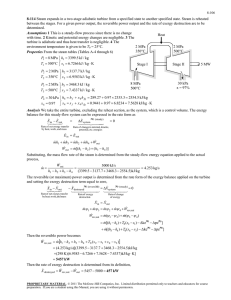

Department of Mechanical Engineering University of Engineering and Technology Energy and Exergy Analysis of a Steam Turbine Power Plant using Bagasse as fuel Student Abdul Mannan Mazhar Supervisor Dr. Muhammad Usman Registration No 2020-MS-RES-501 Date of Registration 02-09-2020 Subjects Passed 08 Date of Completion 1 Department of Mechanical Engineering University of Engineering and Technology Problem Statement • In the modern era, effective energy management is of primary concern as the demand for energy consumption has been increased exponentially. • Contrary to the trend of increasing demand, the energy supply is limited as a consequence of depreciation in fossil resources. • About 80% of the world’s power demand is fulfilled by power plants and most of them utilize fossil fuels as the source [1]. • We have learned about energy and exergy analysis but how to implement it practically. • How to deal with constraints such as internal properties of the working fluid at different inlet and outlet points? • How entropy factor is impacting the actual performance of the power plant? Does load variation will be effecting the power plant? • What are the components providing high and low efficiency? • The research is conducted to answer all the above mentioned queries. Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 2 Department of Mechanical Engineering University of Engineering and Technology Objectives • Inspection of efficiency of the plant when bagasse is used as fuel • Determine the exergy destruction of different components of a steam turbine power plant • Analyze the components that are offering higher energy and exergy losses. • Calculation of energy and exergy efficiency of different components. • Analyzing the effect of mass flow rate of steam with variation in load. • Analyzing the efficiency of different components with variation in load • Determine the cycle energy and exergy efficiency along with their variation with respect to load. • Determine the exergy loss ratio and relative exergy destruction of different components. Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 3 Department of Mechanical Engineering University of Engineering and Technology Methodology Understanding the process Determination of Intensive Properties Developing Equations for Exergy Analysis Calculation of Exergy Efficiencies of different components Calculation of exergy loss ratio Developing Equations for Energy Analysis Calculation of Relative Exergy Destruction Calculation of Energy Efficiency Graphical Interpretation Discussion and Conclusion Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 4 Department of Mechanical Engineering University of Engineering and Technology Cycle of Chanar energy steam power plant Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 5 Department of Mechanical Engineering University of Engineering and Technology Boiler Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 6 Department of Mechanical Engineering University of Engineering and Technology Turbine Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 7 Department of Mechanical Engineering University of Engineering and Technology Condenser Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 8 Department of Mechanical Engineering University of Engineering and Technology Deaerator Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 9 Department of Mechanical Engineering University of Engineering and Technology Literature Review In Pakistan, energy crisis has badly affected the lives of people. Our country mainly relies on fossil fuels to produce energy which are depleting and causing environmental deterioration and concerns. Exergy analysis is an excellent method for investigating the performance of the components of the system. It involves examining the exergy at many points especially close to the energy conversion components. This information is relevant to evaluate the efficiencies and determine the components offering high exergy loss [2]. Analysis that is based on combination of exergy and energy, prove to be well suited for power plants optimization. Exergy is defined in term of maximum work that is obtained by system as it comes to equilibrium with specified reference environment [3]. Thermodynamic imperfections can be described as exergy losses. Degradation of energy can be understood as irretrievable energy losses. Energy analysis is based on law of conservation of energy, first law of thermodynamics. While, exergy balance is based on statement of degradation of energy [4]. Exergetic life cycle assessment involves exergy analysis of complete life cycle. It helps in quantifying environment problems due to decreasing natural resources [5, 6] Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 10 Department of Mechanical Engineering University of Engineering and Technology Literature Review Nemati et al. developed model for analysis of thermoelectric heat pump. Optimization was based on multi-objective genetic algorithm. On basis of exergy efficiency and cost, optimal values of design variables were found [7]. AMK Vandani et al. analyzed the effect of adding feed-water heaters in steam power plant using exergy and economic analysis. They used optimization algorithm to study different configuration of heaters. Adding heaters, improved the exergy efficiency up to 0.33% [8]. [9] conducted energy, exergy-economics and environmental 4E analysis for optimizing steam power plant. Optimum operating conditions were estimated and exergy efficiency was increased by 16.8%. Clety conducted exergy analysis on Olkaria I power plant in Kenia to determine second law efficiency and exergetic losses [10]. In order to locate losses and optimize the power generation, many researchers have provided fundamental foundation. The work of C Birnie et al. evaluated the location of losses in 60 MW power plant [11]. A. Keller used entropy balance diagram to evaluate losses in steam power plant [12]. Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 11 Department of Mechanical Engineering University of Engineering and Technology Literature Review H.Y Kwak used thermo-economic and exergy analyses for 500 MW combined cycle plant. Each component was analyzed with energy and mass conservation laws [13]. J. Zueco et al. performed exergy analysis of steam turbine power generation using different fuels. Boiler was found to be main contributor of the exergy loss. Fuel having simple molecular structure with oxygen molecules reduced the exergy loss [14]. M Elhelw et al. simulated the thermal power plant at full and half operational load to find sources of exergy destruction and concluded that most of the exergy destruction occurred in boilers, followed by turbines and then condensers [15]. P. Regulagadda et al. developed energy and exergy formulations for 32 Mega-Watt coal based plant and suggested boiler to be major location of irreversibility due to combustion and flue gases [16]. [17] applied the concept of 2nd law of thermodynamics to account for irreversibility in the boiler and heat exchanger by changing rate of combustion air and temperature of stack-gas. Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 12 Department of Mechanical Engineering University of Engineering and Technology Literature Review Proper co-ordination, analysis and planning should be done to implement effective energy management system for Power Plants. One way is to conduct analysis of the power plant and then various methods including lean techniques are used to eliminate or minimize the energy losses. In this regard the first and second law of thermodynamics hold great importance which direct towards exergy and energy analysis. Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 13 Department of Mechanical Engineering University of Engineering and Technology References [1] Kaushik, S. C., Reddy, V. S., and Tyagi, S. K., 2011, "Energy and exergy analyses of thermal power plants: A review," Renewable and Sustainable Energy Reviews, 15(4), pp. 1857-1872. [2] Rosen, M. A., and Dincer, I. J. I. J. o. T. S., 2004, "Effect of varying deadstate properties on energy and exergy analyses of thermal systems," 43(2), pp. 121-133. [3] Dincer, I., and Cengel, Y. A. J. E., 2001, "Energy, entropy and exergy concepts and their roles in thermal engineering," 3(3), pp. 116-149. [4] Kotas, T. J., 2013, The exergy method of thermal plant analysis, Elsevier. [5] Cornelissen, R. L., 1999, "Thermodynamics and sustainable development: The use of exergy analysis and the reduction of irreversibility." Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 14 Department of Mechanical Engineering University of Engineering and Technology References [6] Dincer, I., Rosen, M. A. J. R., and Reviews, S. E., 2005, "Thermodynamic aspects of renewables and sustainable development," 9(2), pp. 169-189. [7] Nemati, A., Nami, H., Yari, M., Ranjbar, F., Kolvir, H. R. J. E. C., and Management, 2016, "Development of an exergoeconomic model for analysis and multi-objective optimization of a thermoelectric heat pump," 130, pp. 1-13. [8] Vandani, A. M. K., Joda, F., Ahmadi, F., Ahmadi, M. H. J. M., and Industry, 2017, "Exergoeconomic effect of adding a new feedwater heater to a steam power plant," 18(2), p. 224. [9] Ameri, M., Mokhtari, H., Bahrami, M. J. I. J. o. S., and Technology, T. o. M. E., 2016, "Energy, exergy, exergoeconomic and environmental (4E) optimization of a large steam power plant: a case study," 40(1), pp. 11-20. [10] Kwambai, C. B., 2005, Energy analysis of Olkaria I power plant, Kenya, United Nations University. Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 15 Department of Mechanical Engineering University of Engineering and Technology References [11] Birnie, C., and Obert, E., "Evaluation and location of losses in a 60 MW power station," Proc. Proc. Midwest Power Conf, pp. 187-193. [12] Keller, A. J. T. A., 1950, "The Evaluation of Steam-Power-Plant Losses by Means of the Entropy-Balance Diagram," 72, pp. 949-953. [13] Kwak, H.-Y., Kim, D.-J., and Jeon, J.-S. J. E., 2003, "Exergetic and thermoeconomic analyses of power plants," 28(4), pp. 343-360. [14] Zueco, J., López-Asensio, D., Fernández, F., and López-González, L. M. J. A. T. E., 2020, "Exergy analysis of a steam-turbine power plant using thermocombustion," 180, p. 115812. [15] Elhelw, M., and Al Dahma, K. S. J. A. T. E., 2019, "Utilizing exergy analysis in studying the performance of steam power plant at two different operation mode," 150, pp. 285-293. Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 16 Department of Mechanical Engineering University of Engineering and Technology References [16] Regulagadda, P., Dincer, I., and Naterer, G. J. A. T. E., 2010, "Exergy analysis of a thermal power plant with measured boiler and turbine losses," 30(89), pp. 970-976. [17] Amir, V., "Improving steam power plant efficiency through exergy analysis: ambient temperature," Proc. 2nd international Conference on Mechanical, Production and Automobile Engineering (ICMPAE) Singapore, Citeseer, pp. 209-212. Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Usman 17 Department of Mechanical Engineering University of Engineering and Technology Thank You Registration No: 2020-MS-RES-501 Supervisor: Dr. Muhammad Asim 18