ANALYSIS OF API 5C3 FAILURE PREDECTION FORMULAE FOR

RIALS FOR

CASING & TUBING

EP OIL AND GAS WELL

NSTRUCTION

S. Staelens1, T. Galle1, W. De Waele1, P. De Baets1

1

Ghent University, Laboratory Soete, Belgium

Abstract Due to the increasing demand for oil and gas, coupled with the fact that oil reserves are becoming

rather scarce, the petroleum industry is pushed to drill and complete deeper wells. Threaded connections

are often the weakest link in this process and are therefore the subject of research and optimization.

terials for deep well

At first, this paper presents a brief overview of the design characteristics of today’s premium connections.

n must haveSecondly,

high the failure mechanisms of Oil Country Tubular Goods (OCTG) are discussed. At last, an in-depth

analysis of theatAPI 5C3 formulae is given. Four formulas for collapse are given in API 5C3, each valid for a

d corrosion resistance

specific D/t range. With increasing yield strength of the steel, the difference between the yield strength

atures.

collapse and the plastic collapse gets larger. Also, the elastic collapse zone gets bigger, so stronger

*

materials with relatively large D/t ratios will collapse in the elastic zone instead of the plastic or transition

zone. These four formulas can be approached by a third-order polynomial equation that is valid for all D/t

ratios.

o

Keywords: threaded and coupled; OCTG; buttress thread; premium connection; failure mechanisms

strates some of these successful

ns, in addition to more recent

Texas and the Gulf of Mexico.

as had to pursue ever more hosthan the original HPHT limits

o keep up with demand. In this

ns exceeding 400°F (204°C) and

MPa) at bottomhole have been

sly as Extreme HPHT (xHPHT)

HT. (The term HPHT is used

s article to include both extreme

Reservoir temperature, °F (°C)

1 demand

INTRODUCTION

asing worldwide

for oil

s coupled with the fact that the

and

completion of High Pressure/High Temperature (HPHT) wells are common practice. Some

oil productionDrilling

has been

reached

conditions

of

field examples are illustrated in Figure 1. Well depths up to 12000m are no longer unusual.

will be, has pushed the petroleum

Because

of

this

increasing depth, the pressure and temperature also increases. Clearly, the applied casing

drilling ever deeper wells. Well

and

tubing

have

0 ft (7620 m) and greater are noto be able to withstand extreme conditions. Failure of these OCTG can cost millions of

dollars, can

cause

al, and even deeper

wells

are environmental disasters and hence are to be avoided.

Because of the harsh conditions associated with HPHT wells, traditional OCTG threaded connections can

creasing depthno

means

increasing

longer

guarantee safety and premium connections are required [1]. Such connections have a better leak

mperature. High-pressure/highresistance and an overall

improved

integrity.

Drilling

rig at sunset.

PHT) wells have generally been

s in which temperatures and presInitial reservoir pressure, MPa

om of the well exceed 300 to 350°F

69

83

97

110

124

138

525

and 10,000 psi (69 MPa), respec(274)

HPHT wells have already been

pleted in this category with great

475

(246) Madden

unusual requirements for special

East Texas

Deep

425

(219)

!

!

!

Mobile Bay

Mary Ann

375

(190)

325

(163)

10

Erskine

!

!

Embla

12

!

Shearwater

!

Franklin

Thomasville

! !

! Elgin

Villa/Trecate

!

New Gulf of

Mexico

Fields

! Malossa

14

16

18

Initial reservoir pressure, ksi

20

Fig.

1 — Some

of the prominent

HPHT fields

in thewells

world.in the world [2]

Figure

1: Some

field examples

of HPHT

e challenges will be for both the Updated from Ref. 1.

The design

of premium

connections

differs

from the standard API connections in various ways. At first,

Liners,

tubing, and

strings

selves and materials

engineers

metal-to-metal

(MTM) seals

are

used to

guarantee

sealability.forIn addition, a torque shoulder can be

Figure

2 shows

a typical

wellthe

completion

m industry for the

future. Drilling

used to withstand

high unfamiliar

torques required

in HPHT

wells.

At last, the standard hooked or buttress thread

with the

industry

terminology.

ells requires specialized

methodsthethose

can be have

modified

in numerous

withstand

higher loads and conditions of HPHT wells [3].

Surface

casingways

and to

some

of thethe

intermediate

e planning, butshape

the materials

ed steel drill pipe and steel com- casing strings are not affected by HPHT condigh other alloys such as titanium tions, and thus standard steel tubulars function

well.

dered.

The major components that require greater ate real materials challenges are in

d producing the wells after they tention and represent materials challenges are the

s is the reason this article focuses liner at the bottom of the well, the tieback casing

string, the tubing (and associated jewelry), and

ction rather than drilling.

These design features and their effects are briefly discussed in the following section. More detailed

information can be found in [4, 5]. In the last section of this paper, the failure mechanisms of traditional

OCTG are summarized and an analysis of the formulae in API 5C3 is conducted.

2

DESIGN FEATURES OF PREMIUM CONNECTIONS

A typical premium connection is illustrated in Figure 2. It shows the three main features that can be

changed for obtaining an optimal design: the thread profile, the torque shoulder and the MTM-sealing area.

Though only these are discussed in the following paragraphs, it should be mentioned that the design of

premium connections is not limited to the above-mentioned three aspects. Various other improvements can

and are made to the premium connections of today such as applying a lubricant relief groove and/or stress

relief grooves, the use of “dopeless technology”, ….

SPE

97585

SPE

97585

Wedge effect

Figure 2: Typical premium connection (HES Seal-Lock Apex) [6]

Flank

toto

Flank

toto

Root

Flank

Flank Crest

Crest

Root

SPE

97585

SPE

97585

Figure

1. 1.

Thread

iInterferences

Figure

Thread

iInterferences

2.1

Thread design

The commonly used thread profile of premium connections is trapezoidal. Changes can be made to the

shape of the threads, the pitch (e.g. FOX, JFE [7]) and the interference between the thread of the pin and

the box (e.g. VAM21, VAM Services [8]). Each has its own effects.

Figure

5. 5.

Res

Figure

Re

Sample

Sample

For instance, when changing the shape of the threads, the following geometries are possible (Figure 3):

-

1 1

90°90°

90°90°

Positive load flank + positive stab flank (PLPS)

2 2

Neutral load flank + positive stab flank (0LPS)

Flank

to

Flank

Crest

to

Root

Crest

to Root

Negative load Flank

flankto+Flank

positive

stab

flank (NLPS)

Figure

1. 1.

Thread

iInterferences

Figure

Thread

iInterferences

Figure

5. 5.

Resilient

seal

in in

threaded

and

coupled

connection.

Figure

Resilient

seal

threaded

and

coupled

connection.

Negative load

flank

+ negative

stab flank (NLNS) Positive

Figure

6. 6.

ISO

Figure

IS

Load

Flank

Zero

Load

Flank

Positive

Load

Flank

Zero

Load

Flank

Load flank

Stab flank

90°90°

90°90°

Positive

Load

Flank

Positive

Load

Flank

PLPS

Zero

Load

Flank

Zero

Load

Flank

0LPS

90°90°

7.97"

1.123"-wall

P110

VAM

PRO

7.97"

1.123"-wall

P110

VAM

PRORSRS

E

IP IP

Seal

Seal

Sample

A Series

AS

C Series

Sample

A Series B Series

B Series

A

C Series

Tested

Tested

(psi)

(psi)

(psi)

(psi)

(psi)

(psi) (deg-F)

(deg-F) (p

MTM

- 25000

425

15I

MTM 27500

27500

25000

425 Inte

1 1

25000

425

15

RSRS

25000

- 25000

425

25000

90°90°

25000

425

15

MTM

- 25000 Figure

425

MTM 27500

27500

7. 7.

Typ

Figure

Ty

2 2

RSRS

25000

- 25000

425

15

25000

25000

425

Figure

6.Load

ISO

testing

with

metal

and

resilient

seals.

Negative

Load

Flank

and

Stab

Flanks

Negative

Load

Flank Negative

Negative

Load

and

Stab

Flanks

Figure

6.

ISO

testing

with

metal

and

resilient

seals.

NLNS

Figure

2. NLPS

forms

Figure

2.Thread

Thread

forms

Figure 3: Thread shape design possibilities [9]

Expanded

BoxBox

Expanded

External

Metal

SealSeal

External

Metal

Figure

8. 8.

VAM

Figure

VA

connection.

connection

easy to fabricate and repair, but isn’t often used in

Typical

SemiFlush

(SF)

Connection

Typical

SemiFlush

(SF)

Connection

with positive stab

flank

(0LPS)

diminishes

hoop

Figure

7. 7.

Typical

expanded

box

semi-flush

connection.

Figure

Typical

expanded

box

semi-flush

connection.

Internal

Metal

SealSeal

Internal

Metal

A combination of positive

load and stab flank (PLPS) is

90°90°

90°90°

casing and tubing applications. A neutral

load flank

stresses in the connection and is used for instance in the Hunting Energy Services (HES) FJ-150

connection [10]. Next, a negative load flank with positive stab flank (NLPS) reduces outward radial forces.

Negative

Load

Flank

and

Stab

Also, the connection’s

yield

strength

will Load

be

equal

toFlanks

or

greater than that of the pipe body [9]. However, the

Negative

Load

Flank Negative

Negative

Load

and

Stab

Flanks

pipe

axis

Parallel

toto

thread

cone

Parallel

to

pipe

axis

Parallel

thread

cone

Figure

2. 2.Thread

forms

Figure

Thread

forms the thread, so it isParallel

negative load flank

will

“undermine”

less3.tosuited

for

applications

where

high axial forces

Figure

– root

designs

Figure

3.Crest

Crest

– root

designs

Optional

R

Optional

Seal

Seal

Seal

Metal

occur. Examples of connections with such thread are numerous [8, 10, 11]: HES Seal-lock Apex, KSBEAR, Metal

9. 9.

VAM

Figure

VA

VAM21, TenarisHydril HW… At last, a negative stab flank can also be used. When combined with a Figure

connection

w

connection

negative load flank (NLNS or “dovetail”), the connection can withstand high

torque

loads

[9].

Examples

are

Figure

8. 8.

VAM

PRO

- Pin

nose

toto

pin

nose

with

radial

metal

seal

Figure

VAM

PRO

- Pin

nose

pin

nose

with

radial

metal

sea

connection.

connection.

the Tenaris Wedge 553 and the XL Systems – National Oilwell Varco XLF connections [10].

Secondary

Metal

Seal

Secondary

Metal

Seal

Parallel

toto

pipe

axis

Parallel

toto

thread

cone

Parallel

pipe

axis

Parallel

thread

cone

Figure

3. 3.Crest

– root

designs

Optional

Resilient

Figure

Crest

– root

designs

Optional

Resilient

Figure

4. 4.10!”

x 101

lb/ft

VM110SS

VAM

HPHP

SC80

Threaded

and

Figure

10!”

x 101

lb/ft

VM110SS

VAM

SC80

Threaded

and

2.2

Shoulder design

When applying a torque shoulder (Figure 2), a higher torque load can be applied and the total applied

torque load can be controlled better. Therefore, the risk of galling and over-torque reduces. In addition,

make-up gets easier and the sealability of the connection can be better guaranteed [4, 12].

A connection with a “reversed torque shoulder angle”, as seen in Figure 2, causes a “wedge effect”. This

improves the self-alignment, radial stability and structural strength of the connection [4].

2.3

Metal-to-metal sealing design

The last and essential design characteristic of premium connections is the radial metal-to-metal seal. They

are currently the most effective pressure seal and are located above the torque shoulder. The following two

types exist (Figure 4):

Cone-to-cone MTM seal: both MTM surfaces of pin and box have a conical shape;

Sphere-to-cone MTM seal: the MTM surface of the pin has a toroidal shape, whilst the MTM

surface of the box is conical.

-

Structural Analysis

Figure 4: Schematic diagram of a cone-to-cone MTM seal (left) and a sphere-to-cone MTM seal (right)

'%###

:1.3204/-.0-2;61,,<6127=>.9

If a cone-to-cone

MTM seal is Connections

used, overall, a smaller seal contact pressure will be applied =?2@A4/1B

than when a

OCTG Premium

&%$##

sphere-to-cone MTM seal is used. On the other hand, the

actual seal length will be larger. This!##C2>02@A4/1B

is visualized

!DEC2>02@A4/1B

in Figure 5, were the seal contact pressure in function&%###

of the distance along the seal area is measured

Cone-cone

sealconnections at make-up, 100% collapse pressure and 197%

through numerical analysis for

OCTG premium

!%$##

collapse pressure. The large peaks in the contact pressure at the beginning and the end of the seal area for

!%### rather than being physical truths. They occur

a cone-to-cone MTM seal are due to numerical errors

because of geometric transitions in the connection and$##will enlarge the risk of galling. Based on these

results, it cannot be concluded which MTM seal gives the best results. Additional experimental testing

#

should be conducted.

)

$

(

'

&

!

#

*+, -./012.34/52, 1.32.61.278 8 9

ections

=?2@:;F161B

=?2@A4/1B

!##C2>02@:;F161B

&%$##

!##C2>02@A4/1B

&%$##

:1.3204/-.0-2;61,,<6127=>.9

ne seal

'%###

'%###

:1.3204/-.0-2;61,,<6127=;.9

nalysis

!DEC2>02@A4/1B

&%###

!%$##

!%###

!DEC2>02@:;F161B

&%###

!%$##

!%###

$##

$##

Sphere-cone seal

#

)

$

(

'

&

!

#

#

)

$

(

'

&

!

#

*+, -./012.34/52, 1.32.61.278 8 9

*+, -./012.34/52, 1.32.61.278 8 9

'%###

:1.3204/-.0-2;61,,<6127=;.9

=?2@:;F161B

Figurewww.simytec.com

5: Seal contact pressure and distance

along seal area of a cone-to-cone (left) vs. a sphere-to-cone

!##C2>02@:;F161B

&%$##

G/2-F1284H13+/524I2+/H<,-6+.32;6401,,1,

!"

!DEC2>02@:;F161B

MTM seal (right) [13]

3

one seal

&%###

FAILURE MECHANISMS OF THREADED CONNECTIONS IN OCTG

!%$##

3.1!%### Structural failure

$##

When

a connection fails structurally, an ultimate limit state is crossed: the connection will completely or

partially

“break down”. The following failures comply with this definition:

#

)

$

(

'

&

!

#

Jump-out When

a connection

is axially loaded, excess radial displacement can occur. Space is

*+, -./012.34/52,

1.32.61.278 8 9

created between the thread profiles of pin and box. When this space becomes large enough, the

pin will jump out the box. This is illustrated in Figure 6 for a standard buttress API connection;

G/2-F1284H13+/524I2+/H<,-6+.32;6401,,1,

!"

- Rupture of the pipe or box at the most critical

section without the development of large plastic

strains. This can occur due to an excessive and/or cyclic load (fatigue).

-

-

1278

Collapse failure Pipelines under excessive axial load, external pressure and bending can fail by

global (helical buckling of the pipe) or localized (sectional loss of round shape) collapse. To

quantify the collapse pressure, it is important to take manufacturing imperfections such as (initial)

ovality, eccentricity and residual stress into account. When the imposed bending curvature

increases, the effect of the initial ovality on the collapse pressure diminishes due to the “Brazier

effect” [14].

Y. Guangjie et al. / Engineering Failure Analysis 13 (2006) 1275–1284

the pipe is evidently higher than that of the coupling. The strain at the first engaged thread of the two ends of

the pin is very large even to 6000 le. At make-up about two turns there is a generalized plastification

of the pin

/012#3454

ᑨ

nose.

6#7$8

3.2. Distribution of normal contact force

The normal contact force distribution of the tubing thread flank along the axial direction is shown in Fig. 4.

The shape of the normal contact force distribution is like a saddle. This is in accordance with the phenomenon

that thread galling failure easily appears at the two ends of tubing threaded connections in !"#$%

oil and gas fields. It

was further found that make-up or break out on a tubing connection will affect the taper of the pin and reduce

the pitch diameter. Ovality of tubing or coupling does not affect the contact stress distribution pattern in the

circumferential direction; however, it affects the actual value of the contact stresses.

) W

) W

) W impact

) W

)normal

W contact

W

) W

The tensile load

has a definite

on the !"#$%&,(-.

force )distribution.

The normal contact force of

!"#$%&'()

!"#$%&'*(

!"#$%&+)'

!"#$%&,(-!"#$%&,('( !"#$%&,,*(

the lead flank of the

thread

diminishes

under

the

action

of

tensile

load,

and

is

shown

in Fig. 5. Furthermore, it

6,8

6)8

698

6.8

6*8

6-8

6:8

has a strong influence on the equivalent stress distribution, and the maximal equivalent stress!appears at the

first engaged thread

of the

end of thephenomenon

male thread. for

Thea average

pressure

at the stab flank decreases

Figure

6: Jump-out

standardcontact

buttress

API connection

/tension. The leak resistance

with

increasing

according

to

the

API

(1987)

formula

does

not depend on applied

(P-110

244.47mm

x

11.99mm)

[15]

%&'()'!*+,-'+,#*&'.

0'12,'3"4&4'45%&440'6&789*+45":';2,&)'<$=982$5'!>'4"=$*+5"2,'2

tension. However, the test results and FEA calculations indicate that tension will reduce the sealability of an

$55%&44':2,,&:5"2,'

API- 10-R

tubing

connection.

Galling

When

two metal surfaces are in relative converging contact, for instance during make-up,

there of

is the

a chance

of adhesive

and transport

of material

between of

thenormal

two metallic

The taper

pipe thread

is also anwear

important

factor affecting

the distribution

contactsurfaces.

force of

This leads

directlyThe

to the

deterioration

of sealcontact

performance

connection

[16].

risk of

the oil casing

and tubing.

distribution

of normal

force isand

shown

in Fig. 6strength

under the

APIThe

ultimate

galling

is higher

at the

the pin

and

box.

This

is also

indicated

by the

saddle-shaped

normal

conjugate

of 0.067708

taper

pinend

and of

0.0599

taper

box.

The

work

situation

is named

as small

head and big

hat

contact

forceFig.

distribution

of the

tubing thread

flank

alongforce

the axial

anultimate

API 8-round

in oil and

gas fields.

7 shows the

distribution

of normal

contact

underdirection

the other of

API

conconnection

(Figure

7).0.067708 taper box. This is named as big head and small hat in oil and gas fields.

jugate of

0.0599 taper

pin and

/012#3454

ᑨ

6#7$8

Fig. 4. The normal contact force distribution of tubing thread flank after making-up two turns.

Figure 7: The normal contact force distribution of

tubing thread flank after making-up two turns (API 8-round) [16]

!"#$%

3.2

Functional failure

) W

) W

) W

) W

In addition to structural

failure,

there

is

functional

failure.

Functional

failure

of a threaded connection occurs

6B0D[

6B0D[ 6B0D[ 6B0D[ when the connection

no

longer

complies

with

the

demands

of

serviceability

and sustainability, for instance

6,8

6)8

698

6.8

when a connection fails in preventing a gas or liquid from leaking. This can be due to! misuse of the

connection or poor design. Numerical analysis can estimate the sealability of a connection relatively, but

only laboratory /

or full scale testing can fully quantify the exact sealability [17].

%&'B)'!*+,-'+,#*&'C 0'12,'3"4&4'45%&440'6&789*+45":';2,&)'<$=982$5'!>'4"=$*+5"2,'2

$55%&44':2,,&:5"2,'

Fig. 5. The normal contact force distribution of tubing thread flank after making-up two turns and applying 120 kN tensile load.

3.3

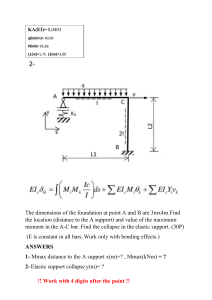

In-depth analysis of API 5C3 formulae

Some of the above-mentioned structural failures can be calculated by the formulae and methods presented

in API 5C3 [18]. The collapse pressure, internal pressure resistance (also known as burst resistance) and

joint strength of threaded connections have been analysed and are discussed in the following paragraphs.

The analysis is limited to standard API buttress threaded connections and forms a first step towards the

research of premium connections.

3.3.1

Collapse pressure

The collapse pressure in the absence of axial loading and internal pressure can be calculated by means of

four formulas (see below). Depending on the type of collapse, which translates itselves to a certain

applicable D/t range, and the minimum yield strength of the pipe body (Yp), another formula governs, rather

than the collapse formula that gives the lowest collapse pressure.

For the smallest D/t ratios (D/t < ∼ 11-16 depending on steel grade) or for thick wall pipe, the yield strength

collapse pressure is decisive. It is derived based on yield at the inner wall using Lamé thick wall elastic

solution. It is thus not a true collapse pressure, but rather the external pressure PYp that generates hoop

stress exceeding the yield strength of the material before a collapse instability failure occurs [19].

!/! !!

!!" = 2!!

(1)

!/! !

Next, for increasing D/t ratios, the plastic collapse pressure governs. It has been empirically derived based

on 2488 tests of K-55, N-80 and P-110 seamless casing. Through regression analysis, the following

formula for the minimum collapse pressure for the plastic range of collapse was found (A, B and C are

curve fit factors depending on the steel grade):

!! = !!

!

(!/!)

−! −!

(2)

A plastic/elastic transition collapse pressure formula was determined on an arbitrary basis to connect the

plastic and elastic regimes with each other (F and G are curve fit factors depending on the steel grade):

!! = !!

!

(!/!)

−!

(3)

At last, for thin-wall pipe or D/t ratios larger than ∼ 20-40 depending on steel grade, the elastic collapse

pressure is conclusive. It is based on a theoretical elastic instability failure and is independent of the yield

strength. It can be calculated by means of the following formula:

!! =

!",!" × !"!

!/!

(4)

!/! !! !

The above-mentioned formulas and their representative zones of validity are graphically presented for steel

tubes of grade N-80 with various D/t ratios in Figure 8 (left). Next, a comparison is made of the collapse

pressures depending on the grade used (J-55, N-80 or P-110) (see Figure 8, right). The vertical lines in the

graphs represent the boundaries of elastic collapse zones. P_YP represents the yield strength collapse

pressure, P_P the plastic collapse pressure, P_T the transition collapse pressure, P_E the elastic collapse

pressure and P_c the effective collapse pressure depending on the type of collapse or the representative

D/t ratio.

%#!"

*.,/0"

1+2,34+5"

%!!"

(/61+.7"

+26318

.+.93""

,/61+.7"

!"##$%&'(%)'&&*)'(+,-$.(

!"##$%&'(%)'&&*)'(+,-$.(

%#!"

$#!"

;316:,"

$!!"

#!"

16:,"

$!"

()*("

02.-345"

$#!"

1*-./0"

$!!"

#!"

-./0"

!"

!"

%!!"

%!"

()("

/01(+2.(

()+"

&!"

'!"

(),"

#!"

()-"

!"

!"

$!"

()##"

%!"

/01(+2.(

*)+!"

&!"

'!"

#!"

,)$$!"

Figure 8: Grade N-80 collapse pressures (left) and grade J-55 vs. N-80 vs. P-110 collapses pressure (right)

As stated above, depending on the type of collapse or D/t range and the minimum yield strength of the pipe

body, another formula governs, rather than the collapse formula that gives the lowest collapse pressure.

This can be seen in Figure 8 (right). The transition collapse pressure formula gives a smaller value in the

first two zones, but there, the yield strength collapse pressure formula or the plastic collapse pressure

formula should be used.

When the grade of the material increases, so does the collapse pressure (Figure 8, right). However, only

the yield strength collapse and plastic collapse show a significant difference between the collapse

pressures of the different grades. When entering the transition and elastic collapse zone, the collapse

pressures of the different grades do not differ (much) from each other.

Another trend that can be seen when the material gets stronger (e.g. N-80 or P-110) is that the yield

strength collapse, plastic strength collapse and transition collapse zone gets smaller while the elastic zone

gets relatively larger (see Figure 8, right). This means that when stronger materials are used, the pipe will

rather fail due to elastic collapse than due to plastic or transition collapse.

!"#$#+,(,,)'./012)#3#,(444%./012%#+#-5(-66./012#3#%)%(6&#

!"##$%&'(%)'&&*)'(+,-$.(

%7,#

!"#$#%&'()*+,(-,-./012#

%,,#

EF8G/#

HIJ8KLIM#

-7,#

-,,#

!GNHIFO#

IJNKH+

FIFPK##

8GNHIFO#

RKHNQ8#

7,#

HNQ8#

,#

,#

-,#

%,#

89:;<*<=>?#1@*<A#?B<*#

/01(+2.(

),#

4,#

!;?C<;DB>?#1@*<A#?B<*#

7,#

!"#$%&'&()&"*+,-(+.$/,"0'&(1",$(&"234"

30/(1/'1"

Through curve fitting, a third-order polynomial trend line and an exponential trend line are found to match

the effective collapse pressures, independent of the sort of collapse or D/t ratio (see Figure 9, left). The

differences (in percentage) between the polynomial trend line and the formulas given in API 5C3 are shown

in Figure 9 (right) for steel tubes of grade N-80. Similar trends and differences were found for the

exponential trend line.

"#$%&

"#$"&

"#'%&

"#'"&

"#"%&

"#""&

!"#"%&

!"#'"&

!"#'%&

,0.12&

3-4.56-7&

!"#$"&

*183-09& -4853!

0-0:5&&

.183-09&

!"#$%&

"&

*+,*&

'"&

$"&

*+*&

#50"678"

*+-&

("&

)"&

*+.&

%"&

*+/&

Figure 9: Polynomial and exponential trend lines of the effective API 5C3 collapse pressure (left) and

Differences (%) between the polynomial trend line and the API 5C3 collapse pressures (right)

When a next type of collapse zone is entered, for instance going from yield strength collapse to plastic

collapse, it can be seen that the difference between the trend lines and the API 5C3 formulas reaches a

peak. This means that API 5C3 changes formulas because the calculated collapse pressure differs too

much from the “real collapse pressure”, calculated with a polynomial or exponential trend line valid for all

D/t ratios.

However, when going from the transition collapse zone to the elastic collapse zone, this peak doesn’t

occur. This can be explained as follows. The plastic/elastic transition zone is derived on an arbitrary basis

to connect the plastic collapse pressures with the elastic collapse pressures for given D/t ratios. As stated

above, depending on the grade of the material, the yield strength collapse and plastic collapse pressures

differ, whilst the elastic collapse pressures remain constant. A peak is therefore expected when going from

the plastic collapse to the transition collapse zone, but not when going from the transition collapse to the

elastic collapse zone.

Figure 10 (left) graphically presents a comparison between the differences of the polynomial and

exponential trend lines (Grade N-80) versus the API 5C3 collapse pressures. It can be seen that a thirdorder polynomial equation gives an overall better result. However, the differences (in percentage) are very

small (between -0,025% and 0,075%), so a single equation to calculate the collapse pressures could be

appropriate. Figure 10 (right) compares the percentual differences between polynomial trend lines and API

5C3 predictions for tubes with J-55, N-80 and P-110 steel grade. When increasing the steel grade, the

difference between the trend line and the in API 5C3 calculated collapse pressures also increases, but

overall the same conclusion can be drawn: the differences (in percentage) are very small compared with

the in API 5C3 calculated collapse pressures. Therefore, it should be possible to derive a single (third

degree polynomial) formula for each steel grade to calculate the collapse pressures as a function of D/t

ratio.

;<+=>%

?@A+BC@D%

"#"'$%

8=E?@<F% @AEB?!

<@<GB%%

+=E?@<F%

"#"$%

"#"&$%

"%

!"#"&$%

!"#"$%

"%

("%

&"%

)"%

*"%

$"%

!"#$%&'&()&"*+,-(+.$/,"0'&(1",$(&2"324"

20/(1/'1"

!"#$%&'&()&"*'+*+,&-".'&(-/$(&,"0,1"

,.2(-2'-"

"#(%

"#"'$%

"#"$"%

"#"&$%

"#"""%

!"#"&$%

!"#"$"%

"%

&"%

)"%

*"%

$"%

#50"678"

#3."456"

+,-./0/123%450/6%37/0%

("%

+!$$%

8.39/.:723%450/6%37/0%

,!-"%

.!(("%

Figure 10: % Difference of grade N-80 polynomial and exponential trend lines vs. API 5C3 collapse

pressure (left) and % difference of grade J-55, N-80 and P-110 polynomial trend lines vs. API 5C3 collapse

pressures (right)

3.3.2

Internal pressure resistance

The internal pressure resistance of a threaded and coupled pipe is equal to the minimum of the internal

yield pressure for pipe or coupling and the internal pressure leak resistance at the seal plane (this is the E7

plane of perfect thread length). Formulas are given in API 5C3 and are repeated here below:

Internal yield pressure for pipe:

! = 0,875

Internal yield pressure for coupling:

! = !!

Internal pressure leak resistance at seal plane:

! = !"#$

!!! !

(5)

!

!!!!

(6)

!

! ! !!! !

(7)

!!! ! !

Where Yp and Yc are respectively the minimum yield strength of the pipe and coupling in pounds per square

inch. D and t are the nominal outside diameter and nominal wall thickness of the pipe, W is the nominal

outside diameter of the coupling and d1 is the diameter at the root of the coupling thread at the end of the

6

pipe in the powertight position, all in inches. Next, E is the modulus of elasticity (= 30 x 10 psi), T the

thread taper (in./in.), N the number of thread turns make-up and p the thread pitch (inches).

!"#$%"&'()%$**+%$(%$*,*#&"-$(./0&1(

The internal pressure resistance for buttress threaded and coupled pipe (D = 7”, grades J-55, N-80 and P110) in function of D/t is presented in Figure 11. Also, the internal pressure leak resistance at the seal plane

(IPLR), which is independent of D/t and the yield strength of the steel, is visualized.

#!!"

D = 7"

+!"

*!"

)!"

(!"

UNSAFE

'!"

&!"

%!"

$!"

SAFE

#!"

!"

!"

#!"

$!"

%!"

&!"

'!"

(!"

23#(.41(

,-''"

.-*!"

/-##!"

0/12"

Figure 11: Internal pressure resistance (Grade J55 vs. N-80 vs. P-110)

In all cases, the internal yield pressure for pipe or coupling is smaller than the internal pressure leak

resistance at the seal plane. For small D/t ratios (D/t ≤ 15,9), the internal yield pressure is no longer a

function of D/t, thus, the coupling is decisive. In all other cases, the pipe body is the weakest member in a

threaded and coupled connection.

3.3.3

Joint strength

The joint strength of a buttress thread casing joint is taken as the minimum of the pipe thread strength and

the coupling thread strength, given by the following formulas [18]:

Pipe thread strength:

!! = 0,95!! !! 1,008 − 0,0396 1,083 −

Coupling thread strength:

!! = 0,95!! !!

!!

!! !

(8)

(9)

Where Ap and Ac are respectively the cross-sectional area of the plain end pipe and the coupling in square

inches and Up and Uc are respectively the minimum ultimate strength of pipe and coupling in pounds per

square inch.

A graphical representation of the buttress casing joint strength for grades J-55, N-80 and P-110 in function

of D/t (D = 7”) is given in Figure 12.

!"#$%&'()$%*'#*+,%&-*'./01'

(!!!"

D = 7"

'!!!"

&!!!"

UNSAFE

%!!!"

$!!!"

#!!!"

SAFE

!"

!"

#!"

$!"

%!"

&!"

'!"

(!"

23*'.41'

)*''"

+*,!"

-*##!"

Figure 12: Casing joint strength (grades J-55 vs. N-80 vs. P-110)

A similar trend as for internal yield pressure can be seen here: the casing joint strength depends for the

most part on D/t, which means the pipe thread strength is determinative. Only for D/t ratios less than ±14,5,

the coupling is the weakest part of a threaded and coupled pipe.

4

CONCLUSIONS

Due to the harsh conditions in HPHT wells, standard threaded OCTG can no longer be used and premium

connections are required. By changing the design of these premium connections, other properties can be

achieved. By modifying the thread form, structural integrity against axial loads, external and internal

pressure and bending can be acquired. The design of a torque shoulder determines how much torque load

can be applied. At last, the metal-to-metal seal provides the sealability of the connection. The design of a

premium connection is however not limited to these three parts of the connection. More information can be

found in other literature [4, 5].

When analysing the failure mechanisms of standard threaded OCTG, the following conclusions can be

drawn for the collapse pressure. When the used material gets stronger (e.g. N-80 and P-110), the

difference between the yield strength collapse and plastic collapse gets larger. Also, the elastic collapse

zone gets larger. This means that when stronger materials are used, the pipe will rather fail due to elastic

collapse than due to plastic or transition collapse. A third-order polynomial trend line can be derived that

describes the collapse pressure independent of the D/t ratio.

When analysing the internal pressure resistance and joint strength of threaded and coupled connections, it

is clear that the pipe body is the weakest link. Only for D/t ratios between smaller than ∼14-15, the coupling

is critical.

5

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

REFERENCES

J. Van Wittenberghe, et al., Fatigue investigation of threaded pipe connections. Sustainable

Construction and Design (SCAD), 2010. 1(1): p. 182-189.

Craig, B., Materials for deep oil and gas well construction, in Advanced Materials & Processes, May

2008: p. 33 - 35.

L.B. Hilbert Jr. and I.A. Kalil. Evaluation of Premium Threaded Connections Using Finite-Element

Analysis and Full-Scale Testing, SPE/IADC Drilling Conference, New Orleans, Louisiana, USA,

1992.

Galle, T., et al., Influence of design features on the structural integrity of threaded pipe connections.

Sustainable Construction and Design (SCAD), 2011. 2(2): p. 237-245.

J. Van Wittenberghe, et al., Design Characteristics that improve the fatigue life of threaded pipe

connections. Sustainable Construction and Design (SCAD), 2011. 2(2): p. 334-341.

Hunting, HES Seal lock Apex, U.S. Pat. No. 4,600,225, 2002

Yamamoto, K., et al., Stress Analysis of Premium Threaded Connection “FOX” by Finite Element

Method, in Kawasaki Steel Giho 20, 1989: p. 202-207.

Sugino, M., et al. Development of an Innovative High-performance Premium Threaded Connection

for OCTG, Offshore Technology Conference, Houston, Texas, USA, 2010.

Bradley, A.B., et al. Premium Connection Design, Testing, and Installation for HPHT Sour Wells,

SPE High Pressure-High Temperature Sour Well Design Applied Technology Workshop, The

Woodlands, Texas, U.S.A, 2005.

World Oil, 2008-09 Casing Reference Tables, November 2008

Takano, J., et al., Development of Premium Connection “KSBEAR” for Withstanding High

Compression, in Kawasaki Steel Giho 34, 2002: p. 21-28.

Santi, N.J., et al. Premium & Semi-premium Connections Design Optimization for Varied Drillingwith-Casing Applications, Offshore Technology Conference, Houston, Texas, USA, 2005.

Dvorkin, E.N. On the modeling of industrial processes, SIM&TEC. 2010.

Dvorkin, E.N. and R.G. Toscano, Finite element models in the steel industry: Part II: Analyses of

tubular products performance. Computers & Structures, 2003. 81(8-11): p. 575-594.

Lian Zhanghua, et al., Analysis of jump-out loads on connectors of buttress and round threads of

casing. China Petroleum Machinery, 2004-05.

Guangjie, Y., et al., Numerical and experimental distribution of temperature and stress fields in API

round threaded connection, in Engineering Failure Analysis 13, 2006: p. 1275 – 1284.

Cernocky, E.P., et al. A standardized approach to finite element analysis of casing-tubing

connections to establish relative sealing performance as a function of design geometry, machining

tolerances and applied loads, Fourth World Congress on Computational Mechanics, Buenos Aires,

Argentinië, 1998. p. 1167 - 1186.

API Bull 5C3, Petroleum and natural gas industries - Formulae and calculation for casing, tubing,

drill pipe and line pipe properties, 1993, American Petroleum Institute.

Mitchell, R.F., Casing Desing, in Petroleum Engineering Handbook, Volume II: Drilling Engineering,

2007.