Statistical Quality Control: Control Charts Explained

advertisement

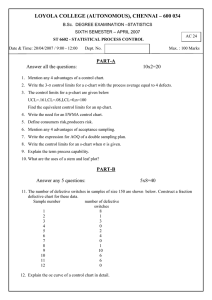

Quality Control Introduction • Statistical Quality Control is a process of maintaining quality of industrial products under some standard specifications. • The term ‘quality’ in statistical quality control means an attribute of the product that determines its fitness for use. • In fact, quality means level of standard which in turn depends on four M’s and they are- materials, manpower, machines and management. • Two apparently identical parts made under carefully controlled conditions, from the same batch of raw material, and only seconds apart by the same machine, can nevertheless be different in many respects. • Any manufacturing process, however good, is characterized by a certain amount of variability, which is of random nature and which cannot be completely eliminated. • In fact, variation in the quality of manufactured product in the repetitive process in industry is inherent and inevitable. • These variations are broadly classified as being due to the two causes, they are … – Chance causes – Assignable causes • Chance causes of variations results from many minor causes that behave in a random manner. The variations due to these causes is beyond the control of human hand and cannot be prevented/ eliminated under any circumstances. • The range of such variation is known as ‘natural tolerance of the process’. • The second type of variation attributed to any production process is due to non-random causes, so called assignable causes. • These type of variation may occur at any stage of production process, i.e., right from the arrival of raw material to final delivery of the manufactured products. • Some of the important factors of assignable causes of variation are– defective raw materials – new technology or operation – negligence of operators – improper handling of machines – faulty equipments – unexperienced technical staffs, etc. • These causes can be identified and eliminated and are to be discovered in a production process before the production becomes defective. • Statistical Quality Control (SQC) is the method of identifying presence of assignable causes in any production process. • The main purpose of SQC is to devise statistical technique which would help us in separating the assignable causes from the chance causes, thus enabling us to take immediate remedial action whenever assignable causes are present. • A production process is said to be statistically under control, if it is governed by the random or chance causes alone, in the absence of assignable causes of variations. • SQC helps in the detection and correction of many production troubles and substantial improvement in the product quality. • It tells us when to leave a process alone and when to take action to correct troubles, thus preventing frequent and unwanted adjustments. • It provides better quality assurance at lower inspection cost. • SQC reduce waste of time and material to the absolute minimum by giving an early warning of the cost of production and hence may lead to more profit. • One of the methods used to detect the presence of assignable cause of variation in a production process is ‘Cotrol Chart’. Control Chart - Introduction • Control chart is a simple pictorial device for detecting unnatural pattern of variation in data resulting from repetitive processes. • The concept of control chart was first discovered and developed by Walter A. Shewart, a physicist, in 1924. • These charts provide criteria for detecting lack of statistical control. • Control charts are based on the theory of probability and sampling. • Control charts provide a powerful tool of discovering and correcting the assignable causes of variation, thus enabling us to stabilize and control processes at desired performance and thus bring the process under statistical control. • Control charts are simple to construct and easy to interpret. • In fact, control charts tell us whether the sample points fall within 3 limits or not. • Any sample point going outside the 3 limits is an indication of lack of control, i.e., presence of some assignable causes of variation which must be identified and eliminated. Basic Theory of Control Chart • No production process is perfect enough to produce all the items exactly alike. Some amount of variation in the produced items is inherent in any production scheme. This variation is the result of both chance causes and assignable causes. • Considering that the measurements are sample statistics from a normal population X, we have P( - 3σ X + 3σ) = 0.99 • These two limits - 3σ and + 3σ are used in control charts for detecting whether a process is in control or not. The limit represented by - 3σ is called lower control limit (LCL) and the limit represented by + 3σ is called upper control limit (UCL). So, – LCL = - 3σ, and – UCL = + 3σ • Since for normal population X, = E(X) and σ2 = V(X) , so it follows that LCL E( X ) 3 V ( X ) UCL E( X ) 3 V ( X ) Types of Control Charts • Following two types of control charts are used as most important statistical tools for data analysis in quality control– A) Control charts for measurements (variables) – B) Control charts for attributes Control Chart for Measurement • Control charts for measurement includes (a) Control Charts of process mean and (b) Control charts for process variability Control Chart for Process Mean • Control charts for process mean is also called X chart. • It is a statistical tool used to detect the presence of assignable cause of variation in a production process by studying the variation in means of sample observations. • The process of constructing X chart consists of drawing ‘k’ number of samples each containing ‘n’ units as follows- Day 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Obervations of Transaction Time 63 55 56 53 60 63 60 65 57 60 61 65 58 64 60 61 79 68 65 61 55 66 62 63 57 61 58 63 58 51 61 57 65 66 62 68 73 66 61 70 57 63 56 64 66 63 65 59 63 53 69 60 68 67 59 58 70 62 66 80 65 59 60 61 63 69 68 56 61 56 62 59 65 57 69 62 70 60 67 79 61 61 66 57 74 56 55 66 61 72 62 70 61 65 71 62 70 61 55 58 • Then the means of all ‘k’ samples are computed and these means are plotted against the sample number as follows: Day 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Obervations of Transaction Time 63 55 56 53 60 63 60 65 57 60 61 65 58 64 60 61 79 68 65 61 55 66 62 63 57 61 58 63 58 51 61 57 65 66 62 68 73 66 61 70 57 63 56 64 66 63 65 59 63 53 69 60 68 67 59 58 70 62 66 80 65 59 60 61 63 69 68 56 61 56 62 59 65 57 69 62 70 60 67 79 Average 61 57.6 61 61.8 66 61.8 57 60 74 69.4 56 60.4 55 58.8 66 58.6 61 64.4 72 68.4 62 60.4 70 64.6 61 61.2 65 63.4 71 69.8 62 61.4 70 65.2 61 59.8 55 61.6 58 66.8 Average 80 70 60 50 40 Average 30 20 10 0 0 5 10 15 20 25 • The final step is to locate three lines, namely, central line (CL), lower control line (LCL) and upper control line (UCL) in the chart. • We consider following cases for constructing these control lines • Case I – When process mean and standard deviation are known (with values and ) • In this case CL LCL 3 UCL 3 n n • Sometime, CL LCL A UCL A where, 𝑨 = 𝟑 𝒏 its value for different levels of n are given in control chart table. The control chart table is shown below- • In above example, if it is known from any source that process mean (or population mean) is 60 and process standard deviation is 2.5, then CL 60 2.5 LCL 3 60 3 56.65 n 5 2.5 UCL 3 60 3 63.35 n 5 • So that complete X-bar chart looks like UCL CL LCL CL 60 2.5 LCL 3 60 3 56.65 n 5 2.5 UCL 3 60 3 63.35 n 5 • In the control chart, if all the points lie between LCL and UCL, then it is interpreted that there are only random causes of variation and there are no assignable cause of variation in the process, or, the process is in controlled condition. • If many points lie beyond LCL and UCL, then it is interpreted that there are assignable causes of variation in the process, or, the process is out of control. • Case II – When process mean and standard deviation are unknown • In this case, it is necessary to estimate them on the basis of preliminary samples. • For the estimation of process mean, usually the grand mean of all ‘k’ samples is calculated as 𝒙 and it is used as the estimate of . 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 60 57 58 79 55 57 58 65 73 57 66 63 68 70 65 63 61 65 70 63 60 64 68 66 61 51 66 66 63 63 53 67 62 59 69 56 57 60 60 61 60 65 62 58 61 62 61 56 65 69 59 66 60 68 62 69 67 65 65 61 61 63 63 57 68 70 64 59 60 58 80 61 56 59 62 79 Grand Average 61 66 57 74 56 55 66 61 72 62 70 61 65 71 62 70 61 55 58 61.8 61.8 60 69.4 60.4 58.8 58.6 64.4 68.4 60.4 64.6 61.2 63.4 69.8 61.4 65.2 59.8 61.6 66.8 62.77 • For the estimation of , there are two methods. One is to consider sample standard deviation and another is to consider sample range. • For the construction of X-bar chart based on sample standard deviation, first of all the standard deviation of all ‘k’ samples (each containing ‘n’ units) is computed by formula 1 n si xij xi n j 1 2 • Then the average of these standard deviations is computed by formula 1 k s si k i 1 Day 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Obervations of Transaction Time 63 55 56 53 60 63 60 65 57 60 61 65 58 64 60 61 79 68 65 61 55 66 62 63 57 61 58 63 58 51 61 57 65 66 62 68 73 66 61 70 57 63 56 64 66 63 65 59 63 53 69 60 68 67 59 58 70 62 66 80 65 59 60 61 63 69 68 56 61 56 62 59 65 57 69 62 70 60 67 79 Grand Average Average Std. Dev. 61 57.6 4.219005 61 61.8 2.167948 66 61.8 3.701351 57 60 2.738613 74 69.4 7.162402 56 60.4 4.722288 55 58.8 3.193744 66 58.6 5.504544 61 64.4 2.880972 72 68.4 4.929503 62 60.4 3.646917 70 64.6 4.037326 61 61.2 5.761944 65 63.4 4.615192 71 69.8 6.723095 62 61.4 2.302173 70 65.2 5.80517 61 59.8 2.387467 55 61.6 5.727128 58 66.8 8.408329 62.77 4.531756 • Next, after plotting sample means in graph the control lines are determined by using formulas CL x LCL x A1 s UCL x A1 s • Here, A1 is a constant and its value is determined from control chart table shown below- • For the construction of X-bar chart based on sample range, first of all the ranges of all ‘k’ samples are computed and then the average of these ranges is computed as 𝑹. Day 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Obervations of Transaction Time 63 55 56 53 60 63 60 65 57 60 61 65 58 64 60 61 79 68 65 61 55 66 62 63 57 61 58 63 58 51 61 57 65 66 62 68 73 66 61 70 57 63 56 64 66 63 65 59 63 53 69 60 68 67 59 58 70 62 66 80 65 59 60 61 63 69 68 56 61 56 62 59 65 57 69 62 70 60 67 79 Grand Average Average Range 61 57.6 10 61 61.8 5 66 61.8 9 57 60 7 74 69.4 18 56 60.4 11 55 58.8 8 66 58.6 15 61 64.4 7 72 68.4 12 62 60.4 8 70 64.6 11 61 61.2 16 65 63.4 10 71 69.8 18 62 61.4 6 70 65.2 14 61 59.8 6 55 61.6 14 58 66.8 21 62.77 11.3 • Then, after plotting sample means in graph the control lines are determined by using formulas CL x LCL x A2 R UCL x A2 R • Here, the value of constant A2 is obtained from control chart table. • For observation given in above table, X-bar chart based on R is constructed as follows• Here x 62.77 • From control chart table, for n = 5, A2 = 0.577 • Also, R 11.3 • So, CL x 62.77 LCL x A2 R 62.77 0.577 11.3 56.25 UCL x A2 R 62.77 0.577 11.3 69.29 UCL CL LCL Control Chart for Process Variability • In controlling a process, it may not be enough to monitor the process mean, but it is also required to monitor process variability. Although an increase in process variability may become more apparent from increased fluctuations on the X ’s, a more sensitive test of shifts in process variability is provided by separate control charts namely (a) -chart and (b) R-chart. - Chart • Not required R - Chart • R-chart measures process variability based on sample ranges. • In this chart, it is assumed that the distribution of range of samples is approximately normal. • For the construction of R-chart, ‘k’ number of samples each containing ‘n’ units are taken randomly. • Then the range of each sample is obtained. • Next, these ranges are plotted against the sample number. Day 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Obervations of Transaction Time 63 55 56 53 60 63 60 65 57 60 61 65 58 64 60 61 79 68 65 61 55 66 62 63 57 61 58 63 58 51 61 57 65 66 62 68 73 66 61 70 57 63 56 64 66 63 65 59 63 53 69 60 68 67 59 58 70 62 66 80 65 59 60 61 63 69 68 56 61 56 62 59 65 57 69 62 70 60 67 79 Range 61 61 66 57 74 56 55 66 61 72 62 70 61 65 71 62 70 61 55 58 10 5 9 7 18 11 8 15 7 12 8 11 16 10 18 6 14 6 14 21 25 20 15 R a n g e 10 5 0 0 5 10 15 Sample Number 20 25 • For determination of control lines in the chart we consider following cases• Case I – When process standard deviation is known • Let the known value of population standard deviation be , then control lines are given by CL d 2 LCL D1 UCL D2 • Where the values of d2, D1 and D2 are given in control chart tables for different values of ‘n’. • Case II – When process standard deviation is unknown • In this case, the average of sample ranges is computed as 𝑹. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 63 60 57 58 79 55 57 58 65 73 57 66 63 68 70 65 63 61 65 70 55 63 60 64 68 66 61 51 66 66 63 63 53 67 62 59 69 56 57 60 56 60 61 60 65 62 58 61 62 61 56 65 69 59 66 60 68 62 69 67 53 65 65 61 61 63 63 57 68 70 64 59 60 58 80 61 56 59 62 79 61 61 66 57 74 56 55 66 61 72 62 70 61 65 71 62 70 61 55 58 Average 10 5 9 7 18 11 8 15 7 12 8 11 16 10 18 6 14 6 14 21 11.3 • Finally, the control lines are determined by following formulas CL R LCL D3 R UCL D4 R • In above problem, 𝑹 = 11.3. From control chart table, for n = 5, D3 = 0 and D4 = 2.114, so CL R 11.3 LCL D3 R 0 UCL D4 R 2.114 11.3 23.9 25 UCL 20 15 R a n g e CL 10 5 LCL 0 0 5 10 15 Sample Number 20 25 Control Chart for Attributes • Although more complete information can usually be gained from measurements on a finished product, it is often quicker and cheaper to check the product against specifications on an “attribute” basis. • In spite of wide applications of 𝑿 and R (or ) charts for detecting the assignable causes of variations in a production process, their use is restricted because firstly they are charts for variables only, i.e., for quantity characteristics which can be measured and expressed in number and secondly, in some cases they are impracticable and un-economic to construct. • In situations like this it would be more appropriate to construct the control charts for attributes. • There are following types of control charts of attributes1. Control chart for the number of defectives (np or d-chart) 2. Control charts for fraction defectives (p-chart) 3. Control chart for number of defective per unit (c-chart) d-Chart or np-Chart • In manufacturing process, it is also called ‘control chart for number of defectives’. • For the construction of d-chart, first ‘k’ samples each of size ‘n’ are taken randomly and the number of defectives in each sample is observed. • Let ‘d’ be number of defectives in a sample, then in this type of chart ‘d’ is plotted against the sample number as follows: • Data on 30 days for number of late flights out of 240 takeoffs daily are presented below26 19 26 22 24 19 19 20 18 18 17 9 13 10 12 14 14 13 9 10 12 15 14 15 16 18 17 16 18 17 30 26 26 25 24 22 20 20 19 19 19 18 18 18 17 18 17 16 15 15 14 14 13 16 15 Ряд1 14 13 12 10 17 12 10 10 9 9 5 0 0 5 10 15 20 25 30 35 • For determination of control lines we proceed as follows: • Here, ‘d’ is number of defectives in a sample of size ‘n’, so sample fraction defective is d p n • So that d p n • If the actual or true proportion of defectives in the population from which samples are drawn is ‘P’, then ‘d’ is a random variable having binomial distribution with parameters ‘n’ and ‘P’, i.e., 𝒅~𝑩 𝒏, 𝑷 • So that, 𝑬 𝒅 = 𝒏𝑷 and 𝑽 𝒅 = 𝒏𝑷 𝟏 − 𝑷 • Thus, 3-control limits for d-chart are given by E(d ) 3 V (d ) nP 3 nP(1 P) • We consider following cases• Case I – When population proportion is known • Let the known population proportion be P0, then control lines are given by CL E (d ) nP0 LCL E (d ) 3 V (d ) nP0 3 nP0 (1 P0 ) UCL E (d ) 3 V (d ) nP0 3 nP0 (1 P0 ) • Case II – When population proportion is unknown • In this case since population fraction defective is not known, so the sample fraction defective (or sample proportion) of all samples are calculated by di pi ni • Then average of all sample proportions are calculated by 1 k p pi k i 1 • This value is used in place of population proportion for defining control lines as- CL n p LCL n p 3 n p (1 p ) UCL n p 3 n p (1 p ) • Since p cannot be negative, so, if LCL given by the above formula comes out to be negative, then it is taken to be 0. p-Chart • It is also called ‘control chart for fraction defectives’. • For the construction of p-chart, first ‘k’ samples each of size ‘n’ are taken randomly and the number of defectives in each sample is observed. • Let ‘d’ be the number of defectives in a sample. • So that sample proportion is given by d p n • In p-chart, the sample proportion ‘p’ is plotted against the sample number. • For example, for data on flight delays, presented above, sample proportions are calculated and pchart is constructed as shown below- • Data on 30 days for number of late flights out of 240 takeoffs daily are presented below26 19 26 22 24 19 19 20 18 18 17 9 13 10 12 14 14 13 9 10 12 15 14 15 16 18 17 16 18 17 • Sample proportions are calculated below Day 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Delays 26 19 26 22 24 19 19 20 18 18 17 9 13 10 12 Proportion Day 0.11 0.08 0.11 0.09 0.1 0.08 0.08 0.08 0.08 0.08 0.07 0.04 0.05 0.04 0.05 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Delays Proportion 14 14 13 9 10 12 15 14 15 16 18 17 16 18 17 0.06 0.06 0.05 0.04 0.04 0.05 0.06 0.06 0.06 0.07 0.08 0.07 0.07 0.08 0.07 Formula ?? p=d/n=26/240 • p-chart is shown below0,12 0,1 0,08 0,06 Ряд1 0,04 0,02 0 0 5 10 15 20 25 30 35 • For determination of control lines we proceed as follows• As discussed above in ‘d’ chart 𝒅~𝑩 𝒏, 𝑷 • So that E (d ) nP V (d ) nP(1 P) • Since, sample proportion ‘p’ is given by d p n • So, 1 d 1 E ( p) E E (d ) nP P n n n • Also, 1 P(1 P) d 1 V ( p) V 2 V (d ) 2 nP(1 P) n n n n • We consider following cases• Case I – When population proportion is known • Let the known population proportion be P0, then control lines are given by CL E ( p) P0 P0 (1 P0 ) LCL E ( p) 3 V ( p) P0 3 n P0 (1 P0 ) UCL E ( p) 3 V ( p) P0 3 n • Case II – When population proportion is unknown • In this case since population fraction defective is not known, it is replaced by average of sample fraction defective, or average of sample proportions given by k 1 p pi k i 1 • Or, equivalently k p k d n p i 1 k i n i 1 i i 1 k i i n i 1 i • So, control lines are given by CL p p(1 p) LCL p 3 n p(1 p) UCL p 3 n • For example, in above problem, average of sample proportions is calculated as follows: Day 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Delays 26 19 26 22 24 19 19 20 18 18 17 9 13 10 12 Proportion Day 0.11 0.08 0.11 0.09 0.1 0.08 0.08 0.08 0.08 0.08 0.07 0.04 0.05 0.04 0.05 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Delays Proportion 14 0.06 k 1 14 0.06 p pi 13 0.05 k i 1 9 0.04 10 10.04 12 0.050.11 0.08 ...... 0.07 30 15 0.06 14 0.06 15 0.06 0.068 16 0.07 18 0.08 17 0.07 16 0.07 18 0.08 17 0.07 • Alternatively, it can also be calculated by using formula k Day Delays Proportion Day Delays Proportion di 1 26 0.11 16 14 0.06 2 19 0.08 17 14 0.06 p i k1 3 26 0.11 18 13 0.05 ni 4 22 0.09 19 9 0.04 5 6 7 8 9 10 11 12 13 14 15 24 19 19 20 18 18 17 9 13 10 12 0.1 0.08 0.08 0.08 0.08 0.08 0.07 0.04 0.05 0.04 0.05 20 21 22 23 24 25 26 27 28 29 30 i 1 10 0.04 12 26 0.05 19 26 ........ 17 15 0.06 240 240 .........30times 14 0.06 15 0.06 16 0.07 490 0.068 18 0.08 7200 17 0.07 16 0.07 18 0.08 17 0.07 • Thus control lines are given by CL p 0.068 p(1 p) 0.068(1 0.068) LCL p 3 0.068 3 n 240 p(1 p) 0.068(1 0.068) UCL p 3 0.068 3 n 240 CL 0.068 LCL 0.019 UCL 0.12 • Complete p-chart is shown belowUCL CL LCL c-Chart • It is also called ‘control chart for number of defects’. • Before discussing the theory behind c-chart, it is required to distinguish between defect and defective. • An article which does not confirm to one or more of the specifications is termed as defective while any instance of article’s lack of confirming to specification is a defect. • Thus every defective contains one or more of the defects. • Unlike a ‘d’ chart, which is related to the number of defectives in a sample, c-chart is related to the number of defects per unit. • Sample size for c-chart may, thus, be a single unit like a radio or a group of units. • While considering the distribution of number of defects in a manufacturing process, we may need to note two essential points• The chance for a defect to occur in any position of the manufactured product is sufficiently large. • The chance of a defect occurring in any particular position is very small. • In such situation, from statistical theory we know that the patterns of variations in data can be represented by Poisson distribution and consequently the 3 control limits based on Poisson distribution are used. • Thus c-chart is based on Poisson distribution. • If c denotes the number of defects in an item, then c is Poisson distribution with parameter, say . • Here, E(c) = and V(c) = , so control limits are given by: CL E (c) LCL E (c) 3 V (c) 3 UCL E (c) 3 V (c) 3 • Case I – If population parameter of the underlying Poisson distribution is known (to be 0, which is the average number of defects in entire population). In this case, CL 0 LCL 0 3 0 UCL 0 3 0 • Case II – If population parameter is not known• In this case grand average of number of defects of entire samples is calculated by 1 k c ci k i 1 where, ci is the number of defects in the ith sample. The unknown population parameter is replaced by it, so the control lines are given by CL c LCL c 3 c UCL c 3 c • Problem – A flow solder machine is used to make mechanical and electrical connections of the leaded components on a printed circuit board. The boards are run through the flow solder process almost continuously, and every hour five boards are selected and inspected for process control purpose. The number of defects in each sample of five boards is given below- Sample 1 2 3 4 5 6 7 8 9 10 No. of Defects 6 4 8 10 9 12 16 2 3 10 Sample 11 12 13 14 15 16 17 18 19 20 No. of Defects 9 15 8 10 8 2 7 1 7 13 Construct c-chart for above data to determine whether the process is in controlled condition. c-chart is shown below by plotting number of defects against sample number- • To determine whether the process is in controlled condition, we need to identify CL, LCL and UCL. • Since the process parameter is not known, so we use CL c LCL c 3 c UCL c 3 c • Here, 1 c 6 4 ...... 13 8 20 • So, CL c 8 LCL c 3 c 8 3 8 0, set to 0 UCL c 3 c 8 3 8 16.484 • Complete c-chart is shown below- UCL CL LCL u-Chart • If number of unit in difference samples is not same, then c-chart is meaningless. In such case, instead of actual number of defects in the sample, average number of defects in each sample is plotted and such a chart is called u-chart. • It is also called defects per unit charge. • If ‘c’ is number of defects in the sample of ‘n’ units then average number of defects per unit is c u n • If process parameter is not known, it is replaced by 1 k u ui k i 1 where ui is the average number of defects in the ith sample. • So, control lines are given by CL u u LCL u 3 n u UCL u 3 n • Problem – To draw u-chart for data presented above in construction of c-chart. • Working table is shown below- Sample no. No. of defects Defects per unit Sample no. No. of defects Defects per unit 1 2 6 4 1.2 0.8 11 12 9 15 1.8 3.0 3 4 5 8 10 9 1.6 2.0 1.8 13 14 15 8 10 8 1.6 2.0 1.6 6 7 12 16 2.4 3.2 16 17 2 7 0.4 1.4 8 9 10 2 3 10 0.4 0.6 2.0 18 19 20 1 7 13 0.2 1.4 2.6 Total 32 • Here to find defects per unit, number of defects is divided by sample size, i.e., by 5. • Here, 1 k 1 u ui x32 1.6 k i 1 20 • So, CL u 1.6 u 1.6 LCL u 3 1.6 3 3.3 n 5 u 1.6 UCL u 3 1.6 3 0 so set to 0. n 5 • U-chart is shown belowUCL CL LCL Control chart for individual measurement • In all types of control charts so far we discussed, more than one units are taken as sample. Taking observations of many units, in some cases, may be too costly and more time consuming. • In such cases, only one unit is observed in each sample. • Each observation is plotted in graph and to define control lines, difference between successive observations are calculated. • The absolute value of such difference is called moving range (MR). • Following expressions are used to define control lines for such control chart of individual observations- CL x MR LCL x 3 d2 MR UCL x 3 d2 where 𝒙 is mean of individual observations and 𝑴𝑹 is average of moving ranges. The value of d2 is taken to be 1.128 from control chart table for n = 2, since moving range is obtained by considering two sample units. • Problem – Batches of a particular chemical product are selected from a process and the purity on each is measured. Data for 15 successive batches are given below0.77, 0.76, 0.77, 0.72, 0.73, 0.73, 0.85, 0.70, 0.75, 0.74, 0.75, 0.84, 0.79, 0.72, 0.74. To draw control chart- Batch Purity (x) Moving Range |MR| 1 0.77 (Leave it blank) 2 0.76 0.01 3 0.77 0.01 4 0.72 0.05 5 0.73 0.01 6 0.73 0.00 7 0.85 0.12 8 0.70 0.15 9 0.75 0.05 10 0.74 0.01 11 0.75 0.01 12 0.84 0.09 13 0.79 0.05 14 0.72 0.07 15 0.74 0.02 Total 11.36 0.65 1 x 11.36 0.757 15 1 MR 0.65 0.046 14 CL x 0.757 MR 0.046 LCL x 3 0.057 3 0.635 d2 1.128 MR 0.046 UCL x 3 0.057 3 0.879 d2 1.128 UCL CL LCL