to remove the fuel module from the vehicle to replace a fill receptacle. 11. Test the door interlock switch for proper operation as follows: Tools required: • 3/4” thin profile wrench a. Leave the fuel module door open. The vehicle should not crank at all when the key is turned. b. Close the fuel module door. The vehicle should crank when the key is turned. • 3/4” thin profile crows foot wrench • 7/8” thin profile crows foot wrench • 1 1/4” thin profile crows foot wrench 12. Return the vehicle to service. • 1 1/16” thin profile wrench • Torque wrench 6.1 CNG Depressurization Prepare the vehicle for receptacle replacement. Depressurize the CNG system as shown in Section 3.0 Depressurizing the CNG Fuel System. CNG — Service Manual 6-10 © 2016 McNeilus Truck and Manufacturing, Inc 6.2 Receptacle Removal and Replacement Component Remove and Replace 4. After the area around the port is clean, remove the damaged receptacle. 5. Apply only one of the following approved lubricants to the O-ring on the new receptacle. Approved lubricants are as follows: After properly preparing the vehicle and the CNG system is completely depressurized, perform the following steps to remove and replace each receptacle. Figure 23 shows receptacle location and Table 1 - Receptacle Details details the wrench size and torque values needed for each receptacle. -- Super O-Lube, Parker -65° to 400° (F); -53.8° to 204.4° (C) -- DC-55, Dow Corning Co. -65° to 275° (F); -53.8° to 135° (C) 1 -- Celvacene, Consolidated Vacuum Corp. -40° to 200° (F); -40° to 93.3° (C) Failure to use an approved O-ring lubricant may cause O-ring degradation which may cause leaks over time. 6. Use a backing wrench to hold the fitting and use a torque wrench to tighten the new receptacle per the torque values shown in Table 1 - Receptacle Details. 2 7. Close the purge valve. 8. Slowly open the tank valves. 9. Check the tank pressure gauge (high pressure) (Figure 4, Item 1) to confirm a rise in fuel pressure. The output pressure gauge (low pressure) (Figure 4, Item 2) may not register pressure until the vehicle ignition is turned to the On position. 3 10. Check for leaks as shown in Section 4.5 Leak Detection. Figure 23 11. Remove Lockout/Tagout from the refuse vehicle. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. Table 1 - Receptacle Details Receptacle Name Figure Location McNeilus Part Number Working Details 12. Return the vehicle to service. Defueling Receptacle Figure 23, Item 1 PN 1551273 Use a ¾” thin profile backing wrench. Torque to 30 ft.-lbs. using 7/8” thin profile crows foot wrench. NGV-1 Receptacle Figure 23, Item 2 PN 1541752 Use a ¾” thin profile backing wrench. Torque to 30 ft.-lbs. using ¾” thin profile crows foot wrench. CL-50 Receptacle Figure 23, Item 3 PN 1496438 Use a 1 1/16 ” thin profile backing wrench. Torque to 43 ft.-lbs. using a 1 1/4” thin profile crows foot wrench. 7.0 Remove and Replace Low Pressure Solenoid Assembly When replacing the low pressure solenoid assembly (Figure 24), ensure that the system is completely depressurized (except the tanks) before disconnecting any lines. If just the solenoid coil needs replaced, see Section 8.0 Remove and Replace Solenoid Coil. Low pressure solenoid is McNeilus part number 1530737. Tools required: 1. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. • 1 1/8” wrench 2. Use a backing wrench to hold the fitting (Figure 23) for the receptacle. Loosen, but do not yet remove the damaged receptacle. • Wire cutters and crimping tool for splices • 15/16” wrench • Torque wrench 3. Use compressed air to remove dirt and debris from the receptacle port and the area around the port. © 2016 McNeilus Truck and Manufacturing, Inc. 6-11 CNG — Service Manual 6 Component Remove and Replace 7.1 CNG Depressurization 4. Locate the low pressure solenoid assembly (Figure 26) and disconnect the Deutsch connector (Figure 25, Item 1) attached to the solenoid assembly from the wiring harness. Prepare the vehicle for low pressure solenoid assembly replacement. Depressurize the CNG system as shown in Section 3.0 Depressurizing the CNG Fuel System. 5. Clip both wires close to the old solenoid coil (Figure 25, Item 2) leaving as much wire as possible for connecting the new solenoid back to the Deutsch connector. Retain the Deutsch connector. 7.2 Low Pressure Solenoid Assembly Removal and Replacement This section describes how to remove and replace the low pressure solenoid assembly. Figure 24 shows the low pressure solenoid assembly as shipped. 1 • Item 1 - Low pressure solenoid assembly • Item 2 - Solenoid coil • Item 3 - Solenoid coil wire 2 • Item 4 - 90° elbow • Item 5 - Splices • Item 6 - Solenoid assembly bulkhead fitting Figure 25 6. Loosen the tubing from the solenoid assembly (Figure 26, Item 1). 1 6 7. Loosen and remove the mounting nut from the solenoid assembly bulkhead fitting (Figure 26, Item 2) and remove the solenoid assembly from the housing. 6 3 1 2 4 2 5 Figure 26 8. Insert the new 90°elbow into the new solenoid assembly and tighten the elbow only until the washer is flat against the assembly and the O-ring is not visible (Figure 27, Item 1) Do not torque this nut until the elbow is connected to the tubing later in this process. Figure 24 After properly preparing the vehicle and the CNG system is completely depressurized, use the following steps to remove and replace the solenoid assembly. 1. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. 1 2. Remove the fuel module from the vehicle mount. See Section 4.0 Remove and Replace Fuel Module. 3. After removing the fuel module, remove the fuel module covers. See Section 4.3 Fuel Module Upper and Lower Covers. Figure 27 CNG — Service Manual 6-12 © 2016 McNeilus Truck and Manufacturing, Inc Component Remove and Replace 9. Remove the new mounting nut from the new solenoid assembly bulkhead fitting (Figure 28, Item 1). To prevent damage to fittings, connectors, and tubing, use a backing wrench to hold all connectors. 13. Splice the new solenoid wires to the wires on the Deutsch connector. (Figure 31, Item 1). 14. Reconnect the Deutsch connector to the wiring harness (Figure 31, Item 2). 1 1 2 Figure 28 10. Insert the new bulkhead fitting through the fuel module housing, properly align the new solenoid assembly, reinstall the nut (Figure 29, Item 1), use a backing wrench to hold the fitting, and use a torque wrench to tighten the nut to 40 ft.-lbs. Figure 31 15. Reinstall the covers. See Section 4.3 Fuel Module Upper and Lower Covers. 16. Reinstall the fuel module. See Section 4.4 Fuel Module Installation. 17. Close the purge valve. 18. Slowly open the tank valves. 19. Check the tank pressure gauge (high pressure) (Figure 4, Item 1) to confirm a rise in fuel pressure. The output pressure gauge (low pressure) (Figure 4, Item 2) may not register pressure until the vehicle ignition is turned to the On position. 1 Figure 29 11. Use a wrench and align the solenoid assembly elbow to the tubing fitting (Figure 30, Item 1), use a backing wrench to hold the fitting, and use a torque wrench to tighten the tubing fitting to 40 ft.-lbs. 20. Check for leaks as shown in Section 4.5 Leak Detection. 21. Remove Lockout/Tagout from the refuse vehicle. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. 12. When the tubing is installed and properly torqued, use a backing wrench to hold the fitting, and use a torque wrench to tighten the nut on the solenoid side of the elbow (Figure 30, Item 2) to 43 ft.-lbs. 22. Return vehicle to service. 2 1 Figure 30 © 2016 McNeilus Truck and Manufacturing, Inc. 6-13 CNG — Service Manual 6 Component Remove and Replace 8.0 Remove and Replace Solenoid Coil 4. Locate the solenoid (Figure 33, Item 1) in the fuel module. (Fuel module removed from vehicle for ease of illustration only.) It may be determined that only the solenoid coil needs replacement. The coil can be replaced without removing the fuel module or the solenoid assembly. 1 This section describes how to remove and replace just the solenoid coil. The solenoid coil kit is McNeilus part number 1549855. Tools required: • 3/4” wrench • Torque wrench Figure 32 • Wire cutters 5. Locate the solenoid coil on the top of the solenoid (Figure 33, Item 1). • Crimping tool for splices 8.1 Vehicle Preparation The CNG system does not need to be depressurized to remove and replace the solenoid coil. However, the vehicle electrical system must be completely disabled. 1 8.2 Solenoid Coil Removal and Replacement After properly preparing the vehicle, use the following steps to remove and replace the solenoid coil. 6 The fuel module or the solenoid assembly do not need to be removed from the vehicle to replace the solenoid coil. 1. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. Figure 33 6. Disconnect the solenoid harness Deutsch connector (Figure 34, Item 1). 2. Turn off battery disconnect switch (if equipped) or disconnect all battery cables. WARNING For trucks without a battery disconnect switch, to prevent accidental vehicle start-up, which could cause death or serious injury, disconnect battery cables (negative cable first) before proceeding. 1 Disconnect negative (-) battery cable first. If positive (+) cable should contact ground with negative (-) cable connected, the resulting sparks can cause a battery explosion, which could result in death or serious injury. Figure 34 3. Remove the lower covers from the fuel module as shown in Section 4.3.2 Lower Cover Removal and Installation on page 6-7. CNG — Service Manual 6-14 © 2016 McNeilus Truck and Manufacturing, Inc Component Remove and Replace 9.0 Remove and Replace Transducer 7. Locate the coil retaining bolt (Figure 35, Item 1). Use a ¾” wrench to loosen, remove and retain the bolt. Remove the coil. When replacing the transducer, ensure the system (except the tanks) is completely depressurized before disconnecting any lines. It is easier to replace the transducer if the fuel module is removed from the vehicle. However, it is possible to access, remove, and replace the transducer with the fuel module installed on the vehicle. 1 The process described in this section assumes that the fuel module is not installed on the vehicle. See Section 4.0 Remove and Replace Fuel Module. Transducer is McNeilus part number 1470836. Tools required: • 7/8” deep well socket • 1/2” drive socket wrench Figure 35 • Torque wrench 8. Assemble the two pin connector on the new coil and connect that to the Deutsch connector on the wiring harness (Figure 34, Item 1). • 3” extension (optional) • 7/8” crows foot wrench (optional) 9. Fit the new coil into the solenoid assembly and tighten the bolt (Figure 35, Item 1) to 15 in. lbs. 9.1 CNG Depressurization 10. Turn on battery disconnect switch (if equipped) or connect all battery cables. Prepare the vehicle for transducer removal and replacement. 11. Remove Lockout/Tagout from the refuse vehicle. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. Depressurize the CNG system as shown in Section 3.0 Depressurizing the CNG Fuel System. 9.2 Transducer Removal and Replacement 12. Cycle the vehicle ignition off and on to confirm that the solenoid makes a distinct clicking sound as the vehicle ignition is turned off and on. 13. Start the vehicle to confirm gas flow through the solenoid. 1. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. 14. Reinstall the lower covers. See Section 4.3.2 Lower Cover Removal and Installation. 2. Remove the fuel module from the vehicle. See Section 4.0 Remove and Replace Fuel Module. 15. Return vehicle to service. 3. Remove the fuel module lower cover and position the module as shown in Figure 36. See Section 4.3.2 Lower Cover Removal and Installation. 4. Locate the transducer (Figure 36, Item 1). 1 Figure 36 © 2016 McNeilus Truck and Manufacturing, Inc. 6-15 CNG — Service Manual 6 Component Remove and Replace 10.0 Remove and Replace Signal Conditioner 5. Disconnect the transducer from the wiring harness (Figure 37, Item 1). 1 When replacing the signal conditioner, the CNG system does not need to be depressurized. • Signal Conditioner (1.75 to .30 voltage range), McNeilus part number, 1549857 • Signal Conditioner (3.33 to .45 voltage range), McNeilus part number, 1549859 • Signal Conditioner (2.48 to .54 voltage range), McNeilus part number, 1549859 Figure 37 6. Remove the transducer from the regulator. Use a deep well 7/8” socket to remove the transducer. If a deep well 7/8” socket is not available, use a 3” extension and a 7/8” crow’s foot wrench. Tools required: • Wire cutters • Crimping tool for splices • Tie wraps 7. Thoroughly inspect the regulator port prior to installing the new transducer and remove any debris. Compressed air is the recommended method of debris removal. 10.1 Vehicle Preparation Prepare the vehicle for signal conditioner removal and replacement. 8. Install the new transducer, use a backing wrench to hold the fitting, and use a torque wrench to tighten to 15 ft.-lbs. The CNG system does not need to be depressurized to install the signal conditioner. However, ensure that the vehicle electrical system is completely disabled. 9. Reconnect the wiring harness to the transducer and ensure that the connection is fully engaged and snapped into place. 6 10.2 Signal Conditioner Removal and Replacement 10. Reinstall the covers. See Section 4.3 Fuel Module Upper and Lower Covers. 1. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. 11. Reinstall the fuel module. See Section 4.4 Fuel Module Installation. 12. Close the purge valve. 2. Turn off battery disconnect switch (if equipped) or disconnect all battery cables. 13. Slowly open the tank valves. 14. Check the tank pressure gauge (high pressure) (Figure 4, Item 1) to confirm a rise in fuel pressure. The output pressure gauge (low pressure) (Figure 4, Item 2) may not register pressure until the vehicle ignition is turned to the On position. WARNING For trucks without a battery disconnect switch, to prevent accidental vehicle start-up, which could cause death or serious injury, disconnect battery cables (negative cable first) before proceeding. 15. Check for leaks as shown in Section 4.5 Leak Detection. 16. Remove Lockout/Tagout from the refuse vehicle. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. Disconnect negative (-) battery cable first. If positive (+) cable should contact ground with negative (-) cable connected, the resulting sparks can cause a battery explosion, which could result in death or serious injury. 17. Return vehicle to service. 3. Leave the fuel module mounted to the vehicle. 4. Remove the lower cover from the fuel module housing. See Section 4.3.2 Lower Cover Removal and Installation. CNG — Service Manual 6-16 © 2016 McNeilus Truck and Manufacturing, Inc Component Remove and Replace 5. Locate the signal conditioner (Figure 38, Item 1). 9. Connect the new signal conditioner to the Deutsch connector (Figure 41). 1 Figure 41 Figure 38 10. Push the signal conditioner wiring harness back into the fuel module and secure the harness and signal conditioner to the tubing with tie wraps like it was in Step 4 (Figure 42, Item 1). 6. Remove the tie wraps that hold the signal conditioner and its wiring harness to the tubing. Note where these tie wraps are located. 7. Gently pull down on the signal conditioner wiring harness to access the Deutsch connector (Figure 39). 6 1 Figure 42 11. Ensure all wires are safely wrapped, routed, and secured. Figure 39 8. Disconnect the old signal conditioner Deutsch connector from the wiring harness (Figure 40). 12. Reinstall the covers. See Section 4.3 Fuel Module Upper and Lower Covers. 13. Reinstall the fuel module. See Section 4.4 Fuel Module Installation. 14. Turn on battery disconnect switch (if equipped) or connect all battery cables. 15. Remove Lockout/Tagout from the refuse vehicle. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. 16. Test the system for proper operation. 17. Return the vehicle to service. Figure 40 © 2016 McNeilus Truck and Manufacturing, Inc. 6-17 CNG — Service Manual Component Remove and Replace 11.0 Remove and Replace Fuel Regulator 11.2 Fuel Regulator Removal and Replacement 1. Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. When replacing the fuel regulator, ensure that the system is completely depressurized before disconnecting any lines to remove the fuel module. Fuel regulator is McNeilus part number 1501936. 2. Turn off battery disconnect switch (if equipped) or disconnect all battery cables. Tools required: • 1/2” open ended wrench WARNING • 1/2” drive socket wrench For trucks without a battery disconnect switch, to prevent accidental vehicle start-up, which could cause death or serious injury, disconnect battery cables (negative cable first) before proceeding. • 7/16” wrench • 9/16” open ended wrench • 7/8” open ended wrench • 3/4” open ended wrench Disconnect negative (-) battery cable first. If positive (+) cable should contact ground with negative (-) cable connected, the resulting sparks can cause a battery explosion, which could result in death or serious injury. • 13/16” crows foot wrench • 15/16” crows foot wrench • 15/16” socket • 15/16” open ended wrench 3. Remove the fuel module from the vehicle. See Section 4.0 Remove and Replace Fuel Module. • Nut drivers for coolant line hose clamps • Pliers • Torque wrench 4. Remove upper and lower covers from the fuel module housing. See Section 4.3 Fuel Module Upper and Lower Covers. • Service Clamps 5. Position the fuel module as shown in Figure 43. • 5 mm Allen wrench 6 11.1 CNG Depressurization Prepare the vehicle for regulator removal and replacement. Depressurize the CNG system as shown in Section 3.0 Depressurizing the CNG Fuel System. At each step during removal and replacement of the regulator and all components, check all tubes, fittings, and O-rings for wear. Also remove any debris, dust, lint, etc. that could cause a leak when the system is reassembled, reinstalled and pressure tested. Figure 43 6. Begin removing the low pressure tube by using a backing wrench to hold the fitting and loosen the low pressure tube from the regulator (Figure 44, Item 1). 1 Figure 44 CNG — Service Manual 6-18 © 2016 McNeilus Truck and Manufacturing, Inc Component Remove and Replace 7. Use 7/8” wrench to loosen the other end of low pressure tube from the tee (Figure 45, Item 1). 10. Use a backing wrench to hold the fitting and loosen the other end of the high pressure tube from the filter manifold (Figure 48, Item 1). 1 1 Figure 45 8. Remove the low pressure tube from the fuel module (Figure 46, Item 1). Figure 48 11. Remove the high pressure tube from the fuel module (Figure 49). 1 6 1 Figure 46 9. Begin removing the high pressure tube by using a backing wrench to hold the fitting and loosen the high pressure tube from the regulator (Figure 47, Item 1). Figure 49 12. Begin removing the Pressure Relief Device (PRD) vent line by rotating the fuel module for access to the PRD vent line (Figure 50). Use an open ended wrench to loosen the tubing at the PRD vent line elbow (Figure 50, Item 1). 1 1 Figure 47 Figure 50 © 2016 McNeilus Truck and Manufacturing, Inc. 6-19 CNG — Service Manual Component Remove and Replace 13. Rotate the fuel module again to access and loosen the other end of the PRD vent line (Figure 51, Item 1). 17. Locate and loosen the two coolant line hose clamps on the coolant lines (Figure 55, Item 1) 1 1 Figure 55 18. Remove the regulator by removing the two regulator mounting screws (Figure 56, Item 1). Retain these screws for installation of the new regulator. Figure 51 14. Remove the PRD vent line from the fuel module (Figure 52, Item 1). 1 1 6 Figure 52 15. Locate the transducer (Figure 53, Item 1). Figure 56 19. Remove the regulator from the fuel module (Figure 57). Split the old coolant lines as needed to more easily remove the regulator. 1 Figure 53 16. Disconnect the transducer’s Deutsch connector (Figure 54, Item 1) and gently move the connector out of the way. 1 Figure 57 Figure 54 CNG — Service Manual 6-20 © 2016 McNeilus Truck and Manufacturing, Inc Component Remove and Replace 20. Remove and discard the nut and ferrule as shipped on the new regulator elbow fitting (Figure 58, Item 1). 23. Ensure both coolant hoses are fully on the brass barbed fittings and secure both hoses by tightening the clamps. Do NOT over-tighten the clamps. Over-tightening may damage the coolant hoses. 1 1 Figure 58 Figure 61 21. Position the replacement regulator inside the fuel module, ensure the hose clamps are already loosely installed on the coolant hoses and line up the coolant hoses with the brass barbed fittings (Figure 59, Item 1). Push the coolant hoses completely on to the brass barbed fittings. Do not tighten the hose clamps yet. 24. Connect the transducer to the wiring harness, (Figure 62, Item 1) and listen for the audible click to ensure the connector is fully seated. 1 6 Figure 62 1 Figure 59 22. Secure the regulator to the fuel module using the mounting screws retained from Step 18. 1 Figure 60 © 2016 McNeilus Truck and Manufacturing, Inc. 6-21 CNG — Service Manual Component Remove and Replace 25. Properly position, align, and reinstall the PRD vent line (Figure 63). Finger tighten the fittings at both ends. 28. Properly position, align, and reinstall the high pressure line (Figure 64, Item 1). Finger tighten the fittings at both ends. 26. Ensure each fitting is still properly aligned and use a wrench to tighten each fitting 1/2 turn at a time until snug (Figure 63, Items 1 and 2). 29. Ensure each fitting is still properly aligned and use a wrench to tighten each fitting 1/2 turn at a time until snug (Figure 64, Item 1). 27. Use a backing wrench to hold the fittings and use a torque wrench to tighten the nuts on both ends to 30 ft.-lbs. 1 1 Figure 64 30. Use a backing wrench to hold each fitting and use a torque wrench to tighten both fittings to 30 ft.-lbs. (Figure 65, Items 1 and 2). 1 6 2 Figure 63 2 Figure 65 CNG — Service Manual 6-22 © 2016 McNeilus Truck and Manufacturing, Inc Component Remove and Replace 31. Properly position, align and reinstall the low pressure line (Figure 66). 35. Ensure that the fitting is still properly aligned and use a wrench to tighten 1/2 turn at a time until snug (Figure 69, Item 1). 36. Use a backing wrench to hold the fitting and use a torque wrench to tighten the nut to 40 ft.-lbs. 1 Figure 66 32. Correctly align the compression fitting end of the low pressure line, rotate tube onto O-ring Face Seal fitting (ORFS) and finger tighten the nut (Figure 67, Item 1). Figure 69 37. Check for leaks as shown in Section 4.5 Leak Detection. 38. Remove Lockout/Tagout from the refuse vehicle. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 Lockout/Tagout and 1910.146 Confined Space as appropriate. 1 39. Test the system for proper operation. 40. Return the vehicle to service. Figure 67 33. Use a backing wrench to hold the fitting (Figure 68, Item 1) and torque the ORFS fitting to 40 ft.-lb. 1 Figure 68 34. On the other end of the low pressure line, align and finger tighten the fitting. © 2016 McNeilus Truck and Manufacturing, Inc. 6-23 CNG — Service Manual 6 Component Remove and Replace 12.0 Remove and Replace Fuel Filter 12.3 Fuel Filter Element Replacement Procedure • Part Number 1449383 for Coalescing Filter - Element and O-Ring 12.1 Fuel Filter Access Procedure The fuel filter can be accessed by opening the maintenance access door. Before opening the filter for maintenance, the filter must be isolated and its pressure relieved. 1. Follow the Filter Access Procedure. 2. Remove the filter bowl (it is threaded into the filter housing and equipped with wrench flats). 1. 3. Empty and clean the bowl. 4. Grasp the filter element and pull it downward to remove. Install the new filter element by pressing it into place. Isolate the filter by closing the shut-off valve on the front panel of the fuel module. This blocks the flow of fuel from the storage tanks. 2. Open the purge valve to relieve remaining pressure in the filter. 3. Check the high pressure gauge to determine if the pressure has been relieved (it should read “0”). The filter can now be safely opened for maintenance. Purge Valve Filter Element WARNING Failure to follow the Filter Access Procedure may cause serious injury or death. 12.2 Fuel Filter Drain Procedure Purge Valve Filter Bowl 6 5. Install a new O-ring (supplied with the filter element) in the housing groove. O-Ring Drain Port 1. Follow the Filter Access Procedure. 6. 2. To drain the filter, locate the plugged drain port in the bottom of the filter bowl. Remove this plug to drain accumulated liquid from the filter. Replace the filter bowl in the filter housing and torque to 40 ft.-lbs. 7. Check that the purge valve is closed. 8. Slowly open the shut-off valve. 3. Replace the drain plug and torque to 20 ft.-lbs. 9. 4. Confirm the purge valve is closed. Check the high pressure gauge to determine fuel pressure has been restored. 5. Slowly open the shut-off valve. 6. Check the high pressure gauge to determine if the fuel pressure has been restored. CNG — Service Manual 6-24 © 2016 McNeilus Truck and Manufacturing, Inc Component Remove and Replace 13.0 Remove and Replace Low and High Pressure Lines To remove pressure from the fuel lines, start by turning the valves on each tank to the OFF position. This will stop more fuel from entering the lines to the engine. Run the engine until it “dies.” Attempt to start the vehicle again. If it starts, let it run until it stalls again. Repeat the step until the vehicle no longer starts. See Depressurizing the CNG Fuel System in this manual for more information. Use proper hand tools (wrenches) to disconnect the fuel lines from the tanks and/or CNG system. 13.1 High Pressure Line Identification Tags High pressure lines have high pressure line identification tags placed every 24 inches on lines that are longer than 30 inches. Look for the tags before performing maintenance on or near high pressure lines. 6 © 2016 McNeilus Truck and Manufacturing, Inc. 6-25 CNG — Service Manual THIS PAGE INTENTIONALLY LEFT BLANK Troubleshooting Table of Contents 1.0 TROUBLESHOOTING CHART.......................................................................................................................................... 7-2 7 © 2016 McNeilus Truck and Manufacturing, Inc. 7-1 CNG — Service Manual Troubleshooting 1.0 Troubleshooting Chart Problem Probable Cause Action O-rings frozen due to gas expansion. 1. Wait for receptacles to warm up to ambient temperature and see if leak persists. Debris in fill receptacle. 1. 2. Depressurize fill manifold. Remove receptacle from the 3. 4. 5. manifold. Inspect for blockage or damage. Reinstall or replace as needed. Test for leaks. After disconnecting fuel nozzle, fuel flows out of the fill receptacle. Check valve damaged. 1. Follow steps above for the check valve. The main shutoff valve does not isolate fuel – engine continues to run even when valves have been turned to the OFF position. Valve seats are worn or debris is not allowing the valve to fully. 1. 2. 3. 4. Depressurize system. Remove the main shutoff valve. Replace valve seats per valve manufacturer instructions or replace the valve. Test for leaks. Too much pressure coming out of the regulator (should be approximately 125 psi). Regulator not working properly. 1. 2. Depressurize system. Remove and replace the regulator. Not enough pressure coming out of the regulator (should be approximately 125 psi). High pressure or low pressure filter is clogged. 1. Replace filter element. 7 CNG — Service Manual 7-2 © 2016 McNeilus Truck and Manufacturing, Inc. Index C CNG Component Remove and Replace Connecting the Fuel Module Door Interlock.......................................................................................................................... 6-9 Depressurizing the CNG Fuel System................................................................................................................................... 6-3 Remove and Replace Fill Receptacles................................................................................................................................ 6-10 Remove and Replace Fuel Module....................................................................................................................................... 6-4 Fuel Module Installation................................................................................................................................................. 6-8 Fuel Module Upper and Lower Covers.......................................................................................................................... 6-7 Remove and Replace Fuel Regulator................................................................................................................................. 6-18 Remove and Replace Low Pressure Solenoid Assembly.................................................................................................... 6-11 Remove and Replace Signal Conditioner............................................................................................................................ 6-16 Remove and Replace Solenoid Coil.................................................................................................................................... 6-14 Remove and Replace Transducer....................................................................................................................................... 6-15 CNG Inspection........................................................................................................................................................................ 5-3 CNG System Inspection........................................................................................................................................................ 5-3 Detailed Visual Inspection..................................................................................................................................................... 5-3 End of Service Life of a Tank................................................................................................................................................. 5-3 Fitting Leak Inspection........................................................................................................................................................... 5-3 General Visual Inspection...................................................................................................................................................... 5-3 Mounting Bracket Inspection................................................................................................................................................. 5-3 Connecting the Fuel Module Door Interlock............................................................................................................................. 6-9 D Defueling the CNG Tanks Procedure....................................................................................................................................... 4-3 Defueling Requirements........................................................................................................................................................ 4-3 Grounding Information........................................................................................................................................................... 4-4 Identify Your Fuel Management Module Box......................................................................................................................... 4-4 Install a Defueling Three-Way Valve to the Fuel Box (MA10 Only)....................................................................................... 4-5 Receptacle Defueling Procedure Set-Up............................................................................................................................... 4-5 Vehicle to Vehicle Defueling Procedure Set-Up.................................................................................................................... 4-5 Depressurizing the CNG Fuel System..................................................................................................................................... 6-3 F Fire and Explosion Hazards..................................................................................................................................................... 2-9 Fuel Control Module Components............................................................................................................................................ 3-3 Coalescing Filter.................................................................................................................................................................... 3-4 Fueling Receptacle................................................................................................................................................................ 3-4 High Pressure Gauge............................................................................................................................................................ 3-3 Low Pressure Gauge............................................................................................................................................................. 3-3 Manual Shut-Off Valve........................................................................................................................................................... 3-3 Pressure Regulator................................................................................................................................................................ 3-4 Pressure Sensor.................................................................................................................................................................... 3-4 © 2016 McNeilus Truck and Manufacturing, Inc. 8-1 CNG — Service Manual 8 Index Purge Valve........................................................................................................................................................................... 3-4 Remote Fueling Receptacle.................................................................................................................................................. 3-5 Fueling Procedure.................................................................................................................................................................... 4-3 Fuel Storage Pod..................................................................................................................................................................... 3-5 Pressure Relief Devices (PRD)............................................................................................................................................. 3-5 Tank Manual Fuel Shut-Off Valves........................................................................................................................................ 3-5 G Glossary................................................................................................................................................................................... 1-4 I Important Safety Information.................................................................................................................................................... 2-3 M Methane Detection/Alarm System (Optional)......................................................................................................................... 2-10 P PRD Vent Locations and Directions......................................................................................................................................... 2-8 Preventive Maintenance........................................................................................................................................................... 5-4 Before Performing Maintenance............................................................................................................................................ 5-4 Maintenance Schedule.......................................................................................................................................................... 5-5 R Remove and Replace Fill Receptacles.................................................................................................................................. 6-10 Remove and Replace Fuel Module.......................................................................................................................................... 6-4 Remove and Replace Fuel Regulator.................................................................................................................................... 6-18 Remove and Replace Low and High Pressure Lines............................................................................................................. 6-25 High Pressure Line Identification Tags................................................................................................................................ 6-25 Remove and Replace Low Pressure Solenoid Assembly...................................................................................................... 6-11 Remove and Replace Signal Conditioner.............................................................................................................................. 6-16 Remove and Replace Solenoid Coil....................................................................................................................................... 6-14 Remove and Replace Transducer.......................................................................................................................................... 6-15 S 8 Safety Decals........................................................................................................................................................................... 2-5 Safety Notices.......................................................................................................................................................................... 2-3 T Troubleshooting Chart.............................................................................................................................................................. 7-2 V Vehicle Fueling......................................................................................................................................................................... 3-6 Filling Standards.................................................................................................................................................................... 3-7 Overpressuring Standards..................................................................................................................................................... 3-7 Vehicle Fueling Through Remote Receptacles...................................................................................................................... 3-6 CNG — Service Manual 8-2 © 2016 McNeilus Truck and Manufacturing, Inc.