ON SYSTEM SAFETY AND RELIABILITY METHODS IN EARLY DESIGN PHASES

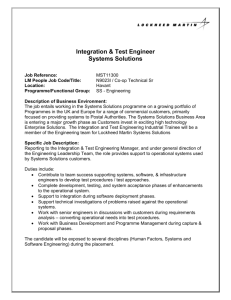

advertisement