Six-Sigma-Yellow-Belt-Certification-Training-Manual-CSSC-2018-06b

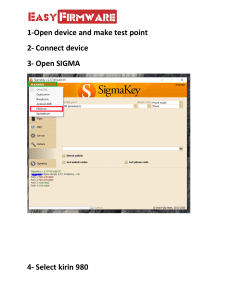

advertisement