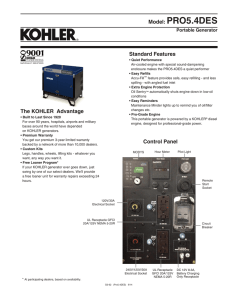

200 kVA 200kVA The Kohler Advantage • One-stop solution for the generating system and accessories with PROGRESSIVE TRADERS. • Manufactured in India with global expertise • Compact design with ease of maintenance • Maux winding provides excellent motor starting capability • Best in class block loading capacity • Flexible & creative customized solutions to meet customer needs • Fast response time • Two-years or 5000 hours as per standard warranty terms from date of initial startup KOHLERPOWER.COM / 3 Special Features • Turbo-charged & after-cooled industrial diesel engine with superior efficiency and fuel economy • Integral vibration isolation eliminates the need for under-unit vibration spring isolators • Advanced Digital Controller (ADC) with 3 auto crank cycles Alternator features: • Alternator meets Indian and international standards • Self-ventilated and drip-proof of IP23 construction • Superior voltage waveform by 2/3 pitch winding stator • Sustained short circuit current of up to 300% of the rated current for up to 10 seconds • Silencer located inside canopy Standard Features 200 kVA • Engine coupled, skid mounted alternator • Single - bearing alternator with insulation Class H • Unit mounted radiator with 50°C ambient temperature • Base frame mounted fuel tank with minimum 8 hrs running capacity • Dry type air filter with restriction indicator • DG circuit breaker • Electric start with battery • Fuel water separator • Conveniently located fuel level indicator • Exhaust tail pipe & rain guard as standard scope of supply • Weather proof enclosure to withstand harsh climate • All routine service points on one side of canopy • Four point bottom lifting Conformance Standards • ISO 3046 • BS 5514 • ISO 8528 • VDE 0530 • IEC 60034-1 • BS EN 60034-1 • EN 60034-1 • AS 1359 • IS 13364-PT. 1 & 2 • BS 5000 • VDE 0530 • NEMA MG1-32 • IEC 34 • CE marking • CDS C22.2-100 KOHLERPOWER.COM / 4 Engine Model Nomenclature- 200 kVA 6. 12 TC E 7.2 litre engine Electronic Turbocharged Series ( 1200 cc/Cylinder) No. of Cylinders KOHLERPOWER.COM / 5 Key Features of Engine(82.5 to 200 kVA) Serviceability Reliability •Connecting Road with “Fracture split Process” technology •Poly V-belt for front end auxiliary • High stiffness monoblock crankcase with high rigidity cover type Oil cooler • Modular cylinder head Fuel efficiency Low Noise •Laminated Sheet •Stainless steel Plate – steel front •Optimized Combustion Chamber design •High pressure common rail system (CRDIe) • 4-Valve Technology Long Life • Oil jet cooled pistons • High strength sputter bearings Emissions •Capable of meeting all the emission norms planned till 2022 •Internal EGR on cam lobe Engine Design Features Cylinder Block • • • It is designed for strength and rigidity while maintaining low weight. Wet liner arrangement. Skirt block design for increased strength • Piston Cooling Nozzles to cool the pistons • Modular Individual cylinder heads makes the engine more user friendly by ease of serviceability and low repair cost. 4 valves /cylinder with 1-2-3-4 Valve Train Technology. Crankshaft : High tensile strength steel forging with induction hardened pins and journals for high fatigue resistance. Dynamically balanced in all places. Fractured cap joint & Split angle connecting rods. Forged Steel, Bolted Cam Gear with integral design on cam lobe for internal EGR The new water pump is designed with seven vanes to increase the water flow. To improve the components durability & engine performance this engine uses the hot & cold side concept for component distribution Single bush camshaft i.e front side KOHLERPOWER.COM / 8 Engine Design Features 24 Valve Centered Injection Minimizes over-spray resulting in longer service intervals. Uniform ring temperatures for increased durability Uniform fuel injection for improved fuel efficiency 18 Water pump Cam back gear 72 Cam front gear FIP Gear 58 58 Special Gear Train 61 Total 7 Gears Camshaft front gear and Fip gear are Helical gear Remaining all gears are spur gear 26 Idler 61 Lube pump Crank 36 KOHLERPOWER.COM / 9 200 kVA DG Set G1R250LD Alternator 6.12 TCE ADC3003 Controller Engine KOHLERPOWER.COM / 242 200 kVA Kohler Vs Competitor KOHLER PARAMETERS Genset Model Basic Engine No. of cylinders Engine capacity (cc) BHP @ rated rpm Rated speed (rpm) KOHLER KDG0200P1 6.12 TCE 6, inline 7118 241.2 1500 Cummins KOEL KOEL KG1-200WS 6SL1500TA G2 6, inline 8860 248 1500 CUMMINS C200D5P QSB6.7-G15 6, inline 6700 248 1500 Greaves GREAVES GPWII-PII-200 6G11TAG29 6, inline 7310 243.1 1500 KOHLERPOWER.COM / 11 Fuel Consumption 200 kVA Fuel Consumption 50 40 34.4 33.3 47.50 46.20 45.90 40.80 34.6 35.4 30 0.12 Lube Oil Consumption Lube oil consumption( Ltrs / Hr.) 0.11 0.10 0.08 20 0.05 0.06 10 0.04 0 KOHLER KOEL CUMMINS GREAVES Fuel consumption @ 75% Load (Lits./hr)* Fuel consumption @ 100% Load (Lits./hr)* Kohler best in class fuel efficiency 0.03 0.03 0.02 0.00 KOHLER KOEL CUMMINS GREAVES Kohler best in class oil consumption KOHLERPOWER.COM / 12 Diesel Cost for 2500 Hours 200 kVA Total Lube oil Costs for 2500 Hrs. Total cost of diesel for 2500 Hrs 6,133,333 6,200,000 5,600,000 80,000 5,733,333 5,800,000 94,250 100,00 0 5,900,000 6,000,000 Oil Cost for 2500 Hours 71,750 51,113 45,000 60,000 5,550,000 40,000 5,400,000 20,000 - 5,200,000 KOHLER KOEL CUMMINS KOHLER GREAVES KOEL Total operating costs Kohler –Low operating cost of diesel than competitors 5,994,250 GREAVES KOHLER GREAVES Kohler- Low operating cost of oil than koel &greaves 6,178,333 CUMMINS KOEL CUMMINS 5,805,083 5,601,113 5,200,000 5,400,000 5,600,000 5,800,000 6,000,000 6,200,000 6,400,000 Kohler 9%Low Operating cost than cummins&6% lower than greaves KOHLERPOWER.COM / 13 Cost/Unit & Units generated/litre 200 kVA Cost/Unit & Unite generated/Litre 25.00 20.00 20.59 19.35 18.67 19.98 Kohler- Low Cost/Unit Generated than Competitors 15.00 10.00 5.00 3.24 3.14 2.93 3.05 Kohler- More units generated/Litre than Competitors 0.00 KOHLER KOEL Cost per unit generated. CUMMINS GREAVES Units generated/litre diesel Substantial saving in operating cost to customer KOHLERPOWER.COM / 14 TECHNO-COMMERCIAL ADVANTAGES OF KOHLER 200 KVA DG SET PARAMETERS Fuel level indication Lube oil specification Lube oil consumption( Ltrs / Hr.) Controller type Serviceable parts Single window service Continuous loading ** Block loading capacity*** KOHLER KOEL CUMMINS Electrical fuel sensor like modern cars Mechanical fuel level gauge Mechanical fuel level gauge Kohler oil KOEL oil Valvoline 0.03 0.05 0.03 GREAVES REMARKS indication in percentage Accurate & easy fuel sensing in on control panel case of Kohler Greaves Maxtherm API Kohler low cost superior oil CI4 15W40 0.11 Lower oil consumption for Kohler World class KOHLER make Powercommand KG545 GCU6120-MKII Advanced controller for Kohler ADC3003 advanced 1.1 digital controller All the serviceable Both sides have to Both sides have to Both sides have to be parts are on one be opened be opened opened Ease in maintenance for Kohler. side of the set during servicing. during servicing. during servicing. Separate service Separate service Single sales, Separate service and and spares dealer and spares dealer service and spares spares dealer for engine Peace of mind in case of Kohler for engine and for engine and dealer and alternator alternator alternator (PROGRESSIVE TRADERS) High Efficiency in case of 90% 80% 80% KOHLER Higher block Loading Ensures least droop thereby easing 70% 45% 60% Syncronization KOHLERPOWER.COM / 15 Thank You KOHLERPOWER.COM / 16