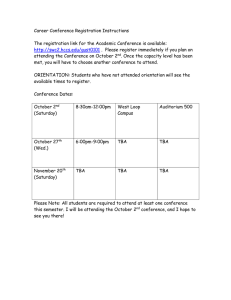

DEFECT ANALYSIS ON CESSNA 152 RUDDER HORN MUHAMMAD IDHAM BIN SAZALI 53211119544 UNIVERSITI KUALA LUMPUR JULY 2021 DEFECT ANALYSIS ON CESSNA 152 RUDDER HORN MUHAMMAD IDHAM BIN SAZALI 53211119544 Report Submitted to Fulfill the Partial Requirements For The Bachelor Of Aircraft Engineering Technology (Hons) In Mechanical. University Kuala Lumpur Malaysian Institute of Aviation Technology JULY 2021 DECLARATION PAGE I declare that this report is my original work and all references have been cited adequately as required by the University. Date: 29/11/2021 Signature: ………………………………... Full Name: MUHAMMAD IDHAM BIN SAZALI ID Number: 53211119544 i COPYRIGHT PAGE Declaration of Copyright and Affirmation of Fair Use of Unpublished Research Work as stated below: Copyright @ May 2021 by Muhammad Idham Bin Sazali 53211119544 All rights reserved for Defect Analysis on Cessna 152 Rudder Horn. No unpublished search may be copied, saved in a recovered system or communicated, in any way or without previous written permission of a copyright owner, electronically, mechanically, photocopying, recording or otherwise, with the exception of the following: i. Any information in or arising from this unpublished study may only be utilised with appropriate recognition by those in their writings. ii. For institutional and academic reasons, UniKL MIAT or its library shall be entitled to produce and transmit (pressed or électronic) copies. iii. If asked by other institutions and research libraries the UniKL MIAT has the right to produce, preserve in a recovery system and provide copies of such unpublished study. ii APPROVAL PAGE We have supervised and examined this report and verify that it meets the program and University and University’s requirement for the Bachelor/Diploma in (Bachelor of Aircraft Engineering Technology (Hons.) In Mechanical). Date: 29/11/2021 Signature: ……………………… Supervisor’s Name: MD KHAIRUL AMIZA BIN MD HAIRUDIN Official stamp: iii ACKNOWLEDGEMENT Assalamualaikum and Alhamdulillah. Thanks to Allah S.W.T, whom with his willing to giving me the opportunity to complete the task given which is Final Year Project (FYP) with the title Defect Analysis on Cessna 152 Rudder Horn. This final year project report was prepared to complete the ungraduated program that leads to the Bachelor of Aircraft Engineering Technology (hons) in Mechanical. This report is based on the requirement given off by the University Kuala Lumpur. Firstly, I would like to express my deepest appreciation and thanks to Mr. Mohd Khairul Amiza Bin Mohd Hairudin, my responsibility supervisor, who always gave me support from the beginning until the final level. His suggestion and opinions really help me to develop our project and polishing our skills along the way on neglecting our weakness in completing the tasks that are related to our project. Without his enthusiasm, encouragement, support and continuous optimism this thesis would hardly have been completed. I would also want to take this opportunity to express our gratitude to our Final Year Project Coordinator, Wahyunah Binti Ghani for his expertise in thesis production and her commitment towards the project was a significant influence in shaping many of the concepts presented in this thesis. Finally, many thanks to my parents for their full support and enthusiasm during my studies. Without their prayer and words of encouragement, this project is impossible to be completed. I offer my regard and blessings to all of those who supported me in any aspect in this research. I wish that this project would be a guidance and reference to the readers. Thank you very much. iv TABLE OF CONTENTS DECLARATION PAGE......................................................................................... i COPYRIGHT PAGE ............................................................................................ ii APPROVAL PAGE ............................................................................................. iii ACKNOWLEDGEMENT ..................................................................................... iv LIST OF FIGURES ........................................................................................... viii LIST OF TABLES ............................................................................................... ix LIST OF ABBREVIATIONS ............................................................................... xi ABSTRACT ....................................................................................................... xii CHAPTER 1: INTRODUCTION ........................................................................... 1 1.1 Introduction .............................................................................................1 1.2 Problem Statement .....................................................................................2 1.3 Objectives ...................................................................................................3 1.4 Significance of Study ..................................................................................4 1.5 Scope and Limitation ..................................................................................4 1.6 Summary ....................................................................................................4 CHAPTER 2: LITERATURE REVIEW................................................................. 5 2.1 Introduction .................................................................................................5 2.2 Non-Destructive Testing (NDT) ..................................................................5 2.2.1 The importance of Non-Destructive Testing (NDT) ..............................6 2.2.2 Non-destructive testing (NDT) in Aviation Maintenance .......................7 2.2.3 Non-destructive testing methods ..........................................................8 2.2.4 Advantages of non-destructive testing ...............................................15 2.2.5 Disadvantages of non-destructive testing ...........................................16 2.3 Eddy current testing ..................................................................................17 v 2.3.1 Principle of eddy current testing .........................................................17 2.3.2 Common application of eddy current testing ......................................19 2.3.3 Eddy current testing applications in aviation.......................................20 2.3.4 Benefits of eddy current testing ..........................................................21 2.4 Cessna 152 ..............................................................................................21 2.4.1 Cessna 152 rudder horn .....................................................................24 2.5 Defect .......................................................................................................24 2.5.1 Crack ..................................................................................................26 2.5.2 Corrosion ............................................................................................26 2.5.3 Conductivity ........................................................................................32 2.5.4 Past aircraft defect accidents .............................................................33 2.6 Defect analysis .........................................................................................33 2.6.2 Defect analysis process .....................................................................34 2.6.3 Benefits of defect analysis ..................................................................34 CHAPTER 3: METHODOLOGY ........................................................................ 35 3.1 Introduction ...............................................................................................35 3.2 Flowchart ..................................................................................................35 3.3 Equipment ................................................................................................36 3.4 Zone of inspection ....................................................................................39 3.5 Safety precaution ......................................................................................40 3.6 Eddy current testing on rudder horn .........................................................40 3.6.1 Conductivity ........................................................................................40 3.6.2 Crack ..................................................................................................41 3.6.3 Corrosion ............................................................................................42 3.7 Result .......................................................................................................43 vi 3.8 Conclusion ................................................................................................44 CHAPTER 4: RESULT AND DISCUSSION ...................................................... 45 4.1 Introduction ...............................................................................................45 4.2 Zone of inspection ....................................................................................45 4.3 To investigate defect on Cessna 152 rudder horn ....................................46 4.3.1 Inspection data zone A for crack ........................................................46 4.3.2 Inspection data zone A for corrosion ..................................................47 4.3.3 Inspection data zone A for conductivity ..............................................47 4.3.4 Inspection data zone B for crack ........................................................48 4.3.5 Inspection data zone B for corrosion ..................................................48 4.3.6 Inspection data zone B for conductivity ..............................................49 4.3.7 Inspection data zone C for crack ........................................................49 4.3.8 Inspection data zone C for corrosion ..................................................50 4.3.9 Inspection data zone C for conductivity ..............................................51 4.3.10 Inspection data zone D for crack ......................................................51 4.3.11 Inspection data zone D for corrosion ................................................52 4.3.12 Inspection data zone B2 for conductivity ..........................................53 4.4 To develop defect database on Cessna 152 rudder horn .........................53 4.5 To analyze defect on Cessna 152 rudder horn .........................................55 4.5.1 Zone A defect analysis .......................................................................55 4.5.2 Zone B defect analysis .......................................................................56 4.5.3 Zone C defect analysis .......................................................................56 4.5.4 Zone D defect analysis .......................................................................57 4.5.5 Crack analysis ....................................................................................58 4.5.6 Corrosion analysis ..............................................................................59 vii 4.5.7 Conductivity analysis ..........................................................................61 4.6 Summary ..................................................................................................62 4.7 Conclusion of Cessna 152 rudder horn defect analysis ............................62 CHAPTER 5: CONCLUSION ............................................................................ 63 5.1 Introduction ...............................................................................................63 5.2 Serviceability of the part ...........................................................................63 5.3 Recommendation .....................................................................................63 5.4 Conclusion ................................................................................................64 Appendix .......................................................................................................... 65 GANTT CHART ................................................................................................. 65 PROJECT TIMELINE FOR FYP 1 ..................................................................65 PROJECT TIMELINE FOR FYP2 ...................................................................66 Reference: ........................................................................................................ 68 LIST OF FIGURES Figure 1. 1 Rudder jammed at 34 degrees deflection. .........................................3 Figure 2. 1 Liquid penetrant testing ...................................................................10 Figure 2. 2 Magnetic particle inspection.............................................................11 Figure 2. 3 Eddy current testing .........................................................................12 Figure 2. 4 Ultrasonic testing .............................................................................13 Figure 2. 5 Principle of radiography testing........................................................14 Figure 2. 6 Basic principles ................................................................................19 Figure 2. 7 Cessna 152......................................................................................22 Figure 2. 8 Cessna 152 rudder horn. .................................................................24 Figure 2. 9 Uniform corrosion. ...........................................................................28 viii Figure 2. 10 Stress corrosion. ............................................................................28 Figure 2. 11 Crevice corrosion. ..........................................................................29 Figure 2. 12 Filiform corrosion. ..........................................................................30 Figure 2. 13 Intergranular corrosion. ..................................................................30 Figure 2. 14 Galvanic corrosion. ........................................................................31 Figure 2. 15 Pitting corrosion. ............................................................................32 Figure 2. 16 Ohms law equation and electrical conductivity equation. ...............32 Figure 3. 1 Methodology of flowchart. ................................................................35 Figure 3. 2 NORTEC 600D. ...............................................................................36 Figure 3. 3 Cables and adapter. ........................................................................36 Figure 3. 4 O-degree probe. ..............................................................................37 Figure 3. 5 90-degree probe. .............................................................................37 Figure 3. 6 conductivity probe. ...........................................................................37 Figure 3. 7 Olympus conductivity standard reference. .......................................38 Figure 3. 8 Eddy current crack standard reference. ...........................................38 Figure 3. 9 Inspection zones of Cessna 152 rudder horn. .................................39 Figure 4. 1 Cessna 152 rudder horn. .................................................................45 Figure 4. 2 Chart for crack test. .........................................................................59 Figure 4. 3 Chart for corrosion test. ...................................................................60 Figure 4. 4 Chart for conductivity test. ...............................................................61 LIST OF TABLES Table 3. 1 Result to be accomplish on eddy current testing. ..............................43 Table 4. 1 inspection data zone A for crack. ......................................................46 Table 4. 2 Inspection data zone A for corrosion. ................................................47 Table 4. 3 Inspection data zone A for conductivity. ............................................48 ix Table 4. 4 Inspection data zone B for crack .......................................................48 Table 4. 5 Inspection data zone B for corrosion. ................................................49 Table 4. 6 Inspection data zone B for conductivity. ............................................49 Table 4. 7 Inspection data zone C for crack.......................................................50 Table 4. 8 Inspection data zone C for corrosion. ...............................................51 Table 4. 9 Inspection data zone C for conductivity. ...........................................51 Table 4. 10 Inspection data zone D for crack. ....................................................52 Table 4. 11 Inspection data zone D for corrosion. .............................................52 Table 4. 12 Inspection data zone B2 for conductivity. ........................................53 Table 4. 13 Overall result of eddy current testing on Cessna 152 rudder horn. .54 Table 4. 14 Summary of all the defect for Cessna 152 rudder horn. ..................62 x LIST OF ABBREVIATIONS NDT Non – Destructive Testing ET Eddy Current Testing TSB Transportation Safety Board of Canada ASTM American Society of Testing and Materials IACS International Annealed Copper Standard TBA To Be Accomplish xi ABSTRACT Research for analysis of defect using non-destructive testing (NDT) on Cessna 152 rudder was conducted at the Universiti Kuala Lumpur Malaysian Institution of Aviation Technology (UNIKL MIAT). Research was to investigate crack, corrosion and conductivity of the Cessna 152 rudder horn respectively. Inspections was conducted in according with ASTM E2882-17 for Eddy Current testing. In 1998, on the right-hand side of the rudder horn of Cessna 152 was discovered firmly jammed behind the fuselage stop bolt. A 34-degree deflection was achieved perpendicular to the hinge line on the rudder, whereas the maximum deflection for placing the stops was achieved at 23 degrees. The rudder horns had flew above and beyond the stop bolt. The main objectives of the research are to investigate defect on Cessna 152 rudder horn, to develop Cessna 152 rudder horn defect database and to analyze defect on Cessna 152 rudder horn. To conclude the Cessna 152 rudder horn need to be reported for a further action due to corrosion at Zone A, C and D. However, any metal reduction exceeds 1.5mm threshold require the part to be discard. The presence of crack at Zone A and D does not need any further action since the depth of crack does not exceed 1.00mm limit. Regarding hardness it confirms that the hardness is within acceptable limit. Regard to crack, corrosion, and conductivity threshold the Cessna 152 rudder horn considered serviceable. xii CHAPTER 1: INTRODUCTION 1.1 Introduction Aircraft defects are a frequent element in aircraft crashes, near-miss events, and runway accidents as well as being a significant contributor to injuries and fatalities. An aircraft component may be unsafe by design or improperly maintained, resulting in a sudden failure that can injure or kill those aboard. With all of the coverage in the media of plane crashes, it's reasonable that many individuals suffer from pteromerhanophobia, or "fear of flying." However, in 2017, the fatal accident rate for commercial passenger aircraft was just 0.06 per million flights, or one fatal accident for every 16 million flights according to (Shepardson, 2018). Aircraft defects are one of several reasons that can lead to a rare and possibly fatal aviation accident. Many technologies have been developed in recent years to make our daily lives easier. As humans, we have our own limitations and limited resources to do things that are beyond our own capabilities. Non-destructive testing (NDT) is a technology that was developed to help us overcome our natural limitations of damaging or destroying the material under test. Generally, the easiest and most effective way of checking for failure is to test materials and components. In the aviation industry, non-destructive testing (NDT) is used to determine the physical properties of materials, components, and assemblies. It can provide valuable information about material properties like ductility, durability, and fracture hardness. Today, the future of the aeroplane industry is entirely dependent on nondestructive testing. Without non-destructive testing, the aviation industry's maintenance and flying costs will rise, while flying safety will reduce. Anyone flying onboard the plane should never be concerned about their safety. Non-destructive 1 testing is important in ensuring that flying is one of the safest modes of transportation. As part of my project for my final year, I choose to carry out about nondestructive test (NDT) on Cessna 152 rudder which is using eddy current testing. (Ghoni et al., 2014) stated that the non-destructive technique of examining conductive materials using an eddy current is called eddy current testing. Eddycurrent testing can identify flaws, examine material and coating thickness, evaluate conductivity, detect heat damage, and check case depth. A kind of Nondestructive Testing (NDT) that utilizes the effect of electromagnetic induction to identify and analyze surface and subsurface flaws in conductive materials is referred to as "eddy-current testing." 1.2 Problem Statement In 1998, a Cessna 152 was failed to recover from an intentional spin by a student and flight instructor. The plane collided with the water surface of Lac SaintFrançois. Despite suffering severe injuries, the student pilot was able to escape the sinking plane through the right rear window. He then attempted, but failed, to rouse the unconscious flight instructor. A nearby fisherman saved the student and brought him to the shore, where emergency vehicles were waiting. The flight instructor died in the crash because he did not leave the plane. The wreckage was examined, and it was discovered that the rudder had become stuck and had travelled beyond its usual flight limit. On the right-hand side of the rudder horn, it was discovered that the rudder stop plate had been firmly jammed behind the fuselage stop bolt. A 34-degree deflection was achieved perpendicular to the hinge line on the rudder, whereas the maximum deflection for placing the stops was achieved at 23 degrees. When the rudder was freed from its jam, the deflection measured 23 degrees. 2 For the rudder to be freed from its jammed position, 36 pounds of constant pushing on the trailing edge was required. If the force delivered to the rudder pedal were the same as the steady draw of 36 pounds, the total force would be 180 pounds. Although the direction of cable pull seemed to exacerbate jamming by shutting the horn, right rudder application would not be able to remove the rudder jam because of the direction of cable pull. Figure 1. 1 Rudder jammed at 34 degrees deflection. The report says that as a consequence of a maintenance check, many aircraft at Saint-Hubert Airport, including five Cessna 152s, were grounded due to excessive rudder travel. A visual examination revealed scratches or scoring marks on each of the five aircraft, suggesting that at some time, the rudder horns had flew above and beyond the stop bolt (TSB, 1998). The purpose of this research is to study defect analysis on Cessna 152 rudder horn by applying non-destructive testing (NDT). 1.3 Objectives 1. To investigate defect on Cessna 152 rudder horn. 2. To develop defect database on Cessna 152 rudder horn. 3. To analyze defect on Cessna 152 rudder horn. 3 1.4 Significance of Study To assure the safe defect detection and evaluate defect on Cessna 152 rudder horn and to provide a trusted supportive document for a safe training on Cessna 152 rudder horn. 1.5 Scope and Limitation This research focusing on the defect analysis on Cessna 152 rudder horn by applying eddy current testing. This research will be conducted via NORTEC 600D Olympus dual frequency flaw detector to detect surface and subsurface crack, corrosion, and hardness only on Cessna 152 rudder horn. Any other deviation from the mention parameter and the setup might not yield the same result. The result of the test will be evaluated and examine the data collected. However, there are a few of limitation when performing the testing are about only conductivity probes and surface probes are available in UNIKL MIAT. There are a lot of measurement and aspect to be taken to generate the accurate data. Aside from that, time can be a barrier for me, as this project must be completed in 5 months. 1.6 Summary Based on the topic discussed in chapter 1, this chapter is about the dissertation title, the context, and the general view of the study in bigger picture. In this chapter also highlighted the problem statement of the research, objective of the study, significant of this study, scope, and limitation of this study. 4 CHAPTER 2: LITERATURE REVIEW 2.1 Introduction The aim of this research paper is to give background knowledge and insight that will be addressed in this analysis, as well as to emphasise the significance of the present study being carried out. The focus of this section is to provide a comprehensive knowledge of the likelihood of detection in eddy current testing. 2.2 Non-Destructive Testing (NDT) In non-destructive testing (NDT), faults in components are identified and analysed without causing any damage to the component under examination. The Instrument is a critical tool in the aviation industry, as it is utilised in the design, manufacturing, and maintenance of aircraft. Non-destructive research techniques and devices, like bubbler system, squirter systems, including immersion chambers, are used by engineers and technicians to conduct inspections that might harm the equipment if done by traditional means. Over the last 25 years, NDT has undergone tremendous growth and unique innovation. It is now regarded as one of the most rapidly evolving innovations in terms of uniqueness and innovation. Recent improvements and modifications to equipment, as well as a better understanding of materials and the application of different devices and processes, have all led to a technology that is very important and has seen common use and recognition in many sectors. Every day, technology influences our lives. It has most likely done more to improve protection than all other technology, even medical technology. Without the successful use of non-destructive testing, one can only consider the large number of injuries and unplanned outages that would arise. (Hellier, 2013) highlighted that non-destructive testing has a lot of uses in industry. It may be used for many applications, such as: 5 1. Evaluating materials during production as a way of process management. 2. Evaluating materials during production as a way of process management. 3. Examining finished items. 4. After a product or structure has been placed into use, evaluate it. To conclude, non-destructive testing is a valuable technology that can offer valuable insights about the state of the material being examined provided all the test's basic elements are considered, accepted guidelines are followed, and the examinations are performed by qualified personnel. 2.2.1 The importance of Non-Destructive Testing (NDT) The non-destructive testing incorporates physical, mathematical, chemical, and biological sciences to create a systemic method which can be used for the evaluation, inspection, and testing of structures/parts to recognise surface/surface defects, defects, or discontinuities while maintaining operability of the component during inspection. NDT is an essential standards and quality assurance management tool, since it may assist avoid mistakes that might result in unsafe, unreliable, and harmful operations. Everything they do depends on it being a key component. The technique should be used to its full potential, but to get the most out of it, it is also necessary to comprehend the different methodologies and their advantages and shortcomings as well as to be aware of various needs and industry standards. Any product, material and equipment has a minimal lifetime and design need. However, it may need to be changed or repaired substantially as a consequence of deficiencies which may go unnoticed throughout manufacture, manufacture, and service delivery; otherwise, hazardous or catastrophic situations may occur if left unsuitable for service. The cost for project closure may be significant in such circumstances. 6 NDT is necessary for maintaining safety and reliability in daily life. NDT is used to inspect ships, spacecraft (shuttle), cars, pipelines, roads, trains, power plants, refineries, homes, and oil platforms, to name a few according to (Kashif Ur Rehman et al., 2016) Undertaken throughout manufacture or life of a material, non-destructive testing methods may safeguard equipment and employees, and help industries to comply with the laws and standards. In addition to stability, NDT is utilised to guarantee dependability and lifespan of the machinery. This is known as protection of the integrity of assets and increases company performance and profitability. For the following reasons, NDT is frequently used: 1. Prevention of accidents and cost reduction. 2. Improve dependability of the product. 3. To find out whether one will be accepted for a specific characteristic. 4. To provide information about maintenance requirements. NDT is the process of determining the quality of a product. The primary use of NDT is to ensure product safety, which has a huge economic impact in terms of preventing loss of life and property. Furthermore, when used as an input to continuous product improvement analysis, numerical measures obtained from NDT add value to the output. 2.2.2 Non-destructive testing (NDT) in Aviation Maintenance In aviation maintenance, repair, and overhaul, NDT encompasses a broad range of inspection techniques (MRO). Non-destructive testing is used to check the exterior and interior surfaces of an aircraft structure and powerplant on surface and subsurface fractures, damage, corrosion, or other irregularities (NDT). To 7 prevent lengthy aircraft downtime, these inspections must be done without disassembling components and accomplished promptly and correctly. (Fahr & Forsyth, 1998) stated that NDT is a piece of the vanguard barrier against the disappointment in avionics designing with the abilities to distinguish defect at the soonest arrange. NDT has contributed enormously to the financially savvy, security, unwavering quality and trustworthiness of the flying machine task and assumes a key job in the wellbeing of airplane support. Endless potential mishaps were maintained a strategic distance from because of the well-planned and exact location and end of the imperfections through cautious utilization of the NDT. Security and administration nature of the NDT were carefully administered by various partners inside the structure of universal standard, for example, European Notice 473 (EN 473), American Society of Non-Destructive Testing (ASNT), National Aerospace Standard 410 (NAS 410) and European Notice 4179 (EN 4179). 2.2.3 Non-destructive testing methods It is very essential to do a visual inspection of mechanical damage and find out how extensive repairs would need to be. Even though routine maintenance has to be done on time in order to meet the service date, it is more difficult to detect problems quickly, since maintenance has to be completed on time as well as the airplane must be released on time for commercial operation. Since NDT is most cost-effective way of conducting inspection while aircraft repairs, and the sole way of identifying flaws. To put this another way, NDT is capable of detecting flaws or faults in the airframe and engine structures that cannot be seen by the human eye. The plane is built out of different materials, including aluminium alloy, steel, titanium, or composites. Due to the length of time needed to thoroughly dismantle 8 the aircraft and each component, an NDT method and equipment that are fast and efficient are required. For the moment, aircraft NDT accounts for about 7080% of all NDT done, with the remaining 10-20% accounted for in engine and associated components. (Khan, 1999) highlighted that to guarantee a constant degree of safety and dependability, the inspection process is normally performed with the use of the various NDT methods such as magnetic particle testing, liquid penetrant testing, eddy current testing, ultrasonic testing, radiography testing, and infrared thermography testing. 2.2.3.1 Liquid penetrant (Fazio et al., 2009) stated that the penetrant testing method, which is used to detect superficial discontinuities in metal and non-porous materials, is given special attention. The entire process is defined, including all its dynamic phases, as well as the parameters and physical laws that govern it. Penetrant research is focused on contrast: finding ways to enhance the difference between a discontinuities and its surroundings. This defect pattern is revealed by using a fluid with highly mobile and penetrating strength that is applied to the afflicted area and allowed to leave. The result is a pattern on the substrate that is white or ultraviolet light visible according to (Khan, 1999) 9 Figure 2. 1 Liquid penetrant testing The liquid penetrating study is based on ability of the penetrator to effectively wet the surface of the solid piece of work, flow over the surface, and then move into spaces that are open to the surface for a continuous, generally even coverage. The kind of interest most often seen is typically very thin, and it is typically undetectable to the human eye. The propensity of a liquid to flow over and through a surface, as well as through surface cavities, is primarily influenced by the following principle: 1. The surface's cleanliness. 2. The cavity's design. 3. The cavity's cleanliness. 4. Dimensions of the cavity's surface opening 5. The liquid's surface tension. 6. The liquid's tendency to wet the surface. 7. The liquid's contact angle. 2.2.3.2 Magnetic particle Magnetic particle inspection (MPI) has been extensively used in the aerospace industry for decades, with the bulk of steel components undergoing MPI 10 inspection at some stage during their lifecycle. Landing gear, engine parts, attachment hardware, and doors are some of the common areas of an aircraft that are tested according to (Eisenmann et al., 2014) Ferromagnetic materials are the only ones that can be subjected to magnetic particle inspection methods. During magnetic particle inspection processes, portable devices equipment, which enables procedures to be performed without the need to remove components from their locations, or permanent, bench-type equipment, such as that used in workshops, may be utilised. Surface-breaking and subsurface discontinuities can also be detected using magnetic particle inspection. However, as the depth of discontinuities below the surface increases, the sensitivity declines rapidly. As a result, the test is essentially made up of three stages: 1. To establish a suitable magnetic flux throughout the test object, use magnets that are circular or longitudinally magnetised. 2. Treat a liquid suspension with magnetic particles to make a dry powder. 3. To interpret and analyse the signals, investigate the test sample under appropriate lighting conditions. Figure 2. 2 Magnetic particle inspection 11 2.2.3.3 Eddy current Eddy current methods are promising for surface layer and treatment characterisation because they are non-destructive, theoretically non - contact, and, most importantly, offer frequency-based penetration depth. Magnetic induction theory claims that if a changeable magnetic field is present, currents are generated in a conductor according to (Burkhardt, 2019). Eddy current testing are also an essential test and widely used technique in the area of non-destructive components and evaluation. This method is particularly helpful for detecting service-induced cracks, that are often produced by wear or stress corrosion. Eddy current inspection may be performed with little part preparation and a high level of sensitivity. A substance's electrical conductivity, magnetic permeability is affected by its chemical and heat treatment condition. Mixed batches of goods or parts that were exposed to fire or high heat may be safely and promptly removed (conductivity testing). As the geometry and uniformity of the test item vary, so will the frequency and dispersion of eddy currents. These fluctuations may be used to detect the existence of fractures and other flaws. Figure 2. 3 Eddy current testing 12 2.2.3.4 Ultrasonic Ultrasonic inspection provides a responsive type of non-destructive testing in most substances, either ferrous, non-metallic, magnetic, or nonmagnetic. It enables the identification of small flaws with just a single surface accessible, as well as determining the location and magnitude of the defect. Whether both surfaces are level and only single surface is accessible, ultrasonic may be used to measure thickness. The success of an ultrasonic test is heavily influenced by subject's surface condition, particle size or orientations, and acoustic impedance. Ultrasonic methods are often used to detect internal flaws in materials. (Khan, 1999) stated that the transmitted or reflected sound waves are the foundation of ultrasonic inspection theory. Because sound has such a constant velocity for each item, a variation in the acoustical impedance of the material involves a shift inside the sound velocity at a certain point, resulting in an echo. The length of the acoustical impedance (flaw) may be measured when the velocity of sound in the test material as well as the time it takes for sound to enter and rebound from the defect are known. Figure 2. 4 Ultrasonic testing 13 2.2.3.5 Radiography testing Radiography is one of the oldest and most frequently used non-destructive testing techniques according to (Khan, 1999). A radiograph is a kind of photographic image produced using electromagnetic radiation (such x-rays or gamma rays) and passed through an object, which then produces an image on film. The emulsion creates an invisible transition known as a 'latent image' when exposed to x-rays, gamma rays, or light. Uncovered portions of the video get black when they are submerged in a solution that is going through a forming process. To prevent the creation of more movies, the film is washed. Once the fixer has been removed, the film is lowered into a cleaning tank where it is scrubbed to remove any remaining fixer. It finally dried out, which allowed it to be interpreted and recorded. Figure 2. 5 Principle of radiography testing 14 2.2.4 Advantages of non-destructive testing (digital_admin, 2019) highlighted that non-destructive testing has four major advantages: 1. Problems with safety may be discovered. - Non-destructive testing is performed to evaluate if a component needs to be serviced and is safe to use. Non-destructive testing that is carried out professionally has the potential to save lives. Areas of particular concern if the operation occurs in industries that utilise unexpected or intense gear or equipment. When utilised properly and when the experiment results are accurately operated upon, the main aim of this is to find and rectify errors that may lead to disaster. 2. Reliability is provided. - Non-destructive testing can provide stability to industry workers who want reliable and accurate results. Any piece of equipment or machinery should be subjected to a series of non-destructive checks to eliminate the possibility of any outcome inaccuracy or oversight. 3. It is cost efficient. - As a result, machinery would need to be tested at various intervals. Non-destructive inspection can often be the most cost-effective method of evaluating and maintaining facilities. This type of checks may also provide information that can lead to the successful removal or restoration of parts or machinery before a true fault or failure occurs, saving costs in the long run. 15 4. It gives reassurance. - Knowing that a plant or factory's equipment is in excellent operating condition provides all of the stability, comfort, and peace that you need. Knowing that procedures are in place to guarantee that regular checks are done will provide an additional layer of security. Staff are more at ease because they know they are secure, which may boost morale and productivity overall. 2.2.5 Disadvantages of non-destructive testing (digital_admin, 2019) referenced that There are very few and very minor disadvantages to non-destructive testing. There may be minor issues that emerge based on the kind of non-destructive testing that is performed on a product. This may include simple elements such as: 1. Components that must be washed prior to and after inspection. 2. The finish of a part will often influence inspection sensitivity. 3. There can be occasions where depth scaling is inadequate. 4. Only comparatively non-porous surfaces can be inspected using certain non-destructive test methods. 5. Any test methods necessitate the use of electricity. 6. Variations of magnetic permeability may also influence others. 7. Some tests are only applicable to conductive materials. 16 2.3 Eddy current testing Eddy current devices are another kind of NDT equipment powered by the basic idea of magnetism. Due to the specialised nature of these manufacturing and service settings, in which light metal must be tested for protection or consistency issues, Eddy current testing is often used in the aerospace sector as well as some other production and service areas. Although Eddy current is used for a wide range of materials thickness tests, including measuring corrosion under aircraft skin, trying to determine the depth of non - conductive coating materials on conductive substrates, and able to monitor the impact of heat treatment, it is also sometimes used to test for corrosion under aircraft skin. A broad variety of testing requirements may be met by both field- or fixed-instrumentation equipment. (Nelligan & Calderwood, 2018) stated Eddy current testing, which was introduced about the same time, is restricted to items that transfer electricity and, as a result, can't be used on plastics. Under some conditions, eddy current or ultrasonic scan are used in conjunction to provide different advantages: Eddy current permits testing at high speeds, while ultrasonic testing extends deep into the object. 2.3.1 Principle of eddy current testing Eddy current testing is based on the physical concept of electromagnetic induction. A current-induced oscillating magnetic field is produced when an eddy current probe sends alternating current via a wire coil. A circular stream of electrons called as an eddy current flows through the metal when the probe and therefore its magnetic field encounter a conductive item, including a metal test piece. A moving electrical current in the metal causes an electromagnetic field to form around the coil, which connects with the coil's magnetic field via mutual 17 inductance. On addition to increasing the thickness of the metal, flaws or cracks in the surface of the metal (e.g., near-surface cracks) affect the overall intensity and magnetic pattern of a eddy current, thereby influencing the power and pattern of the resultant magnetic field. Essentially, this alters the coil electrical impedance to change electron mobility. Eddy current measuring instruments may be used by a competent operator to locate variations in the test piece's impedance using variations in the amplitude and frequency angle. This is the region with the best test resolution because eddy current density is highest near the part's surface. Eddy current density was evaluated at frequency and also permeability or conductivity of a test sample. Test sensitivity, resolution, and penetration would all be affected by variation inside the testing material's conductivity, magnetic permeability, and intensity of the AC pulses moving the coil, and coil shape. Eddy current inspection capabilities are affected by a few variables. When the conductivity of the material increases, it becomes more susceptible to surface flaws, but the current flowing through it will go deeper into the substrate. Frequent testing has an impact on penetration. The higher the test frequency, the better near-surface resolution, but at the cost of reduced penetration depth. Smaller coils are much more sensitive to tiny flaws, whereas bigger coils analyse a greater quantity of material either from place. Roughness differences in a material lead to noise, which diminishes fault detection because of higher background noise. The frequency, form, and size of the coil used for testing are test material characteristics that are out of the operator's control, however conductivity and permeability were different, and may be chosen based on test requirements. The detection capacity of a particular test is governed by equipment and material properties. There are numerous frequencies swept during inspections, as well as different probes used, in order to discover the right solution and penetration, and therefore all possible problems. If you want to maximise the amount of test results, 18 you should only use probes suitable for each application according to (Nelligan & Calderwood, 2018) Figure 2. 6 Basic principles (Peloquin & Anzola, 2019) highlighted that there is three basic principle of eddy current: A. When a current is conducted via a coil, the magnetic field is generated (in blue). B. The produced eddy currents (shown in red) resist the currents on the conductive component. C. Due to the flaws in the part, the course of eddy currents would be disturbed (in yellow). 2.3.2 Common application of eddy current testing In a manufacturing system, the applications for eddy current testing are nearly infinite. It can be easily applied to a wide range of applications due to its extreme simplicity, inherent precision, and ease of deployment. Among these are a few of the following according to (Nelligan & Calderwood, 2018) : 1. Weld inspection is often accompanied with ultrasonic NDT, which probes below surface for exposed surface cracks, and an eddy current tool, which scans the surface to look for weld cap fractures and in-use regions. 19 2. Conductivity testing is the ability to compute conductivity for the classification, sorting and validation of iron and not-ferrous alloys. 3. Surface inspections are performed by eddy current testing can rapidly locate machined components and metal stock surface fractures. This phrase covers the area around aviation fasteners and other important applications. 4. Corrosion Detection – Corrugated surfaces, such as the skin of aluminium aircraft are detected and measured using Eddy's current instruments. Lowfrequency samples may be used to identify corrosion on the 2nd and 3rd layers of metal that cannot be ultrasonically examined. 5. Inspection of Bolt Hole – Bolt Hole samples, frequently used in connection with automated rotary scanners, may be utilised to identify cracking between bolt holes. 6. Inspection tube - Popular applications of current eddy tube include in-line tube inspection during production processes, as well as field tube inspection like heat exchanger applications. Thickness and cracking differences are obvious. 2.3.3 Eddy current testing applications in aviation Eddy current inspection of aircraft structure and components is required during scheduled maintenance. A few eddy current inspection techniques for defect identification in the aircraft industry were explored in this article. Aircraft inspection has become more accurate and repeatable due to new equipment such as the SD-PC-12, which has the benefits of automated accuracy, data collection, data archival, and reporting according to (Godbole & Gokhale, 2006). 20 2.3.4 Benefits of eddy current testing The following are some of the benefits of the eddy current technique: 1. Almost any metallic substance may be examined. 2. Surface and near-surface defects are detected. 3. Inspections can be completed easily, and reports are available instantly. 4. The devices will be very mobile. 5. The method is useful for much more than just defect identification. 6. A minimum amount of component planning is necessary. 7. Using a set of proven good samples, a measuring system may be calibrated to consider parts with a particular range of signal interpretation. 8. It is not necessary for the test probe to touch the component. 2.4 Cessna 152 The Cessna 152 is an aviation aircraft produced in the United States, with a twoseater, fixed-cycle gear. It is used primarily for training on flying and personal usage. It was based on the Cessna 150, but with a few minor structural changes and a considerably stronger motor that could be reworked over a long time. For almost thirty years, the Cessna 152 has been out of production, although many are still airworthy and utilised for flight instruction. (Clarke, 1987) stated that the Cessna 152, which was first offered for sale in 1977, was a redesigned version of the well-proven Cessna 150. 152 was created to compete with the new Beechcraft Skipper and Piper Tomahawk, which were introduced the same year as the 152. Aside from increasing the useable load with a gross weight increase of 760 kg to 1,670 lb (760 kg), other design goals included reducing internal and exterior noise levels and operating effectively on the thennew 100LL diesel. 21 152s were manufactured at the Cessna plant in Wichita, Kansas, the overwhelming majority of which were the 150. F152 and FA152 are aircraft developed by Reims Aviation in France. This small aircraft manufacturing by Cessna stopped in 1985, and as a result, a total of 7,584 copies of the 152 had been manufactured at that time, including Aerobat and FA152 Aerobat variants. This Cessna was bought by Northrop Rice USA and later was ferried to Malaysia for aircraft engineering trainees to do their practical. Figure 2. 7 Cessna 152 All Cessna 152s have utilised the Lycoming O-235 engine, which has been in service since 1942. With an engine capacity of almost twice that of the Cessna 150, the Lycoming outperformed the aircraft and used a newer 100LL gasoline with a lower lead content. Starting in 1977, Cessna 152s were outfitted with Lycoming O-235-L2C engines, which produced 110 horsepower at 2,550 revolutions per minute (rpm). The engine ran into some lead-fouling problems in operation. To solve this issue, a new piston design and a reworked combustion chamber were released in 1983 with an increased power output of 108 hp. Until the conclusion of 152 manufacturing in 1985, the N2C engine remained in service. 22 Aluminum is the predominant material used in the airframe. has a riveted skin composed primarily of 2024-T3 aluminium alloy. Plastic components, such as fairings and wingtips, are made using glass-reinforced plastic. The fuselage is made up of semi-monocoque bulkheads and frames linked by longerons that stretch the whole length of fuselage. Each wing is supported by struts with a 1degree dihedral angle. Every wing has a tapered portion with a washout of one degree. During a stall, increased aileron efficiency is a positive side effect. Differential ailerons on the Cessna 152 raise the wings 20 degrees up and 15 degrees down. It features single-slotted flaps that are controlled by electricity, and which have a deployment angle of 30 degrees. Trim tabs are ground-adjustable and may pivot to the left or right by around 23 degrees. The elevators will have a travel range of 25° and 18°. The control panel is equipped with a tiny wheel that adjusts the elevator trim. To get an idea of how far the trim tab goes compared to elevator chord line, consider this: it moves 10 degrees up or 20 degrees down. Fixed tricycle landing gear is part of the Cessna 152. A truss with tubular steel legs provides support for the main gear, and a full-length fairing covers the whole vehicle with a step built in to access the cabin. seven feet, seven inches (2.31 m). To absorb and reduce daily operating stresses, the nosewheel is linked to the engine mount, which is fitted with an oleo strut. When driven to one side of neutral, the nosewheel will be able to castor, but will only be able to steer 8 degrees to the other side. Under differential braking, the nosewheel can steer up to 30 degrees. To connect the wheel to the pedals, a spring coupling is used. Disc brake assemblies are bolted onto the main gear and have a hydraulic system to power them. When you click the pedals on the rudder, the brakes are applied. Differential brakes may be utilised when taxiing, allowing for tighter turns. In addition to the 152's parking brake system, parking brake systems are supplied for the other vehicles in the fleet. First, the user presses the foot brake pedal, and now the "Park Stop" handle is pressed to a left of the pilot to make it functional. 23 As the toe-brake lever is released, but pressure is kept in the mechanism, the brakes will both be applied. 2.4.1 Cessna 152 rudder horn Figure below show the rudder horn that to be inspect using eddy current testing. Figure 2. 8 Cessna 152 rudder horn. 2.5 Defect A weakness, imperfection, or absence is known as a defect. The use of eddy current equipment encompasses such diverse functions as fracture detection, the computation of metal thickness, deterioration and degradation assessment, and coating thickness measurements. In order to discover surface and near-surface flaws, eddy current examination is a good option. Cracks, such as the ones that interrupt the flow of eddy currents, decrease the power of the currents. The eddy current contact probe can be seen in the pictures to the right, placed on the conductive component. The colour of the eddy current indicates the intensity of the current beneath the probe's coil. When the right side 24 of the coils is considered, there is a flaw beneath the coil, as well as the eddy currents are also less concentrated in this area. Aircraft defect are not just a frequent reason for accidents; they are a contributory element in a number of incidents including closer, runway crashes, and in-flight casualties. A potentially hazardous aircraft component may be intentionally or unintentionally neglected leading in a sudden failure that may cause injury or death. Defects can occur in a number of aircraft systems; here are a few examples according to (Daniel, 2019): 1. The aircraft's control surfaces may get jammed, preventing proper control of the aircraft. 2. Hydraulic systems may malfunction, preventing the aircraft control systems and/or landing gear from moving properly. 3. Fuel leakage may occur, resulting in sudden decreases in aircraft range and mid-air fires. 4. Instrument errors will lead an unsuspecting pilot to believe the aircraft is acting one way when it is acting another. 5. De-icing equipment failure. 6. Pressurization problems in pressurised aircraft. 7. Electrical faults may have a serious impact on navigation systems and other aircraft controls. 8. Mechanical or electrical problems inside the engine may cause an engine to suddenly lose control, converting a single engine aircraft into a very heavy glider and causing a heavy and unwanted workload for a multi-engine pilot. 25 2.5.1 Crack In addition to NDT inspections, checking possible crack resistant regions on a frequent basis until a defect develops can considerably assist to extend the life of an aircraft. When structure undergoes cyclic fatigue, it increases the risk of fractures. An engineer that specialises in stress-strain analysis calculates how much fatigue damage the structure can take before failure occurs. This is achieved by subjecting systems to different levels of stress in a controlled environment. In order to find a small fracture in the component/aircraft, a process is developed and entered the operation schedule for that component/aircraft. During the process, a test piece will be included to verify the calibration and fault detection thresholds. (Hansen, 2014) stated that if a crack is found before the aircraft is scheduled for regular repair, it may be monitored for growing to ensure that it does not reach a critical size and begin to develop at a rapid rate. However, there are times when cracks are found and must be repaired immediately. This is not the case on commercial aircraft, however on military aircraft, owing to the unusual stress that the frame may be subjected to during flight, quick remedial action is needed. 2.5.2 Corrosion Corrosion happens when a refined metal spontaneously converts to a more solid state, such as oxide, hydroxide, or sulphide, resulting in material degradation. according to (twi-global, n.d.). (aircraftcompare, n.d.) stated that airlines are aware that corrosion may develop at any moment, therefore they paint and clean their aircraft on a regular basis to delay the inevitable. Nature, however, will ultimately win, and any corrosion will occur; it is better to address it as quickly as possible so that appropriate measures may be done. Several variables affect how often this 26 happens, including the plane's location, age, and frequency of thorough cleaning. Initially, planes will be white or grey, giving the aluminium a dull or fading appearance. If this occurs, the aircraft will become unserviceable, and it will only be a matter of time before this becomes apparent. 2.5.2.1 Types of corrosion on aircraft There are also many types of aircraft corrosion, or if an airline business knows which kind of corrosion is harming the aircraft, it is much simpler to take a big step to resolve the issue. Several instances of these kinds are shown below according to (aircraftcompare, n.d.): 1. Uniform corrosion - Uniform surface corrosion happens when metal parts of an aircraft are exposure to oxygen in the air over prolonged periods of time. This is a fairly frequent kind of corrosion throughout all types of planes, and it may be affected by a combination of different causes. A bad paint work, inadequate pre-painting preparation by the individuals performing the paint job, certain contaminants and acid, and even continuous exposed to heavy humidity levels are all examples of this. doing the paint job, some pollutants and acid, and even consistent exposure to high humidity levels. 27 Figure 2. 9 Uniform corrosion. 2. Stress corrosion - The only kind of corrosion that may occur under stress is stress corrosion, which is corrosion that happens in the crankshafts of a turbine and the landing gear of an aeroplane under great tension. It is usually caused by minor surface corrosion and even unnoticed scratches, which is not surprising given how difficult it may be to identify this kind of corrosion at times. Figure 2. 10 Stress corrosion. 28 3. Crevice corrosion - Water is trapped between two different components, such as loose paints or an open joint, and is the cause of crevice corrosion. Because this kind of corrosion is more prone to the development of exfoliation corrosion or pitting, it is very hazardous. Corrosion in an aircraft shell is mostly caused by alloy, temper, and form of the material, as well as the lap joints. Figure 2. 11 Crevice corrosion. 4. Filiform corrosion - One of the reasons why this kind of corrosion has become so common in aeroplanes is that it occurs on aluminium surface that have not been subjected to the appropriate pre-painting procedure and are thus unsuitable polyurethane paints that are often used on aircraft. These small worm-shaped lines initially develop on the surface, and with time, the paint peels and cracks. This corrosion can be easily distinguished, being one of the simplest varieties. Corrosion that is harder to prevent than it is to fix is one of the many kinds of corrosion. 29 Figure 2. 12 Filiform corrosion. 5. Intergranular corrosion - When it comes to aeroplanes, intergranular corrosion takes place in grain that make up the metals and alloys. Even though they are usually corrosion-resistant metals, the grain boundaries are damaged, making them vulnerable to corrosion. Ink is made of insoluble (not soluble) components called insoluble compounds. Once insoluble compounds have been formed, the outside regions of the crystallites have a higher risk of corrosion compared to the inside regions of the crystal. Figure 2. 13 Intergranular corrosion. 30 6. Galvanic corrosion - An electrolytic corrosion is often caused by dissolving two distinct metals in a saltwater solution or by exposing a metal to a mixture of electrolyte concentrations. - The much more active metal (the anode) erodes quicker than more noble metal (the cathode) when two metals are submerged in a galvanic pair (the cathode). Incorporating a sacrificial anode will make it easier to protect a structure from corrosion. Figure 2. 14 Galvanic corrosion. 7. Pitting corrosion - Pitting, among the most aggressive forms of corrosion, may be challenging to predict, diagnose, and characterise. This kind of corrosion often happens when an anodic or cathodic spot creates a corrosion cell with surrounding surface. The pit that has formed may act as cavity that is vertically located at the top of the material. - Pitting corrosion may be produced by a rupture or fracture throughout the oxide layer and surface coatings, as well as by inconsistencies in the metal's structure. Despite a relatively modest metal loss, this hazardous form of corrosion has the potential to cause a building to collapse. 31 Figure 2. 15 Pitting corrosion. 2.5.3 Conductivity A material's capacity to carry an electric current is measured by electrical conductivity. This is the inverse of electrical resistivity, that is a property that indicates a material's capacity to overcome an electric current. Figure 2. 16 Ohms law equation and electrical conductivity equation. (ETher NDE, 2018) referenced that Metal conductivity is determined using Ohm's Law, which says that current via a conductor between two locations is exactly proportional to the potential difference between the two sites. Since this substance always resists, the usual mathematical equation that describes the 32 connection between it and other materials is always correct. Material shape is often referred to as conductivity, and its condition of heat treatment is often described as conductivity. 2.5.4 Past aircraft defect accidents At 1346 on April 28, 1988, a Boeing 737-200, N73711, operated by Aloha Airlines Inc. as flight 243, had an explosive decompression and structural collapse at 24,000 feet while flying from Hilo to Honolulu, Hawaii. Approximately 18 feet detached from the aeroplane during flight from the cabin skin and structure aft of the cabin entry door and above the passenger floor line. On board, there were 89 passengers and 6 staff members. During the decompression, one flight attendant was carried overboard and is assumed to have died; seven passengers and one flight attendant were seriously hurt. The aeroplane crew made an emergency descent and landing at Maui's Kahului Airport. (NTSB, 1989) found that the accident was caused by metal fatigue worsened by crevice corrosion. The aircraft was 19 years old and flew in a seaside area where it was subjected to salt and humidity. Next, on September 8, 1994, USAir (now US Airways) flight 427, a Boeing 737-300, crashed while attempting to land at Pittsburgh International Airport in Pittsburgh, Pennsylvania. (NTSB, 1999) concludes that the probable cause of the USAir flight 427 disaster was a loss of aircraft control caused by the rudder surface being moved to its blowdown limit. 2.6 Defect analysis (Teopediach, 2021) stated that defect analysis is an element of continuous quality management planning in which defects are classified and used to classify potential triggers to deter issues from arising. It aids ventures in identifying how problems can be avoided and in limiting or removing large amounts of errors from being introduced into the system. 33 2.6.2 Defect analysis process • Problem identification. • The issue is contained and analysed. • Identifying and executing the measures necessary to find out the source of the problem. • Determining if the measure to avoid recurrence had been successful according to (Inspired Testing, 2018). 2.6.3 Benefits of defect analysis • Give input to developers so that they can enhance and increase the quality and usability of their software products. • By correcting defects, their effect can be avoided in other fields. • Defect analysis decreases the likelihood of defects and reduces the amount of rework needed to correct them, as well as the amount of reinspection required, the expense of correcting defects, and the costs accrued because of poor software quality. • Communication between production teams, research teams, and managers is essential for better defect analysis. As a result, defect analysis enhances group coordination. • Defects are avoided from recurring, which reduces or minimises the time taken for rework and improves task cycle time according to (GeeksforGeeks, 2020). 34 CHAPTER 3: METHODOLOGY 3.1 Introduction This chapter will show the procedure and research approach in according to the accepted framework. The whole project framework shall be depicted by the flowchart in figure 3.1. This project will be constructed using eddy current testing based on American Society for Testing Materials (ASTM) manual. 3.2 Flowchart Start Data Collection Data Collection from Books, Webs and Lecturers Eddy current testing on rudder horn Conductivity Crack Corrosion Result & Analysis End Figure 3. 1 Methodology of flowchart. 35 3.3 Equipment The equipment used for eddy current testing should satisfy any level of approval. The equipment is easily accessible in a variety of specifications. Every eddy current test requires the development of a test probe and also a reference standard. I. Instrumentation-Meters. Figure 3. 2 NORTEC 600D. Figure 3. 3 Cables and adapter. 36 II. Eddy current probes. Figure 3. 4 O-degree probe. Figure 3. 5 90-degree probe. Figure 3. 6 conductivity probe. 37 III. Reference standards. Figure 3. 7 Olympus conductivity standard reference. Figure 3. 8 Eddy current crack standard reference. 38 3.4 Zone of inspection Inspection zone has been developed for research to meet the objectives accordingly. A B C D Figure 3. 9 Inspection zones of Cessna 152 rudder horn. 39 3.5 Safety precaution I. Proper personal protective equipment is used to protect ourselves from any unwanted danger. II. To prevent the entry of operators and others into those areas, barriers should be built. III. The manufacturer's instructions for the equipment should be specifically followed. 3.6 Eddy current testing on rudder horn Eddy current will be used in this project. In order to succeed that, NORTEC 600D type unit will be used during this project. A 90-degree probe, conductivity probe and 0-degree probe will be used for the inspections. Calibration setting will be performed related to the inspection. Test block were previously prepared for this experiment. 3.6.1 Conductivity From ASTM E2884-17, to conduct a conductivity test, conductivity check shall be applied to check the level of the flow of current in the specimen. Conductivity detection shall be conduct in according to procedure below: 1. Prepare the surface area and strip the paint from the area. 2. Plug the conductivity probe to the cable and subsequently plug to the equipment 3. Observe the red dot on the connection for correct plug in 4. Press On button 5. Check the information on the screen display for the information on the probe and frequency accordingly. 6. Adjust Position button to place the dot at the Bottom Right 40 7. Select persistent to 0.3 second 8. Adjust angle to get ‘lift off’ which is right to left 9. Press the probe on 7075-T0 (45% IACS) without shim and press stored 10. Press the probe on 7075-T6 with shim (32%) and press stored 11. Press the probe on 7075-T6 without shim and press stored 12. Check for ‘Success’ Notification on screen accordingly. 13. Hold probe against free of defect standard reference for conductivity 14. Press null as necessary for reset 15. Set each flaw to the grid 16. Calibration complete 17. Inspect the part. 3.6.2 Crack From ASTM E2884-17, crack detection for eddy current testing were followed: 1. Prepare the surface area and strip the paint from the area. 2. Connect the 90-degree probe to the cable and subsequently plug to the equipment 3. Observe the red dot on the connection for correct plug in 4. Press On button 5. Check the information on the screen display for the information on the probe and frequency accordingly. 6. Adjust Position button to place the dot at the Bottom Right 7. Select persistence at 0.3 second 8. Change angle as required to set the “lift off” at the straight line from right to left. 41 9. Hold probe against free of defect standard reference for crack. 10. Press null as necessary for reset 11. Hold the probe against all artificial flaw on standard reference 12. Make sure all flaw detected on the display 13. Set each flaw to the grid 14. Adjust gain to increase or decrease the gain energy 15. Calibration complete 16. Inspect the component 3.6.3 Corrosion From ASTM E2884-17, corrosion detection procedure has been followed such as below: 1. Prepare the surface area and strip the paint from the area. 2. Plug the 0-degree probe to the cable and subsequently plug to the equipment 3. Observe the red dot on the connection for correct plug in 4. Press On button 5. Check the information on the screen display for the information on the probe and frequency accordingly 6. Adjust Position button to place the dot at the Bottom Right 7. Select persistent to 0.3 second 8. Change the angle as needed to set the “lift off” in the straight line from right to left. 9. Hold probe against standard reference obtain all corrosion measure of 10%, 20% and 30% respectively 42 10. Press Null button as necessary for reset 11. Set each flaw to the grid 12. Calibration complete 13. Inspect the component 3.7 Result Result shall be tabulated and analyzed using failure mode analysis accordingly. Eddy Current Testing Data Crack (mm) Inspection Zone 0.1 0.5 A Bushing 1 TBA Bushing 2 B C 1 Inter-Corrosion (%) Conductivity (IACS) 10 20 30 1-100 IACS TBA TBA TBA TBA TBA TBA TBA TBA TBA TBA TBA TBA TBA TBA TBA TBA TBA Rivet 1 TBA TBA TBA TBA TBA TBA TBA TBA TBA Rivet 2 TBA TBA TBA TBA TBA TBA TBA TBA TBA Rivet 3 TBA TBA TBA TBA TBA TBA TBA TBA TBA Rivet 4 TBA TBA TBA TBA TBA TBA TBA TBA TBA Rivet 1 TBA TBA TBA TBA TBA TBA TBA TBA TBA Rivet 2 TBA TBA TBA TBA TBA TBA TBA TBA TBA Rivet 3 TBA TBA TBA TBA TBA TBA TBA TBA TBA Rivet 4 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 1 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 2 TBA TBA TBA TBA TBA TBA TBA TBA TBA 43 D Hole 3 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 4 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 5 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 6 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 7 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 8 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 1 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 2 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 3 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 4 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 5 TBA TBA TBA TBA TBA TBA TBA TBA TBA Hole 6 TBA TBA TBA TBA TBA TBA TBA TBA TBA Table 3. 1 Result to be accomplish on eddy current testing. 3.8 Conclusion This chapter 3 focuses on methodology, which is essentially how to complete this project. It comprises the planning for the experimental NDT framework to fulfil the study objectives. This chapter explains the sequence and preparations for completing this project. The Project shall be governed by the flowchart in figure 3.1, ASTM E2884-17 for ET. 44 CHAPTER 4: RESULT AND DISCUSSION 4.1 Introduction Research for analysis of defects using non-destructive testing (NDT) on Cessna 152 rudder horn was conducted at the ATO 147. This research is to investigate defect on Cessna 152 rudder horn, to develop defect database on Cessna 152 rudder horn and to analyze defect on Cessna 152 rudder horn. Inspection was conducted in according with ASTM E2884-17 for ET. Data was tabulated and analyse to assess the condition of the Cessna 152 rudder horn regard to crack, corrosion and conductivity. 4.2 Zone of inspection A B C D Figure 4. 1 Cessna 152 rudder horn. 45 Inspection zone was developing for research to meet the objectives accordingly. Each zone was separated into zone A, B, C and D respectively. The size for each zone area is and it contains bushing, rivet, and hole. Process flow was conducted in according to flowchart as shown in figure 3.1 4.3 To investigate defect on Cessna 152 rudder horn Inspection data for Cessna 152 rudder horn using Eddy Current testing was presented in table 4.1 until table 4.12 in according to the objective subsector which is crack data, corrosion data and conductivity data respectively. 4.3.1 Inspection data zone A for crack Table 4.1 show a data based on surface crack inspection using a 90-degree probe according to ASTM E2884-17. The crack inspection was conducted by using an equipment eddy current which is Olympus 600D and based on crack standard referenced represented 0.1, 0.5, 1 millimetre which were represented by 2 grids, 4 grids and 6 grids respectively of the length of crack. Inspection was conducted at the each of the section A subsector, which is bushing and rivet area respectively. Inspection Zone A Test 1 Test 2 Test 3 Bushing 1 Nil Nil Nil Bushing 2 <1.0 <1.0 <1.0 Rivet 1 Nil Nil Nil Rivet 2 Nil Nil Nil Rivet 3 Nil Nil Nil Rivet 4 Nil Nil Nil Table 4. 1 inspection data zone A for crack. 46 4.3.2 Inspection data zone A for corrosion Table 4.2 show a data based on surface corrosion inspection using a 0-degree probe according to ASTM E2884-17. The corrosion inspection was conducted by using an equipment eddy current which was Olympus 600D and based on corrosion standard reference represented 10%, 20%, 30% of material loss due to corrosion. Inspection was conducted at the each of the section A subsector, which is bushing and rivet area respectively. Inspection Zone A Test 1 Test 2 Test 3 Bushing 1 20 20 20 Bushing 2 20 20 20 Rivet 1 Nil Nil Nil Rivet 2 Nil Nil Nil Rivet 3 Nil Nil Nil Rivet 4 Nil Nil Nil Table 4. 2 Inspection data zone A for corrosion. 4.3.3 Inspection data zone A for conductivity Table 4.3 show a data based on surface conductivity inspection using a conductivity probe according to ASTM E2882-17. Inspection was conducted at the each of the section A subsector, which is bushing and rivet area respectively. Conductivity inspection was based on 32% for (7075-T6) calibration according to Olympus P/N NEC-6151-SD standard reference. Inspection Zone A 1-100 IACS Bushing 1 35.51 35.51 35.51 Bushing 2 36.69 36.69 36.69 Rivet 1 38.92 38.92 38.92 47 Rivet 2 38.72 38.72 38.72 Rivet 3 38.80 38.80 38.80 Rivet 4 38.75 38.75 38.75 Table 4. 3 Inspection data zone A for conductivity. 4.3.4 Inspection data zone B for crack Table 4.4 show a data based on surface crack inspection using a 90-degree probe according to ASTM E2884-17. The crack inspection was conducted by using an equipment eddy current which is Olympus 600D and based on crack standard referenced represented 0.1, 0.5, 1 millimetre which were represented by 2 grids, 4 grids and 6 grids respectively of the length of crack. Inspection was conducted at the each of the section B subsector, which is rivet area respectively. Inspection zone B Test 1 Test 2 Test 3 Rivet 1 Nil Nil Nil Rivet 2 Nil Nil Nil Rivet 3 Nil Nil Nil Rivet 4 Nil Nil Nil Table 4. 4 Inspection data zone B for crack 4.3.5 Inspection data zone B for corrosion Table 4.5 show a data based on surface corrosion inspection using a 0-degree probe according to ASTM E2884-17. The corrosion inspection was conducted by using an equipment eddy current which was Olympus 600D and based on corrosion standard reference represented 10%, 20%, 30% of material loss due to corrosion. Inspection was conducted at the each of the section B subsector, which is rivet area respectively. 48 Inspection zone Test 1 Test 2 Test 3 B Rivet 1 Nil Nil Nil Rivet 2 Nil Nil Nil Rivet 3 Nil Nil Nil Rivet 4 Nil Nil Nil Table 4. 5 Inspection data zone B for corrosion. 4.3.6 Inspection data zone B for conductivity Table 4.6 show a data based on surface conductivity inspection using a conductivity probe according to ASTM E2882-17. Inspection was conducted at the each of the section B subsector, which is rivet area respectively. Conductivity inspection was based on 32% for (7075-T6) calibration according to Olympus P/N NEC-6151-SD standard reference. Inspection Zone B 1-100 IACS Rivet 1 38.42 38.42 38.42 Rivet 2 38.32 38.32 38.32 Rivet 3 38.40 38.40 38.40 Rivet 4 38.35 38.35 38.35 Table 4. 6 Inspection data zone B for conductivity. 4.3.7 Inspection data zone C for crack Table 4.7 show a data based on surface crack inspection using a 90-degree probe according to ASTM E2884-17. The crack inspection was conducted by using an equipment eddy current which is Olympus 600D and based on crack standard referenced represented 0.1, 0.5, 1 millimetre which were represented by 2 grids, 4 grids and 6 grids respectively of the length of crack. Inspection was conducted at the each of the section C subsector, which is hole area respectively. 49 Inspection Zone C Test 1 Test 2 Test 3 Hole 1 Nil Nil Nil Hole 2 Nil Nil Nil Hole 3 Nil Nil Nil Hole 4 Nil Nil Nil Hole 5 Nil Nil Nil Hole 6 Nil Nil Nil Hole 7 Nil Nil Nil Hole 8 Nil Nil Nil Table 4. 7 Inspection data zone C for crack. 4.3.8 Inspection data zone C for corrosion Table 4.8 show a data based on surface corrosion inspection using a 0-degree probe according to ASTM E2884-17. The corrosion inspection was conducted by using an equipment eddy current which was Olympus 600D and based on corrosion standard reference represented 10%, 20%, 30% of material loss due to corrosion. Inspection was conducted at the each of the section C subsector, which is hole area respectively. Inspection Zone C Test 1 Test 2 Test 3 Hole 1 Nil Nil Nil Hole 2 Nil Nil Nil Hole 3 Nil Nil Nil Hole 4 10 10 10 Hole 5 10 10 10 Hole 6 Nil Nil Nil Hole 7 Nil Nil Nil Hole 8 Nil Nil Nil 50 Table 4. 8 Inspection data zone C for corrosion. 4.3.9 Inspection data zone C for conductivity Table 4.9 show a data based on surface conductivity inspection using a conductivity probe according to ASTM E2882-17. Inspection was conducted at the each of the section C subsector, which is hole area respectively. Conductivity inspection was based on 32% for (7075-T6) calibration according to Olympus P/N NEC-6151-SD standard reference. Inspection Zone C 1-100 IACS Hole 1 37.80 37.80 37.80 Hole 2 38.10 38.10 38.10 Hole 3 37.95 37.95 37.95 Hole 4 36.07 36.07 36.07 Hole 5 35.97 35.97 35.97 Hole 6 37.93 37.93 37.93 Hole 7 38.24 38.24 38.24 Hole 8 38.13 38.13 38.13 Table 4. 9 Inspection data zone C for conductivity. 4.3.10 Inspection data zone D for crack Table 4.10 show a data based on surface crack inspection using a 90-degree probe according to ASTM E2884-17. The crack inspection was conducted by using an equipment eddy current which is Olympus 600D and based on crack standard referenced represented 0.1, 0.5, 1 millimetre which were represented by 2 grids, 4 grids and 6 grids respectively of the length of crack. Inspection was conducted at the each of the section D subsector, which is hole area respectively. 51 Inspection Zone D Test 1 Test 2 Test 3 Hole 1 Nil Nil Nil Hole 2 Nil Nil Nil Hole 3 <0.1 <0.1 <0.1 Hole 4 Nil Nil Nil Hole 5 Nil Nil Nil Hole 6 <0.1 <0.1 <0.1 Table 4. 10 Inspection data zone D for crack. 4.3.11 Inspection data zone D for corrosion Table 4.11 show a data based on surface corrosion inspection using a 0-degree probe according to ASTM E2884-17. The corrosion inspection was conducted by using an equipment eddy current which was Olympus 600D and based on corrosion standard reference represented 10%, 20%, 30% of material loss due to corrosion. Inspection was conducted at the each of the section D subsector, which is hole area respectively. Inspection Zone D Test 1 Test 2 Test 3 Hole 1 Nil Nil Nil Hole 2 Nil Nil Nil Hole 3 10 10 10 Hole 4 Nil Nil Nil Hole 5 Nil Nil Nil Hole 6 10 10 10 Table 4. 11 Inspection data zone D for corrosion. 52 4.3.12 Inspection data zone B2 for conductivity Table 4.12 show a data based on surface conductivity inspection using a conductivity probe according to ASTM E2882-17. Inspection was conducted at the each of the section D subsector, which is hole area respectively. Conductivity inspection was based on 32% for (7075-T6) calibration according to Olympus P/N NEC-6151-SD standard reference. Inspection Zone D 1-100 IACS Hole 1 38.42 38.42 38.42 Hole 2 38.51 38.51 38.51 Hole 3 36.83 36.83 36.83 Hole 4 37.98 37.98 37.98 Hole 5 38.27 38.27 38.27 Hole 6 36.60 36.60 36.60 Table 4. 12 Inspection data zone B2 for conductivity. 4.4 To develop defect database on Cessna 152 rudder horn Eddy Current Testing Data Crack (mm) Inspection Zone A 1 2 Inter-Corrosion (%) 3 Conductivity (IACS) 1 2 3 1-100 IACS Bushing 1 <1.0 <1.0 <1.0 20 20 20 35.51 35.51 35.51 Bushing 2 <1.0 <1.0 <1.0 20 20 20 36.69 36.69 36.69 Rivet 1 Nil Nil Nil Nil Nil Nil 38.92 38.92 38.92 Rivet 2 Nil Nil Nil Nil Nil Nil 38.72 38.72 38.72 Rivet 3 Nil Nil Nil Nil Nil Nil 38.80 38.80 38.80 Rivet 4 Nil Nil Nil Nil Nil Nil 38.75 38.75 38.75 53 B C D Rivet 1 Nil Nil Nil Nil Nil Nil 38.42 38.42 38.42 Rivet 2 Nil Nil Nil Nil Nil Nil 38.32 38.32 38.32 Rivet 3 Nil Nil Nil Nil Nil Nil 38.40 38.40 38.40 Rivet 4 Nil Nil Nil Nil Nil Nil 38.35 38.35 38.35 Hole 1 Nil Nil Nil Nil Nil Nil 37.80 37.80 37.80 Hole 2 Nil Nil Nil Nil Nil Nil 38.10 38.10 38.10 Hole 3 Nil Nil Nil Nil Nil Nil 37.95 37.95 37.95 Hole 4 Nil Nil Nil 10 10 10 36.07 36.07 36.07 Hole 5 Nil Nil Nil 10 10 10 35.97 35.97 35.97 Hole 6 Nil Nil Nil Nil Nil Nil 37.93 37.93 37.93 Hole 7 Nil Nil Nil Nil Nil Nil 38.24 38.24 38.24 Hole 8 Nil Nil Nil Nil Nil Nil 38.13 38.13 38.13 Hole 1 Nil Nil Nil Nil Nil Nil 38.42 38.42 38.42 Hole 2 Nil Nil Nil Nil Nil Nil 38.51 38.51 38.51 10 10 10 36.83 36.83 36.83 Hole 3 <0.1 <0.1 <0.1 Hole 4 Nil Nil Nil Nil Nil Nil 37.98 37.98 37.98 Hole 5 Nil Nil Nil Nil Nil Nil 38.27 38.27 38.27 10 10 10 36.60 36.60 36.60 Hole 6 <0.1 <0.1 <0.1 Table 4. 13 Overall result of eddy current testing on Cessna 152 rudder horn. 54 4.5 To analyze defect on Cessna 152 rudder horn A Cessna 152 rudder horn has been inspected for crack, corrosion, and hardness. The inspection data obtained were tabulated as shown by table 4.1 until 4.12 respectively. 4.5.1 Zone A defect analysis Zone A shows the presence of crack, corrosion, and conductivity. Crack presence has been detected around the bushing measured at lower than 1.00mm standard reference threshold. The indication on the Olympus 600D show curve less than 3 grid (3 grids=1.00mm). The finding on the crack depth shows no further action required. Corrosion found on the area of bore in considered dangerous as the bushing area considered critical area as well as high stress area respectively. The threshold for corrosion as indicated by Cessna 152 rudder horn at 20%. Any value exceeding 30% threshold require the rudder to be remove and inspected further. Recommended remedies involved a blending or discarded of the part from the active service life. Conductivity mean average for the zone A measured at 37.90 IACS. The conductivity mean average does not differ from the acceptable threshold for Al Alloy 2024-T3 which is measured at 35.0% to 39.0% IACS. From the hardnessconductivity table it can be derived that the hardness of the yoke was within acceptable safe threshold. Any value whether exceeding or below the 35.0% to 39.0% would affect the hardness of the yoke which subsequently either deformed the part of fractured the part due to higher hardness led to brittleness. To conclude Sikorsky Cessna 152 rudder horn Zone A has been inspect for a presence of crack, corrosion, and conductivity respectively. Result obtained show that the Cessna 152 rudder horn Zone A did not require a further maintenance. The presence of crack does not need any further action since the depth of crack 55 does not exceed 1.00mm limit. Regarding hardness it is confirm that the hardness is within acceptable limit. 4.5.2 Zone B defect analysis Zone B show no corrosion and crack. However, the mean average conductivity for zone B measured at 38.37% IACS. The conductivity mean average value does not differ from acceptable threshold for Al Alloy 2024-T3 which measured at 35.0% to 39.0% IACS. From the hardness-conductivity table it can be derived that the hardness of the yoke was within acceptable safe threshold. Any value whether exceeding or below the 35.0% to 39.0% would affect the hardness of the yoke which subsequently either deformed the part or fractured the part due to higher hardness led to brittleness. To conclude Cessna 152 rudder horn zone B has been inspect for a presence of crack, corrosion, and hardness respectively. Result obtained show that the Cessna 152 rudder horn zone B did not require a further maintenance. Regarding hardness it confirms that the hardness is within acceptable limit. 4.5.3 Zone C defect analysis Zone C show no presence of crack. However, the area around the hole circumference shows a presence of corrosion measured at 10% reduce of metal thickness. Mean average conductivity for zone C measured at 37.52 IACS. Corrosion found on the area of hole is considered dangerous as the bore area considered as critical area as well as high stress area respectively. The threshold for corrosion as indicated by Cessna 152 rudder horn at 10%. Any value exceeding 30% threshold required the yoke to be inspected further. Recommended remedies involved a blending or discarded of the part from the active service life. 56 The conductivity mean average value does not differ from acceptable threshold for Al Alloy 2024-T3 which measured at 35.0% to 39.0% IACS. From the hardness-conductivity table it can be derived that the hardness of the yoke was within acceptable safe threshold. Any value whether exceeding or below the 35.0% to 39.0% would affect the hardness of the rudder horn which subsequently either deformed the part or fractured the part due to higher hardness led to brittleness. To conclude Cessna 152 rudder horn zone C has been inspected for a presence of crack, corrosion, and hardness respectively. Result obtained show that the Cessna 152 rudder horn zone C did not require a further maintenance. Regarding hardness it confirms that the hardness is within acceptable limit. 4.5.4 Zone D defect analysis Zone D shows the presence of crack, corrosion, and conductivity. Crack presence has been detected around the hole measured at lower than 1.00mm standard reference threshold. The indication on the Olympus 600D show curve less than 1 grid (1 grids=0.1 mm). The finding on the crack depth shows no further action required. Corrosion found on the area of bore in considered dangerous as the bushing area considered critical area as well as high stress area respectively. The threshold for corrosion as indicated by Cessna 152 rudder horn at 10%. Any value exceeding 30% threshold require the yoke to be remove and inspected further. Recommended remedies involved a blending or discarded of the part from the active service life. Conductivity mean average for the zone D measured at 37.77 IACS. The conductivity mean average does not differ from the acceptable threshold for Al Alloy 2024-T3 which is measured at 35.0% to 39.0% IACS. From the hardnessconductivity table it can be derived that the hardness of the yoke was within 57 acceptable safe threshold. Any value whether exceeding or below the 35.0% to 39.0% would affect the hardness of the yoke which subsequently either deformed the part of fractured the part due to higher hardness led to brittleness. To conclude Sikorsky Cessna 152 rudder horn Zone D has been inspect for a presence of crack, corrosion, and conductivity respectively. Result obtained show that the Cessna 152 rudder horn Zone D did not need reported for further action. The presence of crack does not need any further action since the depth of crack does not exceed 1.00mm limit. Regarding hardness it is confirm that the hardness is within acceptable limit. 4.5.5 Crack analysis As evidence by table (table crack) the presence of crack has been detected at the zone A at the bushing area and zone D at the hole area. The presence and sign of crack was consistent with a stress corrosion crack. The bushing area was known to be subjected to a higher tensile stress during operation which subsequently would lead to a possible presence of stress corrosion crack. The presence of crack at the zone A and D were measured at lower than 1.00mm. According to SRM Cessna 152 a threshold for a presence of crack valued at above 1.00mm. thus the Cessna 152 rudder horn condition about presence of crack does not require further inspection as its well within acceptable limit IAW Cessna 152 SRM. On the other hand, zone B and C does not indicate any presence of crack. A presence of crack exceeds 1.00mm required the rudder horn to be remove from the service and discarded accordingly. 58 Inspection zone of crack (mm) 1.2 1 1 1 Crack (mm) 0.8 0.6 0.4 0.2 0.1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0.1 0 0 0 Zone of Inpsection Figure 4. 2 Chart for crack test. 4.5.6 Corrosion analysis Corrosion on a Cessna 152 rudder horn has been investigated and the data on zone A, B, C and D has been tabulated as evidence by table 4.2, 4.5, 4.8, and 4.11 respectively. Zone A indicate a presence of corrosion at the bushing area accordingly. While Zone C and D indicate a presence of corrosion at the hole area accordingly. Area A presence of corrosion has been measured at 20% accordingly. Area C and D presence of corrosion has been measured at 10% accordingly. Corrosion found on the rudder horn are consistent with a sign of uniform surface corrosion. The presence of the dust and deposit confirm that much indication. Uniform surface corrosion can be removed with a light application such as sandpaper and oil. 59 The Cessna 152 rudder horn need to be reported for further action IAW Cessna 152 SRM. It is to be noted that after a repair (blending) if the metal thickness has been reduced to more than 1.5mm then the rudder is to be discarded. Inspection zone of inter-corrosion (%) Inter-corrosion (%) 25% 20% 15% 10% 5% 0% Inspection zone Figure 4. 3 Chart for corrosion test. 60 4.5.7 Conductivity analysis A Cessna 152 rudder horn conductivity test was conducted to measure a level of aircraft rudder horn subsequent hardness value in IACS. A measurement of Cessna 152 rudder horn conductivity then was compared to the conductivity threshold which measured at 35.0% to 39.0% IACS. The mean average for the Cessna 152 rudder horn measured at 37.82% IACS. Conductivity value of the yoke determine the hardness or the deformation tendency of the structure. The measured conductivity at mean average 37.82% was well within acceptable threshold limit conductivity. Inspection zone of conductivity (IACS%) 40.00% Conductivity (IACS%) 39.00% 38.00% 37.00% 36.00% 35.00% 34.00% 33.00% Inspection zone Figure 4. 4 Chart for conductivity test. 61 4.6 Summary The Cessna 152 rudder horn have defects such as crack, corrosion, and conductivity. The rudder horn need to be reported for further action due to corrosion. The corrosion is found on bushing area in A with 10%. while hole area in C and D with 20% material loosed according to standard reference. However, the presence of crack at the bushing area Zone A and crack at the hole area zone C does not need any further action since the depth of crack does not exceed the 1.00mm limit. Regarding hardness, it confirms that the hardness is within acceptable limit. The overall result had been collected and recorded as the table below. Zone Crack Corrosion Conductivity A ✔ ✔ ✔ B X X ✔ C X ✔ ✔ D ✔ ✔ ✔ Table 4. 14 Summary of all the defect for Cessna 152 rudder horn. 4.7 Conclusion of Cessna 152 rudder horn defect analysis To conclude the Cessna 152 rudder horn need to be reported for further action due to a presence of corrosion. Regarding crack and conductivity, the parameter indicate that the rudder horn is within acceptable threshold as prescribed by Cessna 152 SRM. 62 CHAPTER 5: CONCLUSION 5.1 Introduction Based on the result of the tests, it can be concluded that the examination was passed by the eddy current testing study. However, it cannot be simplified that replacing the NDT evaluation with the study is correct since there are a few parameters and measurements that need to be taken to get the best result. For instance, the half-life of the propeller and type of material used on the structure. After repeated cycles of operation, it is difficult to obtain the actual reading of the test. Material properties are another parameter. Over time, predicting the strength of the material is very difficult. The simulated structure analysis produces moderate results in terms of power, and some adjustments and improvements need to be made to pass the test in the future, and some information should be considered to obtain the best results. 5.2 Serviceability of the part To conclude the Cessna 152 rudder horn need to be reported for further action due to corrosion found at Zone A, C, and D. The presence of crack at Zone A and D does not need any further action since the depth of crack does not exceed 1.00mm limit. Regarding hardness it confirms that the hardness is within acceptable limit. So, the Cessna 152 rudder horn is serviceable. 5.3 Recommendation It’s recommended that a complete investigation on the Cessna 152 rudder horn to include ultrasonic testing (UT) and magnetic testing (MT) for bushing area and data analysis base on stress analysis. 63 5.4 Conclusion A series of inspection on Cessna 152 rudder horn has been conducted and result was tabulated and presence accordingly. Research objective has been carried out and completed as evidence by table 4.1 to table 4.13 respectively. The objectives for a project have been completed in according with a research framework of 3.1 flowchart. The main purpose of the research was to investigate defect on Cessna 152 rudder horn, to develop defect database on Cessna 152 rudder horn and to analyze defect on Cessna 152 rudder horn. The investigation on Cessna 152 rudder horn using E.T low & high frequency to detect surface and subsurface crack, corrosion and hardness only on Cessna 152 rudder horn has been done in accordingly to relevant ASTM. 64 Appendix GANTT CHART PROJECT TIMELINE FOR FYP 1 TASK W1 W2 W3 W4 W5 W6 W7 W8 W9 W10 W11 W12 W13 W14 W15 W16 W17 W18 W19 DUE DATE 1/2 8/2 15/2 22/2 1/3 8/3 15/3 22/3 29/3 12/4 19/4 26/4 3/5 10/5 17/5 24/5 31/5 7/6 SUPERVISOR CONFIRMATION SUBMISSION OF REGISTRATION FORM RESEARCH PROPOSAL WRITING SUBMISSION OF RESEARCH PROPOSAL SHORT PRESENTATION IN CLASS SUBMISSION LOG BOOK WRITING REPORT (Chap 1, 2 & 3) SUBMISSION OF FINAL DRAFT TO COORDINATOR VIVA/ PRESENTATION CORRECTION OF FINAL DRAFT 65 PROJECT TIMELINE FOR FYP2 No Task Weeks 1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Discuss with Supervisor 2 Revised test methodology 3 Hangar and lab visit 4 NDT test for crack 5 Discussion with supervisor 6 Begin with Chapter 4 66 7 Discussion with supervisor 8 Begin with Chapter 5 9 Finish report draft and send for review 10 Submit second draft report for review 11 Submit the complete report 67 Reference: aircraftcompare. (n.d.). 6 Types of Aircraft Corrosion To Be Wary Of - Aircraft Compare. Retrieved April 6, 2021, from https://www.aircraftcompare.com/blog/types-of-aircraft-corrosion/ Burkhardt, J. (2019). Determination of the conductivity and thickness of conductive layers on conductive base materials. Advances in Mechanical Engineering, 11(7). https://doi.org/10.1177/1687814019854234 Clarke, W. ‘Bill.’ (1987). Cessna 150 and 152 (1st ed.). TAB Books. Daniel, C. (2019). AIRCRAFT DEFECTS AND THEIR CONSEQUENCES. https://mccartneystucky.com/aircraft-defects-and-their-consequences/ digital_admin. (2019). The Advantages & Disadvantages of Non Destructive Testing & Inspection. https://www.formatndt.co.uk/advantages-anddisadvantages-of-non-destructive-testing/ Eisenmann, D. J., Enyart, D., Lo, C., & Brasche, L. (2014). Review of progress in magnetic particle inspection. AIP Conference Proceedings, 1581 33(1), 1505–1510. https://doi.org/10.1063/1.4865001 ETher NDE. (2018). Introduction to Conductivity. 1. https://ethernde.com/wpcontent/uploads/2021/02/Introduction-to-Conductivity.pdf Fahr, A., & Forsyth, D. S. (1998). POD Assessment Using Real Aircraft Engine Components. In Review of Progress in Quantitative Nondestructive Evaluation (pp. 2005–2012). Springer US. https://doi.org/10.1007/978-14615-5339-7_260 Fazio, R., Caturano, G., Cavaccini, G., Ciliberto, A., & Pianese, V. (2009). Liquid Penetrant Testing: Industrial Process. Liquid Penetrant Testing: Industrial Process Gennaro, 3, 12. https://cab.unime.it/journals/index.php/congress/article/view/319 68 GeeksforGeeks. (2020). Defect Analysis Process. https://www.geeksforgeeks.org/defect-analysis-process/ Ghoni, R., Dollah, M., Sulaiman, A., & Ibrahim, F. M. (2014). Defect Characterization Based on Eddy Current Technique: Technical Review. Advances in Mechanical Engineering, 6, 182496. https://doi.org/10.1155/2014/182496 Godbole, U., & Gokhale, A. (2006). Eddy Current Inspection in Aircraft Industry. Hansen, J. (2014). Eddy Current Testing and Its Role in Improving the Long Term Reliability of Aircraft. https://www.qualitymag.com/articles/92000eddy-current-testing-and-its-role-in-improving-the-long-term-reliability-ofaircraft Hellier, C. J. (2013). HANDBOOK OF NONDESTRUCTIVE EVALUATION. McGraw-Hill Education. https://www.accessengineeringlibrary.com/content/book/9780071777148 Inspired Testing. (2018). What Is Defect Analysis? https://www.inspiredtesting.com/news-insights/insights/343-what-is-defectanalysis Kashif Ur Rehman, S., Ibrahim, Z., Memon, S. A., & Jameel, M. (2016). Nondestructive test methods for concrete bridges: A review. In Construction and Building Materials (Vol. 107, pp. 58–86). Elsevier Ltd. https://doi.org/10.1016/j.conbuildmat.2015.12.011 Khan, M. A. U. (1999). Non-destructive Testing Applications in Commercial Aircraft Maintenance. https://www.ndt.net/article/ecndt98/aero/031/031.htm Nelligan, T., & Calderwood, C. (2018). Introduction to Eddy Current Testing. https://www.olympus-ims.com/en/eddycurrenttesting/ NTSB. (1989). Aloha Airlines, Flight 243, Boeing 737-200, N73711. https://www.ntsb.gov/investigations/AccidentReports/Pages/AAR8903.aspx 69 NTSB. (1999). Uncontrolled Descent and Collision With Terrain, USAir Flight 427, Boeing 737-300, N513AU. https://www.ntsb.gov/investigations/AccidentReports/Pages/AAR9901.aspx Peloquin, E., & Anzola, M. (2019). Detecting Stress Corrosion Cracking with Eddy Current Array Technology Cracking. Shepardson, D. (2018). 2017 safest year on record for commercial passenger air travel: groups | Reuters. https://www.reuters.com/article/us-aviationsafety/2017-safest-year-on-record-for-commercial-passenger-air-travelgroups-idUSKBN1EQ17L Teopediach. (2021). What is Defect Analysis? https://www.techopedia.com/definition/6802/defect-analysis TSB. (1998). Aviation Investigation Report A98Q0114 - Transportation Safety Board of Canada. https://www.tsb.gc.ca/eng/rapportsreports/aviation/1998/a98q0114/a98q0114.html?wbdisable=true twi-global. (n.d.). What is Corrosion? - Definition and Prevention - TWI. Retrieved April 6, 2021, from https://www.twi-global.com/technicalknowledge/faqs/what-is-corrosion 70