Phase Diagrams POM

advertisement

nase diagrams:

Introduction

Phase Diagrams

Introduction

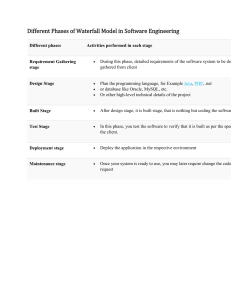

Cu-NiAlloy (Cu-NiSystem)

Cu (CCP) T= l085°C

Ni (CCP

TN= 1453C

Ni C1453°c)

Trm

Liguidus

lia

T

K

12c

S cCPND

(Subs+iwAom Solid

Solution of Cu & Ni

CcCP

C

NIPPEL

7C°5*lo83)/2

w t Ni?

Combositian

Ni

TSC, 1IT OLHI,

E Phase diagrams: Introduction

Equil ibrium Phase Diaqram

Equil ibrium Diagram

Phase Diagram

A diagram in the space of relevamt

thermodynamic vaniables Ceg. temperature

and composition)

equilibrium

22:17/22:35

in dicatin9 bhases in

is called

a

PHASE DIAGRAM,

E Phases and componentsS

Phases

NPREL

I

0:07/14:35

Combonents

Phase: A chemically homoqeneovs,

physically distinct and

mechanically sebanabe bant of

a system is called a

phase

Three phases of matter

Ligvid, Solid, Gas.

Solid Phases: Differmnt crystal Structru

will be considesed difforhnt phasu.

Fe

BCC ( ) ,

CCP (T)

TSC, IT DLH!

EPhases and components

Combonent The Indefpendent chemical speies

which he

Celement, Combound) n terms

Combosi tion

e

a

system

is

specifed

called Cómponénts.

In

Cu-Ni

I

7:48/14:36

NPEL

of

ane Cua

System:Componenhamd

N

is

i

Some 6xamples

System

Phasess

Combonenfs

liqvid

hlater

Water +ice

Brine

Mild Stee

iquid +Jolid

HO

NaCl+ HO

Fe,

igvld Soluton

C

Gibbs Phase Rule: relation

of no. componeni, no.

deqrees

freedorn.

haase

and

ETSC, UT D

E Phases and components

Tybes of Phase Diagrams

Based

numberr of Combonens

on

Unary Diagram

Single Combonent

Ginary

Diagram

Two Combonents

Ternany Diagram

Three Combonents

E Uses of phase diagrams

Three vestions

That

can

be ansarered usin9

Phase Diagram

ConstitutionPoint

Ten

Cu-Ni Binary Diagramn

Combesio

1500

1453 A þolnt(«T)

On the

1400

bha se

Solidus

L+

1300

1200

Liquidus

Liquidus

A

C0tN

1200

1400

2p

ComposiHon

Xhald in

Cquilbrium

af temp.T.

1085

1000

diagran

represents

an aley of

Compositton

w t f Ni

Ni

ETSC, IT DELHI

5 Uses of phase diagrams

The 7hree Questions

Sor any

consihution

point cx, Tphase diagram

can be vsed to anSwien 3

Q1 bat

ore

the

guesions

phases bresent ?

2 : What ane he combositions of the phases ?

Q3

NPTEL I

What

ans

the relative amounh

of

the

phaser?

ETSC JIT DELHL

8:36/8:59

E Phases presentin thesystemn

Phasel Diagramns

What

at

a

are the

bhases bresent

iven constitutian boint

T)?

Comp

Tevop

ETSC IUT OELHI

K

PE

0:35/9:55

Phasees present at a qiven constitution

paint Cx, T

Binan"Cu-Ni Diagram

A:co wt

400

1200c

L

Phase: -phase.

B 50a t N i

1300

1200

A

1250C

Phase

4400

4000

u Cu 20

PTE

Ne

60

wtNi

o

N

+

Tan phases.

ETSC, I T DTLHI

The 1-2-1 Rule

fremove

horizontelly

1500

Clsotherm)

L

rom one

ingle phare

a

1300

anothn single

hane (eq.o «)

t200

m

we will

alays hare q

2-6haa LtR

1100

1000C

1PTE

to

20

40 N Go

wt Ni

to

Ni

region in

bénween.

ETSC, UT DELHI

Phase Diaqrams

Q2

What are

combositions oF

the

the bhases

?

breseht

EComposition of phases present inthe system

Combosition

fracton. cr f

kctA,

differant components

wt fract#on

atom

Co

atom fracien

alloy combositon

Cfrachon of combonens in he whole

alloy

phase

I

3:54/12:40

þhase CombosiHon

fraction of compannG in aginen

hase)

ETSG, IT DELHI

Combosition for

the constitution Pbint A

Co

A

1500

o

t

Ni

4150

1400

Phase:

C

1300

Co

1200

For single phase

A

Phase Combosito

1100

)

1000

O

C

8 0 wty Ni

Alloy

CompesiHen

20

80

60

- w t / Ni+

Ni

ETSC, 1IT DELHI

Combosition of phases in the 2-bhase region

s o wNTie-Line Rule

T: 300°c

L

Phases

400

1300

Tie Lne

Solidus

An isohe rm

in the 2-bhase

C

.looo

TEL.

Ca CL ?1

Liquidu

200

Lt

Ca

reglon rünnin9

om one boun

dany to the otte

50

20

wt

NN

Ni

ETSC, IT DELHI

"ie Line:Calculating Composition and Fraction of Phases

IQU

/ENPEReTURE

|1453'c

IQotOUS

SoLIDUS

Ly

S

t,

085

407, N

2

Cu

N:

CONOsIflON

20/.N

9:41/11:32

Ni

F

"ie Line:Calculating Composition and Fraction of Phases

LEnNG TH OF THE TiE L/NE

FRoM THE OVERALL CoM Po S/T/

RACTIO

To THE

Of ONE PHASE

9:47/11:32

OTHER PAASE BOUNDARY

ToTAL LEN4 TH of TIE

LI'NE

Proportion of phases presentin the system

Phase Diagrams

Q3:

What ane the relaHie amounts

or

probortion of phatds present ?

Proportion of phases present in thesystem

Relative Amounts of Pha:es

f

Single Phare Reqion

500

L

145a'c

properken

in the

whoie alio;

400

proporHon

aa combo

30o

hent in he

hare .

1200

A

Lt

P

1100

1085

wt

C.

20

wtyNi

Ni

Ni

T: I5o'C

phae

1o00

8/13:4

Co

o

:G

10)

Rela tiv Amoun+

14400

of Tio Phasgs Region

40 wt N'

o

o

L 64

L

O.64

CL 2 2

f - = O36

C

300

50

ILEveR RULe

or relatir

200

rgbortons.

total anm

22

I000

20

Ca

40 50 6o

wty N

80

Ni

PR

40-22

So-222

5Microstructure evolution during solidificationinisomorphous systems

Microstructure Evolutiorn

Clurin9 soliclifica tion

1soMOR PHOUs SrstEM)

-ETSC¢+#TDELH

C

NPTEL

0:21/16:06

Microstructure evolution during solidification in isomorphous systems

An

IsoMORPHOUSs PHASE DIAGRAM

Solidificawon

1500

L

L

Dins3/

G 0 wt Ni

40 w t Cu

1453

1400

500

1300-

CL

Solidificw

1200

L+

Compe

4400

1O85

-q

Singe

kAase

dys talpoe

1000

20

Cu

-

15:58/16:06

grin

60

wt f Ni

s

9ran

CNi)

bound

-y

ectic

System

Eutectic system

Pb-Sn Solder Alloy

Soldering:

Low

Need

melting alloy

Strength

CAlloy Stronger

han pure ele mems)

Pb

Sn

D3:08/16:45

e

T .Sn

327 °c

232°c

Eutectic system

(

Pb-Sn Phase Diaqram

327

liguichs

300

200t Solids

p232

20

CPb)

-

D8:55/16:45

wt/ S

(Sn)

TSG 7

D

Pb-Sn

A

System

Eutectie System

Easy melHnn9

400

32

300

20

Bounadanies

&utectc Alloy

20. LiLquidvs

83

SutecR o 2

TAP Pb

%

wt

L/L+d

Liquidvs

EUTECTIC

20

Liguidus +

L

HONzON

TAL

232

Soli

des

Solidus

+L

Solvus

/d+p

(Eutechc Hortevn

Sn

ta

EutecHe combasitm..

utectic reaction

fectic Keaction

0:05/9:32

ETSC, T

DELH

INVARIANT ReCaCTONi EutecHc Reacion

T483

(G2) Coo

327

oL

/

Pb

wty. Snn

EutecHG

232

Sn

(18)

mixture

Eutecic mirtwre

or

Eutechc micro consihuenk

IL

Eutectic, Hypoeutectic

6

Hypereutectic Alloys

E Eutectic, hypoeutectic and hypereutectic alloys

Eutecic Alloy

Pb-Sn Phase Diaqram

400

40

327

300

Eutecic

Lt

200f

183

/

-Hyp9

eute hc

ec

alloy

o

Eutectic mixtue

232

Cmicro cons Hiiest

tvent)

Hyper

eutecHe

aoy

20

Pb

K NPEL C

Polnt

D6:57 /27:42

w t Sn

E62

Sn

TBCTIT DELH

400

Phases n

300

2200

Lt

TE33c

I00

bypoeutectic alloy

GL

Ce

2

a

ot Sn.

Just above TE

20

(40)

80

Sn

w t Sn

Pb

Microstructure evoluthon in

bypoeutectic alloy poeutecHC

o

eutecHe mixturr

1ierocemsikmms

a

S

Just below TE

hypoeutectie alloy

IIT DELHI

Microconstituents in

a

bypeeutechc alley

- þmeute

He

327

Gutectic

183

mixtuna.

62

18

To deter mine the

microconstituens

we dra w h e He

hne in h e

tw-pkaw

P%

c t Sn

region just above he eutechie ttms T

T

roeutectie o vst jus* above Ts = G2-

G2-1

Jutectie metune =

I-o5

o S

22 os

ETSC, T

DELH

Phasos in a

Hybocutechc Alley

To deternine total

and fotal In

L

32

232

the alloy we draw

h e He-line

just below T

40

Taotal

Tstal

ftoto p

gutecHc

q7 4 o

57 : O72

97-18

I-o:*2

total

O

2

&&

Tproeuecte

O72-O

5

O 22

S

eutecHC

ee

YSC, iIT L H I

EGibbs' phaserule

JIBBS

O:06/31:44

PHASE ULE

E Gibbs'phaserule

GbbS Phase Rule

P

No. of Phases in equilibrium

C

No.

of components

F= Degrees of Freedom

NPEL

1:48/31:44

CiBs

phase rule

Thermodyna mic

Vaniables

for

Gibbs Phase

Rule

Pressure and Temperqure Cif both are vnniable)

If Pressure is fxed, hen nly temp is vasiable

Combosiion vaniables

Only phase combositions

ans

considered

asvoiables

Overall

alloy composition

vaiable,except hen

e

is

is nat

have

a

a

aloy

Single phase equilibrium when aloy

Combosiion saso he phase combosi on.

TsCIT

ORLH

6:23/31:44

No.

If

to

f

Combositon vaniables.

thene

ane

specify

C

C-

combonents

then

combositons for

needs

Comboaition vaniables.

for

P

Total no. d

V=

phases

one

one

need

phase.

each

PC-1)

vaiables

PCC-1) 2

iF ossvre amod

emta ani vaniables.

V

=

PCC-1) + 1

P is cmstamt

only

f

ETSC, IT DELHI

Degrees of Freedom:

F: No.

of hermody namic vaniables which

be

without

can

speiKed indebendently

changing the hases ik equilibrium.

Since there is ther

mo

ctynamic equilibrium,

ae equilib riu m rela hions

thermody da mic vaniables. F

bervem me

automahicall ixed by

by

eguilibrum

here

certain no. d

neations.

speci

vaniables, otens ars

hese

ETSC, 1IT DELHI

GIBes PHASE RuLE

F

F

=

C-P

2

C-P

+1

both pressure

if

temberatwre ane

onl

and

vannbles

tempemene is

vaniabte Fixed Areure)

for binan bhase diaqamg

consideud by bs.

aressure 1 am)

Applicabte

b

Cxample of Abplication f

Gibbs Phase Rule

Rule

L

(4) Singte Phase L in

Pru

equi librlumD

Lt

CLT

F=C-P +1

+

Pb

2-

w t Sn.

(2) Tho bhase

GL

V2

L+

In equilibrium

V=3

C - P+ I =

T

L

TE

Pb

w t Sn.

Sn

Three Phase

eguilibrium L , {

CL C CpT (V= 4)

P=3,

F

C-P+|

2 -3 +I = o

T

Horizontal Line

Inraniant

phase reacton

L

oktB

Pb

Three

w

Sn

Phase eguilibrium

Sa p

C-P+l E

P-3,

F

Sn

L *, B

L,

(v= 4i)

2-3+|:O

ETSC, T

DEL

S+L - S

L - S+S

S - S+S

Peritectoid S+S - S

alpha