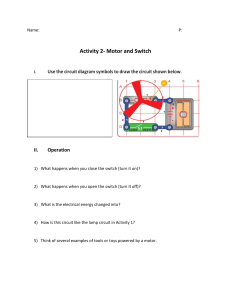

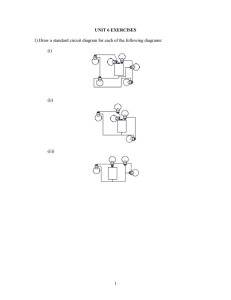

C7S FAILURE FLOWCHARTS Revisions: Rev.01 Rev.02 14.01.2019 26.03.2019 First edition Listen to the customer's complaint PICTURE _1: Supply voltage is being measured on the mains connector. (KN6) Close the machine door, if open. Switch to service mode. To enter the service mode, switch off the machine by pressing the On/Off button. While pressing the "1st auxiliary function" and "2nd auxiliary function" keys at the same time, switch on the machine using the "On/Off" key. KN6 Is there 220 VAC between the suppression filter terminals 1 and 2 (grey-grey)? No Check the mains cable and fuses. Change the mains cable if defective. No When you turn on the machine, are the display and programme selection key LEDs powered? Yes Yes Yes Remove the mains connector and check if the socket is powered. PICTURE: first_1 Is the front door locked? Check by trying to open it. Yes No Check the error code. Is there an E9 error code? No Safety switch cannot be locked. Check the cabling between the control board and safety switch. Open circuit on door triac. Replace the control board Yes 1)Continue testing machine functions in the service mode. Is there an error code? No OR 2)Proceed to the error codes page to find the error code matching the customer's complaints. Yes Go to the relevant error code page. Carry out the checks about the error code. OR 3)Switch the machine back to the customer mode and run it. Wait for the error that the customer experienced. Try to see the error code while the programme is running. No Check the cable between the suppression filter and the board, and make sure that sockets are securely fitted. Replace the control board Replace the safety switch. Try again. * Machine washes poorly CUSTOMER'S POTENTIAL COMPLAINT * Machine does not heat water * Programme takes too long. ERROR CODE *Does not heat. NAME OF ERROR *Machine boils the water. *Machine boiled water once, but now does not heat at all. * No washing movement *Laundry comes out very hot; they get worn. * Door cannot be opened * Programme does not end. E1 E2 * NTC short circuit or * NTC open circuit error * Machine takes in water continuously and does not discharge. * Heateropen circuit error E3 E4 * Valve triac short circuit or * Valve triac diode error * Heater continuously active error Important Note: *Programme takes too long. *Machine does not drain. *Machine does not spin E5 *Pump triac open circuit or *Pump clogged or *Pump triac diode or *Pump rotor locked and not rotating error Error codes given do not necessarily mean that the error is always caused by components. Socket and cable connections must be checked first. Make sure that the problems do not arise from loose contact. * Machine washes poorly. CUSTOMER'S POTENTIAL COMPLAINT ERROR CODE NAME OF ERROR * Machine discharges every time it is turned on. * Programme does start. E7 *Water level sensor reading error Programme takes too long. *Machine does not end the programme *Machine does not take in water. *Machine does not function. *It does not spin or drain *Machine drains continuously. E8 *No water or *Valve triac open or *Pump triac short circuit error * Washing ends before the displayed washing time is over. * Programme is not completed. Door jammed Program is not completed. **Machine drum does not rotate at all. * Machine leaves water inside. *Laundry comes out with detergent. E9 *Door lock triac open circuit error E10 *Door lock triac short circuit error E11 *Motor phase open circuit CUSTOMER' S POTENTIAL COMPLAINT ERROR CODE NAME OF ERROR *Programme is not completed. *Machine does not rotate. E13 *BLAC motor communicati on cable open circuit error * Machine failed to spin. * Time extended. * Although I did not select extra rinse, machine performed another rinse cycle. * Machine failed to spin. , * Time extended. E17 E18 *Programme finished without spinning due to foam *Programme finished without spinning due to unbalanced load *Machine door won't open. E20 *Door solenoid triac or relay short circuit * Machine does not function. *Machine does not take in water. * Programme ended in a longer time. * Machine did not heat well. E28 E29 *Door locked signal (zero cross) cannot be received Important Note: Error codes given do not necessarily mean that the error is always caused by components. Socket and cable connections must be checked first. Make sure that the problems do not arise from loose contact. *Operating voltage out of limit * Machine washes poorly * Machine does not heat water * Programme takes too long. Is there an E1 error? PICTURE E1-1: There is an NTC cable on the KN9 socket (Display board) (6th and 7th pins green-green / Display board) Yes E1 Attach the KN9 socket. (Picture E1-1) * NTC short circuit or * NTC open circuit error No Is the KN9 socket on the control board attached? KN9 Yes PICTURE E1-3: The NTC socket on the heater is removed and the NTC resistance is measured Take out the KN9 socket and measure the resistance on the socket between the 6th (green) and 7th (green) pins (Picture E1-2) PICTURE E1-2: The socket connected to the KN9 connector is removed and the NTC resistance is measured KN9 Yes Replace the control board. PICTURE E1-4: NTC resistance to be measured must be around 5.6K ohm at 25 degrees (Display board) The measured value is NTC resistance value. Does it show approx. 5.6K under 25°C temperature? (Picture E1-3) (There should not be open circuit/short circuit) No Open the rear cover of the machine. After removing the NTC socket on the heater, measure the NTC value directly on the NTC. (Picture E1-4) Important Note: In case of NTC open circuit/short circuit and heater open circuit on the washing machine, i.e. if there is E1, E2 or E3 error, machine performs cold washing and ends the programme without the heater activated. Yes As the value measured on the control board socket is wrong, cabling is improper; check it. There should not be any loose or defective cable or socket. INFORMATION: NTC resistance decreases as its temperature rises. For example, it shows a resistance of 9500 Ohm under 10°C, and 1700 Ohm under 50°C. These values are not faulty. Does it show approx. 5.6K Ohm under 25°C temperature? (There should not be open circuit/short circuit No Replace the NTC. Re-attach the removed sockets into their places *Does not heat. *Machine boiled water once, but now does not heat at all. Is there an E2 error? Yes PICTURE E2-1: Heater socket on the KN1 board is removed. (Power board) E2 PICTURE E2-2: Short circuit check is being carried out between KN1 pin 1 and pin 2. (Power board) For easy measurement, remove the panel and KN1 Heater socket. (Picture E2-1) KN1 KN1 * Heateropen circuit error Yes PICTURE E2-3: Heater socket on the KN15 board is removed to check the cable. (Power board) Check for short circuit between KN1 connector pins 1 and 2. (Picture E2-2) Replace the control board. No KN1 Measure the resistance of the heater on the KN1 heater socket pins, is it approximately 27 ohm?(Picture E2-3) If not, check the heater cable and socket. Open the rear cover of the machine. Remove at least one of the heater terminals and measure the heater's resistance; is it approximately 27 Ohm? (Picture E2-4) Yes No Replace the heater PICTURE E2-4: One of the cables on the heater is removed (left) and heater resistance is being measured. Does the heater work although there is no water? No You may start the washing programme. Yes Check the water level sensor. Measure the frequency between pins 1 and 2 (Blue-White) while the machine is empty and powered. It should be around 625 Hertz. (Picture 2-5) If faulty, replace the water level sensor. Important Note: In case of NTC open circuit/short circuit and heater open circuit on the washing machine, i.e. if there is E1 or E2 error, machine performs cold washing and ends the programme without the heater activated. PICTURE E2-5: Water level sensor is being checked. Machine is boiling the water. Laundry comes out very hot; they get worn. Is there an E3 error? E3 PICTURE E3-2: Short circuit check is being carried out between KN1 pin 1 and pin 2. (Power board) Yes For easy measurement, remove the panel and the heater socket. KN1 (Picture E3-1) * Heater continuously active error KN1 PICTURE E3-1: Heater socket on the KN15 board is removed. (Power board) No KN1 Check for short circuit between KN24 connector pins 1 and 2. (Picture E3-2) Yes Does the heater work although there is no water? Check the water level sensor. While machine is empty and powered, measure the frequency between pins 1 and 2. It should be around 625 Hertz. (Picture E3-4) Replace the control board. Yes Open the rear cover of the machine. Remove at least one of the heater terminals and measure the heater's resistance; is it approximately 25 Ohm? (Picture E3-3) No Replace the heater PICTURE E3-3: One of the cables on the heater is removed (left) and heater resistance is being measured. PICTURE E3-4: Water level sensor is being checked. You may start the washing programme. Important Note: In case of NTC open circuit/short circuit and heater open circuit on the washing machine, i.e. if there is E1 or E2 error, machine performs cold washing and ends the programme without the heater activated. * Machine takes in water continuously and does not discharge. * No washing movement * Door cannot be opened * Programme does not end. E4 PICTURE E4-1: Water inlet valves Is there an E4 error? Yes Is the machine taking water continuously? PREWASH VALVE MAIN WASH VALVE Yes * Valve triac short circuit or * Valve triac diode error Unplug the machine and check if it continues taking in water. Yes Does the machine continue taking in water although it is not powered? Yes Replace the control board. No Replace the valve with a water inlet (Picture E4-1) *Programme takes too long. *Machine does not drain. *Machine does not spin Is there an E5 error? Yes E5 Check the machine's supply voltage. If there is low supply voltage, the pump will not work. *Pump triac open circuit or *Pump clogged or *Pump triac diode or *Pump rotor locked and not rotating error Yes Start the machine after switching to the pump programme. PICTURE E5-1: Measuring the voltage going from KN8 on the board to the pump (Power board) Is the pump motor running? (It can be understood by touching the filter cover.) *Check and clean the pump filter * Check if the drain hose's height and length are appropriate, and correct if necessary. * Make sure that the drain hose is not twisted or kinked. Restart the pump programme after taking in water. Yes No KN8 While the Nopump programme is running, check if there is 220 VAC between KN8 pin 1 and pin 2 (purple-purple) without removing the control board or any socket. Picture E5-1 Can the pump drain water? (Pump may be in triac diode. The pump cannot pump even if it creates vibration.) PICTURE E5-2: Pump resistance is being measured on the pump connector Is there 220 VAC voltage? No Replace the control board. Yes Switch off machine and remove its front wall in order to check its pump coil resistance. There should be approx. 180 Ohms between the two pins (purple-green) of the pump connector. Check Picture E5-2. There should not be any open circuit or short circuit Is the pump resistance correct? No Replace the pump. Yes Repair the cables and/or cable terminals. Yes Is there any loose connection or break on the socket terminals or connections between the control board and pump motor? No Assemble and restart the machine PICTURE E7-1: The socket on the level sensor must be fitted Is there an E7 error? * Machine discharges every time it is turned on. * Programme does start. E7 Yes Are the Level Sensor socket (Picture E7-1) and control board KN9 socket fitted (Picture E7-2) and are the connections secure? No Repair the socket and cables PICTURE E7-2: Socket to which the KN9 level sensor cables are attached (Display board) Yes *Water level sensor error While machine is empty and powered, measure the frequency between pins 1 and 2 (Pink-Orange). It should be around 625 Hertz (Picture E73). Is the measured value equal to the required value? No Yes KN9 Replace the level sensor PICTURE E7-3: Water level sensor is being checked. Try to start a programme again. Programme takes too long. *Machine does not end the programme *Machine does not take in water. *Machine does not function. *It does not spin or drain *Machine drains continuously. PICTURE E8-1: AC voltage is being measured on the valve connectors Is there an E8 error? Yes Yes Is the machine taking in water? E8 No *No water or *Valve triac open or *Pump triac short circuit error Yes Is the machine continuously pumping and discharging water although it takes in water? PICTURE E8-2: KN10 connector on the board (Power board) Check taps and filters, check if they are on. Is the tap turned off or the filter clogged? KN10 Yes No Turn the taps on and try again. Replace the main board and try to run a programme again except spinning or pump. INFORMATION: For KN10 Main wash pin 1-3 blue Main wash pin 4-6 yellow PICTURE E8-3: AC voltage is being measured on the valve connectors (Power board) Make sure that the valve connectors (Picture E8-1) and control board KN10 (Picture E8-2) are fitted. Are the connectors fitted? No Attach the connectors and try again. KN10 Yes Replace the valve. Try again. No Is there 220 VAC between the connectors of the valve that has to run? (Picture E8-1) Yes Is there 220 VAC between KN10 connector pins 1 and 3 on the control board? (Picture E8-3) Yes Replace the control board and try again. Important Note: In the softener step, prewash and main wash valves are activated together. Thus, water is sent to the softener compartment. Correct and check the connections. Try again Yes Is there any error on the cable connections between the control board and the water inlet valves? * Machine washes poorly. * Washing ends before the displayed washing time is over. * Programme is not completed. * Machine leaves water inside. Laundry comes out with detergent. Is there an E9 error? Door jammed Yes Replace the control board and try again. E9 *Door lock triac open circuit error Is there an E10 error? Yes Replace the control board and try again. E10 *Door lock triac short circuit error Program is not completed. *Machine makes sudden startups. *Machine drum does not rotate at all. Is there an E11 error? Picture E11_1: Motor sockets Yes Motor 3-phase socket E11 Are the motor sockets (3-phase) fitted? (Picture E11-1) Yes *Motor phase open circuit Are the cables between the motor and the motor control board secure? (The 3-phase cables must be checked) Picture E11_2: Motor Yes Replace the motor (Picture E11-2) Try to start a program again. Does the error persist? Picture E11_3: Motor control board Yes Replace the motor control board (Picture E11-3) Motor board 3-phase socket Try to start a programme again. Picture E13-1: Connector connection on the display board (KN9) *Machine washes poorly. , * It ends the programme. Is there an E13 error? Yes KN9 E13 Are the display board communication KN10 socket (Picture E13-1), Motor sockets (Picture E13-2) and Motor driver board KN3 socket (Picture E13-3) fitted and are the connections secure? Picture E13-2: 3-phase sockets on the motor (ATLAS MOTOR) *Communicatio n cable open circuit. Yes Motor 3-phase socket Check if the motor coil and thermal measurement values are correct through the inlet points on the motor using a measuring device. Are the measurement values correct? (See E13_Motor coil Yes measurement) PICTURE-E13-3: ATLAS Motor driver board sockets KN3- COMMUNICATION KN5- MOTOR THREE-PHASE KN6- MOTOR BOARD AC INPUT No Replace the motor KN 3 Yes Check the socket inlets on the motor driver board and replace the motor driver board Does the error persist? KN 5 Yes KN 6 Also check the socket inlets on the display and power boards and replace. Does the error persist? No Start a programme again to check the motor movement. No Check the sockets and the cablesand repair if there is any loose contact. Picture E17-1: Valves and drawer hose connection * Machine failed to spin. * Time extended. * Although I did not select extra rinse, machine performed another rinse cycle. E17 Is there an E17 error? Yes *Programme finished without spinning due to foam. PREWASH VALVE Check if the main wash and prewash valves are correctly connected to the related compartment of the detergent drawer. If prewash is selected, water fills in the prewash compartment when the machine takes in first water. If prewash is not selected, first water is taken from the main wash compartment. Is it so? (Picture E17-1) Yes Explain the customer the following antifoam measures. Foam formation reasons and prevention methods 1) If you add detergent in the prewash compartment although you have not selected prewash, detergent will be taken from this compartment while rinsing the laundry and cause foam formation. 2) You should use detergents designed for automatic machines. 3)Laundry can remain with detergent as a result of using excessive detergent. You should try to use only adequate amount of it. 4) Keep your detergent in a closed and dry place. 5) You should use less amount of detergent than ever for your lacy laundry. 6) You should not use too much softener. No MAIN WASH VALVE Correct the water intake hoses. Is there an E18 error? * Machine failed to spin. * Time extended. Yes E18 Explain the customer the following methods for preventing unbalanced load. Reasons of ending the programme without spinning as a result of detecting unbalanced load *Programme finished without spinning due to unbalanced load. 1) When you use the machine with less laundry, laundry may pile up on one side of the drum. There is the risk of damaging the washing machine when it is operated at higher speeds with unbalanced load. Therefore, when the unbalanced load in the machine exceeds the limit value, the machine will not spin for safety reasons. 2) The possibility of piling up of laundry at one point in the drum will be higher when the machine is operated with a single pullover, bathrobe or towel. Avoid washing such laundry as one piece as much as you can. Is there an E20 error? *Machine door won't open. Yes Replace the solenoid door lock Does the error persist? E20 Yes Replace the main board *Door solenoid triac or relay short circuit Start a programme again and check. Is there an E28 error? * Machine does not function. *Machine does not take in water. Yes Replace the solenoid door lock Does the error persist? E28 Yes Replace the main board *Door locked signal (zero cross) cannot be received Start a programme again and check. Is there an E29 error? * Programme ended in a longer time. * Machine did not heat well. Yes E29 Measure the supply voltage. Is the operating voltage lower than 150 VAC or higher than 290 VAC? *Operating voltage out of limit Yes Brief the customer about operating voltage of the product and making necessary changes on the electrical installation to enable the customer to use the product within the specified operating voltage range. Programme selection key does not select, or the selected programme is not the same as the running programme, or Some programmes cannot be selected. For example, machine takes in water although spin is selected Replace the control board Picture 1: Valves socket connection Machine takes in water from the wrong detergent compartment Are the valves connected to KN18 - Prewash (Blue), KN18 - Main wash (red) (Picture-1) terminals? PREWASH VALVE MAIN WASH VALVE Fix the connections. Check with a function test. Picture 2: Valves drawer hose connection Yes Perform a function test on the machine to check compartments of the detergent box. (Picture-2) Check if there is 220V AC on the relevant valve during the test steps PREWASH VALVE DRAWER HOSE INLET Yes Is there 220VAC voltage on the relevant valve during water intake from each compartment? No Replace the control board Replace the valve MAIN WASH VALVE DRAWER HOSE INLET Is the machine continuously blowing the fuse and is there not an error code? Make sure that water is not coming upon the control board, motor, heater, pump, door lock or valves of the machine. Yes Remove the heater sockets to check if there is short circuit on the heater. Replace the heater. Yes Is there short circuit on the heater? No Fix the cabling. Yes Check the cabling of the machine; is there any stripped, broken, burnt or melted cable? Run the machine one more time; can it operate for a while without blowing the fuse? Yes During the function test, check which component blows the fuse. Remove the connected socket terminals of the part that blows the fuse and perform a short circuit check. Replace that part if there is short circuit. If not, recheck the cabling. No Is there any trace of burning-blowing on the control board? Yes No Does the machine continue blowing the fuse? Yes Replace the control board C7S Bluetooth setup Add / Remove Products Select a product Which product do you want to add? There is no product in your Homewhiz account or network. Connect new product to the network> Select a product Enter the product code of the product. Open the door of your washing machine. The product code can be found on the label on the inside of the door. Start waiting C7S Bluetooth setup Bluetooth setup 1 Step HomeWhiz setup cancel HomeWhiz setup Connecting with Bluetooth 2 Step Completed ! Last step: name your product. Press the temperature and distance control buttons at the same time. Press and hold the temperature and remote control keys on the product for 3 seconds Usage tip 1 If your product is connected, you can follow it at any time. Temperature button To control the product, set the product to the downloaded program and press the remote control button. Remote control button Name of the product Remote control button Usage tip 2 Go to the next step. Add the white goods HomeWhiz It can be connected to the product with only one mobile device at the same time. PICTURE-1 Power board and display board PICTURE-2 Power board sockets POWER BOARD KN 10 KN 8 KN 1 KN 3 KN 6 DISPLAY BOARD PICTURE-3 Power board sockets PICTURE-4 Power board sockets KN 11 KN 10 KN 8 KN 1 KN 3 KN 6 KN 9 KN 7 POWER BOARD SOCKET CONNECTIONS KN1- HEATER - MOTOR BOARD 220 VAC KN3- DOOR LOCK KN6- MAINS 220 VAC KN7- POWER BOARD GROUNDING KN8- DRAIN PUMP KN9- COMPONENTS POWER BOARD HIGH KN10- PREWASH - MAIN WASH VALVE KN11- COMPONENTS POWER BOARD HIGH PICTURE-5 Display board socket connections KN 9 DISPLAY BOARD SOCKET CONNECTIONS KN9- MOTOR COMMUNICATION – NTC – WATER LEVEL SENSOR KN23- COMPONENTS DISPLAY BOARD LOW KN24- COMPONENTS DISPLAY BOARD LOW KN7- POWER BOARD GROUNDING KN8- DRAIN PUMP KN10- PREWASH - MAIN WASH VALVE KN 24 KN 23 KN 7