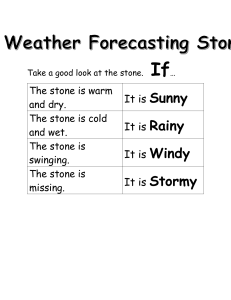

HOSTED BY Available online at www.sciencedirect.com ScienceDirect Soils and Foundations 59 (2019) 1579–1590 www.elsevier.com/locate/sandf Technical Paper Short-term and long-term behavior of geosynthetic-reinforced stone columns Ahad Ehsaniyamchi ⇑, Mahmoud Ghazavi Civil Engineering Department, K.N. Toosi University of Technology, Tehran, Iran Received 28 December 2018; received in revised form 10 May 2019; accepted 31 July 2019 Available online 14 September 2019 Abstract Stone columns are often used to improve the load-carrying characteristics of weak soils. In very soft soils, however, the bearing capacity of stone columns may not significantly improve the load-carrying characteristics due to the very low confinement of the surrounding soil. In such cases, encased stone columns (ESCs) or horizontally reinforced stone columns (HRSCs) may be used. Although ESCs have been studied extensively, few studies have been done on HRSCs. In addition, very limited studies are available on ESCs and HRSCs under the same conditions. Moreover, no studies have been carried out to compare the long-term and short-term behavior of HRSCs with that of ESCs. In this research, therefore, numerical analyses are performed on various types of reinforced end-bearing stone columns to compare their behavior under both long-term and short-term conditions under various loading conditions. The Advanced Modified Cam-clay model for clay and the Hardening Soil model for stone column materials are used. The results show that with proper reinforcing stone columns, in addition to a considerable reduction in settlement, the consolidation time can be greatly decreased and most of the settlement will occur during the loading period. Also, the consolidation settlement rate may be increased by using a smaller column diameter and a larger area replacement ratio for the unit cell, stiffer geosynthetic reinforcements, and greater values for the internal friction angle of the stone column materials. Ó 2019 Production and hosting by Elsevier B.V. on behalf of The Japanese Geotechnical Society. This is an open access article under the CC BYNC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/). Keywords: Geosynthetics; Reinforced stone columns; Numerical analysis; Short-term and long-term behavior; Consolidation settlement 1. Introduction Stone columns are often used as a ground-improvement method to improve the bearing capacity, to reduce the settlement of saturated clayey soil, to increase the consolidation rate of fine soils, and to decrease the liquefaction potential. In very soft soils, however, the bearing capacity of ordinary stone columns (OSCs) is small due to the very low lateral confinement of the surrounding soil that leads to bulging failure at a depth of D-2.5D (Nazariafshar Peer review under responsibility of The Japanese Geotechnical Society. ⇑ Corresponding author. E-mail addresses: aehsani@mail.kntu.ac.ir (A. Ehsaniyamchi), ghazavi_ma@kntu.ac.ir (M. Ghazavi). and Ghazavi, 2014). In such situations, the loadsettlement behavior of the stone columns can be improved by geosynthetic reinforcements. Fig. 1 shows two main reinforcing methods of stone columns. As seen in the figure, a stone column may be reinforced by an encasement, called an encased stone column (ESC), wrapped with a geosynthetic like a wick drain, or by placing horizontal sheets of a geosynthetic within the column body at regular intervals, called a horizontally reinforced stone column (HRSC). The encasement may be wrapped around the whole length of the stone column (Le = L), called a fulllength ESC, or just wrapped around the upper portion of the stone column, for example, the half-length of the column (Le = 0.5L), where Le is the encased length of the ESC. https://doi.org/10.1016/j.sandf.2019.07.007 0038-0806/Ó 2019 Production and hosting by Elsevier B.V. on behalf of The Japanese Geotechnical Society. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/). 1580 A. Ehsaniyamchi, M. Ghazavi / Soils and Foundations 59 (2019) 1579–1590 Applied pressure Le=0.5L Soft soil Geosynthetic encasement Le=L Soft soil Stone column (a) Sr (b) Horizontal reinforcing layers (c) (d) (e) Fig. 1. Examples of various models used in numerical analyses. Unit cell models of: (a) OSC, (b) full-length ESC, (c) half-length ESC, (d) HRSC with Sr = 0.5D, and (e) single HRSC with Sr = 0.25D. The encasing of stone columns has been studied using analytical solutions (Pulko et al., 2011; Zhang and Zhao, 2015), experiments (Gniel and Bouazza, 2009; Murugesan and Rajagopal, 2010; Ghazavi and Nazariafshar, 2013; Ali et al., 2012, 2014; Miranda and Da Costa, 2016; Hong et al., 2016), and numerical methods (Murugesan and Rajagopal, 2006; Khabbazian et al., 2010; Keykhosropur et al., 2012; Elsawy, 2013; Hosseinpour et al., 2014; Yu et al., 2016). Most of the analytical and numerical studies used the unit cell concept, assuming an infinitely wide loaded area with end-bearing stone columns having a constant diameter and spacing, where the stone column and the surrounding soil were treated as axisymmetric forms (Pulko et al., 2011). Murugesan and Rajagopal (2006) and Khabbazian et al. (2010) reported that encasing the top portion of ESCs may be sufficient for preventing bulging failure and enhancing the bearing capacity. However, Gniel and Bouazza (2009) and Ghazavi and Nazariafshar (2013) reported that, in very soft soils, reinforcing the upper half part of ESCs may lead to the relocation of the bulging failure to the lower unencased parts of the columns; and thus, it may be more useful to encase the full length of the ESCs. HRSCs have been studied by Sharma et al. (2004), Wu and Hong (2008), Ali et al. (2012, 2014), Nazariafshar and Ghazavi (2014), Hosseinpour et al. (2014) and Ghazavi et al. (2018). Their results showed that the beneficial effect of HRSCs mainly depends on the vertical spacing between the horizontal reinforcing sheets and that the bearing capacity of HRSCs increases with a decrease in the spacing between the reinforcing layers (Ghazavi et al., 2018). Although various studies have been conducted on ESCs and HRSCs, only a very limited number of studies have compared the two methods under the same conditions (Ali et al., 2012, 2014; Hosseinpour et al., 2014). Moreover, although several studies have been conducted on the con- solidation of OSCs (Wang, 2009; Cimentada et al., 2011; Ng and Tan, 2014; Lu et al., 2017; Deb and Behera, 2017), most of the studies on ESCs have been focused on either the short-term or the long-term behavior and only a few studies investigated the consolidation of ESCs (Castro and Sagaseta, 2011; Zhang et al., 2012; Castro et al., 2013; Pulko and Logar, 2017). Castro and Sagaseta (2011) presented an advanced analytical method for predicting the consolidation settlement of ESCs based on Barron’s solution. Pulko and Logar (2017) used Biot’s theory and presented a fully coupled semi-analytical solution in order to account for the consolidation settlement of ESCs. In addition, to the best knowledge of the authors, there have been no studies that compared the long-term behavior and the consolidation settlement of HRSCs with those of ESCs. Although the behavior of the granular aggregates and geosynthetic reinforcements of stone columns is almost independent of the loading speed, due to the presence of soft compressible clay around columns with very low permeability, after applying the initial loading on the stone columns and the surrounding soil, horizontal and vertical consolidation deformation is generated in the soil around the stone columns. This will cause additional deformation and the regeneration of stress in both the stone columns and the reinforcements. Therefore, the effects of consolidation on the soft clay surrounding the columns should be taken into account when calculating the stress and deformation of the various elements of the stone columns. This paper performs numerical analyses to compare both the long-term and short-term behavior and the consolidation settlements of end-bearing ESCs and HRSCs. To this aim, advanced constitutive models are used to compare the long-term and short-term behavior of ESCs and HRSCs. The present results may assist practicing engineers in choosing the best reinforcement method for stone A. Ehsaniyamchi, M. Ghazavi / Soils and Foundations 59 (2019) 1579–1590 columns with respect to the site, the loading conditions, the available materials, and the soil-improvement target. 2. Finite element analyses 1581 linear-elastic behavior was used for reinforcing the material simulation. To allow the mobilization between the reinforcement and the soil materials, interface elements were used by applying a strength reduction factor of 0.67, as suggested by the PLAXIS manual and used by Khabbazian et al. (2010). 2.1. Model description and boundary conditions 2.2. Numerical analysis validation The finite element model was verified for both reinforcing methods using data reported by others in the literature (Figs. 2 and 3). The predicted ESC data were verified by the data reported by Khabbazian et al. (2010) for an OSC and a full-length ESC, both with a diameter of 80 cm and a length of 5 m. The predicted HRSC data were verified by the experimental data reported by Ghazavi et al. (2018) for an OSC and an HRSC, both with a diameter of 10 cm and a length of 50 cm. As seen in Fig. 3, there is a good agreement between the test data and the simulations. Therefore, the adopted numerical analysis methods can be used to further discover the behavior of HRSCs and ESCs. Fig. 2. Validation of numerical analysis for ESCs. Vertical stress (kPa) 0 100 200 300 400 500 600 700 800 0 10 Settlement (mm) Finite element analyses were performed using PLAXIS 2D in an axisymmetric condition. In the numerical analyses, two configurations of full-length ESCs and halflength ESCs were adopted, and their characteristics were compared with HRSCs with Sr = 0.25D and Sr = 0.5D, where Sr is the spacing of the horizontal reinforcing strips (Fig. 1d) and D denotes the stone column diameter. The reinforcing material used for the two cases of full-length ESC and HRSC with Sr = 0.25D was the same and equal to p.D.L, where L is the column length. In the same way, the area of the reinforcing material used for the two cases of half-length ESC and HRSC with Sr = 0.5D was equal to p.D.L/2. This facilitated a comparison between ESCs and HRSCs in terms of the consumption of the reinforcing material. Two types of stone column configurations for a single column and the unit cell concept, representing the stone column group, were studied by means of various numerical parametric analyses (Fig. 1). The length of all the stone columns was assumed to be 5 m. All the stone columns were located on a rigid stratum. Fig. 1 also shows some examples of the geometric models adopted for various types of stone columns with various loading conditions. Fig. 1a to 1d show the configurations of the unit cell conditions for the interior column conditions in the group of stone columns supporting a rigid spread footing. Fig. 1e shows a single HRSC supporting a rigid footing. In all the numerical analyses, the initial in-situ stress levels were predicted by considering a value of 0.5 for the at-rest pressure coefficient. Then, the analyses were carried out by removing the hole, replacing the column materials, and applying vertical pressure on the top of the rigid footing or adopting a prescribed displacement on the top of the model to simulate the rigid footing condition on the top of the stone column and the tributary area. To remove the effects of the element size, a fine mesh discretization was considered for all the models. As seen in Fig. 1, the boundary conditions in modeling single stone column loading were sufficiently extended. However, the boundary conditions of the unit cell models were adopted according to three assumed area replacement ratios, namely, 0.15, 0.25, and 0.35, which are the ratios normally used in practice. The soft soil and stone column materials were modeled using 15-noded triangular elements, and the geosynthetic reinforcements were simulated using 5-noded geogridtype elements. The Modified Cam-Clay (MCC) model and the Hardening Soil (HS) model were used for the clay and stone column materials, respectively. Moreover, a 20 PLAXIS, OSC, D=100 mm 30 PLAXIS, HRSC, D=100 mm, S =D 40 Experiment by Ghazavi et al. (2018), OSC, D=100 mm Experiment by Ghazavi et al. (2018), HRSC, D=100 mm, S =D 50 Fig. 3. Validation of numerical analysis for HRSCs. 900 1582 A. Ehsaniyamchi, M. Ghazavi / Soils and Foundations 59 (2019) 1579–1590 3. Numerical results In the literature, most of the tests performed on ordinary or reinforced stone columns were under quick undrained loading conditions for soft clay materials. However, the presence of a stone column causes the rapid dissipation of the excess pore pressure that is generated due to the undrained loading conditions. As a result, the insufficient column-bearing capacity and the changes in settlement are due to the consolidation of the surrounding clay. In this research, the Advanced Modified Cam-Clay and Hardening Soil constitutive models for clay and stone column materials, respectively, were used in the numerical analyses to study the long-term and short-term behavior of both HRSCs and ESCs. Also, to consider the free drainage effects of the stone column materials, a fully coupled flowdeformation analysis was used to simulate quick loading conditions and free drainage was assumed for the geosynthetic reinforcements. The clay parameters in the numerical analyses were the same as those used by Khabbazian et al. (2010) for Bangkok clay. For the stone column material, typical values were used (Table 1). For the various types of reinforced stone columns in the unit cell, various series of numerical analyses were conducted, details of which are given Table 2. To assess the effect of each parameter, all other parameters were kept constant according to the underlined values given in Table 2. Table 1 Material parameters for numerical models. Property name Soft soil Stone column Behavior Model csat (kN/m3) / (deg) c (kPa) w (deg) Eref 50 (MPa) Eref oed (MPa) Eref ur (MPa) M Ν Κ K eint kx (m/day) Ky (m/day) undrained MCC 20 – – – – – – 1.00 0.2 0.09 0.5 2 0.0003 0.0001 drained HS 20 40 1 0 150 150 450 0.5 0.2 – – – 3 1 Two different series of numerical analyses were performed to study the short-term bearing capacity and the long-term consolidation settlement of various types of single stone columns. The first series of analyses consisted of a short-term two-day coupled loading, performed by applying a prescribed settlement of 20 cm. However, the second series of analyses included a short-term two-day coupled loading performed by applying vertical stress that caused a 20-cm settlement at the end of the two-day loading period determined from the first series of analyses that was followed by a 100-day consolidation period. In all the analyses, constant values of 80 cm and 500 cm were considered for the diameter and the length of the stone columns, respectively. However, three different ratios of footing diameter (D0 ) to stone column diameter (D), namely, D0 / D = 1, 2, and 3, were adopted for the single stone columns. To determine the efficiency of the geosynthetic reinforcement on the load-bearing capacity of the stone columns, the bearing improvement factor (B.I.F.) is defined as the ratio of the bearing capacity of a reinforced stone column to the bearing capacity of an ordinary stone column with the same conditions at the same settlement values. In addition, to evaluate the settlement improvement of the reinforcements, the settlement improvement factor (S.I.F.) is defined as the ratio of the settlement caused by an ordinary stone column to the settlement caused by a reinforced stone column with the same conditions. The definition of both parameters, B.I.F. and S.I.F., are illustrated in Fig. 4. Moreover, as shown in Fig. 4b, parameter SEOL is defined as the settlement value of a stone column at the end of the loading stage, while parameter SF is defined as the final settlement value of a stone column at end of the consolidation process. 3.1. Unit cell modeling 3.1.1. Influence of loading rate and consolidation time To study the behavior of various types of reinforced stone columns at various loading rates, 15 coupled numerical analyses were carried out using three loading durations, namely, 2, 20, and 100 days, for applying 200 kPa of vertical stress on the top of the unit cell. These durations were selected to simulate rapid, medium, and slow loading rates, respectively. All analyses were followed by a consolidation analysis until 200 days had passed from the start of the loading period, in order to assess and compare the long-term behavior of all the stone column types. Table 2 Various numerical parametric analyses for unit cell concept of stone column. Series of parametric analyses Parameter details 1 Loading duration and consolidation time = 2 days of loading + 198 days of consolidation, 20 days of loading + 180 days of consolidation, 100 days of loading + 100 days of consolidation Column diameter = 50, 80, and 110 cm Area replacement ratio = 0.15, 0.25, and 0.35 Reinforcement stiffness = 1000, 3000, and 5000 kN/m Internal friction angle of stone column materials = 35, 40, and 45° 2 3 4 5 A. Ehsaniyamchi, M. Ghazavi / Soils and Foundations 59 (2019) 1579–1590 Fig. 4. Definition of reinforcement improvement parameters: (a) B.I.F. and (b) S.I.F. 1583 Fig. 5 shows the variation in the time-settlement behavior at the top of the unit cell in the OSC and various types of reinforced stone columns, while Fig. 6 compares the final settlement (sF) and the S.I.F. values at the end of 200 days. As seen in Figs. 5 and 6, all types of reinforcements were able to reduce the settlement of the OSC. The HRSC with Sr = 0.25D and the full-length ESC show the best reinforcement performances, providing high confining effects on the stone column materials. However, the halflength ESC and the HRSC with Sr = 0.5D show smaller improvement effects with low confining effects on the stone column material. Also, as seen in Fig. 6, the final long-term settlement of the OSC or the reinforced stone columns is independent of the column loading rate. In fact, the amount of final settlement of the loaded stone columns is seen to depend on the soil and the stone column material properties, the reinforcement stiffness, and the geometric conditions, and it is independent of the loading rate. Fig. 7 shows the excess pore water pressure levels at the end of the 2-day loading duration. As seen in the figure, by reinforcing the columns, the excess pore pressure decreases and the greatest decreases in excess pore pressure occur for the full-length ESC and the HRSC with Sr = 0.25D. Therefore, due to the small excess pore pressure generation with these types of reinforcements, minimum consolidation settlement is expected. Fig. 8 shows the variation in the ratio of the settlement at the end of the loading time (sEOL) to the final settlement at the end of consolidation (sF). As seen from Figs. 6 and 8, the loading rate has a very minimal effect on the final long-term settlements for all types of stone columns. However, the ratio of sEOL/sF varies greatly Fig. 5. Time-settlement behavior of various stone columns with different loading rates. 1584 A. Ehsaniyamchi, M. Ghazavi / Soils and Foundations 59 (2019) 1579–1590 Fig. 6. Variation in (a) final settlement (sF) and (b) S.I.F. values at end consolidation vs loading duration. for the various types of stone columns and the various loading rates. For example, for the 2-day loading rate, the value of sEOL/sF for both the full-length ESC and the HRSC with Sr = 0.25D is about 0.66. This indicates that these reinforcing types can reduce the consolidation settlement to the minimum value, even with very rapid loading. It is also seen that, by using the moderate time of 20 days of loading, the value of sEOL/sF for both the full-length ESC and the HRSC with Sr = 0.25D is more than 0.93. This means that most of consolidation settlement occurs within the first 20 days for these stone columns. However, the consolidation settlement rates for the half-length ESC and the HRSC with Sr = 0.5D are remarkably lower than those in the above cases, especially at rapid loading rates. Fig. 7. Excess pore pressure generated in various stone columns at end of 2-day loading duration: (a) OSC, (b) full-length ESC, (c) half-length ESC, (d) HRSC with Sr = 0.25D, and (e) HRSC with Sr = 0. 5D. Fig. 8. Variation in (sEOL/sF) vs loading duration for various stone columns. 3.1.2. Influence of stone column diameter Fig. 9 shows the time-settlement behavior of various diameters of 50, 80, and 110 cm for stone columns loaded up to 200 kPa of vertical stress in 2 days, followed by 198 days of consolidation time. As seen in the figure, with an increase in the diameter of all types of stone columns in the unit cell with a constant area replacement ratio, the consolidation settlement rate decreases and more time is required to reach the final settlement for larger diameters. The difference in the consolidation time for various diameters of the full-length ESC and the HRSC with Sr = 0.25D is very small, ranging from 2 days for D = 50 cm to 10 days for D = 110 cm. However, the consolidation time for the half-length ESC increases from 4 days for D = 50 cm to 20 days for D = 110 cm. Moreover, for the OSC and the HRSC with Sr = 0.5D, the consolidation time has the largest increase from about 15 days for D = 50 cm to about 60 days for D = 110 cm. In fact, the load-bearing behavior of the full-length ESC and the HRSC with Sr = 0.25D has minimum dependency on the surrounding clay behavior, and a minimum amount of excess pore pressure is generated for these types of reinforced stone columns. As a result, they experience minimum consolidation settlements. Fig. 10 shows the variation in the S.I.F. versus the diameter of the stone columns for various reinforcement types. A. Ehsaniyamchi, M. Ghazavi / Soils and Foundations 59 (2019) 1579–1590 1585 Fig. 9. Time-settlement behavior of various stone columns with different column diameters: (a) D = 50 cm, (b) D = 80 cm, and (c) D = 110 cm. the benefit of the encasement decreases with an increase in the diameter of these columns. It should be noted that, with an increase in the stone column diameter from 50 to 80 and 110 cm, the area ratio of the reinforcing material to the volume for the unit cell decreases from 2 to 1.25 and 0.91, respectively. In other words, with an increase in the diameter of the full-length ESC and the HRSC with Sr = 0.25D from 50 to 110 cm, the use of reinforcement material brings about a two-fold decrease. However, the S.I.F. decreases just about 19% for the HRSC with Sr = 0.25D. Therefore, from the viewpoint of the amount of consumption of the reinforcing material, the best reinforcement type is the HRSC with Sr = 0.25D for larger stone column diameters. Fig. 10. Variation in S.I.F. with column diameter for various stone columns. As shown in the figure, for all reinforcement types, the S.I. F. value decreases with an increase in the stone column diameter. However, the rate of decrease is much larger for the full-length ESC than for the HRSCs. Murugesan and Rajagopal (2010) and Castro and Sagaseta (2011) reported the same results for ESCs and concluded that 3.1.3. Influence of area reinforcement ratio Fig. 11 shows the time-settlement behavior of stone columns with various area replacement ratios. As seen in the figure, the rate of consolidation increases with an increase in the area replacement ratio for all types of stone columns. This is due to a reduction in the drainage path length and to bearing a larger part of the applied load by the stiffer stone column. In addition, the time it takes to reach the final settlement for the full-length ESC and the HRSC with Fig. 11. Time-settlement behavior of stone columns with different area replacement ratios: (a) 0.15, (b) 0.25, and (c) 0.35. 1586 A. Ehsaniyamchi, M. Ghazavi / Soils and Foundations 59 (2019) 1579–1590 Fig. 12. Variation in S.I.F. with area replacement ratio for various stone columns. Sr = 0.25D is minimum. This is because their behavior has only minimum dependency on the surrounding clay. Fig. 12 shows the variation in the S.I.F. with the area replacement ratio for various reinforced stone columns. As seen in the figure, the S.I.F. increases with an increase in the area replacement ratio for all cases. However, the rate of increase in the S.I.F. decreases for larger area replacement ratios. 3.1.4. Influence of reinforcement stiffness Fig. 13 shows the time-settlement behavior of various stone columns with reinforcement stiffness. As seen in the figure, for the full-length ESC and the HRSC with Sr = 0.25D, the total consolidation time decreases from about 10 days for J = 1000 kN/m to about 3 days for J = 5000 kN/m. However, the variation in reinforcement stiffness has no sensitive effect on the total consolidation time in the half-length ESC and or the HRSC with Sr = 0.5D. Fig. 14 shows the variation in the S.I.F. with reinforcement stiffness for various types of stone columns. As seen in the figure, the S.I.F. values increase with an increase in the reinforcement stiffness for all reinforcement types. However, the increases in the S.I.F. for the Fig. 14. Variation in S.I.F. with reinforcement stiffness for various stone columns. full-length ESC and the HRSC with Sr = 0.25D are much larger than those for the half-length ESC and the HRSC with Sr = 0.5D. In fact, the loading behavior of the fulllength ESC and the HRSC with Sr = 0.25D has a strong dependency on the reinforcement material stiffness and has much less dependency on the properties of the surrounding clay. However, the loading behavior of the half-length ESC and the HRSC with Sr = 0.5D not only depends on the reinforcement material stiffness, but also on the properties of the surrounding clay. Moreover, for the half-length ESC and the HRSCs, the rates of increase in the S.I.F. decrease with an increase in the reinforcement stiffness. This is because, with these reinforcement types, a moderate level of reinforcement stiffness of about 3000 kN/ m can produce a sufficient level of confinement effect on the column material in the reinforced parts of these columns and, by increasing the reinforcement stiffness from 3000 kN/m to 5000 kN/m, the main effective parameter on the behavior of stone columns is the bulging of the column materials at the unreinforced parts located between the horizontal layers of the HRSCs or at the lower unreinforced part of the half-length ESC. Therefore, the use of high stiffness for the reinforcements cannot bring about Fig. 13. Time-settlement behavior of various stone columns with reinforcement stiffness: (a) J = 1000 kN/m, (b) J = 3000 kN/m, and (c) J = 5000 kN/m. A. Ehsaniyamchi, M. Ghazavi / Soils and Foundations 59 (2019) 1579–1590 1587 greater improvement for either the half-length ESCs or the HRSC with Sr = 0.5D. However, in the cases of the fulllength ESCs and the HRSC with Sr = 0.25D, due to the full confinement of all parts of the columns, the horizontal displacements of the columns of all lengths were limited and the behavior of the stone columns was seen to mainly depend on the reinforcement stiffness. Therefore, with an increase in the stiffness of the reinforcements, even for high stiffness values, the S.I.F. value will increase. 3.2. Single stone column loading 3.2.1. Short-term bearing capacity of single stone columns To study the short-term bearing capacity of single reinforced stone columns and to predict the B.I.F. of various types of reinforcements, some coupled flow-deformation Fig. 16. Variation in S.I.F. with internal friction angle of column material for various stone columns. Vertical stress (kPa) 0 50 100 150 200 0 OSC Settlement (mm) 3.1.5. Influence of internal friction angle (/) of stone column materials Fig. 15 shows the time-settlement behavior of various stone columns with three values of 35, 40, and 45° for the internal friction angle of the stone column material. As seen in the figure, with an increasing /, the consolidation settlement rate increases slightly for all types of stone columns. In fact, by using a stronger material for the stone columns, a greater part of the load is tolerated by the column material, leading to a lower generation of excess pore pressure in the surrounding clay, and thus, the occurrence of lower consolidation settlement. Fig. 16 shows the variation in the S.I.F. with the internal friction angle of the column material for various types of reinforced stone columns. As seen in the figure, the S.I.F. value for all the stone columns increases with an increase in the internal friction. However, the rate of increase for the HRSCs is greater than that for the ESCs. This is due to the interlocking effect between the horizontal reinforcement layers and the column materials. In practice, this may help in choosing the type of reinforcement. Thus, HRSCs may be used when stronger column materials are available. Also, ESCs are preferable when poor materials are present in the stone columns. 40 HRSC, S =0.5D Half-length ESC 80 Full-length ESC HRSC, S =0.25D 120 160 200 Fig. 17. Variation in vertical stress-settlement behavior of various types of single stone columns. analyses were performed by applying a prescribed settlement of 20 cm for the duration of one day. In these analyses, three ratios, namely, D0 /D = 1, 2, and 3, and D = 80 cm, were considered for all cases. Figs. 17 and 18 show the variations in the vertical stress-settlement behavior and the excess pore pressure generated under Fig. 15. Time-settlement behavior of various stone columns with internal friction angle for stone column material: (a) 35°, (b) 40°, and (c) 45°. 1588 A. Ehsaniyamchi, M. Ghazavi / Soils and Foundations 59 (2019) 1579–1590 Fig. 18. Excess pore pressure under footing area for case of D0 /D = 2, due to 20-cm settlement of footing for various stone columns: (a) OSC, (b) HRSC with Sr = 0.5D, (c) half-length ESC, (d) full-length ESC, and (e) HRSC with Sr = 0.25D. the footing area, respectively, of various types of stone columns for D0 /D = 2. Table 3 presents the bearing capacity and the B.I.F. values at the end of 1 day of loading for various cases. As seen in Fig. 17 and Table 3, for all the D0 /D values, the HRSC with Sr = 0.25D and the full-length ESC have the best B.I.F., while the HRSC with Sr = 0.5D has the lowest B.I.F. value. In addition, the half-length ESC has a moderate effect on the B.I.F. In fact, as shown in Fig. 18, using a full encasement along the column or horizontal reinforcing layers with a low interval spacing provides a full confining effect on the stone column material. As a result, most of the applied load on the footing is tolerated by the stone column and a minimum amount of vertical stress is transferred to the surrounding clay. Thus, low excess pore pressure is generated in the soft soil. However, for the cases of the half-length ESC and the HRSC with Sr = 0.5D, no sufficient confinement is provided for the stone column materials. As a result, greater vertical stress is transferred to the surrounding clay; and thus, greater excess pore pressure is generated. This leads to an increase in the long-term consolidation settlement in such types of reinforced stone columns compared with the other cases. 3.2.2. Long-term consolidation settlement of single stone columns To investigate the long-term behavior, various types of single reinforced stone columns were initially modeled using a rigid plate on the top of the stone columns with various D0 /D and applying the amount of vertical stress that would lead to the same 20-cm settlement for all cases, according to bearing capacity values mentioned in Table 3. The vertical stress is applied for 1 day with a coupled analysis and, after that, a consolidation analysis is conducted to dissipate the excess pore pressure in the clay medium and to reach a steady state condition of the settlements. 1. The results of the time-settlement analysis for D0 /D = 2 are shown in Fig. 19. As seen in the figure, a maximum settlement of 4 cm occurs during consolidation for the HRSC with Sr = 0.5D. This is approximately equal to the consolidation settlement of an OSC. However, for the full-length ESC and the HRSC with Sr = 0.25D, the minimum consolidation settlements of 0.4 cm and 1.2 cm, respectively, occur. Therefore, by using fulllength ESCs or HRSCs with Sr = 0.25D, the long-term settlement of single stone columns can be significantly reduced, in addition to there being an improvement in the short-term load-bearing behavior. Fig. 19. Time-settlement variations for various types of single-stone columns during short-term, 1-day of loading, and long-term consolidation time to 200 days. Table 3 Bearing capacity and B.I.F. values at end of two days of loading for various single stone columns. D0 /D (D = 80 cm) OSC Bearing capacity (kPa) HRSC, Sr = 0.5D B.I.F. Half-length ESC B.I.F. Full-length ESC B.I.F. HRSC, Sr = 0.25D B.I.F. 1 2 3 63.5 25.9 19.9 2.87 2.97 2.4 6.53 4.14 2.71 10.74 6.8 4.34 9.88 7.07 4.55 A. Ehsaniyamchi, M. Ghazavi / Soils and Foundations 59 (2019) 1579–1590 1589 4. Conclusions References In this paper, various short-term coupled flowdeformation analyses and long-term consolidation analyses have been performed to investigate the behavior of various types of reinforced stone columns. Based on the numerical analyses, the following concluding remarks can be made: 2. All types of reinforcements can improve the short-term load-settlement behavior of OSCs and reduce their long-term consolidation settlement in both the unit cell configuration and the single stone column configuration. 3. The final long-term settlement of OSCs or reinforced stone columns is approximately independent of the column loading rate. This means that for all types of stone columns under a constant vertical load, the final longterm settlement will be equal for quick, medium, or slow loading rates. 4. By considering the results of the parametric analyses under both short-term and long-term conditions, the HRSC with Sr = 0.25D is the most efficient type of reinforcement for stone columns with the greatest B.I.F. and S.I.F. The full-length ESC is the second most efficient type, with a minimum difference between them. 5. With proper reinforcements, such as full-length ESCs or HRSCs with Sr = 0.25D, in addition to a considerable reduction in the settlement of the OSCs, the consolidation time can be greatly decreased and most of the settlement will occur during the loading time. 6. From the viewpoint of the amount of consumption of the reinforcing material, the best reinforcement type for stone columns is the HRSC with Sr = 0.25D. 7. For the unit cell concept, the long-term consolidation settlement rate of stone columns may be increased by using stone columns with smaller diameters and a larger area replacement ratio for the unit cell, stiffer geosynthetics for the reinforcements, and a greater internal friction angle for the stone column material. 8. Due to the interlocking effects between the reinforcement and the stone materials, the bearing capacity of HRSCs is more dependent on the internal friction angle of the stone column material than ESCs. This means that HRSCs are more effective when using stone materials with higher internal friction angles. However, when only poor materials are available, the use of full-length ESCs is preferable. 9. The bearing capacity of full-length ESCs and HRSCs with Sr = 0.25D is more dependent on the stiffness of the reinforcement material than the half-length ESCs and HRSCs with Sr = 0.5D. 10.By using the proper type of reinforcement, such as fulllength ESCs or HRSCs with Sr = 0.25D, the long-term settlement behavior of single stone columns will be decreased significantly, in addition to there being an improvement in the short-term load-bearing behavior. Ali, K., Shahu, J.T., Sharma, K.G., 2012. Model tests on geosyntheticreinforced stone columns: a comparative study. Geosynth. Int. 19 (4), 292–305. Ali, K., Shahu, J.T., Sharma, K.G., 2014. Model tests on single and groups of stone columns with different geosynthetic reinforcement arrangement. Geosynth. Int. 21 (2), 103–118. Castro, J., Sagaseta, C., 2011. Deformation and consolidation around encased stone columns. Geotext. Geomembranes 29, 268–276. Castro, J., Cimentada, A., Costa, A., Canizal, J., Sagaseta, C., 2013. Consolidation and deformation around stone columns: comparison of theoretical and laboratory results. Comput. Geotech. 49, 326–337. Cimentada, A., Costa, A.D., Izal, J.C., Sagaseta, C., 2011. Laboratory study on radial consolidation and deformation in clay reinforced with stone columns. Can. Geotech. J. 48 (1), 36–52. Deb, K., Behera, A., 2017. Rate of consolidation of stone columnimproved ground considering change in permeability and compressibility during consolidation. Appl. Math. Model. 48, 548–566. Elsawy, M.B.D., 2013. Behavior of soft ground improved by conventional and geogrid-encased stone columns, based on FEM study. Geosynth. Int. 20 (4), 276–285. Ghazavi, M., Ehsaniyamchi, A., Nazariafshar, J., 2018. Bearing capacity of horizontally layered geosynthetic reinforced stone columns. Geotext. Geomembranes 46 (3), 312–318. Ghazavi, M., Nazariafshar, J., 2013. Bearing capacity of geosynthetic encased stone columns. Geotext. Geomembranes 38, 26–36. Gniel, J., Bouazza, A., 2009. Improvement of soft soils using geogrid encased stone columns. Geotext. Geomembranes 27 (3), 167–175. Hong, Y.S., Wu, C.S., Yu, Y.S., 2016. Model tests on geotextile-encased granular columns under 1-g and undrained conditions. Geotext. Geomembranes 44, 13–27. Hosseinpour, I., Riccio, M., Almeida, M.S.S., 2014. Numerical evaluation of a granular column reinforced by geosynthetics using encasement and laminated disks. Geotext. Geomembranes 42 (4), 363–373. Keykhosropur, L., Soroush, A., Imam, R., 2012. 3D numerical analyses of geosynthetic encased stone columns. Geotext. Geomembranes 35, 61– 68. Khabbazian, M., Kaliakin, V.N., Meehan, C.L., 2010. Numerical study of the effect of geosynthetic encasement on the behavior of granular columns. Geosynth. Int. 17 (3), 132–143. Lu, M., Jing, H., Wang, B., Xie, K., 2017. Consolidation of composite ground improved by granular columns with medium and high replacement ratio. Soils. Founds. 57 (6), 1088–1095. Miranda, M., Da Costa, A., 2016. Laboratory analysis of encased stone columns. Geotext. Geomembranes 44 (3), 269–277. Murugesan, S., Rajagopal, K., 2006. Geosynthetic-encased stone columns: numerical evaluation. Geotext. Geomembranes 24, 349–358. Murugesan, S., Rajagopal, K., 2010. Studies on the behavior of single and group of geosynthetic encased stone columns. J. Geotech. Geoenviron., ASCE 136 (1), 129–139. Nazariafshar, J., Ghazavi, M., 2014. Experimental studies on bearing capacity of geosynthetic reinforced stone columns. Arab. J. Sci. Eng. 39, 1559–1571. Ng, K.S., Tan, S.A., 2014. Design and analyses of floating stone columns. Soils Founds 54 (3), 478–487. Pulko, B., Majes, B., Logar, J., 2011. Geosynthetic-encased stone columns: analytical calculation model. Geotext. Geomembranes 29 (1), 29–39. Pulko, B., Logar, J., 2017. Fully coupled solution for the consolidation of poroelastic soil around geosynthetic encased stone columns. Geotext. Geomembranes 45 (6), 616–626. Sharma, S.R., Kumar, B.R.P., Ngendra, G., 2004. Compressive load response of granular piles reinforced with geogrids. Can. Geotech. J. 41 (1), 187–192. 1590 A. Ehsaniyamchi, M. Ghazavi / Soils and Foundations 59 (2019) 1579–1590 Wang, G., 2009. Consolidation of soft clay foundations reinforced by stone columns under time-dependent loadings. J, Geotech. Geoenviron. Eng. ASCE 135 (12), 1922–1931. Wu, C.S., Hong, Y.S., 2008. The behaviour of a laminated reinforced granular column. Geotext. Geomembranes 26 (4), 302–316. Yu, Y., Bathurst, R.J., Damians, I.P., 2016. Modified unit cell approach for modeling geosynthetic-reinforced column-supported embankments. Geotext. Geomembranes 44 (3), 332–343. Zhang, L., Zhao, M., 2015. Deformation analysis of geotextile-encased stone columns. ASCE Int. J. Geomech. 15 (3), 04014053. Zhang, Y., Chan, D., Wang, Y., 2012. Consolidation of composite foundation improved by geosynthetic-encased stone columns. Geotext. Geomembranes 32, 10–17.