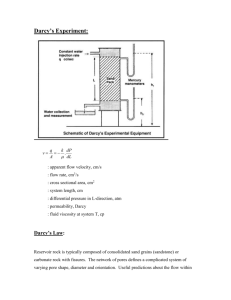

Well Testing Analysis: Reservoir Characteristics & Flow Equations

advertisement