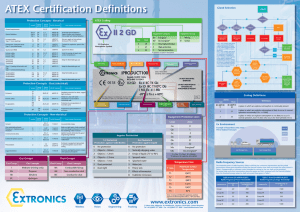

Extronics Products • Explosion Proof & Pressurised Solutions • Engineered Solutions, Bespoke Certification and Development • Training & Certification Services ATEX Certification Definitions Zoning Definitions Categories Zones Gas ATEX Cat. Definitions Dust Non-electrical Equipment Typical Zone Suitability EN 60079-10 EN 61241-10 0 1 2 20 A place in which an explosive atmosphere is continually present 1G 1D Equip. suitable for zone 0 Equip. suitable for zone 20 21 A place in which an explosive atmosphere is likely to occur in normal operation occasionally 2G 2D Equip. suitable for zone 1 Equip. suitable for zone 21 A place in which an explosive atmosphere is not likely to occur in normal operation, but if it does only occurs for short periods 3G 3D 22 IP Code Dusts 1st Numerical 2nd Numerical Protection against Solid Bodies Protection against Liquid 0 1 2 3 4 5 6 0 1 2 3 4 5 6 7 8 No protection Objects > 50mm Objects > 12mm Objects > 2.5mm Objects > 1mm Dust-protected Dust-tight US Enclosure Ratings NEMA, UL & CSA type rating Equip. suitable for zone 2 Equip. suitable for zone 22 Approximate IEC/IP classification 1 2 3 3R 4 IP20 IP22 IP55 IP24 IP66 4X IP66 6 IP67 Zone No protection Vertically dripping water Drops of liquid (75° to 90°) Sprayed water Splashed water Water jets Heavy seas Effects of immersion Indefinite immersion 20 Requires 1D equipment IP6X 21 Requires 1D or 2D equipment IP6X 22 Requires 3D, 2D or 1D equipment IP5X* 0.14 * 0.2 0.35 0.5 0.7 1 5 10 Cable Gland Selection No Is equipment Ex d concept? Yes Yes c EN 13463-6 Control of ignition sources b EC-Type Examination B III EN 13463-7 Pressurisation p Internal Control of Production A VIII EN 13463-8 Liquid immersion k Unit Verification G IX O Production Quality Assurance D IV Y Product Quality Assurance E VII Product Verification F V Conformity to Type C VI Internal Control of Production A VIII Unit Verification G IX KEY ✔ = mandatory unless Unit Verification is used O = optional as an alternative to other modules Y = one of two production phase modules for the equipment category to be chosen by the manufacturer *refer to note 1 Ex e concept Note 1: Non certified cable glands may be used provided that they maintain the minimum IP rating on the certified equipment of IP54 for outdoors and IP20 for indoor equipment. DUST Type of Protection – EN 60079-0 General Requirements ATEX Code Standard – EN 61241-0:2006 Ex ia & ib EN 60079-11 Protection by Enclosures tD EN 61241-1:2004 Increased Safety Ex e EN 60079-7 Protection pD EN 61241-4:2006 Flameproof Ex d EN 60079-1 Intrinsic Safety iD EN 61241-11:2006 Pressurisation Ex p EN 60079-2 Powder Filling Ex q EN 60079-5 Encapsulation Ex ma & mb EN 60079-18 Oil Immersion Ex o EN 60079-6 Type n Ex n EN 60079-15 Temperature T-Class Max surface temp in °C 20 T1 450 T2 300 T3 200 T4 135 T5 100 T6 85 No Encapsulation mD Type n EN60079-15 Enclosed break device Non-incendive component Hermetically sealed device Sealed device Encapsulated device Energy limited apparatus & circuits Restricted breathing enclosure Non sparking Does the hazardous gas require IIC apparatus? Yes Ex e concept Gland type Use a barrier gland Yes Is the volume of enclosure greater than 2 dm3? O O ✔*4 ✔ O O O O O Y Y Y Y Y Y Y Y Y ✔ O O O ✔ O O O ✔ O O II Electrical equipment intended for use in places with an explosive gas atmosphere other than mines susceptible to firedamp III Electrical equipment intended for use in places with an explosive dust atmosphere other than mines susceptible to firedamp* Gas Groups EN 61241-18:2004 nC nC nC nC nC nL nR nA Brass Does this enclosure contain an internal source of ignition? Propane IIIA Combustible Flyings IIB Ethylene IIIB Non-conductive Dust IIC Hydrogen/Acetylene IIIC Conductive Dust *Taken from the new IEC60079-0 2007 Simple Apparatus Passive components EN1127-1 Explosive atmospheres - Explosion prevention and protection. Part 1, Basic concepts & methodology for surface industry EN1127-2 Explosive atmospheres - Explosion prevention and protection. Part 2, Basic concepts & methodology for mining EN60079-10 Classification of hazardous areas EN60079-14 Electrical installations in hazardous areas (other than mines) EN60079-17 Electrical installations inspection and maintenance EN60079-19 Equipment repair, overhaul and reclamation EN60079-28 Protection of equipment and transmission systems using optical radiation Marking for Dust or Flyings and Fibres Hazards *refer to note 2 II 2 G Ex d IIC T4 XXXX EC Mark Gas Type of Protection Explosion Protection Equipment Category Sources of generated energy not more than *1.5V, 100mA & 25mW NOT piezoelectric crystal protected components voltage or current enhancement Temperature Gas Group* Class A, B or C (T1-T6) * Note: North America still uses 1.2V and 20 microjoules *If omitted suitable for all gas groups III 2 D Ex tD A21 IP66 T80°C XXXX Complies with European Directive Equipment Group EC Mark Equipment Group Notified Body Number Dust Equipment Category Type of Protection Ingress protection and max. surface temperature Explosion Protection The threshold power of radio frequency (10 kHz to 300 GHz) for continuous transmissions and for pulsed transmissions whose pulse durations exceed the thermal initiation time shall not exceed the values shown in Table 4. Programmable or software control intended for setting by the user shall not be permitted. For pulsed radar and other transmissions where the pulses are short compared with the thermal initiation time, the threshold energy values Zth shall not exceed those given in Table 5. Table 4 from IEC 60079-0 Radio Frequency Power Thresholds No No Well defined sources of stored energy considered in safety analysis Radio Frequency Sources Use certified cable glands No Is the area of installation of Zone 1? Dust Groups* IIA Assessment of inadvertent ignition of flammable atmospheres by radio frequency radiation (guide) Notified Body Number *refer to note 3 No ✔*4 ✔ Electrical equipment intended for use in mines susceptible to firedamp BS6656 Ex n* or N concept Plastic Yes ✔ Other Useful Standards Marking for Gas Hazards Use non-certified cable glands Yes ✔ 5V in Zone 2 No Note 2: Non certified cable glands may be used provided they meet the requirements of EN60079-0 and EN60079-7 or EN60079-15. Note 3: Internal sources of ignition include sparks or equipment temperatures occurring in normal operation which can cause ignition. An enclosure containing terminals only or an indirect entry enclosure is considered not to constitute an internal source of ignition. ✔ I Yes Refer to Ex d cable selector chart ✔ Production Phase * Notes: 1 “Global Approach” OJEC No.L220, 1993 2 ATEX Directive 94/9/EC 3 Suffix (E) refers to electrical equipment and internal combustion engines Suffix (N) refers to non-electrical equipment 4 Technical Files to be deposited with a notified body Complies with European Directive Use non-certified cable glands Design Phase Conformity Assessment ‘Quality Modules’ Table General Requirements Is area zoned? Zone 1? No Constructional safety Standard START Yes Is equipment Ex i concept? d EN 13463-5 ATEX Code IK08 IK09 IK10 2 fr Flame-proof enclosure GAS Type of Protection Intrinsic Safety Mechanical Impacts (UK) Code EN50102 Impact Energy (Joules) Flow restricting enclosure EN 13463-3 Types of Protection Indoor, from contact with contents Indoor, limited, falling dirt and water Outdoor, from rain, sleet, windblown dust & ice damage Outdoor, from rain, sleet & ice damage Indoor & outdoor, from windblown dust, rain, splashing & hose directed water & ice damage Indoor & outdoor, from corrosion, windblown dust, rain, splashing & hose directed water & ice damage Indoor & outdoor, from hose directed water, water entry during submersion & ice damage IK06 IK07 EN 13463-2 Protective System Groups Abbreviated Protection Description IK01 IK02 IK03 IK04 IK05 Module Annex Equipment Category *3 *1 *2 M1 M2 M2 1 2 2 3 (E) (N) (E) (N) Basic methods & requirements * Must be IP6X if dust is electrically conductive NEMA 7 to 10 Hazardous Area Enclosures IK Code IK00 IP Rating ATEX Category Conformity Assessment ‘Quality Modules’ (concepts) EN 13463-1 Use a suitable flameproof cable gland with a sealing ring. (Gland with elastomeric seals) Table 5 from IEC 60079-0 Radio-frequency Energy Thresholds Equipment for Threshold power (W) Thermal Initiation Time (averaging period) (µs) Equipment for Threshold Energy Zth (µJ) Group I 6.0 200 Group I 1500 Group IIA 6.0 100 Group IIA 950 Group IIB 3.5 80 Group IIB 250 Group IIC 2.0 20 Group IIC 50 Group III 6.0 200 Group III 1500 Extronics Ltd · Meridian House · Roe Street · Congleton · Cheshire · CW12 1PG · Tel: +44 (0)1260 292651 · Fax: +44 (0)1260 297280 · www.extronics.com · info@extronics.com The information in this wall chart is for guidance only. For detailed information see relevant Directives and Regulations. © Extronics Ltd 2008 07/08