How Natural Frequency Limits Frequency of Acceleration Power & Motion

advertisement

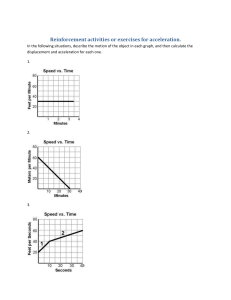

7/2/22, 11:25 AM How Natural Frequency Limits Frequency of Acceleration | Power & Motion LATEST FROM CONTROLS & INSTRUMENTATION System Integrators: The Key t… Sept. 1, 2021 Encoders and Their Applicatio… Aug. 11, 2021 SENSORS & SOFTWARE CONTROLS & INSTRUMENTATION How Natural Frequency Limits Frequency of Acceleration Sept. 24, 2018 The natural frequency of a hydraulic system refers to the system’s iff i h hi h lf i https://www.powermotiontech.com/sensors-software/controls-instrumentation/article/21887755/how-natural-frequency-limits-frequency-of-acceleration 1/10 7/2/22, 11:25 AM How Natural Frequency Limits Frequency of Acceleration | Power & Motion stiffness. Systems with higher natural frequency are easier to control when accelerating quicker than systems with low natural frequency. Peter Nachtwey Encoder Types: M ki Aug. 9, 2021 Quickly Filling the Need May 26, 2021 Controlling Two or More… A hydraulic cylinder can be simply modeled as a mass between two springs. Systems with a low natural frequency (the frequency at which the system oscillates after a sudden start or stop) have a low spring constant relative to the mass of the load. Conversely, systems exhibiting a high natural frequency have a high spring constant relative to the load mass. So how high should the Feb. 16, 2021 natural frequency of the cylinder be relative to the frequency of acceleration? Troubleshoot Challenge: Fl Control… Ideally, the natural frequency should be at least four times the required March 18, 2020 load accelerate. This is true when using a standard hydraulic motion Press Leveling and… controller. Feb. 3, 2020 Is It Time to Cut the Cable? frequency of acceleration —the frequency at which the cylinder’s piston and 1. In this plot, the frequency of acceleration is 5 Hz and the natural frequency of the system is 10 Hz. The actual position and velocity values do Dec. 30, 2019 not accurately follow the target Multi-Axis Motion values; note the Root Mean Squared https://www.powermotiontech.com/sensors-software/controls-instrumentation/article/21887755/how-natural-frequency-limits-frequency-of-acceleration 2/10 7/2/22, 11:25 AM Motion Control… Dec. 11, 2019 How Natural Frequency Limits Frequency of Acceleration | Power & Motion Error (RMSE). The motion will be “jerky.” Natural Frequency and Frequency of Acceleration In a hydraulic system, the natural frequency is calculated from the mass of the load, the areas of both the rod- and cap-end of the piston, and the bulk modulus of the hydraulic fluid. ωn = [4´ βA2/(V´M)]1/2 Where: ωn is the natural frequency of the cylinder and load; β is the bulk modulus of oil; A is the average area of the piston; V is the total volume of oil trapped between the valve and the piston; and M is the mass of the load A simple example illustrating frequency of acceleration is a cylinder and load following a sinusoidal motion at 5 Hz. In this case, the frequency of acceleration is 5 Hz. If the cylinder is just making a simple move from one position to another, the frequency acceleration is 0.5 seconds divided by the minimum of the acceleration or deceleration time This assumes the https://www.powermotiontech.com/sensors-software/controls-instrumentation/article/21887755/how-natural-frequency-limits-frequency-of-acceleration 3/10 7/2/22, 11:25 AM How Natural Frequency Limits Frequency of Acceleration | Power & Motion minimum of the acceleration or deceleration time. This assumes the acceleration and deceleration ramps are sinusoidal S-curves having one fundamental frequency with no harmonics. (Linear ramps have the fundamental frequency and many harmonics that may cause problems.) 2. The same system as shown in Fig. 1, but with the natural frequency increased from 10 to 20 so that it is 4 times the frequency of acceleration. Now the actual motion more accurately follows the target motion profile. Note the RMSE value in this plot. Most motion controllers express the acceleration as a rate. For instance, 2,500 mm/sec2 is about one fourth the acceleration due to gravity. The acceleration time to 250 mm/sec takes 0.1 second at 2,500 mm/sec2, so the frequency of acceleration is 5 Hz (0.5/0.1 sec. = 5 Hz). If the acceleration is to 100 mm/sec. the acceleration time is 0.04 sec., so the frequency of acceleration is 12.5 Hz. I have been asked many times why the tuning for short moves needs to be different from that for long moves. The reason is that short moves have very short acceleration times; consequently, the frequency of acceleration is https://www.powermotiontech.com/sensors-software/controls-instrumentation/article/21887755/how-natural-frequency-limits-frequency-of-acceleration 4/10 7/2/22, 11:25 AM How Natural Frequency Limits Frequency of Acceleration | Power & Motion ; q y, q y higher. If the natural frequency is not at least four times that of the maximum frequency of acceleration, the system will not control well. In the example above, the 12.5 Hz frequency of acceleration may be greater than 1/4 the natural frequency. Therefore, for good control with a typical motion controller, it may be better to slow the acceleration ramp down to 1,000 mm/se.c2 so the acceleration time is still 0.1 sec. 3. In this system, the frequency of acceleration is 8, but the natural frequency is only 20. Without advanced control, the following error is large. Why Does Natural Frequency Need to be Four Times the Frequency of Acceleration? The natural frequency does not actually “need” to be four times the frequency of acceleration. If it isn’t, you’ll find it difficult or even impossible to optimize the controller gains so the actual position follows the target position with little error. If the natural frequency is much greater than the frequency of acceleration, the controller gains will be much easier to optimize. https://www.powermotiontech.com/sensors-software/controls-instrumentation/article/21887755/how-natural-frequency-limits-frequency-of-acceleration 5/10 7/2/22, 11:25 AM How Natural Frequency Limits Frequency of Acceleration | Power & Motion Here’s a graphical example: In Fig. 1, the frequency of acceleration is 5 Hz, and the natural frequency is 10 Hz. The natural frequency is only two times the frequency of acceleration, so the following error is large. (Note the root mean squared error value, RMSE.) Figure 2 shows that increasing the natural frequency to 20 Hz reduces the error between the target and actual position. This analysis assumes the controller is capable of proportional and integral (PI) control with both velocity and acceleration feedforwards (feedforwards predict the needed control output rather than waiting for the control output FLUID ENGINEERING to be generated by errors). If the controller isDIRECTORY not capable of PI control, or POWER RESOURCES ACADEMY WEB LOG IN REGISTER BASICS HYDRAULICS SEARCH does not support velocity and acceleration feedforwards, the ratio of natural PNEUMATICS MECHATRONICS SENSORS & SOFTWARE TECHNOLOGIES DATA SHEETS frequency to frequency of acceleration needs to be much higher to keep the following error small. For instance, a controller with proportional only control will still have 30 deg. of following error even if the natural frequency is 10 times greater than the frequency of acceleration. Do not use proportional-only control if the following error must be close to zero. The most advanced motion controllers can keep the error between the target position and actual position small even if the natural frequency is only two times the frequency of acceleration. https://www.powermotiontech.com/sensors-software/controls-instrumentation/article/21887755/how-natural-frequency-limits-frequency-of-acceleration 6/10 7/2/22, 11:25 AM q y How Natural Frequency Limits Frequency of Acceleration | Power & Motion 4. With an advanced motion controller with second derivative gain and jerk feed forward, it’s possible to achieve precise control even when the natural frequency is not 4 times the frequency of acceleration. Note the reduction in the RMSE value from Fig. 3. What Does This Mean? Saving money! As a general rule, systems with lower natural frequency can use smaller components (cylinders, pumps, etc.), which cost less. The key is selecting the right motion controller. Advanced electrohydraulic motion controllers can perform well when the ratio of the natural frequency to frequency of acceleration is less than four. Advanced motion controllers, such as the RMC motion controller family from Delta Computer Systems, have control algorithms beyond basic PID gain and velocity and acceleration feed forwards. The diameter of the cylinder is roughly proportional to the natural frequency. If the motion controller allows the natural frequency to be only two times the frequency of acceleration the cylinder diameter may be reduced up to half https://www.powermotiontech.com/sensors-software/controls-instrumentation/article/21887755/how-natural-frequency-limits-frequency-of-acceleration 7/10 7/2/22, 11:25 AM How Natural Frequency Limits Frequency of Acceleration | Power & Motion frequency of acceleration, the cylinder diameter may be reduced up to half. How much less depends on the VCCM equation. Reducing the hydraulic cylinder diameter by half means the pump, valve, piping, and accumulator sizes can all be reduced. The cost savings can be much more than the total cost of the hydraulic motion controller. Plus, the machine will be much more economical to operate. Figures 3 and 4 demonstrate the benefits of an advanced controller. The first plot (Fig. 3), shows a short-distance move of a system where the natural frequency is 20 and the acceleration and deceleration take only 0.125 sec. Therefore, the frequency of acceleration is 8 Hz. The actual motion doesn’t follow the target because the natural frequency is only 2.5 times the frequency of acceleration. The last plot (Fig. 4) assumes the same conditions, but with control by an advanced motion controller. The following error is very small. Peter Nachtwey is president of Delta Computer Systems Inc., Battle Ground, Wash. https://www.powermotiontech.com/sensors-software/controls-instrumentation/article/21887755/how-natural-frequency-limits-frequency-of-acceleration 8/10 7/2/22, 11:25 AM How Natural Frequency Limits Frequency of Acceleration | Power & Motion VOICE YOUR OPINION! This site requires you to register or login to post a comment. Email Address* By submitting this form and personal information, you understand and agree that the information provided here will be processed, stored and used to provide you with the requested services in accordance with Endeavor Business Media’s Terms of Service and Privacy Policy. As part of our services, you agree to receive magazines, e-newsletters and other communication about related offerings from Endeavor Business Media, its brands, affiliates and/or third-party partners consistent with Endeavor’s Privacy Policy. Contact us at emailsolutions@endeavorb2b.com or by mail to Endeavor Business Media, LLC, 331 54th Avenue N., Nashville, TN 37209. You can unsubscribe from our communications at any time by emailing emailsolutions@endeavorb2b.com. Continue No comments have been added yet. Want to start the conversation? RELATED Feed-Forward Compensates for Servo Loop Errors Applying Integral Control to Electrohydraulic Servosystems July 31, 2018 July 25, 2018 Filter noise to improve machine productivity Closed-loop tuning secrets revealed! Jan. 13, 2013 Sept. 19, 2006 https://www.powermotiontech.com/sensors-software/controls-instrumentation/article/21887755/how-natural-frequency-limits-frequency-of-acceleration 9/10 7/2/22, 11:25 AM How Natural Frequency Limits Frequency of Acceleration | Power & Motion Sign up for Power & Motion eNewsletters Email Address SIGN UP Load More Content About Us Contact Us Advertise California Do Not Sell Privacy & Cookie Policy Terms of Service © 2022 Endeavor Business Media, LLC. All rights reserved. https://www.powermotiontech.com/sensors-software/controls-instrumentation/article/21887755/how-natural-frequency-limits-frequency-of-acceleration 10/10