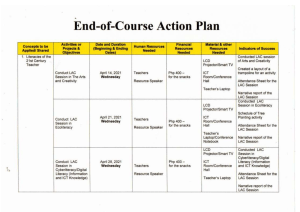

POSITION

CONTENT

EQUIPMENT

REQUIRED

CONTROL

ASSIGNMENT

SYSTEM

The use of motor drive in an open

system is investigated.

loop positional control

Qty

Designation

Description

1

OA150A

Op Amp Unit

AU150B

Attenuator Unit

PA150C

Pre-Amp Unit

SA150D

Servo Amplifier

PS150E

Power Supply

DCM150F

DC Motor

IP150H

Input Potentiometer

OP150K

Output Potentiometer

GT150X

Reduction Gear Tacho Unit

DC Voltmeter 30-0-30V

(or voltmeter in GT150X)

PRELIMINARY

PROCEDURE

mM

Attach the OA150A, PS150E, IP150H and OP150K to the

Baseplate by means of the magnetic fixings.

m™

Connect the Power Supply to the mains supply line. DO

NOT switch on yet.

56

5

oa (ae fi eine tot te ee

SIMPLE

*

Modular Servo

Scanned

by CamScanner

Scanned by

|b bok

ww

Modular Servo

SIMPLE

POSITION

OBJECTIVE

CONTROL

ASSIGNMENT

5

When you have completed this assignment you will:

™

M™

KNOWLEDGE

LEVEL

SYSTEM

Have observed the operation of a basic open-loop position

control system.

Appreciate the need for closed-loop feedback in a position

control system.

Before starting this assignment you should:

M™

Be familiar with the components of the DC Modular Servo

and preferably have completed Assignment 1,

Familiarisation.

Understand the term ‘error channel’.

mM

Understand how two rotary potentiometers can be used to

form an error channel.

BELEK

EUDUDU

UU

Mm

a7

Scanned

by CamScanner

Scanned by

Position

INTRODUCTION

Control

System

Assignment

5

Two rotary potentiometers can be used to generate an error

signal to show the misalignment of the output cursor with that

of the input cursor.

Now if the output potentiometer is mounted on the shaft of a

geared motor, we would have the basis of an automatic

position control system. That is, we use the error signal to drive

the motor in a direction such as to reduce the misalignment to

zero.

Before going on to carry out such an investigation, it would be

as well to see what happens in a manual system.

So

set up as in fig 3.5.1, but remember

students

will

to

work

together

to

that ideally two

carry

out

the

al uk kk

investigation.

have

©) Input Praeriicameter

®

Op. Awp. Unit OAISOA

Fig 3.5.1

58

(alla ec at a ft a Mat

Simple

nn el eu el ede bee

Modular Servo

Scanned

by CamScanner

Scanned by

Modular Servo

Glinple

Poaltion Control System

PRAGCTIGAL

Manual

Control

Assignment

5

6.4

Posttion

System

Sel the feedback selector switch on the OA150A to the 100kQ

resistor,

Set the rotary potentiometers to zero and zero

operational amplifier output, using the voltmeter.

set the

Initially one student should slowly turn the knob on the input

potentiometer and set it at any value in the ranges 0 to -15V

and 0 to 415V.

Let the other student watch the voltmeter connected to the

output Vo and by turning the shaft of the other

potentlometer return the voltmeter reading to zero.

rotary

After setting the input cursor to various positions, each time

first returning to zero, try seeing if the student operating the

output potentiometer can manage to keep the needle of the

voltmeter at zero if the position of the input is slowly and

continuously varied.

Finally, try suddenly changing the position of the input cursor,

whilst attempting to keep the error at zero.

Question

5.1

Write down

the needle,

zero point.

your observations on what

for the different inputs, as

happened

it neared

to

its

You will, no doubt have noticed that it was quite easy to get the

voltmeter to register zero for a slow movement but when the

movement was fast (step input), the correcting action needed

to bring the needle to zero could not occur immediately

because of over-compensation or what is known as overshoot.

Now if we analyse our experiment we can see that the position

of the input potentiometer slider gives us a reference voltage

and that the position of the output potentiometer slider is used

to feed back an inverted signal that is summed and compared

in the operational amplifier to form our error signal Vo, which

will then give a reading on the voltmeter.

In this system muscle power is the Controller with finger

movement being used as the Actuator. There is even a stage

of pre-amplification in which our eye observes the meter

reading and signals the brain to send a message along the

nerve fibres to the muscles in our arm and hand.

=

Scanned

by CamScanner

Scanned by

CamScanner

Modular Servo

reference

{ transducer

+

3

3

comparator

(eyes)

—

pre-amplifier

(input

:

: potentiometer) }

oeneacacncsecnst

5

Assignment

System

Control

Position

|

actuator

controller

(brain)

(muscles)

(fingers)

transducer

(output

jg $<

potentiometer)

Fig 3.5.2

Because in fig 3.5.2 information is fed back for comparison

with a reference signal, the system is a closed loop one.

We

are

now

going to show

how the motor can

be used

make a simple automatic positional control system. As a

to

first

step we shall simply cause the motor, through a gear box, to

drive the shaft on the output

position.

What

sort

of

automatic

control

system

would

As there is no electrical feedback signal to form

signal, the system is an open loop one.

an

this

error

be?

PTT

5.2

anapnpp?

Question

potentiometer to a required

IEeeee)

Simple

60

Scanned

by CamScanner

Scanned by

Modular Servo

Simple

Position

Control

System

Assignment

5

6

tT

8

YY

Pi Feedback

DCMI150F

LE

ren

/

owe

deM

|

/

i

Reduction Gear Tacho Unit

/

O_))

w

1

Oo

ov

a

1

Jum

@a Sow

Fl input Potentiometers

eet | El ouput Potentiometer

PASAT

°

OPIS

Fig 3.5.3

62

Scanned

by CamScanner

Scanned by

a

Modular Servo

Simple Position Control System

PRACTICAL

5.2

Assignment 5

Attach the AU150B, SA150D and DCM150F to the Baseplate

by means of the magnetic fixings.

Fix the plug from the Servo Amplifier into the Power Supply.

Fix the plug from the Motor Unit into the Servo Amplifier.

Attach the GT150X to the baseplate by means of the magnetic

fixing and position it so that it is connected to the motor shaft

by means of the flexible coupling.

Set up as in fig 3.5.3

A simple

open-loop

Control

motor-driven

Position

System

Use the push-on

coupling to link a low-speed

GT150X to the output potentiometer shaft.

Starting

with

AU150B

the

potentiometer

knob

shaft of the

at the

fully

counter-clockwise position gradually turn it till the motor just

rotates and record:

Scale position at which the

motor just rotates

(1)

Direction in which the output

rotary potentiometer moves

(2)

Return the output rotary potentiometer cursor to zero by turning

the GT150X high-speed shaft.

Decide on a position in the direction (2), you wish the

potentiometer shaft to turn to and then turn the AU150B

potentiometer knob to position (1). As the cursor nears the

required angle, reduce this input signal so that the cursor

comes to rest nearly at the required point.

Repeat using increasingly large input signals instead of value

(1).

Question

5.3

What happens as you try to get

rest at the required angle?

the

cursor

to

come

to

The system is limited in that the motor drive was unidirectional;

let us see if we can control the direction of rotation of the motor

by, say, reconnecting Terminal

connection of the power supply.

Question

5.4

1 on the AU150B

to a -15V

What result did you get on changing from a positive

to a positive and negative supply and trying to drive

the

motor?

63

Scanned

by CamScanner

Scanned by

Control

System

Assignment

5

As Terminal 3 is at +15V and Terminal 1 at -15V then

positions 0 to 5 will give you decreasing positive voltages and

5 to 10 increasing negative voltages.

Now let us look at the mimic on the Servo Amplifier, fig 3.5.4.

Inputs 1 and 2 are connected to a pair of transistors which are

part of a circuit arrangement known as a ‘long tailed pair’. The

emitter currents of each transistor are added together and the

total current is held at a fixed value by a constant current

source which is represented on the mimic diagram by the

resistor to -15 volts. When both inputs are at the same voltage,

the current in each transistor will be equal and so the output

voltage (measured at the collector of each transistor) are the

same. This means that no current flows through the motor.

SA150D

Feedback

+24V

control

voltage

ree

9s

monitor

control

ov

+15V

-15V

OV

current

monitor

-15V

Servo Amplifier

Fig 3.5.4

7

Position

rpreprrrrrrprrr

Simple

8 FPF HHASAAASAAAAKRSHA

Modular Servo

Now if the voltage at Input 1 is raised, then the current through

transistor 1 increases (and so the voltage at its collector falls).

But, since the sum of the emitter currents is fixed this means

that the current in the other transistor must reduce (and so the

voltage at its collector increases).

64

So we

get a voltage

Scanned

by CamScanner

Scanned by

Simple

Position

Control

Assignment

System

5

a

la

eh

Modular Servo

amplifiers to provide a high current drive for the motor

armature.

Similar reasoning applies if we have the voltage at Input 1

lower than Input 2 except that the output voltage across the

motor is reversed and so it rotates in the other direction.

To summarise; the circuit arrangement provides two ways to

drive the motor as shown in fig 3.5.5.

*

+

*

armature

Vi, i vi

Vin [ V2

-

OV

Fig 3.5.5

(

|

Luu

( ,ueUDECDROXDDBY

difference across the collectors which is then input to power

Dual input in which speed in each direction is determined by

which of the two inputs, Vi or Vo, is the greater. The motor is

stationary when Vy = Vo.

Any voltage which is common to both inputs will not result in

any motor current and this is often an advantage, for instance,

in industrial systems where there may be noise or interference

affecting the signal wires to a power amplifier.

In later assignments the necessary input signals are provided

by a specialised

Inputs 1 and 2.

Pre-Amplifier Unit which

is connected to

“aT yO

‘ae

»

wh

ib

18

“wb

ib

a

tb

a

ib

ip

ib

{

S| bu

Single input in which direction and speed are controlled by

varying either V4 or Vo.

65

Scanned

by CamScanner

Scanned by

Modular Servo

Simple

Position

PRACTICAL

ASPECTS

Control

Assignment

System

5

Let us draw together the threads of understanding that we

have gained from this assignment.

We started by setting up a control system that produced an

error which we visually had to interpret before making a

manual correction to the system output. It was seen that the

delay between the change in state i.e a step input and action

to follow could cause over-compensation or ‘overshoot’.

We then started to mechanise the system by attaching a

geared motor to the output rotary potentiometer but found that

the control was difficult because visual interpretation was

needed to determine when the motor should be stopped.

In the following assignment we will deal with three points. The

use of a special amplifier, the Pre-Amplifier that can output

forward or reverse drive signals depending on whether it

receives a positive or negative input. Using the error signal as

an input into the Pre-Amplifer, with its magnitude used to

determine the amount of motor drive and its polarity as to the

direction of rotation. However, the last item of overshoot can

be a more difficult problem to deal with and later assignments

will spend some considerable time on some of the methods

available to deal with the problem.

66

Scanned

by CamScanner

Scanned by

TYPICAL RESULTS AND ANSWERS

ASSIGNMENT 5

~F

i

y

eo ee

Modular Servo

=

Question 5.1

You will find that for a fixed position of the input dial the meter

can be set to zero quite rapidly and accurately.

For a steady rotation of the input it will be difficult to hold the

Pn

meter exactly at zero.

os

==

er

For sudden dial movements the meter can be brought to zero

but only after a large initial error and possibly several

overshoots.

wo

This will be an open-loop control system.

=a

| -

‘

Question

5.2

=

.

|

=~

Question 5.3

‘

Question 5.4

The output dial will usually overshoot the desired position but,

if reactions are fast, it could fall short of it and then be ‘inched

On’ to the desired position.

The output dial can now be brought

to a desired position by

g

rotating in either direction although this is difficult to do

manually.

=

=

i>

i

——?

—_

=

—

|

2

a)

2

2

2

@

@

67

Scanned

by CamScanner

Scanned by

CLOSED-LOOP

POSITION

SYSTEMS

CONTROL

ASSIGNMENT

6

The use of a servo motor in an automatic position control

system is investigated.

EQUIPMENT

REQUIRED

Qty

Designation

Description

1

OA150A

Op Amp Unit

AU150B

Attenuator Unit

PA150C

Pre-Amp Unit

SA150D

Servo Amplifier

PS150E

Power Supply

DCM150F

DC Motor

IP150H

Input Potentiometer

OP150K

Output Potentiometer

GT150X

Reduction Gear Tacho Unit

3

CONTENT

fF § RKCKAERKAAAAAA

SS § 8 SF _§_8.

Pe Pr_. RP PRPPS

Modular Servo

DC Voltmeter 30-0-30V

(or voltmeter in GT150X)

m

Attach the AU150A, PA150C and PS150E to the Baseplate

™

Connect the Power Supply to the mains supply line. DO

NOT switch on yet.

Pf

} aS

by means of the magnetic fixings.

68

i

PRELIMINARY

PROCEDURE

Scanned

by CamScanner

Scanned by

Modular Servo

CLOSED-LOOP

OBJECTIVE

POSITION

SYSTEMS

ASSIGNMENT

6

When you have completed this assignment you will:

M™

M@

KNOWLEDGE

LEVEL

ConTROL

Have established the operating characteristic of the

Pre-Amplifier

Have observed the action of a simple motor driven

closed-loop position control system

Before starting this assignment you should:

mM

Be familiar with the components of the DC Modular Servo

and preferably have completed Assignment 1,

Familiarisation.

m@

Understand the operation of electronic amplifiers.

mM

Understand the operation of a simple position control

system.

69

Scanned

by CamScanner

Scanned by

sdular Garvo

Closed-Loop

Position

Control

Assignment

Systems

6

Set up as in fig 3.6.1 and switch on power,

@

Aterandor Unit AUISB

@

Preamplifier Unld PAIS

Switch In ‘normal position

@

Power Supply '

J

Fig 3.6.1

In this assignment we will look at the Pre-Amplifier, PA150C,

which has two signal inputs and two outputs. If there is a

positive voltage on either of its inputs then one of its outputs

INTRODUCTION

becomes positive; whilst if one of its outputs becomes negative

then the other output becomes positive.

Before we use the PA150C to control the motor, we will carry

out a practical to find its characteristics.

PRACTICAL

6.1

Characteristics

the

of

Pre-Amplifier

PA150C

On the upper potentiometer of AU150B,

using the voltmeter,

set the output between terminal 2 and OV to +1V.

To be able to obtain accurate readings we need a fine control

and so we are going to use the lower potentiometer to give us

fractions of the one volt that we have selected.

Connect terminal 6 of the lower potentiometer to terminal 2 of

the upper potentiometer. This means that the scale positions 1

to 10 give us input values in tenths of a volt.

We are now in a position to measure output values of the

PA150C for different values of inputs to see how the amplifier

behaves.

70

Scanned

by CamScanner

Scanned by

Madular Sorva

Closed-Loop

a

ST

Poston

TSR

Control

RTS RTS Ee Ral ence

Systems

Assignment

6

=

For each scale position on the lower potentiometer take

readings with the valtmeter of each of the PA150C outputs win

respect to OV as In tig 3.6.2. After you have done this repeat for

the differant outputs with the voltmeter across both outputs.

Record your results In your own copy of fig 3.6.2

Now connect tarminal 3 of the upper potentiometer to the -15V

Supply and repeat your readings.

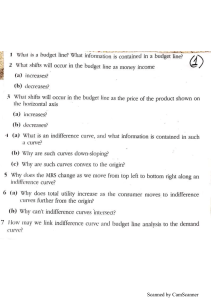

Input signal

Pre-amplitier output

Vi volts

Vo (3)

Vo (4)

Vo (4-3)

Fig 3.6.2

Exercise

6.1

Plot

as

on

graphs

of

in fig 3.6.3

how

amplifier

you

the

and

have

outputs.

input

fig

volts

3.6.4.

connected

against

The

the

the

curves

voltmeter

output

will

volts

depend

across

the

71

Scanned

by CamScanner

Scanned by

CamScanner

Systems

Control

Assignment

A

15

pre-amplifier output V (4)

\

>

e| |

|

2

>

\

3

2

\Lat

3

/

HAA BAAR

pre-amplifier output V 9(3)

{10

‘a.

\Let I

E

o

Q

40.4

40.30

402

«40.1

Qo

0.1

02

pre-amplifier input volts V j

Fig 3.6.3

03

04

O05

-06

fe

205

nner

+0.6

6

PP RHF HH

Position

annannaen

Closed-Loop

SSA SAADA.

Modular Servo

72

Scanned

by CamScanner

Scanned by

CamScanner

Modular Servo

Position

Closed-Loop

>

_

|-08 Y

2

|-o6

$

|

2

\

16

s

-0.4

E

-0.2

3

PS

“12

NY

6

Assignment

Systems

Control

8

Qa.

-8

a

0

voltage across pre-amplitier

+4

+8

+12

outputs V,6(4-3)

+0,2

>

«+16

V

N.

40.4

»

+0.6

}

+0.8

Fig 3.6.4

The ratio of the output voltage V, to the input voltage V; gives

the gain K.

Exercise

6.2

Question

6.1

State

why

you

should

measure

straight part of the curve.

Question

6.2

Explain

Question

6.3

State the range of

should be kept to.

Question

6.4

What input

outputs?

Using

the

the

straight

Pre-Amplifier.

curves.

the

reasons

value

part

for

of the

the

signals

will

give

curves

find

the

non-linear

that

a

you

nil

the

gain

gain

on

portions

think

voltage

the

of

the

of

the

inputs

across

the

If the answer to this is not zero it is because there is a

zero

offset in PA150C. This can be eliminated using the ‘zero set'

control.

73

Scanned

by CamScanner

Scanned by

Closed-Loop

Position

PRACTICAL

6.2

A simple Motor Driven

Closed-loop Position

Control System

Control

Assignment

Systems

6

Retain the units of the first practical and also attach the

OA150A, DCM150F and IP150H and OP150K

Baseplate by means of the magnetic fixings.

to the

Connect the Servo Amplifier connector plug into the Power

Supply.

Connect the

Amplifier.

Motor

Unit

connector

plug

into the

Servo

We are now in a position to use the outputs of the PC150C to

control the motor rotation and provide to it an error signal from

the OA150A

Set up as in fig 3.6.5.

74

AAN.

RePe

AARAAA

RRPR

SF ATAAAA

PePprrrrrPrr

Modular Servo

Scanned

by CamScanner

Scanned by

Closed-Loop

Position

Assignment

Contro} Systems

6

ea et

{ia

» » »

vb

bebo

1 Ecce | Grace 1 ead)

as

bw

ed Rema

bw

eet

a

a

a aad wa ve

ee

TUT

Ob

7%

i

ée¢¢ed

Modular Seno

Ons pad Avomdum eer

OP1SeK

Fig 3.6.5

75

Scanned

by CamScanner

Scanned by

bs

Modular Servo

Closed-Loop

Position

Control

This time

Assignment

Systems

we

shall utilise the

error signal

output

6

V, of the

operational amplifier to drive the output potentiometer via the

pre-amplifier and motor.

The upper potentiometer on the AU150B can now be used as

a gain control and should initially be set to zero before

switching on the power. Adjust the PA150C ‘zero set' so that

the motor does not rotate.

Now set the IP150H to some arbitrary angle and increase the

gain control setting. The output potentiometer cursor should

rotate to an angle nearly equal to that of the input potentiometer cursor .

If the output cursor stops before arriving at the set position, one

is faced with the fact that the system is tolerant to an error and

the motor will not respond till the error exceeds a certain value.

In the next assignment we shall study this effect, which is know

as 'deadband'. For the purpose of this practical, increase the

gain so that this tolerance is overcome and you get the correct

alignment.

Exercise

6.3

Note the different results obtained in your copy of

fig 3.6.6 for several settings of the input shaft angle.

Output cursor position in degrees

Required

PRACTICAL

ASPECTS

Actual

Misalignment

Fig 3.6.6

In a position control system it is of great importance that there

should be a smooth stop at any required position. If there is an

overshoot then there must be a reverse movement to

compensate. If movement is rapid where the system gain is

high, it becomes very difficult to get smooth, accurate arrest.

Indeed, the correcting movement might also produce an

overshoot that will again need correction and in an extreme

case a system could be moving to and fro across a required

position in a state of instability.

So far we have dealt with motors in the unloaded state. The

Speed/Torque characteristics of a motor may not produce a

suitable response under load. To overcome this problem

gearboxes are very often used. However, they then introduce

the further problem of free play in the gears or backlash.

76

Scanned

by CamScanner

Scanned by