Solar Thermal Conversion of

Biomass to Methanol

Instructor: A. W. Weimer

CHEN 4520

Bernard Britt

Robert McGugan

Sarah Stoeck

Andrew Weidner

Vanessa Witte

1

Table of Contents

I. Executive Summary ...................................................................................................................... 7

II. Introduction ................................................................................................................................ 8

Project Description and Scope .................................................................................................... 8

Mission Statement ................................................................................................................... 8

Process Description ................................................................................................................. 8

III. Background Information .......................................................................................................... 11

Market for Renewable Methanol .............................................................................................. 11

Renewable Methanol from Biomass ......................................................................................... 13

Solar-Thermal Processing .......................................................................................................... 14

IV. Environmental, Health & Safety .............................................................................................. 16

Chemical Hazards ...................................................................................................................... 16

Health and Safety Considerations ............................................................................................. 20

Operator Safety ..................................................................................................................... 20

Licensure and Permits ........................................................................................................... 22

Environmental Considerations .................................................................................................. 24

Worst-Case Scenarios................................................................................................................ 29

Life Cycle Analysis...................................................................................................................... 32

Goal and Scope Definition ..................................................................................................... 32

Inventory Analysis.................................................................................................................. 34

Impact Assessment and Interpretation ................................................................................. 37

V. Project Premises ....................................................................................................................... 38

Design ........................................................................................................................................ 38

Biomass Pre-Processing ......................................................................................................... 38

Biomass Gasification and Methanol Production ................................................................... 39

Amine Scrubbing .................................................................................................................... 39

Methanol Purification ............................................................................................................ 39

Economics.................................................................................................................................. 40

VI. Approach.................................................................................................................................. 42

Hand Calculations ...................................................................................................................... 42

Heat of Reactions: Cellulose and Steam ................................................................................ 42

2

Heat of Reaction: Lignin and Steam ...................................................................................... 43

Waste Biomass Feed Estimation ........................................................................................... 43

Theoretical Energy Requirement for Solar-Thermal Reactor ................................................ 45

VII. Process Flow Diagrams with Material & Energy Balances ..................................................... 46

Biomass Pre-Processing............................................................................................................. 46

Process Description and PFD ................................................................................................. 46

Material Balances .................................................................................................................. 48

Heat Duty ............................................................................................................................... 49

Biomass Gasification ................................................................................................................. 49

Process Description and PFD ................................................................................................. 49

Heat Duty ............................................................................................................................... 61

Amine Scrubbing ....................................................................................................................... 62

Process Description and PFD ................................................................................................. 62

Material Balance .................................................................................................................... 70

Heat Duty ............................................................................................................................... 71

Product Separation & Post-Processing ..................................................................................... 71

Process Description and PFD ................................................................................................. 71

Material Balances .................................................................................................................. 73

Heat Duty ............................................................................................................................... 74

VIII. Process Description & Equipment Specifications .................................................................. 75

Generalized Equipment Design ................................................................................................. 75

Pumps .................................................................................................................................... 75

Shell-and-Tube Heat Exchangers ........................................................................................... 78

Vapor-Liquid Separators ........................................................................................................ 82

Pressure Vessels and Towers................................................................................................. 90

Cyclones ................................................................................................................................. 94

Biomass Pre-Processing............................................................................................................. 98

P-1 / SR-101 Shredding .......................................................................................................... 98

P-2 / RDR-101 Rotary Drying ............................................................................................... 100

P-3 / GR-101 Grinding .......................................................................................................... 103

P-4 / HP-101 Hopper............................................................................................................ 105

3

Solar Field and Tower .............................................................................................................. 110

Biomass Gasification ............................................................................................................... 112

Solar Reactor........................................................................................................................ 112

Zinc-Oxide Reactor .............................................................................................................. 118

Methanol Reactor ................................................................................................................ 119

Spray Quench Tank .............................................................................................................. 122

Heat Exchangers .................................................................................................................. 124

Compressor .......................................................................................................................... 126

Pumps .................................................................................................................................. 128

Vapor-Liquid Separators ...................................................................................................... 130

ZN-SPLIT Cyclone ................................................................................................................. 134

Amine Scrubbing ..................................................................................................................... 134

Pressure Vessels, Separators, and Towers .......................................................................... 134

Heat Exchangers .................................................................................................................. 138

Pumps .................................................................................................................................. 143

Product Separation & Post-Processing ................................................................................... 144

Separator V-100 ................................................................................................................... 144

Distillation Column T-100 .................................................................................................... 145

IX. Utility Summary and Heat Integration ................................................................................... 150

Utility Summary ....................................................................................................................... 150

Heat Integration ...................................................................................................................... 152

X. Estimation of Capital Investment and Total Product Cost...................................................... 157

Capital Investment .................................................................................................................. 157

Equipment Cost Summary ................................................................................................... 157

Operating Costs ....................................................................................................................... 172

Metrics of Plant Operation .................................................................................................. 172

Variable Operating Costs ..................................................................................................... 172

Fixed Operating Costs .......................................................................................................... 172

XI. Profitability Analysis............................................................................................................... 174

Profitability .............................................................................................................................. 174

Base Case ............................................................................................................................. 174

4

Modified Base Case: Life Cycle Analysis with Carbon Credit ............................................... 179

Sensitivity Analysis .................................................................................................................. 181

XII. Conclusion ............................................................................................................................. 188

XIII. References ........................................................................................................................... 189

XIII. Appendix .............................................................................................................................. 196

Appendix I: Engineering Calculations ...................................................................................... 196

Appendix I-A: Approach Calculations .................................................................................. 196

Appendix I-B: Material and Energy Balances ...................................................................... 200

Appendix I-C: Split Fraction for AG-CLEAN .......................................................................... 205

Appendix I-D: Adiabatic Temperature Rise for Methanol Reactor ..................................... 206

Appendix II: Design and Costing Spreadsheets ....................................................................... 207

Appendix II-A: Solar Field Design ......................................................................................... 207

Appendix II-B: Cyclone Design ............................................................................................. 208

Appendix II-C: Aspen PLUS Separator Design ...................................................................... 209

Appendix II-D: Pump Design ................................................................................................ 211

Appendix II-E: Compressor Design ...................................................................................... 213

Appendix II-F: Pre-Processing Design .................................................................................. 214

Appendix II-G: Amine Scrubbing Design .............................................................................. 216

Appendix II-H: Methanol Purification System Design ......................................................... 224

Appendix II-I: Quench Tank Design...................................................................................... 228

Appendix II-J: Heat Exchanger Design ................................................................................. 230

Appendix II-K: Reactor Heat Exchanger Design ................................................................... 235

Appendix II-L: Reactor Design.............................................................................................. 236

Appendix II-M: Solar Field Costing....................................................................................... 241

Appendix II-N: Cyclone Costing ........................................................................................... 242

Appendix II-O: Aspen PLUS Separator Costing .................................................................... 243

Appendix II-P: Pump Costing ............................................................................................... 244

Appendix II-Q: Compressor Costing..................................................................................... 247

Appendix II-R: Pre-Processing Costing................................................................................. 248

Appendix II-S: Amine Scrubbing Costing ............................................................................. 250

Appendix II-T: Methanol Purification System Costing ......................................................... 252

5

Appendix II-U: Quench Tank Costing ................................................................................... 253

Appendix II-V: Heat Exchanger Costing ............................................................................... 254

Appendix II-W: Reactor Heat Exchanger Costing ................................................................ 256

Appendix II-X: Reactor Costing ............................................................................................ 257

Appendix III: Computer Process Modeling and Simulations ................................................... 258

Appendix III-A: Biomass Pre-Processing Simulation ............................................................ 258

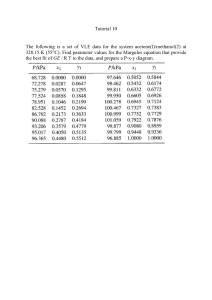

Appendix III-B: Aspen PLUS Simulation ............................................................................... 259

Appendix III-C: Amine Scrubbing Simulation ....................................................................... 260

Appendix III-D: Methanol Purification Simulation .............................................................. 261

Appendix III-E: Heat Integration .......................................................................................... 262

Appendix III-F: Reactor Computer Code .............................................................................. 263

Appendix IV: Economic Analysis Spreadsheets ....................................................................... 266

Appendix IV-A: Base Case without Carbon Credit ............................................................... 266

Appendix IV-B: Base Case with Carbon Credit..................................................................... 274

Appendix IV-C: Summary of Utilities ................................................................................... 282

6

I. Executive Summary

As carbon emissions become a growing cause for global concern, greater pressure has been

placed on industry to develop innovative alternatives to traditional commodity chemical

production. In order to investigate such an alternative, a design report has been written

examining the construction and economic feasibility of a Solar-Thermal Biomass Gasification

facility. This facility will serve as an alternative means of high-purity, industrial scale methanol

production.

The facility modeled here utilizes 204 million pounds of corn stover biomass per year as feed

stock, employs 111 full-time operators, and produces 58,300,000 gal/year of methanol end

product. The plant operates in five distinct subunits. Waste corn stover enters the biomass preprocessing portion of the facility where it is ground into usable cellulose and lignin. The usable

biomass is then sent to the biomass gasification subsystem, in which a series of three reactors

convert the biomass to methanol. In order to mitigate the environmental impact and utility

costs of the largest reactor, a solar field operating as part of the facility supplies thermal energy

to the solar reactor. An amine scrubbing system purifies the waste gas stream of environmental

toxins, while the final stage of product processing entails the purification of the end product

methanol, resulting in a final product stream with 99.97% purity by weight. The capital cost of

the facility was determined to be $300.5M.

An economic analysis was performed for plant operation in which 12.5% fixed IRR was

stipulated for facility investors. This economic analysis returned a 10.8% ROI, 9.2 year PBP and

$62.462M NPV based on a 30-year expected facility lifespan with a single year construction

period and single year of 50% capacity startup operation. In order to obtain the required 12.5%

IRR, the final product selling price was determined to be $1.69/gal methanol. This price is not

competitive with the current commodity market value of $1.05/gal (Methanex, 2015). Because

of the fa ilit s i a ilit to e su e i esto s suita le etu s hile

eeti g e d-product market

value, it is the recommendation of this design team that the Solar-Thermal Biomass Gasification

facility not be constructed. In the event that a carbon credit is granted to the facility to

incentivize eco-forward industry, a subsidy of $0.21/lb CO2 avoided would be required to

reduce the product selling price to market value and render the project economically viable.

7

II. Introduction

Project Description and Scope

Mission Statement

United States methanol consumption is on the rise and is expected to increase 26% by 2020

(The American Oil and Gas Reporter, n.d.). This opens the market for increased demand in

chemicals, transportation, and power generation, as methanol is a key commodity in all three

sectors. The chemical industry uses this versatile compound in hundreds of chemicals including

solvents, plastics, paints, and adhesives. Combustion of fossil fuels, namely petroleum based

products, in the transportation sector is the second largest source of CO2 emissions in the US

and accounts for a third of all greenhouse gas (GHG) emissions to the atmosphere (EPA, n.d.).

Alternative fuel sources that result in significantly less GHG emissions than conventional fuel

has e o e a e essit as the o ld s populatio a d e o o

o ti ues to i

ease.

Methanol provides an attractive alternative fuel option to replace petroleum due to a variety of

advantages. Implementing methanol into the transportation fuel industry could help to

significantly reach federal and state carbon reduction goals. In addition, companies are

exploring ways to use methanol as an additional fuel source for power generation to drive

turbines and create electricity.

This design project proposes to develop a renewable methanol production plant in Daggett, CA.

A techno-economic analysis will be performed to ascertain the viability of the plant in terms of

health and safety, equipment design, and return on investment. The plant will utilize waste

biomass as the feedstock and subsequently produce 58.3 million gallons of 99.97% pure

methanol annually. Slight excess of methanol was produced to account for unforeseen major

mainte a e issues that ould ut i to p odu tio ti e. I this

a

e , the u e s suppl

ould ha e li ited i te uptio s o e the ou se of the pla t s lifeti e, if a

at all. The

gasification of the biomass will be operated using a hybrid reactor with energy sources from

o e t ated sola po e a d atu al gas, hi h ill lo e the pla t s o e all GHG e issio s.

Process Description

This process is utilizing waste biomass, corn stover, in a thermochemical gasification reaction to

produce methanol. The plant will be located in Daggett, CA and will operate 24 hours a day, for

8

a total of 8000 hours per year. The plant can be divided into pre-processing, gasification, and

purification sections. Pre-processing involves drying the corn stover feedstock and grinding into

small particles applicable for gasification. Corn stover is delivered to the plant after harvest and

is initially shredded to reduce the bulk size to no larger than 6mm. The feedstock is sent to a

direct-contact air-dryer to convectively pull moisture from the particles. A hammer mill is then

employed to reduce the particles to micron size. Lastly, a hopper is used to pressurize the feed

to 35 bar to meet the specifications of the solar reactor.

At this point the feedstock is at the correct temperature and pressure for the gasification

reaction. Because biomass reactions are complicated and novel, software such as Aspen PLUS

requires multiple pieces of equipment to model them, though the reaction would take place in

a single vessel. The gasification reactor has concentrated solar power and natural gas as the

energy sources. Concentrated solar power (CSP) is produced by a field of heliostats targeted at

a solar tower with a compound parabolic concentrator. CSP is one of few renewable

technologies able to achieve the high temperatures required in the gasification process

(>1000°C) due to concentrating the thermal energy. Natural gas is fed as a supplement to CSP

to allow 24 hour operation.

In the gasification step, the pre-treated biomass must be reacted in high temperature, lowoxygen conditions with water and a methane stream. A controlled level of oxygen limits the

combustion reaction formation of carbon dioxide, but provides enough heat for subsequent

gasification reactions. High temperatures yield fewer hydrocarbons such as char, tar, and ash

and increases conversion directly to carbon monoxide and hydrogen (syngas). The addition of

water and methane also serves to reach to the desired 2:1 ratio of H2:CO in the syngas and to

diminish the selectivity of carbon dioxide formation. The chief gasification reactions are shown

in the equations below:

�

→[

+

+

+

+

+

→

]+

→

+

+

+

ℎ

(1)

(2)

(3)

9

+

+

+

→

+

+

→

→

→

→

(4)

(5)

+

(6)

+

(7)

(8)

The gasification process produces dirty, contaminated gas streams that undergo various

separation processes to clean the gas and remove particulates, such as ash solids, acid-gas,

sulfur, and chlorine. The resulting vapor stream is sent to the methanol processing reactor.

Maximum production of methanol follows from a high concentration of CO, a low

concentration of CO2, and an optimal ratio of H2:CO:H2O in the feed stream, values that are

dependent on specific reactor conditions. Equations (9), (10) and (11) below summarize the

simultaneous methanol synthesis reactions:

+

+

+

→

→

→

+

(9)

(10)

+

(11)

The output stream from the methanol reactor is split into a recycle stream back to the solar

reactor, a purge stream that is flared, and a product stream sent downstream for purification.

The downstream methanol purification process operates 24 hours a day as well. The dirty

methanol stream employs distillation to obtain a final methanol product stream with 99.97%

purity.

10

III. Background Information

Market for Renewable Methanol

The $36 billion methanol industry has 90+ plants in operation worldwide and produces 49.8

million tons annually to be used in the chemical, transportation and power generation sectors

(Methanol Institute, n.d.). Methanol is the simplest alcohol, with a chemical formula of CH3OH.

Its simplicity brings forth a variety of characteristics; methanol occurs naturally in the

environment, it is biodegradable, light and colorless, and it quickly breaks down in aerobic and

anaerobic conditions (Methanol Institute, n.d.). Methanol can be produced from a diverse array

of feedstocks which gives it the distinct advantage of polygeneration: the ability to be made

from any resource that can be converted into synthesis gas. As a result, methanol is classified as

o e tio al o

e e a le. Conventional methanol is produced from steam reformation

with the use of a fossil fuel, coal or natural gas, and steam. This produces a synthesis gas, as

shown below in Equation (12) for steam reformation (Methanol Institute, n.d.).

+

→

+

+

→

+

ℎ �

(12)

+

(13)

The syngas is then processed over a catalyst to yield CH3OH, as shown in Equation (13).

+

+

Renewable methanol is produced from the synthesis of waste biomass such as switchgrass,

forest trimmings, corn stover, or other agricultural residue products in a very similar manner of

gasification and catalysis. Using biomass as the feedstock is considered carbon neutral due to

the sizeable carbon absorbance of the feedstock before processing. Additionally, renewable

biomass has an advantage in that it looks to include a CO2 stream as the feedstock,

consequently utilizing a GHG in its process (Karen Law, 2013).

Methanol is an exceptionally diverse chemical and thus has many advantages as a material for

chemical production or as a fuel source. With its unique ability for polygeneration,

manufacturers can tap into multiple resources to supply the increasing methanol demand.

Since methanol production is already well established in the global marketplace, the existing

infrastructure and logistics would allow for production conversion between conventional and

11

renewable means, and possibly allow for a full transition to renewable methanol in the future.

As well, the US and other countries can leverage the economic benefit of the increased demand

of methanol. This is seen in two recent development projects: a 10 year Chesapeake Energy

Corp-Methanex contract and G2X Energy methanol-to-gasoline plant construction (The

American Oil and Gas Reporter, n.d.). Collaborations with natural gas energy companies and

new plant development projects represent a growing market that is seeking ways to utilize the

full potential.

At 40% of supply, the chemical sector has the largest demand for methanol, which is usually

provided through conventional means. The largest chemical use fo

etha ol is i the plasti s

industry to produce resins and polymers (The University of York, n.d.). Common methanol

derivatives include dimethyl ether, formaldehyde, acetic acid, methyl methacrylate, and

methylamines.

In the

sa d

s,

etha ol e ei ed atte tio as a alte ati e fuel sou e, a el to

create a fuel blend with gasoline and possibly ethanol. It did not become a substantial

commodity though, primarily due to falling petroleum prices which negated any economic

incentive to its usage. In recent years, as petroleum prices and supply has been more volatile,

many countries including the United States are seeking ways to gain energy security and

mitigate uncertainties. As a result, the US has a seen a steady rise in alternative fuel demand

over the last decade. Federal Renewable Fuel Standards (RFS) calls for 18.11 billion gallons of

alternative fuel production in 2016; a 7% increase over the 2015 standards (EPA, n.d.).

Additionally, the Open Fuel Standard bill, if approved, would greatly promote the need for

methanol and demand could increase exponentially (Open Fuel Standard, n.d.) Methanol is

seen as one of the chief commodities able to fill the demand gap in alternative fuels due to a

variety of advantages specifically in the transportation sector: studies have shown a 65-95%

carbon reduction from well-to-tank and a 15-20% lower tailpipe emissions with fuel blends of

methanol, it cuts nitrogen oxide and volatile organic compound emissions, there are no toxic

additives necessary and has a half-life of 1-7 days versus gasoline and other constituents at over

a hundred days (Methanol Institute, n.d.). Another significant advantage is its ability to be used

in advanced efficiency technologies such as PEM fuel cells. While there are considerable

12

advantages, methanol use in transportation fuels has disadvantages as well, such as it has half

the energy content as gasoline on a volume bases and it is corrosive in nature and miscible with

water which places different material requirements in vehicles (Methanol Institute, n.d.).

Lastly, methanol is being explored as an emerging fuel for electrical power generation. It can be

used as an energy carrier for hydrogen storage and delivery. Research has shown it can be

incorporated into existing dual-fueled gas turbines and can stand alone as a turbine fuel

(Methanol Institute, n.d.).

Renewable Methanol from Biomass

As opposed to bioethanol, methanol production from biomass has very few limitations in

feedstock choice. Agricultural resides, wastes, forest trimmings, and wood can be used – any

material able to undergo gasification to produce syngas. Since the feedstock can be a waste

material, there is little competition between materials usable as food sources. Furthermore, the

Energy Independence and Security Act mandates that non-food based bio-fuels ramp

production to meet the goal of 36 billion gallons by 2022, where methanol can obviously play a

major role.

A disadvantage to using biomass is that several additional production steps need to be taken

into consideration. The biomass must be pretreated by conditioning and drying to break down

cellulose and lignin and densify the material. Additionally, the use of biomass has a lower H:C

ratio compared to natural gas and thus produces char and ash to be taken into consideration in

the separations and waste disposal process. Also, conditions in the syngas formation reactions

eed to e

a ipulated fo

a i u

o e sio . The s gas eeds to e upg aded to

increase the H2 content and lower the methane content by utilizing the water-gas shift

reaction. Overall, biomass lowers the efficiency of the overall process due to these factors,

though methanol selectivity over 99% can still be achieved (Cheng, 2010).

Many feedstock options are available, though corn stover is the most plentiful non-food, noncrop source of biomass in the US, due to corn crops producing the highest volume of residue in

comparison to all other major crops (Dupont, 2012). The current supply has been estimated at

75 million tons per year (Roth, 2014). As well, due to the increase in demand of corn and higher

13

crop yields, the level of corn residue has increased as well, though the removal must be

sustainable.

Solar-Thermal Processing

Solar energy is one of the most accessible forms of renewable energy, and the amount available

is more than enough to power the entire world, provided it can be harnessed (Clean Technica,

n.d.). Currently, the capacity in the United States is 1.75 operating GW, with 2.2 GW in

development. Globally, there are 4.7 GW total current operating capacity with 22GW expected

by 2025 (Heba Hashem, 2015) . Among the solar energy possibilities, concentrated solar power

(CSP) has emerged as the major conversion technology due to many of its unique features and

relatively high efficiencies. CSP has the capability to achieve extremely high temperatures and

can be integrated with other conventional fossil fuel plants to create hybrid systems.

Consequently, a traditional fossil fuel pla t s o e all GHG e issio s a e lo e ed

edu i g

the fossil fuel input and relying partially on solar. CSP also has the ability for thermal energy

storage which allows for extended operation beyond when the sun is radiating energy.

A CSP process is constructed to collect the sunlight using heliostat mirrors that concentrate

solar energy using compound parabolic concentrators (CPC) to a centrally located tower. This

type of concentration allows for temperatures greater than 1000°C, which is beneficial to many

reaction systems. Figure 1 shows an aerial view of a solar power tower and heliostat field.

Figure 1: Aerial view of solar power tower and heliostat field

14

In the biomass to methanol plant, a renewable energy source was sought to mitigate the use of

natural gas and GHG emissions. As well, biomass gasification requires high temperatures in

order to avoid tar formation and to increase the conversion to higher energy gases such as CO

and H2. CSP was the obvious choice to meet both the high temperature demands and the

lowered GHG emissions.

15

IV. Environmental, Health & Safety

As in any chemical manufacturing system, it was paramount to consider the effects of the

proposed biomass gasification and methanol production plant on the environment and the

health and safety of the operators. This process involved a variety of chemical components

including reagents, catalysts, and waste products that are toxic, flammable, or highly reactive.

Waste treatment or management was considered for all streams exiting from the process. In

addition, the simulated process operated at temperatures over 1000°C and pressures up to 80

bar, conditions which can cause serious harm or disaster if not well-controlled and monitored.

Accordingly, worst-case scenarios were developed and evaluated. Finally, a life cycle analysis

(LCA) was performed to evaluate the environmental impacts of the proposed process across its

30-year lifetime on public health and land.

Chemical Hazards

A summary of all the chemical components present in the system is presented in Table 1 below.

Included in this table are the chemical formulas, lower explosion levels (LELs) of each

component, their auto-ignition temperatures, important safety hazards, general safety hazards,

and the permissible exposure limits (PELs) established by the Occupational Safety and Health

Administration (OSHA) (OSHA, 2011). In the following sections, methodologies to reduce these

chemical hazards will be discussed.

Table 1: Overview of chemical components in the biomass gasification and methanol production process. OSHA PELs are

obtained from (OSHA, 2011) or the indicated source (material safety data sheet, MSDS). GHG = greenhouse gas. *OSHA PELs not

considered because the limiting safety factor is the available oxygen in the atmosphere.

Component

(phase)

Chemical

formula

Biomass fly ash

(s)

Hydrogen (g)

N/A

Lower

explosion

level

N/A

H2

4 vol%

Auto-ignition

temperature

(°C)

Wide range

(232-2760)

565.5

Nitrogen (g)

N2

Not

flammable

Not

flammable

Water (g, l)

H2O

Not

flammable

Not

flammable

Safety and

environmental

hazards

Irritant; solid

hazardous waste

Flammable,

asphyxiant*; none

Asphyxiant*;

none

Slipping; none

OSHA

PELs

(ppm)

6

-

None

Source

(Weyerhaeuser,

2014)

(Air Products,

1994)

(Air Products

and Chemicals,

Inc., 1997)

(Sciencelab.com,

Inc., 2013)

16

Corn stover

biomass (s)

Multicomponent

25 g/m3

Hydrogen

sulfide (g)

H2S

4.3 vol%

Dust layer:

215

Dust cloud:

450

270

Methane (g)

CH4

1.8 vol%

287

Carbon

monoxide (g)

CO

≥

700

Hydrochloric

acid (g, aq)

HCl

Not

flammable

Not

flammable

Carbon dioxide

(g)

CO2

Not

flammable

Not

flammable

Ethane (g)

C2H6

2.9 vol%

N/A

Ethylene (g)

C2H4

2.7 vol%

450

Nitric oxide (g)

NO

Not

flammable

Not

flammable

Nitrogen

dioxide (g)

Ammonia (g,

aq)

NO2

Not

flammable

16 vol%

Not

flammable

651

Zinc oxide (s)

ZnO

Not

flammable

Not

flammable

Zinc sulphide

(s)

ZnS

Not

flammable

Not

flammable

Zinc chloride

(s)

ZnCl

Not

flammable

Not

flammable

Methyl

diethanolamin

e (MDEA) (l,

aq)

Mineral oil

CH3N(C2H4O

H)2

1.4 vol%

280

Varies

N/A

N/A

NH3

.

ol%

Explosive, irritant;

none

6

(IEA Bioenergy,

2013)

Flammable, toxic;

toxic to aquatic

life

Flammable,

asphyxiant*; GHG

Flammable, toxic;

lethal to fish,

pollutant

Corrosive, toxic,

irritant; acidifies

water

Asphyxiant; GHG

10

(Airgas, 2015)

-

(Airgas, 2015)

Flammable,

asphyxiant*; none

Flammable,

asphyxiant*; none

Toxic, oxidizer,

irritant, reactive;

pollutant

Toxic, carcinogen;

pollutant

Flammable,

corrosive, irritant;

toxic to aquatic

life, pollutant

Toxic, irritant;

hazardous solid

waste

-

Toxic, irritant,

reactive;

hazardous solid

waste

Toxic, corrosive,

irritant;

hazardous solid

waste

Irritant;

biodegradable,

low toxicity to

aquatic life

Irritant, slightly

flammable;

hazardous waste

25

(Matheson TriGas, Inc., 2008)

0.3

(Sciencelab.com,

Inc., 2013)

5000

(Air Products

and Chemicals,

Inc., 1994)

(Sigma-Aldritch,

2015)

(Airgas, 2015)

25

(Matheson TriGas, Inc., 2008)

1

(Matheson TriGas, Inc., 2008)

(Air Products

and Chemicals,

Inc., 1999)

25

5 (fume),

6

(particulat

e)

N/A

(Sciencelab.com,

Inc., 2013)

1 (fume),

6

(particulat

e)

N/A

(Sciencelab.com,

Inc., 2013)

5 (mist)

(Sciencelab.com,

Inc., 2013)

(Sciencelab.com,

Inc., 2013)

(Union Carbide

Corporation,

2015)

17

From this table and the accompanying MSDS documents, the most serious chemical hazards

were evaluated. Many of the chemical components in this process were present in the gas

phase, posing hazards regarding the availability of oxygen in the atmosphere on-site. In

particular, methane, ethane, ethylene, nitrogen, hydrogen, and carbon dioxide are classified by

OSHA as simple asphyxiants. A simple asyphxiant poses a hazard when the amount of available

oxygen in the air drops below 10%, which can cause unconsciousness and, in the absence of

further action, death by suffocation. If a large process gas leak occurred, this chemical hazard

would be a concern.

In addition, many of the components involved in the gasification of biomass are highly

flammable: hydrogen, carbon monoxide, hydrogen sulfide, methane, ethylene, ammonia, and

the biomass itself. Since the process gases are at pressures of at least 35 bar, it is unlikely that

ambient air would leak into the process. If the gas were exposed to ambient air at the

simulated temperatures up to 1450°C, the gas would likely auto-ignite, causing flaming jets of

high temperature, high pressure gas to be ejected from the equipment. These jets could start

fires in other equipment elsewhere in the plant, severely injure operators, and potentially cause

an explosion in other high pressure equipment. In addition, there is a risk of biomass fires

occurring. After the corn stover used in the process is unloaded, it is likely to be stored in a silo

before pre-processing. Since the biomass is not already dried (25% moisture by mass), there

exists a possibility of self-heating by microbial heat generation and exothermic side reactions in

ambient air. High temperatures can result at the core of a biomass silo as a result of thermal

runaway, ultimately resulting in spontaneous combustion of the biomass material (IEA

Bioenergy, 2013). The off-gassing of the moist biomass can also produce flammable compounds

such as CO, CH4, and aldehydes. The storage silo can then explode as a result of this volatile

mixture reaching high temperatures; an example of a silo explosion can be seen in Figure 2

below.

18

Figure 2: Silo explosion caused by the ignition of biomass off-gasses (IEA Bioenergy, 2013)

Many of the components in this process are also harmful to human health, particularly

ammonia, carbon monoxide, nitrogen oxide, nitrogen dioxide, and hydrogen sulfide. When

ammonia is inhaled, it is severely irritating to the lungs. The chemical is also corrosive to the

skin and eyes as a gas and an aqueous solution, where it contributes to an overall alkaline

solution. Upon inhalation, carbon monoxide can cause suffocation, blood damage, reproductive

complications, nerve damage, brain damage, and death. Inhalation of nitrogen oxide is fatal at

low concentrations, and eye contact with the chemical causes serious eye damage. Nitrogen

dioxide burns mucous membranes in the eyes, nose, and lungs and can be fatal if too much is

inhaled. Finally, hydrogen sulfide is very toxic to pulmonary tissue and is fatal if inhaled. The

biomass can also be harmful, as workers can become exposed to bacteria, spores, or other

pathogens living in the pre-dried biomass.

O“HA sets sta da ds ega di g o ke s e posu e to ha

ful he i als i the o kpla e. Table

1 outlines the permissible exposure limits (PELs) to various chemicals, expressed in parts of

compound per million parts of air (ppm). It is also required by OSHA that all chemical containers

19

a e p ope l la elled ith the ide tit of the haza dous chemical and appropriate hazard

a i gs a d that M“D“s a e a aila le ith detailed i fo

thei effe ts, ho to p e e t e posu e, a d e e ge

atio a out he i al haza ds,

t eat e t if a e posu e o u s

(OSHA, 2014). Finally, an inventory of chemicals present at the facility must be kept current and

available for reference. Personal protective equipment (PPE) is required for workers exposed to

these chemicals – these specifics will be addressed in the following section.

Health and Safety Considerations

Operator Safety

In order to legally employ operators, engineers, and other staff to run the plant, OSHA dictates

that certain minimum safety standards in plant operation and design be met. These regulations

are in place to protect employees from hazards in the workplace, as well as provide protections

to o ke s i

epo ti g these haza ds. It is the e plo e s responsibility to provide certain

information to meet OSHA standards (OSHA, 2014). Injury and illness records must be available

to employees if these injuries or illnesses are a result of workplace conditions. Workers have

the right to exposure data; that is, employers must monitor levels of chemicals or substances

regulated by OSHA PELs and provide this data to employees. Finally, workers have the right to

thei

edi al e o ds, espe iall if a o ke s health has ee affe ted e ause of e posu es

at o k (OSHA, 2014).

In case of an evacuation of the plant because of a disaster or other safety concern, exit routes

must be provided and meet certain OSHA requirements according to the Code of Federal

Regulations Title 29 (CFR 29), standard 1910.36 (OSHA, 2012). Exit routes must be permanent

and be built out of fire- esista t

ate ials. The e it

ust e protected by a self-closing fire

door that remains closed or automatically closes in an emergency upon the sounding of a fire

alarm or employee alarm system (OSHA, 2012). The exit must also be unlocked and have

direct, unobstructed access to an open space. For example, the open space can be a street,

alley, or walkway. Outdoor exit routes are permitted under standard 1910.36.

Occupational noise exposure is an important workplace condition that must be met in industrial

settings; CFR 29, standard 1910. 95 outlines some requirements (OSHA, 2012). Table 2 presents

20

permissible noise exposures in duration per day versus sound level in decibels (dB). Proper

engineering and PPE should be provided if workers are exposed to sound exceeding these

values and durations. Examples of proper PPE include earplugs and noise-cancelling earmuffs.

Noise levels must also be monitored with calibrated audiometers and the data recorded.

Hearing protectors must also be provided free of charge to the workers.

Table 2: Permissible noise exposures (OSHA, 2012)

Duration per day, hours

Sound level, dB

8

90

6

92

4

95

3

97

2

100

1 1/2

102

1

105

1/2

110

1/4 or less

115

OSHA also regulates the quality and condition of working-walking surfaces within industrial

plants, according to CFR 29, standard 1910.22 (OSHA, 2012). These surfaces must be kept clean

and dry in order to prevent slips and falls by workers. If the area surrounding process

equipment is wet, drainage systems must be installed and dry standing areas must be

maintained nearby. Aisles and passageways must be kept clear of debris and clutter. On

platforms and ladders, guard rails must be installed to prevent employees and operators from

falling from great heights.

For equipment operating at high pressures, OSHA requires the installation of pressure relief

valves according to CFR 29, standard 1910.101 (OSHA, 2012). These safety measures are

implemented to prevent the explosion of vessels in the case of overpressurization.

Overpressurization may result from blockage in a line or a larger temperature than expected in

a process unit. Pressure monitors equipped with alarms should also be installed in the process

to alert operators to rapidly rising pressures. Since this process also uses a variety of flammable

21

chemicals with a possibility for fires, a fire suppression system should be installed throughout

the plant and within the biomass silos to prevent flames.

Finally, personal protective equipment (PPE) must be worn by operators at all times to prevent

harm by chemicals, equipment, or operating conditions in the plant. Biomass or fly ash dust

clouds may form in the plant, so respirators should be worn at all times. Respirators also

prevent the inhalation of solid hazardous waste such as spent zinc oxide catalyst. If there is a

process gas leak, self-contained breathing apparatuses should be used to prevent the inhalation

of potentially fatal chemicals. Gloves and safety glasses should be worn at all times to prevent

injuries to the hands and eyes and block these bodily areas from discharges of chemicals.

Chemical goggles should be used upon if there is a process gas leak or if handling pure

chemicals or hazardous waste. Protective clothing such as overalls and long sleeves should be

worn at all times to prevent chemical exposure and skin injuries. A hard hat should be worn at

all times to prevent head injuries from falling equipment. Finally, to prevent the formation of

sparks from static charge, anti-static clothing and conductive boots should be worn at all times.

With these plant design and PPE enforcements in place, operator safety is enhanced.

Licensure and Permits

In order to operate a chemical processing facility in unincorporated San Bernardino County, CA,

a collection of licensures, permits, and information must be obtained from a variety of federal,

state, and county sources. These specifics are outlined in Table 3 below. A Certificate of

Disclosure of Hazardous Substances must be obtained from the Certified Unified Program

Agency (CUPA), Hazardous Materials Division within the San Bernardino County Fire

Department since hazardous materials are on site; this document is also known as a Business

Emergency/Contingency Plan. CUPA also provides hazardous materials and waste generation

information. Fire prevention information is supplied by the County of San Bernardino; this

authority will provide an inspection of the plant to ensure fire suppression and control systems

are being maintained effectively. The Air Quality Management District (AQMD) provides

Authority to Construct, Permit to Operate, and Building permits to industrial projects that emit

air emissions in the county. AQMD also provides Certificates of Occupancy. Since preliminary

hazardous waste treatment is done in the proposed plant, a Hazardous Waste Facility Permit

22

will be required from the Department of Toxic Substance Control. A State EPA ID Number is

e ui ed f o

the Depa t e t of To i “u sta es Co t ol fo

usi esses that generate,

surrender to be transported, transport, treat, or dispose of hazardous waste (California

Governor's Office of Business and Economic Development [GO-Biz], 2015). Since wastewater

will be discharged after treatment, an Industrial Activities Storm Water General Permit must be

obtained from the California Environmental Protection Agency (Cal/EPA). Cal/EPA also sets

Waste Discharge Requirements (WDRs). The Department of Industrial Relations provides

Occupational Safety and Health Information for businesses to use to develop an Injury and

Illness Prevention Plan. The Depa t e t of I dust ial ‘elatio s also p o ides Wo ke s

Compensation Information. The Employment Development Department provides registration

forms for employers that pay over $100.00 in wages to one or more employees. The Franchise

Tax Board provides state income tax information and forms. An Employer Identification

Number (EIN) or Social Security Number (SSN) is required by the Internal Revenue Service (IRS)

in the U.S. Department of Treasury for all employers for income tax purposes. Employees are

required to submit Proof of Residency forms to demonstrate proof of eligibility to work in the

U.S. Finally, a Title V Air Permit is required for any facility that emits large quantities of nitrogen

oxides, or operates in a state subject to federal Acid Rain regulations. (Environmental

Protection Agency [EPA], 2015).

Table 3: Summary table of permits, licenses, and information eeded fo a Che i al o Pai t Fo ulatio

usi ess i

unincorporated San Bernardino county, California (California Governor's Office of Business and Economic Development [GO-Biz],

2015)

Licensure, permit, or information needed

Certificate of Disclosure of Hazardous

Substances

Hazardous Materials/Waste Generation

Fire Prevention Information/Inspection

Authority to Construct/Permit to Operate

Certificate of Occupancy/Building Permit

Hazardous Waste Facility Permit

State EPA ID Number

Industrial Activities Storm Water General

Permit

Waste Discharge Requirements

Distributing authority

San Bernardino County Fire Department

Level of government

County

San Bernardino County Fire Department

County of San Bernardino

Air Quality Management District

Air Quality Management District

Department of Toxic Substances Control

Department of Toxic Substances Control

California Environmental Protection

Agency

California Environmental Protection

Agency

County

County

Regional

Regional

State

State

State

State

23

Occupational Safety and Health

Information

Workers' Compensation Information

Registration Forms for Employers

State Income Tax Information

Employer Identification Number (EIN or

SSN)

Proof of Residency Requirement

Title V Permit

Department of Industrial Relations

State

Department of Industrial Relations

Employment Development Department

Franchise Tax Board

U.S. Department of Treasury

State

State

State

Federal

U.S. Immigration and Naturalization

Service

California Environmental Protection

Agency

Federal

Federal?

Environmental Considerations

One of the largest goals in the proposed biomass gasification for methanol production process

was to utilize a renewable energy source to provide the high temperatures needed in the

gasification reactor rather than burn fossil fuels. However, there were other environmental

considerations that were taken into account to evaluate the environmental impact of the plant,

including individual chemical considerations, possible chemical spills, greenhouse gases, and

waste disposal. Greenhouse gas emissions over the lifetime of the plant were considered in a

life cycle analysis (LCA).

Some of the chemicals given in Table 1 are listed as hazardous by the California Environmental

Protection Agency (Cal/EPA). These hazardous materials were classified as characteristic

hazardous wastes or used oils. The characteristic wastes are classified as such if they exhibit

a

of the fou

to i it

ha a te isti s of a haza dous aste ig ita ilit , o osi it , ea ti it , a d

a d a e gi e i Table 4 (California Department of Toxic Substances Control, 2014). An

ignitable substance is one that can cause a fire, spontaneously combust, or has a flash point less

than 60°C. Corrosive substances are materials that produce acidic or alkaline solutions (pH < 2

o pH >

.

o

o ditio . To i

o ode

etal sto age o tai e s. ‘ea ti e astes a e u sta le u de

ate ials a e ha

e tai

ful o fatal [to fish o hu a s] when ingested or

a so ed. Fi all , used oil efe s to a

oil that has ee

efi ed f o

ude oil, o a

synthetic oil that has been used and, as a result of use, is contaminated with physical or

he i al i pu ities (California Department of Toxic Substances Control, 2014).

24

Table 4: Classification of hazardous waste components in the biomass gasification for methanol production process. Chemicals

from Table 1 are classified according to their characteristic waste codes or their status as a used oil.

Chemical

(I)

(R)

(C)

(T)

Used

oil

Biomass fly ash

Hydrogen

Nitrogen

Water

Corn stover biomass

Hydrogen sulfide

Methane

Carbon monoxide

Hydrochloric acid

Carbon dioxide

Ethane

Ethylene

Nitric oxide

Nitrogen dioxide

Ammonia

Zinc oxide

Zinc sulphide

Zinc chloride

MDEA

Mineral oil

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

After classifying these streams as hazardous waste, the waste disposal of these streams was

considered. A table of all of the outlet streams from the process is given in Table 5 below. Two

of these streams were immediately flared: Waste Vap and PURGE. These streams are purged

because the products of their combustions are not hazardous. Two more streams require some

treatment before being flared: Light HC and Acid Gas. These streams will be passed over zinc

oxide (ZnO) to react all the hydrochloric acid (HCl) and hydrogen sulfide (H2S) according to

Equation (79) as presented in the Zinc-Oxide Reactor equipment design section, then the

streams are flared. In this way, harmful sulfur oxide (SOx) emissions can be avoided, and HCl will

not be emitted to the atmosphere. The amount of ammonia to be flared is small compared to

the outlet mass flow rate to be flared, and syngas burns with a lean flame and a combustion

speed

u h ui ke tha

atu al gas (U.S. Department of Energy, 2006). So, it was

determined to be acceptable to flare ammonia, despite the nitrogen oxide emissions.

25

Table 5: Summary of all outlet streams from the proposed process with compounds that are hazardous, sorted by simulation.

Components with mole fractions less than 1E-7 are not included.

Stream

Simulation

Mass flow rate

(lb/hr)

Composition (wt%)

Phase

Waste disposal

method

Bottoms

HYSYS (MeOH)

6037

H2O: 0.9524

MeOH: 0.0476

Liquid

Modified LuckEttinger process,

then discharged as

wastewater

Waste Vap

HYSYS (MeOH)

126.5

H2: 0.0193

CH4: 0.0363

C2H4: 0.0001

N2: 0.0483

H2O: 0.0125

CO: 0.3085

CO2: 0.0024

MeOH: 0.5725

Vapor

Flared

Light HC

HYSYS (Acid Gas)

1.316

H2O: 0.0117

CO2: 0.1359

H2S: 0.0015

CH4: 0.0087

CO: 0.7370

H2: 0.0984

N2: 0.0068

Vapor

Passed over ZnO,

then flared

Acid Gas

HYSYS (Acid Gas)

1317

H2O: 0.6201

CO2: 0.3729

H2S: 0.0046

CO: 0.0011

NH3: 0.0012

H2: 0.0001

Vapor

Passed over ZnO,

then flared

Purge

HYSYS (Acid Gas)

616.9

MDEA: 0.4500

H2O: 0.5262

HCl: 0.0238

Liquid

Passed over ZnO,

then recycled into

amine scrubbing

system

QNCH-H2O

Aspen PLUS

59227.1

All H2O

Liquid

Released as steam to

the atmosphere

SLDWASTE

Aspen PLUS

226.878

All Ash

Solid

Sold

AQ-WASTE

Aspen PLUS

2141.34

H2O: 0.99915

H2S: 1.3E-6

NH3: 0.00084

CO2: 4E-6

Liquid

Modified LuckEttinger process,

then discharged

ACIDS

Aspen PLUS

See HYSYS

26

ZN-SOLID

Aspen PLUS

0.336905

ZnS: 1.0000, trace

ZnCl

Solid

Solid hazardous

waste

PURGE

Aspen PLUS

3141.47

N2: 0.05385

MeOH: 0.04060

C2H4: 0.00002

H2O: 0.00145

H2: 0.11288

CO: 0.77194

CO2: 0.00029

CH4: 0.01896

Vapor

Flared

The final waste products zinc chloride (ZnCl) and zinc sulfide (ZnS) are disposed of as solid

hazardous waste. The solid waste stream ZN-SOLID is also disposed of as solid hazardous waste.

The amount of ZnO required to react with the HCl and H2S in each of solid waste streams was

determined by assuming 100% conversation of the gases and is given in Table 6. This analysis

yielded a total amount of 112,612 kg/yr needed of ZnO and 163,206 kg/yr of solid waste for

disposal. This solid waste will be placed into a satellite accumulation area on-site and routinely

taken to a waste disposal and treatment center (EPA, 2012). The waste solid ash from

SLDWASTE can be sold as fly ash to a concrete producer for $0.012/lb (The Aberdeen Group,

1985). The excess quench water from the QNCH-H2O stream will be emitted as steam to the

atmosphere.

Table 6: ZnO catalyst needed for waste treatment. ZnO costs $0.20/kg, and it costs $0.31/kg of solid waste for disposal. Assumes

8000 hr/yr of operation.

Stream

Mass flow rate of ZnO needed

Mass flow rate of ZnS +

Cost of disposal of ZnO

(kg/hr)

ZnCl2 (kg/hr)

and waste disposal ($/hr)

Light HC

0.004

0.004

0.002

Acid Gas

6.51

7.80

3.72

Purge

7.43

12.45

5.35

ZN-SOLID

0.128

0.153

0.073

TOTAL

14.1

20.4

9.14

112,612

163,206

73,120

TOTAL (per yr)

To treat the remaining wastewater, a single-process wastewater treatment process called the

Modified Luck-Ettinger (MLE) process will be used (Exponent, 2012). MLE is a simple process

that utilizes two steps to remove nitrogen from wastewater – a simplified schematic is given in

27

Figure 3 below. The first step is the feeding of nitrogenated wastewater (AQ-WASTE) to an

alkaline anoxic tank, where bacteria take ammonia and oxidize it to nitrates; this process is

called denitrification. The bacteria needed reside in municipal waste, which is assumed to be

readily available from Daggett nearby. In MLE, an additional carbon source is needed; in this

process, the methanol waste stream Bottoms supplies this additional carbon. This decision

makes sense because the methanol is relatively dilute, reducing the toxicity of the methanol to

the bacteria. These nitrates and the added methanol are then consumed by heterotrophic

bacteria in nitrification, which emit the reduced nitrogen from the nitrates as nitrogen (N2) gas,

which is inert and not hazardous. A clarifier then removes the waste activated sledge (WAS)

from the effluent wastewater, which is disposed as municipal waste. Some of the WAS is

recycled to the process as recycled activated sledge (RAS). The large benefit of MLE in the scope

of the proposed process is that MLE consumes some of the methanol and ammonia hazardous

waste at the same time. The overall nitrification reaction is given in Equations (14) and (15)

below. The overall denitrification reaction is given in Equation (16) below.

+

−

+

+

�

→

−

+

−

→

→

+

+

+

−

+

+

(14)

(15)

+

−

(16)

Figure 3: Simplified schematic of the Modified Luck-Ettinger (MLE) process for the denitrogenation of wastewater (Exponent,

2012).

28

Worst-Case Scenarios

When designing any chemical processing plant, it is critical to evaluate the worst-case scenarios

that could occur in order to design ways to prevent disaster. In this section, a few possible

scenarios were considered. First, a leak of high-pressure process gases could occur, as discussed

earlier. Gas monitors and alarms should be installed throughout the plant in order to detect the

presence of H2 or CO gas in the atmosphere, as this would indicate a leak in the process

equipment. From there, the plant would be evacuated to ensure safety of the operators and

engineers. If the leak occurred in a unique piece of process equipment, the process would be

shut down by defocusing the heliostat mirrors off of the solar tower and shutting off the

regenerative natural gas burner in the solar reactor. To avoid shutdown of the whole process,

redundant lines could be installed throughout the process. In the event of a leak, valves at

either end of a redundant line could be opened to divert flow away from the leaky pipe. The

leaky pipe would then be shut off from the system by closing the valves and repaired.

The quench tank serves an integral role in quenching the gasification reaction by drastically

lowering the temperature of the solar reactor effluent from 1450°C to 120°C. If cooling water

flow to the quench tank were to suddenly stop, the very hot process gas would flow further

into the process, damaging many pieces of equipment not designed to withstand temperatures

over 1000°C. To avoid this occurrence, multiple pumps of the same specifications of the one

feeding cooling water to the quench tank could be purchased and installed in parallel. One of

these pumps could be used if another were to malfunction or break. Temperature sensors

should be installed in the piping downstream from the quench tank to detect its possible

malfunction.

As mentioned before, biomass fires could occur in storage silos. Self-heating of biomass can

cause the internal temperature of the biomass to reach upwards of 400°C, causing a fire to

ignite. Figure 4 shows the progress of a silo fire over 30 hours. At 30 hours, the fire begins to be

extinguished with inert gas. This figure demonstrates the importance of placing thermocouples

at the center of the biomass silo in order to detect the higher temperatures present in a silo

fire. A fire suppression system should be installed at the bottom of any storage silo to

extinguish the biomass with inert gas in case of a fire.

29

Figure 4: Visualizatio of the easu ed te pe atu es i side a o k-up silo, 1 m diameter and 6 m height. The smoldering fire

was triggered in the middle of the silo and then allowed to develop freely which resulted in a slow fire spread downwards in the

silo. The combustion gases did not reach the top of the silo until about 20 hours. After about 30 hours, inert gas was applied

th ough the otto of the silo whi h esulted i a fast edu tio of the s olde i g i te sity (IEA Bioenergy, 2013).

Finally, the exothermic reaction present in one of the three methanol synthesis reactors could

go out of control if the cooling water to the cooling coils within the vessel were to abate. The

temperature in the system would rise, eventually causing the system to overheat and perhaps

fail. To explore this idea further, an approximate adiabatic temperature rise was calculated for

one reactor. The methanol reactors are filled 25/26 of the way with a slurry of mineral oil

(Witco-40 oil) and catalyst. If the catalyst volume is assumed to be negligible, the volume of the

reactor filled with oil

�

is calculated as follows with Equation (17):

�

where

=(

)

(17)

is the volume of all three reactors combined. The

found with using the heat capacity

and density

, �

�

�

, �

of the oil can then be

of mineral oil (Engineering Toolbox,

n.d.) (Sciencelab.com, Inc., 2013). This calculation is shown in Equation (18) below:

�

It was assumed that all of the heat duty

, �

�

�

, �

(18)

of the reactor that would normally be removed by

the cooling coils goes into the mineral oil. The

be negligible. The reactant gas

=

value of the solid catalyst was assumed to

was calculated using values from Aspen PLUS and dividing

30

the

ass flo

ate

the ea to eside e ti e τ, which was found using Excel and Polymath

during the reactor design (see Appendix III-F). This value was calculated along with

Table 7 below and was found to be 69. Therefore, the

greater than that of the gas, so the

�

, �

in

value for the oil is substantially

value of the gas can be neglected. Therefore, the

energy balance for this simplified system is given in Equation (19) as follows:

where

=

�

(19)

, �

is the temperature of the reactor and is the time after the cooling coils stop

functioning. Separating and integrating Equation (19) yields Equation (20):

where

=

=

=

+

�

(20)

, �

ℎ . A plot of Equation (20) with Excel can be seen in ___. From this plot, it

was determined that the mineral oil does a good job of diluting any temperature runaway that

may occur in the operation of this reactor. It was noted that this analysis did not take into

account the change in reaction rate with temperature. However, the small temperature

changes per minute that occur in this analysis show that there would exist a large amount of

time to detect problems with the cooling coils via thermocouples installed in the reactor. Flow

meters installed in the pipes leading to the cooling coils and temperature could also detect

shutdown of the coils. To avoid this occurrence, multiple pumps should be installed in parallel

to feed the cooling coils with water. The adiabatic temperature rise calculations can be found in

Appendix I-D.

Table 7: Calculation of parameters for the simplified adiabatic methanol reactor energy balance

Computation of temperature of reactor versus time

Total volume

1094.027

m3

Volume of one reactor

364.6757

m3

Volume of oil

350.6497

m3

Density of oil

0.838

838

Total mass of oil

Heat capacity of oil

293844.4

1.67

g/mL

kg/m3

kg

kJ/kg-K

31

mCp of oil

490720.2

kJ/K

Mass flow rate of gas

49033.97

kg/hr

Heat capacity of gas

7.226894

kJ/kg-K

Residence time of gas

0.02

hr

mCp of gas

7087.266

kJ/K

Heat duty of reactor

6.61E+07

kJ/hr

2.20E+07

kJ/hr/reactor

Initial reactor temperature

210

483.15

°C

K

Simplified MeOH Reactor Temperature vs. Time

300

T (°C)

280

260

240

220

200

0

20

40

60

80

100

120

t (min)

Figure 5: Plot of reactor temperature (in °C) versus time (in min)

Life Cycle Analysis

A life cycle assessment (LCA) identifies, measures, and evaluates the environmental impact of

e e

stage of a p odu t s life a o di g to the i te atio al sta da ds set fo th ithi I“O

14040. These standards dictate the four stages to be analyzed in an LCA are: Goal and Scope

Definition, Inventory Analysis, and LCIA (life cycle impact assessment) and Interpretation.

Goal and Scope Definition

The goal of this LCA is to identify the environmental impacts of building and operating a solar

thermal biomass to methanol plant over the entirety of its operation, and then quantifying this

impact in terms of greenhouse gas (GHG) emissions, namely carbon dioxide, and other

influential factors. The LCA should be an integral part of the decision making process when

32

developing a new plant to ensure long term and short term public and land health and safety

issues are being addressed properly.

The plant operates with corn stover as the feedstock input, solar thermal, electricity, and

natural gas as the energy inputs, utilities as commodity inputs, and carbon dioxide, CO2,

emissions as the main output. An inventory analysis was performed on inputs and outputs for

pre-processing, gasification, and methanol purification, as well as a collective analysis over the

lifetime of the plant. Input data was generated from Aspen PLUS, the U.S Lifecycle Inventory

Database, and other resources. Figure 6 illustrates the system boundary used in this LCA.

The pre-processing unit inventory analysis involves analyzing the impact of the feedstock

agriculture, transportation, and CO2 absorption. By tracing the feedstock to its source, assuming

the corn is grown in Nevada, IA, the transportation emissions can be estimated. Land use,

fertilizer use and the resulting emissions were quantified as well and explained in detail in the

inventory analysis. Energy inputs to the plant include solar thermal energy, natural gas, and

electricity, with outputs being GHG emissions. Indirect effects, such as utility usage, are not

considered in this analysis.

33

Figure 6: System boundary for LCA for biomass to methanol plant

Inventory Analysis

The pre-processing unit uses corn stover as the biomass feedstock. The analysis of this product

assesses direct influences, such as CO2 emissions from transportation and CO2 absorption of

corn. As well, other factors were evaluated, such as the land use to grow the crop and fertilizer

needed for agriculture and the resulting emissions. A report from Iowa State University cites

the yield of corn stover to be 2.1 dry tons/acre (Zhang, Yanan, 2014). The biomass plant

requires an input of 82,000 tons/yr of feedstock, which equates to 39,048 acres of land/year to

34

provide enough corn stover to fuel the plant. When corn stover is used in biofuels production,

the entirety of the crop is depleted. Otherwise, the majority of the crop residue is left on the

fields to naturally replenish the soil with key elements such as nitrogen (N), phosphorous (P),

and potassium (K). Using all of the corn stover residue will require farmers to purposely

replenish the land with lost nutrients. Replacement rates for N, P, and K fertilizers were

calculated by Argonne Laboratory and are as follows: 7700 g N, 873 g P, and 9957 g K per 1 ton

of removed corn stover (Argonna National Laboratory, n.d.). The results of these calculations

are displayed in Table 8.

Table 8: Environmental factors from the waste feedstock

Factor

Amount

Unit

Land use

39,048

Acres land/year

Fertilizer added - Nitrogen

6.31x108

g N/year

Fertilizer added - Phosphorous

7.16x107

g P/year

Fertilizer added - Potassium

8.16x108

g K/year

N2O emission from added fertilizer

8.37x106

g N2O/year

NO emission from added fertilizer

4.10x108

g NO/year

Further, the CO2 emissions resulting in the transportation of the corn stover to the plant was