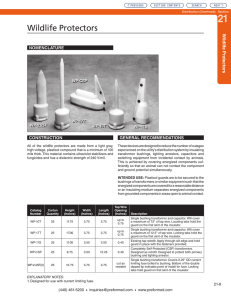

4.2 High voltage bushings Author: Douglas. M. Getson Document updated: 2002-11-06 e-mail: douglas.m.getson@de.abb.com A bushing is a device used to carry current at high potential through a grounded barrier, e.g. a transformer tank. There are bushing designs to meet various transformer interconnections such as air, oil and SF6 gas. ABB also manufactures bushings with and without condenser bodies. Stud or bulk type bushings have no condenser and use as its major insulation oil and ceramic. Stud bushings are available up to 35 kV system voltages where low partial discharge are not required. Condenser bushings facilitate electrical stress control through insertion of floating equalizer (electrode) plates. The condenser core decreases the field gradient and distributes the field along the length of the insulator, which provides for low partial discharge readings well above nominal voltage readings. Condenser bushing design The condenser core is built up around a center tube that may or may not be in the current carrying path depending on the design (see connection systems). The condenser core is wound from kraft paper and in some cases Nomex® for high temperature and current applications. The equalization plates are constructed of either metallic (aluminum) inserts or nonmetallic (ink) patches. These plates are located coaxially so as to achieve an optimal balance between external flashover and internal puncture strength. The condenser cores of today are either impregnated with oil or resin for a totally dry product. High stress region Grounded mounting flange Field grading (condenser body) No-field grading (no condenser body) 1 4.2 Oil-impregnated paper (OIP) bushings Open-air insulation OIP bushings remain the predominant technology in 80% of today’s deliveries. The condenser core is impregnated with transformer grade mineral oil and placed inside an insulating envelope of oil and porcelain (or composite), which keeps the bushing oil from mixing with the transformer oil. However, some bushing designs when applied horizontally do allow for exchange of bushing and transformer oil. OIP bushings maintain a low and stable capacitive loss with low partial discharges over their product life. ABB uses this construction across various designs for meeting IEC (Type GOB, GOE(K), GOM & GOH), CSA and IEEE (Type AB, O Plus C & T) transformer standards. For open air applications, the bushing is equipped with an insulator made of either porcelain or silicone rubber whose sheds provide the necessary creepage distance for withstanding voltages under all conditions. ABB has traditionally used alternating long and short profile sheds, which have the benefit of being self-cleaning. Resin-impregnated paper (RIP) bushings RIP bushings have a resin impregnated condenser core that is in contact with the transformer oil. This technology is used in combination with either porcelain or silicon insulators for a completely dry construction. Their lightweight and compact construction provides greater withstand to handling and severe service conditions. RIP is not to be confused with resinbonded technology that has been on the market for many years. Resin-bonded condenser core designs use a kraft paper that has been preimpregnated with resin which cures upon heating. Most major bushing suppliers have discontinued resin-bonded core manufacturing and have gone to the more stable resin-impregnated technology. The resin-impregnated cores are also wound with kraft paper, but the resin is introduced during a heating and vacuum process of the core. RIP bushings provide for a low and stable tan delta (or power factor) reading over the service life of the product. ABB uses this construction across several product lines (Type GSA, PORIP and CORIP) for meeting various industry standards and applications. 2 Silicone insulator with self-cleaning sheds Silicone insulators have the added benefit of being hydrophobic, a Greek term meaning "fears water". This characteristic helps break up water films and create separate droplets which reduces leakage current, prevents flashover and elevates the voltage withstand capability during wet and highly contaminated conditions. In affect, the hydrophobicity acts as a self cleaning property which extends service life and lowers substation maintenance cost. 4.2 Manufacturing ABB has been manufacturing bushings since 1908. More than half a million units have been put into service, and designs cover ratings between 600V-800kV and up to 50 kA. When manufacturing condenser bushings, the kraft paper is wound on a heated central tube to lower the moisture content of the paper. Depending on the design and/or rating, the condenser may go through an additional drying and impregnation process (oil or resin) to further reduce moisture levels. The different components are assembled around the condenser and held in compression by a spring mechanism. The springs also maintain adequate pressure on the seals (Nitrile or in some special cases Viton®) during the thermal contraction and expansion of its parts. The air inside the assembly is then evacuated, and oil is introduced while continuously checking seal integrity. The drying, final evacuation and oil filling process must be handled with care in order to avoid premature aging of the insulation. In a RIP bushing, there is no final evacuation and oil filling. Bushing assembly Final evacuation and oil filling Testing Finally, routine tests are performed which include, one minute power frequency tests, continuous partial discharge readings, tan ∂ or power factor (capacitive losses) tests, as well as capacitance, and tightness testing. Also, lightening impulse tests (BIL) are performed on bushings having ratings equal to or greater than 300 kV. Test laboratory 3 4.2 In-tank connection system The unique, ABB tank connection system with draw rods is offered on selected products (such as Type GOE, AB, O Plus C and others) to allow on-site installation without accessing the leads from inside the transformer main tank. After transformer testing, the lower part of the bushing’s connection system is left inside the transformer before sealing. During transformer field installation, the upper part of the draw rod and the bushing itself is lowered into its final position on the transformer tank, guided by a guiding cone. To ensure low through resistance, the necessary contact force is applied from the outside following a careful procedure to achieve sufficient contact force. This design has been sucessfully used by ABB for more than thirty years. Type GOE optional draw rod transformer lead connection (design can vary by product type) 4 4.2 Bushing products Type GOB, AB, O Plus C, GOE & GOM are oil-impregnated condenser bushings for use in transformers and oil-filled circuit breakers. They are available for 15 kV through 800 kV ratings meeting or exceeding applicable IEC, IEEE/ ANSI, and CSA standards. These designs have power factor and partial discharge levels well below industry requirements. The bushings are suitable for new equipment as well as for direct field replacement of existing power apparatus. Type CORIP & GSA are resin-impregnated condenser bushings with composite insulator materials. These designs are perfect for coastal and highly polluted environments. The environmentally friendly products perform according to the latest seismic specifications. The bushings can be stored and installed in any position. Being oil free, easy to handle, water repellant, virtually maintenance free, light and safe, this is the ultimate bushing for both new, replacement and mobile power transformer applications. The bushings meet or exceed the latest IEC and/or IEEE/ANSI standards. Type T & GOH are oil-impregnated condenser bushings designed for both vertical and horizontal mounting on high-current transformers. The Type T bushing is the right choice for high temperature applications in bus ducts. It incorporates high temperature materials, such as Nomex® insulation and Viton® seals. The Type T combines the performance of a condenser or capacitance graded design bushing with the capability of performing in open air up to 125 ºC. Our Type GOH can also be applied in bus ducts by following the loading guidelines found in the technical guide. They are available from 25 kV through 34.5 kV voltage ratings and 600 to 21,500 ampere current ratings. 5 4.2 The Type A bushing is a stud-type design offering an economical and versatile bushing for transformer, regulator and generator applications. It can be vertically or horizontally mounted and is availabel in 600 to 23,000 ampere current rating range and from 1.2 kV through 34.5 kV. The simple design and rugged construction means that the bushing requires little maintenance other than periodic cleaning. The Type LCRJ bushing is a robust stud-type design suitable for vertical or horizontal mounting on power transformers. Similar to the Type A, this bushing requires little maintenance due to the simple design. Type LCRJ is best suited when the specification calls for a high current application with low partial discharges in a non-condenser design. Partial discharge is guaranteed to be less than 50 microvolts at a test voltage of twice the normal line-to-ground operating voltage. The bushings are available from 15 kV through 25 kV and from 2,900 to 23,000 ampere ratings. 6