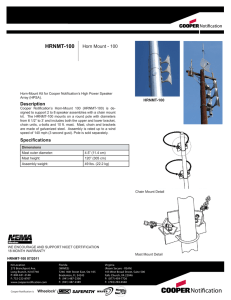

BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY Technical Specification for Design, Supply, Erection, Testing & Commissioning of High Mast Systems Page 1 of 13 BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY 1.0 LOCATION: The High Masts are to be installed inside battery area of Barauni Refinery 2.0 TIME OF COMPLETION: Refer Works Schedule As per Tender for the entire work of planning, supply, installation, testing and commissioning and handing over the entire system to the satisfaction of Engineer-in-charge. 3.0 SCOPE OF WORK: 3.1 The scope of work includes the design, engineering, manufacture, inspection, painting, testing, at works, supply, packing, loading, transportation, unloading, storage of equipment at site, erection, commissioning and performance testing of High Mast Systems, complete with all accessories on turnkey basis in different locations at Barauni Refinery. Bidder is advised to visit site before quoting. 3.2 The owner will provide power supply only up to marshalling box of each high mast. 3.3 Based on high mast OEM’s approved design and approval of IOCL, construction of shallow foundation with appropriate grade concrete for the high mast considering the safe soil bearing capacity at site (Min. 2.5mtr depth) with all materials and labour shall be done. Erection of the high mast with the help of suitable equipments and wiring of luminaries with all wiring materials and labour. 3.4 Erection of the high mast with the help of suitable tools and plants, wiring of luminaries with all wiring materials like PVC insulated PVC sheathed flexible cable of suitable copper conductor cores of 2.5 sq. mm, lugs, MCB and all labour. 3.5 Provision of GI pipe earthing along with dedicated pit for High mast with 2.5 M long 40 mm dia GI Pipe including connection to High mast earth terminal with 25 x 3 mm GI flats with all materials and labour. (2nos per mast required). 3.6 Erection of the feeder pillar panel on suitable foundation including all materials and labour.The feeder pillar should be of IP65. Page 2 of 13 BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY 4.0 Codes & Standards and service conditions: 4.1 The following shall be the applicable Reference Standards for the High Mast: CODE NO. B.S. Code of Practice CP-3 Chapter V Part-II B.S. 4360 B.S. 5135 B.S. 729 Technical Report(TR)No.-71996 of ILE,UK I.S. 875(Part III) 2003 I.S. 2309 I.S. 2629 I.S. 3043 I.S. 4759 I.S. 694 I.S. 1554 I.S. 5220/30 I.S. 11353 LM 80/IS: 20/30105 IEC 62471/EN 62471/IS: 20/30108 EC: 62384/ IS: 20/30104 I.S. 10322-Part 5 TITLE Gradient of wind speeds related to height above ground. Grades of MS plates Welding Galvanizing Specification for Mast and Foundation Code of practice for design loads for buildings & structures – wind loads Code of practice for protection of buildings and allied structures against lighting Code of practice for galvanizing Code of practice for earthing Code of practice for hot dip galvanizing PVC insulated cables (for voltages upto 1100 volts) PVC insulated (heavy duty) electrical cables Guide for safety procedures and practices in electrical works Guide for uniform system of marking and identification of conductor and apparatus terminals Required compliance for LED type floodlight luminaire Photo biological safety of LED and LED systems. Electronic control gear for LED modules – Performance requirements Applicable part for required LED type Flood Light Luminaries In case of imported equipment, standards of the country of origin shall be applicable, if these standards are equivalent or stringent than the applicable IEC/ Indian standards. The equipment shall also confirm to the provisions of Indian Electricity rules and other statutory regulations currently in force in the country. In case Indian standards are not available for any equipment, standards issued by IEC/ BS/ VDE/ IEEE/ NEMA or equivalent agency shall be applicable. In case Indian of any contradiction between various referred standards/ specifications/ data sheet and statutory regulations the following order of priority shall govern: – Statutory regulations – Data sheets – Job specification – This specification – Codes and standards Page 3 of 13 BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY 4.2 Service Conditions Equipment to be supplied against this specification shall be suitable for satisfactory continuous operation under the following tropical conditions. Maximum Ambient Temperature (Degree C) 50 Maximum temperature in shade (Degree C) 45 Min. Temperature of Air in Shade (Degree C) -10 Relative Humidity (Percent) 50- to 100 Maximum annual rain fall (mm) 1450 Maximum Wind pressure (Kg/Sq. M.) 150 Maximum altitude above mean sea level (Meters) 3000 lsoceranic level (days per year) 50 Seismic level (Horizontal Acceleration) Moderately hot and humid tropical climate conducive to rust and fungus growth 5.0 0.3g Technical Requirement 5.1 Structure The High mast shall be of continuously tapered, galvanized polygonal cross section, at least 20 sided, presenting a good and pleasing appearance, based on proven In-Tension design, conforming to the standards referred to above, to give an assured performance, and reliable service. The structure shall be suitable for wind loading of 50 meter/sec as per IS - 875 Part - III, 1987. 5.2 Construction The mast shall be fabricated from special steel plates, conforming to BS EN 10025 / BS EN 10027 or equivalent, cut and folded to form a polygonal section and telescopically jointed and welded. The welding shall be in accordance with BS-5135. The sections are joined together by slipstressed-fit method. No site welding shall be done. Only bolted joint shall be done on the mast at the site. The minimum over lap distance shall be 1.5 times the diameter at penetration. The dimensions of the mast shall be decided based on proper design and accordingly design calculations shall be submitted for review / approval. Page 4 of 13 BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY The mast shall be provided with fully penetrated flange, free from any lamination or incursion. The welded connection of the base flange shall be fully developed to the strength of the entire section. The base flange shall be provided with supplementary gussets between the bolt holes to ensure elimination of helical stress concentration. The entire fabricated mast shall be hot dip galvanized both internally and externally. 5.3 Door Opening An adequate door opening shall be provided at the base of the mast and the opening shall be such that it permits clear access to equipment like winches, cables, plug and socket, etc. and also facilitate easy removal of the winch. The door opening shall be complete with a close fitting, vandal resistant, weatherproof door, provided with a heavy- duty double internal lock with special paddle key. 5.4 Dynamic Loading for the Mast The mast structure shall designed as per TR No-7 of Institutions of lightning engineers of UK and shall be suitable to sustain maximum reaction arising from a wind speed as per IS-875 (three second gust), and is measured at a height of 10 meters above ground level. 5.5 Lantern Carriage A fabricated Lantern Carriage shall be provided for fixing and holding the 16 nos. LED flood light fittings for 30 mtrs High Mast. The lantern Carriage shall be of special design and shall be of steel tube construction, the tubes acting as conduits for wires, with holes fully protected by grommets. (The lantern carriage tube should not be used as conduit. Separate flexible conduits are used from CG Boxes to the Flood Light Fixtures) The Lantern Carriage shall be designed and fabricated to hold the required number of flood light fittings and the control gear boxes, and also have a perfect self balance. The Lantern Carriage shall be fabricated in two halves and joined by bolted flanges with stainless steel bolts and plastic lock type stainless steel nuts to enable easy installation or removal from the erected mast. The inner lining of the carriage shall be provided with protective PVC arrangement, so that no damage is caused to the surface of the mast during the raising and lowering operation of the carriage. The entire Lantern Carriage is hot dip galvanized after fabrication. 5.6 Junction Box The junction box shall be weather proof IP 65 junction box. It shall be provided on the Carriage Assembly as required, from which the inter-connections to the designed number of the flood light luminaries and associated control gears fixed on the Page 5 of 13 BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY carriage, is made. 5.7 Raising and lowering mechanism It will be necessary to lower and raise the Lantern Carriage Assembly to install and maintain the luminaries and lamps. To enable this, a suitable Winch Arrangement shall be provided, with the winch fixed at the base of the mast and the specially designed head frame assembly at the top. 5.8 Winch The winch shall be of completely self-sustaining type, without the need for brake, shoe, springs or clutches. Each driving spindle of the winch is positively locked when not in use. Individual drum also should be operated for the fine adjustment of lantern carriage. The capacity, operating speed, safe working load, recommended lubrication and serial number of the winch shall be clearly marked on each winch. The gear ratio of the winch shall be 53: 1 or as recommended by manufacturer. However, the minimum working load shall not be less than 750 kg. The winch shall be self- lubricating type by means of an oil bath and the oil shall be readily available grades of reputed manufacturers and details of the oil shall be furnished. The winch drums shall be grooved to ensure perfect seat for stable and tidy rope lay, with no chances of rope slippage. The rope termination in the winch shall be such that distortion or twisting is eliminated and at least 5 to 6 turns of rope remains on the drum even when the lantern carriage is fully lowered and rested on the rest pads. It should be possible to operate the winch manually by a suitable handle and by an external power tool. It would be possible to remove the double drum after dismantling, through the door opening provided at the base of the mast. Also, a winch gearbox for simultaneous and reversible operation of the double drum winch shall be provided as part of the contract. The winch shall be type tested in a reputed test lab/ Institution and the test certificates shall be furnished before supply of materials. Test certificate shall be furnished by the bidder from the original equipment manufacturer, for each winch in support of the maximum load operated by the winch. 5.9 Head Frame The head frame, which is to be designed, as a capping unit of the mast, shall be of welded steel construction, galvanized both internally and externally after assembly. The top pulley shall be of appropriate diameter, large enough to accommodate the stainless steel wire ropes and the multi-core electric cable. The pulley block shall be made of corrosion resistant material, and is of the cast Aluminium Alloy (LM-6) or SS. Pulley made Page 6 of 13 BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY of synthetic materials such as Plastic or PVC is not acceptable. Self-lubricating bearings and stainless steel shaft shall be provided to facilitate smooth and maintenance free operation for a long period. The pulley assembly shall be fully protected by a canopy galvanized internally and externally. Close fitting guides and sleeves shall be provided to ensure that the ropes and cables do not dislodge from their respective position in the grooves. The head frame shall be provided with guides and stops with PVC buffer for docking the lantern carriage. 5.10 Stainless Steel Wire Ropes The suspension system shall essentially be without any intermediate joint and shall consist of only non-corrodible stainless steel of AISI - 316 or better grade. The stainless steel wire ropes shall be of 7/19 construction, the central core being of the same material. The overall diameter of the rope shall be minimum 6 mm keeping in mind contingency. The breaking load of each rope shall not be less than 2350 kg. The design shall have a factor of safety over 5 for the system at full load. The end constructions of ropes to the winch drum shall be fitted with talurit. The thimbles are secured on ropes by compression splices. Two continuous lengths of stainless steel wire ropes are used in the system and no intermediate joints are acceptable in view of the required safety. No intermediate joints, either bolted or else, shall be provided on the wire ropes between winch and lantern carriage. 5.11 Electrical System, Cable and Cable Connections A suitable terminal box shall be provided as part of the supply at the base compartment of the high mast for terminating the incoming cable. The electrical connections from the bottom to the top shall be made by special trailing cable. The cable is EPR insulated and PCP sheathed to get flexibility and endurance. Size of the cable is minimum 5 core 2.5 sq mm copper; in case of failure of any core 2 spare cores shall be available. The cable shall be of reputed make. At the top necessary weatherproof junction box to terminate the trailing cable shall be provided. Connections from the top junction box to the individual luminaries is made by using 3 core 2.5 sq mm flexible PVC cables of reputed make. The system shall have in built facilities for testing the luminaries while in lowered position. Also, suitable provision shall be made at the base compartment of the mast to facilitate the operation of externally mounted, electrically operated power tool for raising and lowering of the lantern carriage assembly. The trailing cables of the lantern carriage rings shall be terminated by means of specially designed, metal clad, multi pin plug and socket provided in the base compartment to enable easy disconnection when required. Page 7 of 13 BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY 5.12 Power Tool for the Winch A suitable, high-powered, electrically driven, internally mounted power tool, with manual over ride, together with an operating handle shall be supplied for the raising and lowering of the lantern carriage for maintenance purposes. The speed of the power tool may preferably of slow speed, of 1.5 to 1.8 m/minute, so that vibrations associated with high speed operation are avoided. The power tool shall be single speed, provided with a motor of the required rating. The capacity and speed of the electric motor used in the power tool shall be suitable for the lifting of the design load installed on the lantern carriage. Also, a handle for the manual operation of the winches in case of problems with the electrically operated tool shall be provided and shall incorporate a torque-limiting device. A separate torquelimiting device to protect the wire ropes from over stretching shall be provided. It shall be mechanical with suitable load adjusting device. The torque limiter is a requirement as per the relevant standards in view of the overall safety of the system. The Power tool motor shall be FLP suitable for Zone-2 Gas group IIA/IIB. 5.13 Lightning Finial One number heavy-duty hot dip galvanized lightning finial shall be provided for each mast. The lightning finial shall be minimum 1.2 m in length and shall be provided at the centre of the head frame. It shall be bolted solidly to the head frame to get a direct conducting path to the earth through the mast. The lightning finial shall not be provided on the lantern carriage under any circumstances in view of safety of the system. 5.14 Aviation Obstruction Lights: Based on site and project specific requirements, 2 nos. Low Intensity Type-B (as per Table 6.3 of Volume-1, Annexure-14 of ICAO Guideline for Aerodrome Design & Operations) LED cluster type aviation obstruction lights of reliable design and reputed manufacturer shall be provided on top of each mast. 5.15 Earthing Terminals Suitable earth terminal pad using twin 12 mm diameter stainless steel bolts shall be provided at a convenient location on the base of the Mast, for lightning and electrical earthing of the mast. Page 8 of 13 BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY 5.16 Luminaries Minimum 240 W LED floodlight meeting technical specification for LED light fittings given in Annexure-II, suitable for mounting on the above high mast. The Luminaries and its control gear should have minimum IP66 or better protection. 5.17 Feeder Pillar Feeder pillar required for feeding power to the Lighting mast shall also be supplied along with the mast and its accessories. The feeder pillar is fed from the main switchgear / main lighting distribution board. The outgoings of this feeder pillar are connected to the MCBs in the mast. The feeder pillar shall be flame proof IP65 aluminium die cast enclosure suitable for Zone-2 Gas Group IIA/IIB and finished with grey enamel paint of shade 631 of IS-5. The feeder Pillar shall comprise of incoming 64 Amp four poles MCB, 32 Amp SP outgoing MCBs, Timer switch and contactor for automatic on & off of circuit with manual override, TP MCB for power tool contactors for reversing the motor and overload Protection of motor. Feeder pillar shall be mounted on suitable foundation at safe distance from the foundation. 6.0 Inspection, testing and acceptance at works 6.1 During manufacturing, the High Mast lighting system equipment and materials shall be subject to inspection by owner, or IOCL approved TPI agency. The manufacturer shall furnish all necessary information/data concerning the supply to Owner’s inspectors. The vendor shall give at least 10 days notice to the purchaser regarding the date of testing to enable him or his representative to witness the tests. 6.2 Tests shall be carried out at the manufacturer’s works under his care and expense. All routine tests as specified by the applicable standards shall be conducted. Type test certificates for the high mast lighting system equipments used shall be furnished from a recognized testing organization. 6.3 All type test certificates for the tests as per relevant standards, conducted on identical masts shall be submitted to IOCL along with bid. Routine tests & acceptance tests as per relevant IS shall be conducted by TPI as per IOCL approved vendor’s QAP to check mechanical and electrical operation. Page 9 of 13 BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY 7.0 Annexure A: Technical Data Sheet –30 mtrs High Mast with 16X240Watt LED Flood Lights. Particulars IOCL Requirement Name and address of manufacturer Overall height of high mast Bidder to specify 2.1 Make Bidder to specify 2.2 Material of construction of shaft Grade S355 J O as per BSEN 10025 or equivalent 2.3 Cross section of mast Sl. No. 1 2 2.4 2.5 2.6 2.7 Bidder's Data 30 mtrs. Min. 20 sided polygon, continuously tapered telescopically joint as per BS 5135 or Equivalent. Number of sections Three No. of Longitudinal welds / section One No of Circumferential welds/section None Minimum thickness of shaft Bottom section: 8 mm, (mm) middle Section: 6mm, Top section: 4 mm Bottom: 10500mm Approx Length of individual Middle : 10500mm, section (mm) Top: 10500mm Approx Minimum Base and top 600mm (Bottom) and 150mm diameter (Top) 2.8 Type of joints Telescopic slip joint, stress fitted 2.9 Length of overlap Min. 450 mm 2.10 Metal protection treatment of fabricated mast section Hot dip galvanization through single dipping process 2.11 Thickness of galvanizations 2.12 Size of opening door at base Minimum 85 microns as per IS:2629 Approx. 250 X 1200 mm 2.13 Type of locking arrangement and door construction Anti vandal type 2.14 Lightning Protection Finial G.I. Single Spike of suitable length 2.15 Approx size of base plate diameter (Minimum) 840mm OD 2.16 Approx size of base plate thickness (Minimum) 32 mm thick Page 10 of 13 BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY 2.17 3 3.1 3.2 3.3 3.4 3.5 3.6 Minimum size of anchor plate thickness 8 mm Dynamic loading as prevailing at site Maximum wind pressure (basic wind speed) Maximum gust speed time 50m/s as per IS:875, p-3 Height above ground level at which wind speed is consider Factor of safety for wind load 10 mtrs 3 seconds 1.25 4 4.1 Factor of safety for other load Application standard for mast design Foundation details Type of foundation 4.2 Size of foundation 4.3 4.4 4.5 4.6 4.7 4.8 Design safety factor Considered wind speed Depth of foundation Average soil bearing capacity Numbers of foundation bolts PCD of foundation bolts Open raft shallow footing or pile as applicable as per design conforming to IS:456 2 50m/s as per IS:875, Part-3 As per requirement of design As per site condition Min. 12 nos. Approx 740 mm 4.9 Type of foundation bolt TS-600 Grade. 4.10 Bolt diameter / length Min. 30mm dia. / 850 mm 5 Lantern Carriage 5.1 Diameter of Carriage Ring 5.2 Construction 5.3 Number of joints 5.4 Buffer arrangement between carriage and mast Load carrying capacity 5.5 6 6.1 1.15 Technical report #7:2000 by ILE, UK Min. 710 mm (ID)/ 2200 mm (OD) Hot dip Galvanised (Minimum 85 microns as per IS:2629) steel Suitable to carry the nos. & type of fittings and fixtures. 2 PVC sleeve on carriage. 750 kg Winch Make of winch Bidder to specify Page 11 of 13 BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY 6.2 Number of drums/ winch Double drum as per IS-807 6.3 Capacity SWL 750 kg 6.4 Method of operation Manual / power tool 6.5 Lubricant Arrangement Permanent oil bath 6.6 Material of construction of gear Phosphorus Bronze / EN 19 6.7 Tested load per drum 750 kg 6.8 SWL of winch at 410 rpm 750 kg SWL 7 7.1 7.2 7.3 7.4 7.5 Wire rope Make Grade Construction Diameter of Wire rope Factor of safety 7.6 Breaking capacity 8 8.1 8.2 Cable Type Material 8.3 Make 8.4 9 conductor size (min.) Torque limiter 9.1 Lifting capacity Upto 750 kg 9.2 Adjustable / non adjustable Adjustable 10 Flood Light Luminaries Bidder to specify AISI 316 or Better 7/19 6mm without intermediate joints. Not less than 6 times the safe working load. Minimum 2350Kgs. X 2 EPR insulated PCP sheathed Multicore multi strand copper conductor Finolex/torrent/Polycab/KEI/ Havells/BMI/SUN/MANSFIELD or equivalent make 5CX2.5 sqmm. 10.1 Wattage 240 10.2 Type of Fitting LED light fittings 10.3 model and Make of LED flood lights fittings Philips/Havells/Bajaj/GE or equivalent-Refer Tender 10.4 No. of lighting Fixtures 16 Page 12 of 13 BARAUNI REFINERY Annexure-I SCOPE OF WORK AND TECHANICAL SPECIFICATIONS OF 30 METER HIGH MAST AT BARAUNI REFINERY 11 12 12.1 Power Tool (Integral to System) 3 PH, 415 Volts.± 12.5% Winch motor (Permanently placed Rating of the Motor suitable to the inside the main shaft). FLP Motor. design with control & torque limiting protection. Single speed. Others Make of 24 hour Differential Legrand/ GE/ Schnider/ L&T or Timer Switch equivalent make 12.2 Make of 32A TPN MCB GE/ Hager/ Legrand/ Schneider or equivalent make 12.3 Make of 32A Contactor 13 GTP and Drawing Submitted L&T/ Schnider/ GE or equivalent make YES/NO 14 Type Tests Submitted YES/ NO 15 Technical Brochure of luminaries submitted Operation and maintenance manual submitted Warranty of complete system YES / NO 16 17 8.0 YES / NO 60 Months from date of commissioning. Bidder to submit the warranty certificate of OEM along with supply of material. Documents to be submitted along with the bid for technical evaluation Sl. No Required Technical Document 1 All type test certificates for the tests as per relevant standards, conducted on identical masts shall be submitted to IOCL along with bid. GA Drawing of the complete mast assembly clearly showing the make of the High mast lighting system. 2 Bidder’s confirmation Page 13 of 13 BARAUNI REFINERY Annexure-II Technical specification for Minimum 240W LED Light Fittings Technical Specification for Minimum 240W LED Light Fittings Page 1 of 6 BARAUNI REFINERY Annexure-II Technical specification for Minimum 240W LED Light Fittings Technical Specification for LED Lighting System 1. 240W LED Flood Light Fitting (For High Mast Lights) (A) General Requirement S. No. 1 2 3 4 Criteria Supporting documents at offer stage The vendor should be Manufacturer /authorized i. Sales Tax registration certificate or dealer in the business of LED lightings. excise registration certificate or factory registration or MSME certificate of manufacturing firm. ii. In case of authorized dealer, party to submit the authorization certificate from their OEM and also to submit above mentioned certificate of their LED lighting manufacturer (OEM) Note: Certificate to clearly mention details related to manufacturing of LED products. Experience in LED business-min 2 years. Date of incorporation of the products in sales tax registration certificate or taxable invoices which should be at least two years old from the date of issue of tender. The Vendor/Manufacturer of LED Luminaries should Copy of valid certificates. be an ISO 9001:2008 / ISO 9001: 2015 certified organization. Shall have sales/distribution network Confirmation on letter head giving full details of sales/distribution network with undertaking of timely delivery. 5 Party to have service network to ensure that response time is not be greater than two working days. 6 LED Luminaries manufacturer should have an in house design & development facility for the lights and their electronic drivers. 7 LED luminaire manufacturer should have the following infrastructure / facilities: i. Automatic pick and place machine for LEDs and electronic components ii. Temperature controlled automatic wave soldering machine with auto fluxing facility for through hole devices. iii. Automatic temperature controlled re flow soldering machine for SMD iv. Heat chamber having minimum range of 0-50 Deg. Cel. With alternate arrangement of standby power supply Party to provide confirmation on letter head giving full details of service network with undertaking of timely service within two working days. Party to provide confirmation on letter head giving details subject facilities with undertaking for the allowing verification of the same by IOCL / Approved TPI. Party to provide Confirmation on their letter head (in case of OEM) or letter head of their authorized contract LED luminaries manufacturer from where the LED luminaries is being outsourced (in case of authorized dealer) giving details of each subject facilities like photographs, make, model, serial no. etc to support the same. Also party to provide undertaking on their letter head or letter head of their authorized contract LED luminaries manufacturer from where the LED luminaries is being outsourced for allowing verification of the same by IOCL / Approved TPI. Page 2 of 6 BARAUNI REFINERY Annexure-II Technical specification for Minimum 240W LED Light Fittings v. vi. vii. viii. for carrying out endurance tests. Electronic driver testing meter with programmable input supply of vary input voltage. Meter shall be able to report input parameters like wattage, PF, THD, Input current and output Voltage, Output current etc. Integrating sphere for LM 79 / IS16106:2012 testing of CCT & CRI Gonio-Photometer for LM79/ IS16106:2012 testing for Photometric & Electrical parameters. Ingress protection, testing facility for testing of outdoor products with rating up to IP66 (B) Technical requirement of LED Sr. No. Parameter IOCL requirement 1 Wattage, MAKE and Model LED Efficacy Min 240W Type LED technology approved makes SMD / COB type SMD- Nichia, Osram, Lumileds (Erstwhile Philips Lumileds), CREE 2 3 4 5 6 LED lifespan report Life span >140 Lumens / Watt Documents to be submitted for the offered MAKE Manufacturers data sheet Manufacturers technical data sheet with LM-80 test report Manufacturers data sheet Vendor to specify MAKE from the specified list only COB - Citizen, Bridgelux LM-80/IS:16105 test report along with TM21 report from international accredited lab For SMD type Test report for ambient temperature of 55 /85 /105 Deg C at rated and maximum current shall be submitted. For COB type LM-80 test report Life of LED chips shall be more than 50,000 hrs LM-80/IS:16105 test report along with TM21 report from international accredited lab confirming TM21 life projection calculations Vendor to Confirm/ Specify Data Page 3 of 6 BARAUNI REFINERY Annexure-II Technical specification for Minimum 240W LED Light Fittings along with LM80 for all three ambient temperature of 55 /85 /105 Deg C as per standard. IEC 62471 /EN 62471/ IS 16108. Should fall in the exempt or low risk group. life of LED. 7 Photo biological safety norms Report from international accredited lab from LED supplier. 8 View Angle Typical 120 degree Manufacturers data sheet 9 Colour temperature In the range of 5665K±355K LED Manufacturers data sheet Step 7 MacAdam as per ANSI standard C78.377A, on account of colour consistency. 10 Colour rendering index CRI >70 LED Manufacturers data sheet CRI should include all the colour range from R1 to R15 (B). Technical requirement for LED driver Sr. No. 11 12 13 14 Parameter IOCL requirement Minimum Efficiency Power factor of complete fitting In built high and low voltage cutoffs Short Circuit & Open Load protection >= 87% for driver power Greater than 0.90 Recommended Cut off at voltages >=290 Volts required Documents to be submitted for the offered MAKE LED Manufacturers data sheet and Type Test Report LED Manufacturers data sheet Vendor to Confirm/ Specify Data Manufactures datasheet and type test report Manufactures datasheet and type test report 3kV (minimum) 15 20 Driver Surge Protection Standard EMI/EMC Compliance If the Surge Protection Device (SPD) provided then it should be series type with fail safe. i) CISPR 15/ IS: 6873(CE,RE ,CDN) or compliance to equivalent EN standard. Manufactures datasheet and type test report Manufactures datasheet and type test report ii) IEC:61547 Page 4 of 6 BARAUNI REFINERY Annexure-II Technical specification for Minimum 240W LED Light Fittings (C). Technical Requirement of Electronic component used Sr. No. 23 Parameter LED Module PCB IOCL requirement MCPCB is to be used for SMD technology for LED wattage in excess of 0.5. The minimum thickness should be 1.6 mm Documents to be submitted for the offered MAKE Vendor to Confirm/ Specify Data Manufacturer’s data sheet and type test report This is not applicable for COB Minimum thickness of 1.6 mm 24 Driver PCB Not applicable for COB Manufacturer’s data sheet and type test report (D). Technical requirements of luminaries Sr. No. Parameter IOCL requirement 25 Min system lumen efficiency >= 100 lm/W 26 Minimum system lumens >= 24000 lm 27 Housing Pressure die-cast LM6/ ADC12/ LM24. 28 Housing Protection IP65 or better Manufactures datasheet and type test report 29 Impact Resistance IK -05 or better Manufactures datasheet and type test report 30 Secondary lens /optics Luminare must have secondary lens/optics of type PMMA/Borosilicate glass/ Polycarbonate 31 Cover Type Toughened glass UV stabilized polycarbonate cover 32 Thermal/Temperature rise test SMD- Soldering point temperature of LEDs <=85 deg C for thermally stabilized Luminare Documents to be submitted for the offered MAKE Manufactures datasheet and type test report (LM-79 / IS 16106 test report) Vendor to Confirm/ Specify Data Manufactures datasheet and type test report (LM-79 / IS 16106 test report) Manufactures datasheet and type test report Manufactures datasheet and type test report Manufactures datasheet and type test report Manufactures datasheet and type test report Page 5 of 6 BARAUNI REFINERY Annexure-II Technical specification for Minimum 240W LED Light Fittings 34 Color Temperature 35 Color Rendering index (CRI) 36 Electrical and Photometric testing Not applicable for COB type Range of 5665K±355K Step7 McAdam as per ANSI standard C78.377A. CRI should include all color range from R1 to R15 Certificate from NABL Lab only Certificate from NABL Lab only CRI >70 LM-79 test report Certificate from NABL Lab only (E). Other requirements Sr. No. Parameter 37 Warranty 38 BIS Registration IOCL requirement 60 Months warranty for complete Luminaries including LED. To be as per prevailing BIS notification; presently compulsory for surface mounted luminaries. Documents to be submitted for the offered MAKE Vendor to Confirm/ Specify Data Warranty Certificate for manufacturer BIS Registration as applicable Page 6 of 6