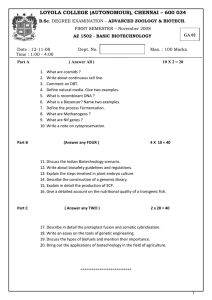

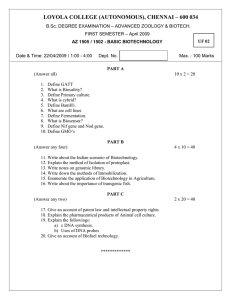

Studies in Surface Science and Catalysis 164 Advisory Editors: B. Delmon and J. T. Yates Series Editor: G. Centi Vol. 164 BIOCATALYSIS IN OIL REFINING M. M. Ramírez-Corredores Strategic Options-Refining Technology, B.P. International Ltd., Sudbury on Thames, UK. Abhijeet P. Borole Oak Ridge National Laboratory, Oak Ridge, Knoxville, USA. Amsterdam • Boston • Heidelberg Paris • San Diego • San Francisco • • London • New York • Oxford Singapore • Sydney • Tokyo Elsevier Radarweg 29, PO Box 211, 1000 AE Amsterdam, The Netherlands Linacre House, Jordan Hill, Oxford OX2 8DP, UK First edition 2007 Copyright © 2007 Elsevier B.V. All rights reserved No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means electronic, mechanical, photocopying, recording or otherwise without the prior written permission of the publisher Permissions may be sought directly from Elsevier’s Science & Technology Rights Department in Oxford, UK: phone (+44) (0) 1865 843830; fax (+44) (0) 1865 853333; email: permissions@elsevier.com. Alternatively you can submit your request online by visiting the Elsevier web site at http://elsevier.com/locate/permissions, and selecting Obtaining permission to use Elsevier material Notice No responsibility is assumed by the publisher for any injury and/or damage to persons or property as a matter of products liability, negligence or otherwise, or from any use or operation of any methods, products, instructions or ideas contained in the material herein. Because of rapid advances in the medical sciences, in particular, independent verification of diagnoses and drug dosages should be made Library of Congress Cataloging-in-Publication Data A catalog record for this book is available from the Library of Congress British Library Cataloguing in Publication Data A catalogue record for this book is available from the British Library ISBN: 978-0-444-52212-2 ISSN: 0167-2991 For information on all Elsevier publications visit our website at books.elsevier.com Printed and bound in The Netherlands 07 08 09 10 11 10 9 8 7 6 5 4 3 2 1 Working together to grow libraries in developing countries www.elsevier.com | www.bookaid.org | www.sabre.org PREFACE Biotechnology is a powerful enabling technology to achieve clean industrial products and processes while promoting industrial sustainability. Biotechnology has been penetrating industrial operations in many sectors, because of its ability to reduce the number of manufacturing steps, thereby reducing material and energy consumption, and reduction in pollution and waste generation, for the same level of industrial production. Numerous applications of biotechnology can be found in Pharmaceuticals, Fine Chemicals, Life Science Research, Agriculture, Food & Beverage, and Cosmetics industries but not in the Oil industry. The potential of biotechnology in the oil refining industry is the subject of this book. Significant research has been done in one major area, biodesulfurization, although commercialization has not taken place. This book describes the efforts in biodesulfurization and other areas of oil refining. The need for this book was realized due to the large gap in the knowledge of a typical researcher in a petroleum or petrochemical industry in investigating or developing a biotechnology-based solution to a refinery problem. Secondly, there was a need to compile all the findings in the petroleum biorefining and bioupgrading area to facilitate future research in this area. Thus, this book is geared towards helping researchers and technologists catch up on previous and current research in this field. Chapter 1 describes the current scenario and the need for biotechnological solutions. In the first Chapter, we have also provided definitions of some general biology terms to bring the petroleum industry researcher up to speed and referred to the particular appli­ cation where the terms may be useful. Chapter 2 gives an overview of the conventional hydroprocessing schemes currently in use in refining operations. This Chapter is included for the biotechnology researcher who has little knowledge of the refinery operations. Chapter 3 provides the details of the biocatalyst and bioprocess developments to date. This includes the widely studied biodesulfurization (BDS) as well as the less studied bio­ denitrogenation (BDN), biodemetallization (BDM), and bioconversion or bioupgrading (BCK). Chapter 4 is included to provide the reader with an information resource to help with research and development activities. This Chapter lists companies actively involved in the biotechnology arena, both for R&D and for commercial operations, which can be used to find molecular biology and enzyme supplies, or to find companies offering services in the biotechnology area. Chapter 5 describes the technological results, in the form of awarded patents and analyzes their chronology and implications for refining operations. Developing a bioprocess for removing heteroatoms from petroleum or for upgrad­ ing heavy crudes involves two main components. The first is biocatalyst development and second is bioprocess development. Both of these topics are discussed in this book, x Preface although there has been much more work done in biocatalyst development compared to the processing aspects. The complexity of finding a suitable biocatalyst for say, biodesulfurization or any other refining operation, is enormous. This is because of two reasons. First reason is related to the complexity of the material to be converted and second, is related to the multi-phase bioprocess involving, an oil, aqueous, gas (usually air), and a solid (biocatalyst) phase. The effort needed to find the solution is no doubt a multi-disciplinary one, involving petroleum chemistry, analytical chemistry, microbi­ ology, molecular biology, enzymology, and chemical engineering. The first problem is that petroleum or any refined stream contains numerous species of molecules on which the biocatalyst needs to act on. Thus, the substrate specificity needed is very broad. Unfortunately, biocatalysts, by design are supposed to be very specific. This is what enables the biocatalysts to overcome reaction energy barriers at low temperatures and pressures, unlike chemical catalysts. To develop suitably broad and highly active bio­ catalysts, newly developed genetic engineering and molecular biology techniques have to be employed. These techniques are discussed in the book as well, with reference to their application. Companies involved in providing services in these areas are listed in Chapter 4 and cover expertise in gene identification, sequencing, strain development and bioprocess engineering needs. In addition, several Universities and research orga­ nizations are also discussed with reference to screening of microorganisms, enzyme characterization, and pathway identification. In addition to the bioprocessing of petroleum, the book also contains a small section on bioremoval of hydrogen sulfide from gaseous streams. This applies to removal of hydrogen sulfide from effluents from hydrotreatment operations. It forms an essential part of the biotechnology portfolio for the petroleum refining industry. Chapter 3 as well as Chapter 5 includes discussion on bioprocesses capable of removing hydrogen sulfide. The Chapter 5 provides an integrated list of companies and research organizations involved in petroleum biorefining research. The background of each company and its efforts leading to its patent portfolio in this area are discussed. We have tried to include all known companies that have participated to date in this area; however, the list is not strictly exhaustive. Finally, hoping that this book provides every reader with the information he/she is looking for. If you do not, you may contact us the address provided and we will make every effort to respond. You may reach us to provide your feedback or tell us about the deficiencies in this book. We wish you an informative and pleasant reading. Abhijeet P. Borole and Maria Magdalena Ramírez-Corredores September 2006. CONTENTS Foreword vii Preface ix Chapter 1 Introduction 1 1. Refining Scenarios 2. Biocatalysis 1 3 Chapter 2 Conventional refining processes 9 1. Introduction 2. Hydrotreating Processes 2.1. Chemistry 2.1.1. Reactions 2.1.2. Catalysts 2.2. Process 3. Gasoline Hydrotreating 3.1. Chemistry 3.2. Process 4. Diesel Hydrotreating 4.1. Chemistry 4.2. Process 5. Vacuum Gas Oil Hydroprocessing 5.1. Vacuum Gas Oil Hydrotreating 5.2. Vacuum Gas Oil Hydrocracking 6. Residue Hydroprocessing 6.1. Residue Hydrotreating 6.2. Residue Hydrocracking References 9 14 15 15 18 22 24 25 26 28 29 35 40 41 43 46 48 51 56 Chapter 3 Emerging biocatalytic processes 65 1. Preamble 2. BDS 2.1. General 2.2. Biocatalytic Technologies (Microorganisms and Derivations) 2.2.1. Initial biodesulfurization efforts 2.2.2. Anaerobic Pathways 65 67 67 68 68 70 xii Contents 2.2.3. 2.2.4. 2.2.5. 2.2.6. 2.3. 2.4. 2.5. Aerobic sulfur-specific pathways Aerobic Destructive and Ring Opening Pathways Genetics of desulfurizing organisms Purification and characterization of desulfurization enzymes 2.2.7. Specificity of desulfurization enzymes 2.2.8. Enzymatic desulfurization 2.2.9. Biocatalyst production, recycle, and regeneration 2.2.10. Engineered strains for desulfurization 2.2.11. Strategies for further microbial catalyst improvement Process Aspects 2.3.1. Overall process designs and patented technologies 2.3.2. Process parameters and operating conditions 2.3.3. Bioreactor design and development 2.3.4. Separation of oil-water-biocatalyst mixtures 2.3.5. Other process options 2.3.6. Diesel biodesulfurization 2.3.7. Biodesulfurization of gasoline Desulfurization of Gaseous Streams Summary 2.5.1. Pioneering biocatalytic work 2.5.2. Biocatalyst concept and BDS-active Microorganisms 2.5.3. Biocatalytic enzymes 2.5.4. Activity improvement 2.5.5. Specificity improvement 2.5.6. Biocatalyst production and regenerability 2.5.7. Bioreactor and process schemes 2.5.8. Product separation 3. BDN 3.1. General 3.2. Metabolic Pathways 3.2.1. Acridine 3.2.2. Carbazole and derivatives 3.2.3. Quinoline and derivatives 3.2.4. Isoquinoline 3.2.5. Indole 3.2.6. Pyridine and derivatives 3.3. Enzymes 3.3.1. Quinoline and related compounds 3.3.2. Carbazole 3.3.3. Indole 3.3.4. General 3.4. Microorganisms 3.5. Process Aspects 3.6. Summary of BDN Advances 71 88 91 93 101 102 103 107 115 116 116 126 128 130 134 135 141 141 144 144 144 145 145 146 147 147 148 149 149 151 152 152 154 160 161 163 165 166 171 172 172 172 179 183 Contents 4. BDM 4.1. General 4.2. Technical findings 4.2.1. Enzymatic work 4.2.2. Microbial work 5. Bio-Upgrading 5.1. General 5.1.1. Heavy oil characteristics 5.1.2. Pathways for upgrading heavy crudes 5.2. Viscosity and MW reduction 5.2.1. Structural splitting 5.2.2. Oxygen introduction 5.2.3. Aromatic ring saturation 5.3. Processes 5.3.1. Viscosity reduction processes 5.3.2. Chemical conversion processes References Chapter 4 Biotechnology and supporting companies 1. General 2. Biology-Based Organizations 2.1. Introduction 2.2. Molecular Biology Companies 2.2.1. 454 Corporation 2.2.2. Advance ChemTech 2.2.3. Agowa 2.2.4. AlphaGene 2.2.5. Alpha Innotech 2.2.6. Amplicon Express 2.2.7. Ana-Gen 2.2.8. Anaspec, Inc. 2.2.9. Applera 2.2.10. Aurora Biomolecules 2.2.11. Biacore 2.2.12. Biopro International, Inc. 2.2.13. Bioserve Biotechnologies, Ltd. 2.2.14. BioVentures 2.2.15. BioWorld Products 2.2.16. Caliper Life Sciences 2.2.17. ChemGenes Corporation 2.2.18. Commonwealth Biotechnologies, Inc. 2.2.19. DGT Digital Gene Technologies 2.2.20. European Molecular Biology Laboratory’s 2.2.21. GATC Biotech 2.2.22. Miltenyi Biotec 2.2.23. Proteinlabs, Inc. xiii 184 184 186 186 187 189 189 190 191 192 192 194 199 199 199 200 204 227 227 231 231 232 232 232 233 233 233 233 234 234 234 234 234 235 235 235 236 236 236 236 237 237 237 238 238 xiv 2.2.24. Structural Genomics Consortium 2.2.25. Structural Genomics Centers 2.2.26. Zyomyx, Inc. 2.3. Genetic Engineering Companies 2.3.1. Aptagen Gene 2.3.2. Biotage 2.3.3. Cambio 2.3.4. Entelechon 2.3.5. Geneart 2.3.6. Invitrogen 2.3.7. Joint Center for Structural Genomics 2.3.8. Operon Technologies, Inc. 2.3.9. Orchid Cellmark 2.3.10. Oxford Gene Technologies 2.4. (Microbiology) Depositary Agencies 2.4.1. American Type Culture Collection (ATCC) 2.4.2. German Collection of Microorganisms and Cell Culture 2.4.3. Ferm 3. Biocatalyst (Enzyme/Protein) Companies 3.1. Altus Biologics, Inc. 3.2. Applied Enzyme Technology Ltd. 3.3. Bachem 3.4. Biocatalysts Ltd. 3.5. BioCatalytics, Inc. 3.6. Biopract 3.7. BioResearch Products, Inc. 3.8. Diversa Corporation 3.9. Enzyme Services and Consultancy 3.10. Iogen Corporation 3.11. Maps (India) Ltd. 3.12. Novozymes A/S 3.13. N-Zyme BioTec GmbH 3.14. Worthington Biochemical Corporation 4. Biotechnology-Based Companies 4.1. Acacia Research Corp. 4.2. Affymetrix 4.3. Apocom Genomics 4.4. Aurora Biosciences Corporation 4.5. Avecia Biotechnology 4.6. AVIVA Biosciences Corporation 4.7. Ben Venue Laboratories 4.8. Beyond Genomics, Inc. 4.9. Bio-Concept Laboratories Inc. 4.10. BioZone Laboratories 4.11. Biologics Process Development, Inc. 4.12. Bio Science Contract Production 4.13. BioMetics Contents 238 239 239 239 239 239 240 240 241 241 242 242 243 243 243 243 246 246 247 249 249 250 250 251 251 251 251 252 253 253 254 255 255 256 256 257 257 258 258 258 259 259 260 260 260 260 261 Contents 4.14. Cedra Corporation 4.15. Cell & Molecular Technologies, Inc. (CMT) 4.16. ChemOvation Ltd. 4.17. Ciphergen Biosystems 4.18. Cogenics 4.19. deCODE Genetics 4.20. Delaware Biotechnology Institute 4.21. DiscoveRX Corporation 4.22. Dyadic International, Inc. 4.23. Enchira Biotechnology 4.24. Genencor International, Inc. 4.25. Goodwin Biotechnology, Inc. 4.26. GPC Biotech’s 4.27. HyClone 4.28. Illumina, Inc. 4.29. Integrated Genomics 4.30. Large Scale Biology Corporation 4.31. Maxygen, Inc. 4.32. MediChem International 4.33. Millipore 4.34. Molecular Machines & Industries GmbH 4.35. Nanogen, Inc. 4.36. Novagen, Inc. 4.37. Organix, Inc. 4.38. PerkinElmer Life Sciences (Formerly: NEN Life Science Products) 4.39. Prior Separation Technology 4.40. Proteus 4.41. Sangamo BioSciences, Inc. 4.42. The Center for Biotechnology 4.43. Xencor References Chapter 5 R&D technological results Overview 1. Agip Petroli (Italy); Enichem Anic Spa (Italy), and Eni Tecnologie Spa (Italy) 2. Archaeus Technology Group Ltd. (Great Britain) 3. Arctech Inc/Atlantic Research Corporation (United States) 4. ASS Universities Inc/Brookhaven Science (United States) 5. Atlantic Richfield Co (United States) 6. Atlas, Ronald/Southern Pacific Petroleum (United States) 7. Babcock & Wilcox Co (United States) 8. BHP Minerals International Inc. (United States) 9. Biostar BV (Netherlands) 10. BWN Live Oil (Australia) 11. Clean Diesel Technologies, Inc. (United States & International) xv 261 261 262 262 262 263 264 264 265 265 266 266 267 267 267 268 269 269 271 271 272 272 273 273 274 274 274 275 276 276 277 279 279 281 285 286 287 291 291 292 293 294 295 296 xvi Contents 12. Combustion Engineering (United States) 13. Environmental Bioscience Corporation/Energy Biosystems Corp./Enchira Biotechnology Corp. (United States) 13.1. Environmental Bioscience Corp (EBC1) 13.2. Energy Biosystems Corporation (EBC2) 13.3. Enchira Biotechnology Corporation (EBC3) 14. Exxon Research and Engineering (ER&E) Co (United States) 15. Gas Research Institute (United States) 16. Houston Industries Inc. (United States) 17. Imperatrix (United States) 18. Institute Francais Du Petrol (France) 19. Instituto Mexicano De Petroleo/Universidad Nacional Autonoma De Mexico (Mexico) 20. Institute of Gas Technology (United States) 21. Institute of Process Engineering (China) 22. Intevep S. A. (Venezuela) 23. Japanese Cooperating Organizations (Japan) 23.1. Agency of Industrial Science & Technology/National Institute of Advanced Industrial Science & Technology 23.2. Japan Cooperation Center, Petroleum (JCCP) 23.3. Petroleum Energy Center (PEC) 24. Kansai Electric Power (Japan) 25. Korea Advanced Institute of Science and Technology (Korea) 26. Kurashov, Viktor Mikhajlovich (Russia) 27. Kyushu Kankyo Kanri Kyokai (Japan) 28. Lambda Group Inc. (United States) 29. Marine Biotechnology Institute Co Ltd (Japan) 30. Microbes Inc. (United States) 31. Ni Aoot; Vatel Skij Inst Neftepromyslov (Russia) 32. Nippon Oil Co Ltd (Japan) 33. Oldfield, Christopher, Court of Napier University 34. Paques Biological Systems BV (Netherlands) 35. Petroleo Brasileiro SA (Brazil) 36. Petrozyme Technologies Inc (Canada) 37. Petroleum Industry Development Center (Sekiyu Sangyo Kasseika Center); Mitsubishi Oil Co Ltd (Japan) 38. Plummer, Mark A (United States) 39. Shell Oil Co (Netherlands) 40. Standard Oil Co (United States) 41. Technology Licensing Organization 42. Tonen Corp (Japan) 43. Unitika Ltd (Japan) 44. Universidad De Alcalá, Universidad Complutense De Madrid, and Consejo Superior De Investigaciones Científicas (Spain) 45. University of Osaka (Japan) 46. University of Shandong (China) 47. University of Waseda (Japan) 297 298 306 307 322 323 326 328 329 330 331 332 337 337 338 339 341 342 345 346 347 348 348 349 349 350 351 351 352 353 354 355 356 356 357 358 359 360 361 361 362 362 Contents 48. UOP LLC (United States)/Paques Biological Systems BV (Netherlands) 49. Valentine, James M (United States) General Discussion References Chapter 6 Research needs and future directions 1. Research Needs 1.1. Biodesulfurization 1.1.1. Over-expression of DszB 1.1.2. Substrate specificity of Dsz enzymes 1.1.3. Thermostability 1.1.4. Benzothiophene desulfurization 1.1.5. Desulfurization of highly substituted alkyl and aryl DBTs 1.1.6. Process Development 1.2. Biodenitrogenation 1.3. Biodemetallization 1.4. Bioupgrading 2. Future Directions 2.1. Future scenario 2.2. Technology needs References Subject Index xvii 362 363 364 366 375 375 375 379 379 380 380 380 381 382 383 383 384 384 386 387 389