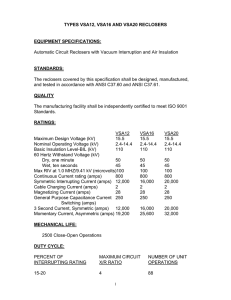

Reclosers Cooper Power Systems Service Information Types VWE and VWVE Maintenance Instructions S280-40-6 CAUTION Do not energize this equipment out of oil. N RADIATION WARNING Before performing electrical tests on types VWE and VWVE Reclosers, refer to Service Information S280-90-1. Figure 1. Type VWVE vacuum interrupting, three-phase, electronically controlled, automatic circuit recloser. CONTENTS Introduction ..........................................2 Description and Operation .................2 General ...............................................2 Ratings ...............................................3 Electrical Ratings .............................3 Interrupting Ratings .........................3 Duty Cycle ........................................3 Mechanism Operation .........................4 Maintenance ..........................................5 Frequency of Maintenance ..................5 Periodic Maintenance Inspection ........5 Manual Operation of the Recloser .....................................6 Mechanism in Oil .............................6 Mechanism Out of Oil ......................6 Insulation Withstand Tests ...................7 Oil Condition .........................................8 Current Transformers ....................18 Shop Maintenance Procedures ......... 8 Continuity Check .........................18 Bushings ........................................... 8 Ratio Test for Sensing CT’s .........18 Type VWE Bushings ....................... 8 Polarity Test for Type VWVE Bushings .................... 10 Sensing CT’s ...........................18 Vacuum Interrupters ........................... 10 Output Test of Battery Closing Solenoid Contactor................ 11 Charging CT ...........................18 Closing Solenoid ................................ 12 Closing Solenoid Fuse ....................... 13 Service Parts List ...............................20 Bushing Parts (Figure 30)..................21 Removing Mechanism From Head . 13 Head and Tank Assemblies Re-lnstalling Mechanism (Figure 31) .....................................23 Into Head ...................................... 14 Closing Coil Mechanism Operation Checks.............................. 14 (Figure 32) .....................................25 Control Cable ................................ 14 Interrupter Mechanism Circuit Components........................ 14 (Figure 33) ......................................27 Trip Solenoid................................ 18 Rotary Solenoid and Closing Contactor .................... 18 Switches (SW1, SW2, SW3) . ..... 18 These instructions do not claim to cover all details or variations in the equipment, procedure, or process described, nor to provide direction for meeting every possible contingency during installation, operation, or maintenance. When additional information is desired to satisfy a problem not covered sufficiently for the user’s purpose, please contact your Cooper Power Systems sales engineer. March, 1983 • New Issue 1 INTRODUCTION Service Information S280-40-6 provides the maintenance instructions for Type VWE and VWVE three-phase, electronically controlled, vacuum reclosers. Included is a general description of the recloser and its operation, instructions for periodic inspection and routine maintenance, testing procedures, and instructions for shop repairs. A service parts list, keyed to exploded-view drawings of the recloser is included at the back of the manual. Procedures for testing the recloser and control together are found in the control installation manual S280-75-1. DESCRIPTION AND OPERATION General The Type VWE and VWVE reclosers, are self-controlled devices that protect distribution lines and equipment. A complete unit consists of the recloser, a Type ME electronic control, and an interconnecting cable. Fault current sensing is provided by the control which actuates the recloser. Circuit interruption is provided by the recloser. Figure 2. Untanked Type VWE vaccum recloser. 2 The Type VWE and VWVE reclosers trip open on overcurrent (either phase or ground faults) and then reclose automatically. If the overcurrent is temporary the automatic reclose restores normal service. If the fault is permanent a preset number of trip and reclose operations are performed to lockout. All three phases of the VWE and VWVE reclosers open, reclose and lockout simultaneously Opening sequences can all be fast, all delayed, or any combination of fast operations followed by delayed operations up to a total of four. Fast operations clear temporary faults before branch-line fuses can be damaged. Delayed operations allow time fuses or other downline protective devices to clear so that permanent faults can be confined to smaller sections of line. Arc interruption takes place within the three sealed vacuum interrupters. Oil is used as an insulating medium but is not involved in arc interruption. The moving contacts of the vacuum interrupters are driven by the release of opening springs that are loaded when the recloser is closed. Closing energy, as well as energy to charge the opening springs, is supplied by a high-voltage closing solenoid momentarily connected phase-to-phase through a high-voltage contactor. The contactor is mechanically closed by a rotary solenoid actuated by a signal from the electronic control. NOTE: The closing coil of Type VWVE reclosers below serial 1304 is connected phase to ground. An instruction plate, mounted on the head indicates the proper connections for the closing coil of the particular recloser. A trip-free, yellow operating handle located under the sleet hood will manually lock open the recloser. It cannot manually close the recloser but must be in the CLOSED position for the rotary close solenoid to operate. A red contact position indicator linked to the recloser mechanism but independent of the operating handle is also located under the sleed hood. The location of the major operation components of the VWE recloser is shown in Figure 2. They are the same for the VWVE recloser except for the configuration of the bushings and the rating of the vacuum interrupter. Being aware of the location of these components and their S280-40-6 part in the operation of the recloser will give a quicker and clearer understanding of the recloser maintenance and repair procedures that follow. Ratings ELECTRICAL RATINGS Nominal system voltage, kv Maximum rated voltage, kv Rated impulse withstand voltage (BIL) kv crest 60-Hertz withstand voltage, kv Dry, one minute Wet, ten seconds Rated maximum continuous current, amps Type VWE Type VWVE27 Type VWVE38 2.4-14.4 15.5 110 14.4-24.9 27.0 125 24.9-34.5 38.0 150 50 45 560 60 50 560 70 60 560 INTERRUPTING RATINGS Interrupting Current (RMS Symmetrical Amps) Minimum Trip Current (Amps) 25 35 50 70 100 120 140 170 200 240 280 340 400 480 560 600 680 800 960 1120 Type VWE Type VWVE 27 and Type VWVE38 Above Serial 2680 Type VWVE Below Senal 2680 Phase Ground Phase Ground Phase Ground _ _ _ 3000* 4200* 6000* 8400* 12000 12000 12000 12000 12000 12000 12000 12000 12000 12000 12000 _ _ _ 3000* 4200* 6000* 8400* 10000 10000 10000 10000 10000 10000 10000 10000 10000 10000 10000 _ _ _ 3000* 4200* 6000* 8400* 12000 12000 12000 12000 12000 12000 12000 12000 12000 12000 12000 3000* 3600* 4200* 5100* 6000* 7200* 8400* 10200* 12000 12000 12000 12000 12000 12000 12000 12000 _ _ _ 3000* 3600* 4200* 5100* 6000* 7200* 8400* 10000* 10000 10000 10000 10000 10000 10000 10000 10000 _ _ _ 3000* 3600* 4200* 5100* 6000* 7200* 8400* 10200* 12000 12000 12000 12000 12000 12000 12000 12000 _ _ _ _ * A protective accessory on the type ME electronic control can extend the interrupting current to the maximum rating. DUTY CYCLE No. of Unit Operations % ot Interrupting Rating X/R Ratio 15-20 45-55 90-100 4 8 15 Type VWE Type VWVE27 Type VWVE38 88 112 32 232 88 112 32 232 88 112 32 232 3 MECHANISM OPERATION The recloser mechanism performs the actual opening and closing of the vacuum interrupter contacts in response to signals from the electronic control. Contact opening is initiated by an electrical signal to a trip solenoid which acts upon the toggle latch to release charged opening springs. Contact closing is initated by an electrical signal to a rotary solenoid which mechanically closes the closing coil contactor to energize the high voltage closing coil which closes the vacuum interrupters and charges the opening springs. With the contacts closed, Figure 3, the opening springs are fully extended and the mechanism is in the rest (closed) position. When the trip solenoid is energized, its push rod acts upon the toggle latch to open the toggle and allow the opening springs to act upon the contact bar (Figure 4). As soon as the toggle breaks, the contact arm assemblies are rotated on their fixed pivots to instanteously open the interrupter contacts. I the same motion the trip lever is rotated to snap the toggle closed. This motion of the reset lever also pulls the plunger out of the closing coil. At this point the mechansim is in the open (tripped) position (Figure 5). A signal to the rotary solenoid closes the contactor and energizes the high voltage closing coil solenoid. As the plunger is drawn down into the coil, the reset lever is pulled down and latched, the interrupter contacts are closed and the closing springs are extended (charged) figure 6). The mechanism is then ready for another opening operation. 4 S280-40-6 MAINTENANCE Frequency of Maintenance Because reclosers are applied under widely varying operating and climatic conditions, maintenance intervals are best determined by the user based on actual operating experience. To assure proper operation, reclosers must be maintained when they have operated the equivalent of a complete duty cycle and before the dielectric strength has deteriorated below prescribed levels. In the absence of specific operating experience, the following procedures are recommended. • When Type VWE and VWVE reclosers are operated under usual service conditions as defined in ANSI (American National Standards Institute) C37.60, “Standard Requirements for Automatic Circuit Reclosers for Alternating Current Systems,” it is recommended that the following maintenance procedures be performed at the completion of an equivalent duty cycle. NOTE: ANSI C37.61, “Guide for the Application, Operation and Maintenance of Automatic Circuit Reclosers” gives a procedure for converting the standard duty cycle, as shown on page 3 of these instructions into an equivalent duty cycle based on the actual operating duty of the recloser. • However, if the recloser has not completed an equivalent duty cycle within three years, it is recommended that an external inspection, oil-level check, and a check of the dielectric strength of the oil be made at that time. (See steps 1, 2, and 8 of “Maintenance Procedure” below.) • Also it is strongly recommended that the vacuum interrupters be replaced after 7000 operations of the recloser. Periodic Maintenance Inspection Each periodic maintenance inspection at the completion of an equivalent duty cycle should include at least the following: 1. Bypass and remove the recloser from service. A. Disconnect the control cable from the recloser. 2. Inspect external components. A. Check for broken or cracked bushings. Replace as necessary. (See page 8 for procedure.) B. Check for paint scratches and other mechanical damage; paint to inhibit corrosion. C. Note counter reading and enter in the record log in the control. Figure 7. Location of scribe mark on movalbe contact rod of vacuum interrupter 3. Perform a dielectric withstand test to check the insulation level of the recloser and the vacuum integrity of the interrupters. (See page 7 for procedure. ) 4. Lower the tank to expose the internal components. CAUTION Be sure the recloser is open (yellow operating handle inder the sleet hood is down) before lowering the tank, so that the mechanism will not be tripped accidently while the mechanism is out of oil. A. Attach the sheaves of the tank hoisting windlass mechanism to the recloser tank and take up the slack. B. Remove the ten head bolts that attach the tank to the head casting and carefully lower the tank. 5. Clean all internal components. A. Remove all traces of carbon by wiping with a clean, lint-free cloth. NOTE: Although current interruption takes place in a sealed vacuum chamber, the closing solenoid contactor operates in oil and will produce some carbon deposits. B. Flush the mechanism with clean transformer oil. CAUTION Never use volatile solutions, detergents, or water-soluble cleaners 6. Check the contact erosion of the vacuum interrupters. A. Locate the scribe mark on the moving contact rod at the top of the interrupter, Figure 7. B. If the scribe mark falls below the top of the phenolic guide when the interrupter is closed, the interrupter has reached the end of its useful life and must be replaced. (See page 10 for replacement procedure.) NOTE: Procedure for manually operating the recloser when the mechanism is out of oil is described on page 6. 7. Check circuit components attached to the recloser head, frame and operating mechanism. A. Check condition of the wiring to the terminal strip and make sure all connections are tight. B. Make sure that the rotary solenoid and the trip solenoid are fir mly attached to the recloser frame. C. Check that the two mercury switches are securely held in place by the nylon mounting straps. D. Check condition of microswitch mounted above main shaft. 5 E. Check condition of the bushing current transformers and the associated wiring. F. Check the control cable receptacle. If circuit component malfunction is suspected, see page 15 for an operational check procedure. 8. Check the dielectric strength of the insulating oil. A. An oil sample taken near the bottom of the tank should have a dielectric strength of not less than 22 kv rms. B. Low dielectric strength indicates the presence of water or carbon deposits. Replace the oil as necessary. 9. If oil must be replaced, A. Drain the tank, and clean out all sludge and carbon deposits. B. Fill with new, clean insulating oil up to 2-1/4 inches below the top of the tank flange. Tank capacity is approximately 53 U.S. gallons. See Oil Condition on page 8. 10. Clean and examine the head gasket. Replace if it is cracked, cut, or otherwise damaged, or if it has been permanently deformed. 11. Clean the head gasket seat and retank the recloser. A. Move the yellow operating handle under the sleet hood to the up position to avoid any possible binding while raising the tank. B. Replace the head bolts and torque to 35-55 ft-lbs. Apply clamping force gradually and equally, in rotation, to each bolt to achieve an evenly distributed gasket sealing pressure. 13. Repeat the high voltage dielectric withstand test (Step 3) to make sure the dielectric clearances within the tank have not been compromised. Manual Operation of the Recloser The recloser may be closed and opened manually while the mechanism is either in or out of oil. MECHANISM IN OIL For a tanked recloser (mechanism immersed in oil) use the following manual operating procedure. A. To close the recloser. 1. Remove the closing tool port cover and gasket from the side of the head casting. (See Figure 2 for location.) 2. Insert the KA9OR T-handle closing tool (furnished as an accessory) into the closing tool port (Figure 8) and engage the pin on the closing shaft. 3. Lift up the yellow operating handle under the sleet hood to reset the mechanism. 4. Turn the closing tool one-quarter turn clockwise to close the main contacts. WARNING Never use the KA90R closing tool to close an energized reclsoer. CAUTION Forcing the closing too beyond the mechanism stop may shear the pin on the closing shaft. B. To open the recloser. 1. Pull down the yellow operating handle to trip open the recloser. MECHANISM OUT OF OIL To operate the mechanism out of oil, proceed as follows: A. To close the recloser. 1. If the mechanism is still mounted in the head use the procedure for a tanked recloser above (Mechanism in Oil). 2. If the mechanism is removed from the head turn the trip-reset shaft (Figure 9) with a pair of needlenose pliers to reset the mechanism, then turn the closing shaft clockwise with the closing tool to close the main contacts. NOTE: Type VWE reclosers below serial 1340 and VWVE reclosers below serial 1060 require the following special thread-sealing procedure to keep moisture from entering the tank along the threads of the head bolts. 1. Before reinstalling the head bolts, apply a liberal amount of a nonhardening pliable sealant, Permatex FormA-Gasket No. 2, to the end of each bolt. The four leading threads should be completely coated. 2. When the bolt is installed, a slight bead of material (resembling an O-ring) should remain on the top of the tank flange. Apply the sealant each time the head bolts are removed and reinstalled. 12. Check the oil level with the dipstick in the head and adjust the level to the upper line on the dipstick. NOTE: If the recloser is equipped with an oil-sight gage, the oil level should be above the sight gage. If the oil surface line is visible in the window, add oil to raise the level to the upper line on the dipstick. 6 Figure 8 Manually closing the recloser with KA90R closing tool. S280-40-6 CAUTION The mechanism may be damaged if it is "quick-tripped" with the yellow operating handle while out of oil. B. To open the recloser. To open the contacts while the mechanism is out of oil, proceed as follows: 1. Using the T-handle closirig tool turn the closing shaft clockwise and hold against the stop. 2. Release the trip lever (Figure 10) by moving it to the right. 3. Then slowly allow the closing tool to rotate counterclockwise to open the main contacts. NOTE: This procedure requires two people; one to operate the closing tool, the other to operate the trip lever. Insulation Level Withstands Tests High-potential withstand tests provide information on the dielectric condition of the recloser and the vacuum integrity of the interrupters. Testing is performed at 75% of the rated low-frequency withstand voltage (37.5 kv for the VWE and 45 kv for the VWVE). N RADIATION WARNING At voltages up to 45 KV the radiation emitted by the vacuum interrupter is negligible. However at higher test voltages radiation injurious to personnel may be emitted. See Radiation Warning Service Information Bulletin S280-90-1 for further details Figure 9 Location of trip-reset shaft. TEST 1: Proceed as follows: 1. Manually close main contacts of recloser (see page 6 for procedure). 2. Ground recloser tank and head. 3. Connect all three source-side bushings (1, 3, 5) together. 4. Apply proper test voltage to sourceside bushings. 5. The recloser should withstand the test voltage for 60 seconds. TEST 2: Proceed as follows: 1. Manually close main contacts of the recloser (see page 6 for procedure). 2. Ground recloser tank and head. 3. Ground Phase A (bushing 2) and Phase C (bushing 6). 4. Apply proper test voltage to Phase B (bushing 3). 5. The recloser should withstand the test voltage for 60 seconds. TEST 3: proceed as follows: 1. Open main contacts of recloser (see page 6 for procedure). 2. Ground recloser tank and head. 3. Connect and ground all three loadside bushings (2, 4, 6). 4. Connect all three source-side bushings (1, 3, 5). 5. Apply proper test voltage to sourceside bushings. 6. The recloser should withstand the test voltage for 60 seconds. 7. Reverse the connections: ground source-side bushings (1, 3, 5); apply test voltage to load-side bushings (2, 4, 6) for 60 seconds. 8. The recloser should withstand the test voltage for 60 seconds. Figure 10 Trip lever releases mechanism whe opening recloser out of oil. 7 TEST RESULTS: These high potential withstand tests provide information on the dielectric condition of the recloser and the vacuum integrity of the interrupters. A. If the recloser passes the closed-contacts tests (Tests 1 and 2) but fails the open-contacts test (Test 3) a deteriorated vacuum in one or more of the interrupters is most likely the cause. Retest each vacuum interrupter individually to determine the failed phase or phases, and replace the interrupter(s). Retest to confirm the repair. B. If the recloser fails the closed-contacts tests (Test 1 and 2) the cause is likely to be a diminished electrical clearance or a failed insulation. After correcting the problem, retest to confirm the repair. Oil Condition Oil provides the internal insulation barrier between phases and from phase to ground, and must be replaced before it deteriorates below a safe dielectric level. Replace the oil if its dielectric strength falls below 22 kv. New oil should always be filtered before using even though it is obtained from an approved source. Passing the oil through a blotter press will remove free water and solid contaminants such as rust, dirt, and lint. Keep aeration to a minimum during filtering to prevent moisture in the air from condensing in the oil and lowering its dielectric strength. Used oil must be treated before reusing. Filtering may remove absorbed and free water and other contaminants to raise the dielectric strength to acceptable levels. However, filtering does not always remove water-absorbing contaminants and the dielectric strength may fall rapidly after being returned to service. Therefore the recloser should be filled with new oil, or oil that has been restored to like-new condition. Oil used in these reclosers conforms to ASTM Standard D3487, Type l; its property limits are shown in Table 1. SHOP MAINTENANCE PROCEDURES The operations described in this section should be performed under the cleanest conditions possible. The repair work, except for bushing replacement, will be simplified if the work bench is arranged so the mechanism/head assembly can be inverted (bushings down). No special tools are required for any of the repair procedures. 8 Table 1 Specifications for Oil Used in Cooper Power System's Distribution Switchgear Characteristic Acceptable Value Color Reaction Neutralization no. Corrosive sulfur Steam emulsion no. Flash point Fire point Pour point Viscosity, max cST (SUS) at 100 C 40 C 0C Specific gravity at 15 C Coefficient of expansion (from 25 to 100 C) Interfacial tension Dielectric constant Dielectric strength Water content (by Karl Fischer test) PCB content Weight 0 . 5 max (ASTM colorimeter) Neutral 0.03 mg KOH/g max Noncorrosive 25 seconds max 145 C min 160 C min -40 C max ASTM Test Standard* D1500 D974 D1275 D1935 D92 D92 D97 D445, D88 3.0 (36) 12.0 (66) 76.0 (350) 0.91 g/cc max D1298 0.0007 to 0.0008 40 dynes per cm min 2.2 - 2 3 30 kV min D1903 D971 D924 D877, D1816 35 ppm No detectable amount 0.9 kg/liter 7.5 Ib/gal D1533 D3304 *Tests are described in latest revision of ASTM standards. BUSHINGS Bushing maintenance generally consists of a thorough cleaning and a careful examination for chips, cracks, or other mechanical damage during the periodic maintenance inspection. Bushings must be replaced whenever damage is discovered. TYPE VWE BUSHINGS A damages bushing can be replaced with the recloser either tanked or untanked, depending upon the circumstance or the damage. • If the bushing porcelain is accidentally chipped during installation of the recloser, an it is obvious that no other damage has occured, the bushing porcelain only can be replaced without untanking the recloser. • If the bushings has been damaged while in service or storage, the recloser must be untanked. Water or other contaminants may have entered the tank (test the oil) the bushing lead may be damaged (either mechanically or electrical flashover), or pieces of porcelain may have fallen into the tank. Replacing the Bushing Porcelain with the Recloser Tanked Refer to Figure 11 and proceed as follows: 1. Unscrew the bushing terminal and discard the terminal gasket. 2. Remove the three hex head capscrews and clamps that secure the bushing to the head and lift out the porcelain. 3. Remove and discard the lower bushing gasket. 4. Twist off the split aluminum clamping ring from the old porcelain. If it is in good condition install it on the new porcelain; replace with new ring if damaged. NOTE: The clamping ring cushions and distributes the pressure between the porcelain and the clamps. DO NOT OMIT. 5. Using a new gasket, install the new porcelain over the bushing rod and into the head. Make sure the roll pin on the end of the rod is seated into the locking groove at the top of the porcelain. 6. Position the clamping ring with the split centered between two clamping bolts. 7. Reassemble the bushing to the head casting with the bushing clamps. Tighten the clamping bolts evenly, a little at a time, to a torque of 10-15 ft-lbs S280-40-6 NOTE: Clamping forces must be applied gradually and equally in rotation to each bolt. This results in an evenly distributed gasket sealing pressure. 8. Install a new ter minal gasket and reassemble the terminal to the bushing rod with 35 ft-lbs of torque. NOTE: Apply a ver y small amount of petroleum jelly to the knurled surface of the inside face of the terminal before assembling the terminal to the bushing rod. Replacing the Bushing with the Recloser Untanked. Refer to Figure 12 and proceed as follows: 1. Disconnect the appropriate bushing lead from the bottom end of the bushing rod. 2. Remove the three hex head capscrews and clamps that secure the bushing to the head and lift out the complete bushing assembly. 3. Remove and discard the lower bushing gasket. 4. The complete bushing assembly can be replaced or new porcelain only can be installed depending upon the extent of damage. If new porcelain only is to be installed, proceed as follows: A. Unscrew the bushing terminal and withdraw the rod from the bottom of the procelain; discard the terminal gasket. B. Insert the rod assembly all the way into the new porcelain, making sure the roll pin is seated in the locking groove in the top of the bushing. C. Assemble the terminal to the bushing rod using a new terminal gasket; tighten to a torque of 35 ftlbs. NOTE: Apply a very small amount of petroleum jelly to the knurled surface of the inside face of the terminal before assembling the terminal to the bushing rod. 5. Twist off the split aluminum clamping ring from the old bushing and install on the new bushing if it is in good condition; replace the ring if damaged. NOTE: The clamping ring cushions and distributes the pressure between the procelain and the clamps. DO NOT OMIT. 6 Install the bushing assembly (new or reworked) into the head using a new lower bushing gasket. Position the bushing with the stud-end of the terminal pointing outward. 7. Position the clamping ring with the split centered between two clamping bolts. 8. Reassemble the bushing to the head casting. Tighten the clamping bolts evenly, a little at a time, to a torque of 10-15 ft-lbs. NOTE: Clamping forces must be applied gradually and equally in rotation to each bolt. This results,in an evenly distributed gasket sealing pressure. 9. Reconnect the lead to the bushing rod. Figure 11 Replacing bushing with recloser tanked. Figure 12 Bushing parts VWE recloser. 9 TYPE VWVE BUSHINGS The bushings of the Type VWVE recloser are oil-filled. The special fixtures and procedures required to assemble these bushings is beyond the scope of normal shop maintenance repair. Therefore if a Type VWVE bushing is in any way damaged, the complete bushing assembly must be replaced. Refer to Figure 13 and proceed as follows: 1. Disconnect the appropriate bushing lead from the bottom end of the bushing rod. 2. Remove the three hex head capscrews and bushing clamps that secure the bushing to the head casting and lift out the complete bushing assembly. 3. Remove and discard the lower bushing gasket. 4. Twist off the split, aluminum ring from the old bushing and install on the new bushing assembly if it is in good condition; replace ring if damaged. NOTE: The clamping ring cushions and distributes the pressure between the porcelain and the clamps. DO NOT OMIT. Figure 13 Removing Type VWVE bushing. 10 5. Install the new bushing assembly into the head using a new lower bushing gasket. Position the bushing with the stud-end of the terminal pointing outward. 6. Position the clamping ring with the split centered between two clamping bolts. 7. Reassemble the bushing to the head casting. Tighten the clamping bolts evenly, a little at a time, to a torque of 10-15 ft-lbs. NOTE: Clamping forces must be applied gradually and equally, in rotation, to each bolt. This results in an evenly distributed gasket sealing pressure 8. Reconnect the lead to the bushing rod. Vacuum Interrupters Vacuum interrupters must be replaced when: • They lose their vacuum as evidenced by a failure during the low frequency dielectric withstand test across the open contacts; • The interrupter contacts have eroded beyond their useful life as evidenced by the position of the scribe mark on the moving contact rod, or • The interrupters have completed their mechanical life of 7000 operations. To replace an interrupter, refer to Figure 14 and proceed as follows: Figure 14 Vacuum interrupter replacement. 1. Make sure the closer contacts are open, the yellow manual operating handle under the sleet hood is pulled down. 2. Cut the three nylon tie straps which secure the vertical insulating barrier and remove the barrier. 3. Loosen and remove the upper interrupter clamp. As the clamp is loosened, atmospheric pressure on the bellows will cause the contact rod to move down into the interrupter. This action can be verified by observing the scribe mark on the contact rod. It will move downward to just above (or below) or just below the fiber disk at the top of the interrupter. NOTE: If the contact rod does not move, the interrupter may have lost its vacuum or the contact rod may be sticking in the clamping fingers of the contact operating rod assembly. Use a screwdriver to gently spread the clamping fingers to free the rod. 4. Disconnect the bushing lead from the lower contact plate assembly. 5. Loosen and remove the lower interrupter clamp. 6. Remove the hardware attaching the lower contact plate to the three ver tical stringers and remove the contact plate and the vacuum interrupter. S280-40-6 7. Install a new vacuum interrupter into the clamping fingers of the contact operating rod and the lower contact plate and attach the plate to the stringers. NOTE: On the side with the single stringer, a spacer on the stringer stud provides a 1/16inch gap between contact plate and the attaching flat washer and locknut when the interrupter contacts are open. This gap is intentional. 8. Manually close the recloser. 9. Coat the threads of the interrupter clamps and attaching screws with a film of transformer oil and install, but do not tighten, the upper and lower interrupter clamps. 10. Position the upper and lower interrupter clamps just below the shoulder on the finger-type current exchange connectors so that the clamping force will be applied to the center of each as shown in Figure 15. 11. Rotate the interrupter so that one of the hex nuts at the top of the interrupter is centered directly beneath the gap on one side of the upper clamp. (See Figure 15.) CAUTION When rotating the interrupter avoid twisting the contact rod to prevent damaging the bellows and destroying the interrupter. Figure 15 Orientation of interrupter and clamp. Closing Solenoid Contactor Type VWE reclosers below serial 3901 and Type VWVE reclosers below serial 1304 are equipped with a double pole contactor, KA430R3, which provides a single break in each line (Figure 16). Type VWE reclosers, serial 3901 and above, and Type VWVE reclosers serial 1304 and above are equipped with a double pole contactor, KA1143R, which provides two breaks in series in each line (Figure 17). Maintenance procedures are the same for both contactors. If the contacts are badly burned or eroded, the entire contactor must be replaced. See Figure 18 and proceed as follows: 1. Unhook the two toggle openings from the pin that connects the operating shaft of the contactor to the toggle arm. 2. Remove the three C-type retaining rings indicated in Figure 18 and withdraw the pin. 3. Disconnect the two coil leads from the contactor. 12. Tighten the screws of each interrupter clamp evenly to a torque of 75 in-lbs. NOTE: Clamps must be tight to prevent slippage of the interrupter contact rods in their current-exchange connectors. 13. Reconnect the bushing lead to the lower contact plate. 14. Re-install the vertical insulation barrier plate between the long bushing lead and the mechanism. Position the plate and secure it with cotton coil-tying cord, or similar cotton lacing. Wrap the cord snuggly at each tie point three of four turns, knot and cut the loose ends about 1/4 inch from the knot. A drop of Pliobond on the loose ends and the knot will prevent raveling. The two ties securing the barrier to the vertical stringer should also encircle and secure the bushing lead. 15. Manually trip and close the recloser several times to check interrupter operation. NOTE: Contact movement can be verified by observing the movement of the scribe mark on the upper contact rod of the interrupter. When the recloser is open the scribe mark will be about 5/8-inch above the fibre disk; on closing the mark will travel 1/2-inch downward. Figure 16 KA4304R3 single break contactor. 11 NOTE: On the KA430R3 (Figure 16) contactor configuration, reattach the lockwasher and hex nut to the contactor terminal immediately after disconnecting the coil lead to prevent loss of moving contact parts which are attached to the support plate with the same hardware. 4. Disconnect the two fuse leads from the contactor. 5. Remove three hex head capscrews and lockwasher that attach the contactor to the underside of the recloser mechanism frame and remove the contactor. 6. Install the new contactor by reversing the disassembly procedure. Use new C-rings to secure the toggle-link pin. 7. Connect the solenoid coil leads to the lower terminals of the KA430R3 “singlebreak” contactor or the inside terminals of the KA1 143R “double-break” contactor. 8. Connect the fuse leads to the upper terminals of the KA430R3 or the outside terminals of the KA1143R contactor. 9. Check Figures 16 and 17 for properlead connections. Be sure coil and fuse leads are positioned for maximum clearance to other grounded parts. Closing Solenoid The closing solenoid coil of Type VWVE/ VWVE27 recloser below serial 1304 is connected phase-to-ground and is rated to operate on the system’s phase-to-neutral voltage. It is protected with a fuse on the hot side. The other side of the coil is grounded by a lead connected from the contactor to the frame. The closing solenoid coil of type VWVE/VWVE27 reclosers serial 1304 and above, and all Type VWE and Type VWVE38 reclosers, is connected phase-to-phase and is rated to operate a full system voltage. It is protected with two fuses, one on either side. A data plate attached to the recloser head between source side bushings 3 and 5 provides the coil connection information. If the solenoid coil must be replaced, due to damage or change in operating voltage, refer to Figure 19 and proceed as follows: 1. Disconnect the two coil leads from the closing solenoid contactor. NOTE: On the KA430R3 (Figure 16) contactor configuration, reattach the lockwashers and nut to the contactor terminal immediately after disconnecting the coil lead to prevent loss of parts of the moving contact arm assembly which is attached to the support plate with the same hardware. Figure 17 KA1143R double-break contactor. 2. Remove the four capscrews and lockwashers which attach the base plate to the bottom of the solenoid frame posts and lower the coil and base plate. 3. Remove the coil from the base plate and discard the coil gasket. 4. Using a new coil gasket, install the new closing coil on the base plate. NOTE: A new coil gasket is included in the closing coil replacement kit. 5. Reassemble the base plate to the solenoid frame posts and connect the coil leads to the contactor terminals. Make sure the coil leads clear the solenoid frame by at least 1/2-inch. 6. The closing coil replacement kit includes two new coil fuses which should be installed with the new coil. See Closing Solenoid Fuses on page 13 for fuse replacement procedure. 7. The closing coil replacement kit also includes a new voltage date plate. Replace the plate on the sleet hood of the recloser head if the operating voltage of the recloser is being changed. Figure 18 Changing closing solenoid contactor. 12 S280-40-6 Figure 19 Parts involved in solenoid coil replacement. Closing Solenoid Fuses Only one fuse (on the hot side) is used with closing coils connected phase-toneutral. Two fuses are used with closing coils connected phase-to-phase. New fuses are provided with the closing solenoid coil replacement kit and should be installed with the replacement coil. Fuses can also be ordered separately for individual replacement if damaged. A label, attached to the closing coil, specifies the catalog number, and color band coding of the properfuse required to protect the coil. This information is also listed in Table 2. Note the voltage rating is either phase-to-phase, or phase-to-neutral depending upon type of closing solenoid coil connection. To replace a closing solenoid fuse: a. Disconnect the long fuse lead atthe closing solenoid contactor. b. Disconnect the lead wire from the ter minal at the other end of thefuse. c. Loosen the mounting strap and slide out the fuse. d. Install the new fuse and reconnect the fuse leads. NOTE: Be sure the long fuse lead clears and grounded parts and insulating supports by at least 1/2-inch. TABLE 2. Closing Solenoid Fuse Data Closing Solenoid Voltage* 2.4 - 3.3 kv 4.16 - 6.0 kv 7.2 - 11 kv 12 - 24.9 kv Fuse Catalog Number Color Band KA259R904 KA259R901 KA259R902 KA259R903 Two Red Black Yellow Red *Either phase-to-phase or phase-to-ground neutral depending upon coil connection. Removing Mechanism from Head To gain access to components located in or on the main frame, the following procedure may be used to remove the mechanism from the head. NOTE: These procedures will be simplified if the untanked head and mechanism assembly can be inverted (bushings down). The unit can be supported on its bushings. 1. Disconnect all six bushing leads from the rods at the ends of the bushings. 2. Disconnect the lockout lever and contact position indicator shafts by disengaging the spring loaded couplers and locking them in the disengaged position, Figure 20. 3. If the recloser is equipped with the auxiliary switch accessory, remove the C or E-ring and washer, Figure 21, and disconnect the operating lever of the switch from the recloser mechanism. 4. If the recloser is equipped with the CTtype batter y charger power source, remove the screws that secure the 0.2 mfd bathtub capacitor to the recloser frame, Figure 22. NOTE: The CT-type batter y charger power source is standard on Type VWE reclosers below serial 2100 and Type VWVE reclosers below serial 1500. It may be provided as an accessory on later units. 13 5. Disconnect the seven leads connected to the bottom of the terminal block attached to the recloser frame, Figure 23. Be sure all leads are labeled before removing. With the unit inverted as shown in Figure 23, the leads are labeled A, B, C, D, E, R and N from left to right. 6. The lead bundle is secured with a nylon strap attached to the mechanism frame, Figure 23. Remove the attaching screw to free the strap from the mechanism. 7. Remove the six socket head bolts and lockwashers that secure the frame to the head casting and carefully lift the mechanism from the head. Six long pipe spacers will be released when the mechanism is lifted. Table 20 Couplers locked in disconnection position. NOTE: By temporarily substituting eyebolts for two of the hex head bolts in the bottom of the closing solenoid frame, the mechanism can be easily lifted and handled with a hoist (Figure 24). 8. Remove the two spring-loaded couplers disengaged in Step 2 for safekeeping. The components remaining in the head are shown in Figure 25. Re-lnstalling Mechanism into Head Table 21 Remove E-ring to disconnect auxiliary switch operating lever. To re-install the recloser mechanism assembly into the head, the following procedure may be used. 1. Install the couplers on the lockout lever and contact position indicator shafts of the mechanism and lock them in the disengaged position. 2. Carefully lower the mechanism assembly onto the six pipe spacers which have been positioned over the attaching holes in the casting. (Figure 25) 3. Install the six attaching socket head bolts and tighten evenly to avoid any binding of the mechanism. NOTE: Replace the hex head bolts in the bottom of the closing solenoid frame if eyebolts were used for handling the recloser mechanism. Table 22 Capacitor for CT-type battery charger. 14 4. Re-engage the lockout lever and contact position indicator shaft by releasing the shaft couplers. 5. Reconnect the operating lever of the auxiliary switch (if used) to the mechanism and secure with the washer and E-ring. (Figure 22) 6. Attach the 0.2 mfd bathtub capacitor (if present) to the mechanism frame. (Figure 22) 7. Reconnect the leads to the respective terminals on the terminal block, and reattach the nylon strap to the frame to secure the lead bundle. (Figure 23) 8. Reconnect the bushing leads to their respective bushings. S280-40-6 Operational Checks An internal connection diagram of the recloser circuits is shown in Figure 26. The operating sequence for the various circuit components is diagrammed in Figure 27. These components should provide trouble-free operation with little or no maintenance. However, if the recloser does not operate properly, the following checks can be made to trouble-shoot the recloser circuits. NOTE: Procedures for checking, testing and trouble shooting the electronic control are provided in a separate manual (S280-75-1) The recloser need not be untanked to perform these checks. Figure 23 Connections to terminal strip attached to reclose mechanism frame. CONTROL CABLE Using an ohmmeter, check the continuity between like pins and pin sockets of the connector plugs on either end of the electronic control cable and for discontinuity between unlike pins and pin sockets to determine the condition of the control cable. NOTE: Pins or pin sockets N and P on either plug are not connected. Repair or replace the control cable if defective. CIRCUIT COMPONENTS Figure 24 Lifting mechanism inand out of the head. All measurements are made at the pin sockets of the control cable receptacle on the recloser head. A reading within + 15 percent of the specified value indicates components are operational. Any component failing to meet the specified checks should be replaced. Figure 28 identifies the various circuit components. NOTE: If the electronic control battery is used to supply the 25 vdc power, connect as directed for only as long as necessary to perform the specified action to prevent excessive battery drain. Figure 25 Head casting detached from operating mechanism. Hexsocket-head bolts have been attached to head casting for illustrative purposes. 15 SW1 - MICROSWITCH ON MAINSHAFT—CLOSED WHEN CLOSING SOLENOID PLUNGER IS DOWN* SW2 - MERCURY SWITCH ON MANUAL OPERATING HANDLE—CLOSED WHEN HANDLE IS UP ON “CLOSED” POSITION. SW3 - MERCURY SWITCH *ON MAIN SHAFT—OPEN WHEN CLOSING SOLENOID PLUNGER IS DOWN* *PLUNGER IS DOWN WHEN RECLOSER IS CLOSED NOTE 1: FOR VWVE BELOWSERIAL1304, CLOSING COIL IS CONNECTED PHASE C TO GROUND AND PHASE B FUSE IS ELIMINATED. NOTE 2: FOR VWE BELOW SERIAL 2000 AND VWVE BELOW SERIAL 1500 BATTERY CHARGING TRANSFORMER IS STANDARD. IT IS SUPPLIED AS AN ACCESSORY ON LATER UNITS. Figure 26 Internal connection diagram type VWE-VWVE recloser. 16 **FOR PHASES-TO-GROUND NEUTRAL CONNECTED COIL THIS FUSE IS ELIMINATED S280-40-6 Figure 27 Sequential operation of contacts in VWE-VWVE reclosers. 17 2. Connect the ohmmeter to pin sockets K and L to check the continuity of the battery charger CT winding if used. • The meter should read approximately 1000 ohms. A zero ohms reading indicates the 0.2 mfd capacitor may be short-circuited. Readings deviating more than + 20% from 1000 ohms indicate a damaged resistor or transformer winding. Ratio Test for Sensing CT’s 1.Connect all three phases of the recloser in series as shown in Figure 29 and close the recloser contacts with the manual closing tool. 2. Connect a 100 ampere a-c test current to test points 1 and 2. 3. Energize the 100 ampere test source. 4. Using a 0-500 millimeter check the current output across socket pins K-G, K-H, and K-J. (Figure 29A) • The output of each CT should measure 100 ma + 10%. Figure 28 Location of circuit components on mechanism frame. Trip-Solenoid 1. Connect an ohmmeter between pin sockets A and B. • The meter should read approximately 9.5 ohms. 2. Lift up the yellow manual operating handle under the sleet hood and manually close the recloser with the handle closing tool as described on page 6. 3. Momentarily apply 25 vdc to pin sockets A (+) and B (-). • The recloser should trip. Rotary Solenoid and Closing Solenoid Contactor 1. Connect an ohmmeter between pin sockets E and F. The meter should read approximately 19 ohms. 2. With the yellow manual operating handle in the up position and the recloser contacts open, momentarily apply 25 vdc to pin sockets F (+) and E (-) • The rotary solenoid should operate producing an easily distinguishable sound. Repeat two or three times. 3. Connect the ohmmeter across source side B and C phase bushings, or from source side C bushing to recloser ground (depending upon the recloser coil connection) and again energize the rotary solenoid. • The meter should indicate closing coil continuity (read the effective dc resistance of the closing coil) confirming that the closing solenoid contactor is closed. 4. With the rotary solenoid still energized, manually close the recloser with the closing tool. 18 • The ohmmeter should indicate loss of continuity indicating that the closing solenoid contactor has opened. Switches (SW1, SW2, SW3) Table 3 shows switch for manual operating lever/recloser contact combinations. An ohmmeter connected across the designated pin sockets of the control cable receptacle will indicate zero for a closed contact and infinity for an open contact. CURRENT TRANSFORMERS The current sensing transformers are mounted on the source side bushings underneath the head casting. The battery charger CT power source (if applicable) is mounted on the load side center bushing. Continuity Check 1. Connect an ohmmeter, in turn, to pin sockets K and G, K and H, and K and J to check the continuity of the three current sensing transformers. • The meter should readapproximately 7 ohms, the d.c. resistance of each winding. NOTE: Be sure to allow for the tolerances of meter being used. The resistance of certain type of meters is not negligible. Use as high a scale (lower resistance) as is accurately readable. 5. A 100 ma reading verifies the 1000:1 ratio of the sensing CT’s. If the 100 ma is not attained the CT winding is probably faulty. 6. De-energize the test source. Polarity Test for Sensing CT’s 1. With the phases still connected in series from the previous test, connect the secondaries of the CT’s in parallel by connecting pin socket G to H to J and measure the output between pin sockets K and J as shown in Figure 29B. 2. Energize the 100 ampere a-c test source. A. All three transformers should have the same polarity the output should measure 300 ma. B. If one transformer has its polarity opposite of the remaining two the output will measure 100 ma. 3. De-energize the test source and remove the jumper wire from the receptacle. TABLE 3. Switch Status. Recloser Contacts Manual Operating Lever SW1 Pin Sockets C&D SW2 Pin Sockets F&N SW3 Pin Sockets A&N OPEN DOWN OPEN OPEN CLOSED OPEN UP OPEN CLOSED CLOSED CLOSED UP CLOSED CLOSED OPEN S280-40-6 Output Test of Battery Charging CT 1. With the phases still connected in series, energize 100 ampere a-c source. 2. Measure the output between pin socket K and L of the control cable receptacle. • Output should measure 40-60 ma. 3. Readings within this range indicates sufficient output to maintain control battery charge. Figure 29 Test circuit for checking bushing current transformers. NOTE: Ratio and polarity test-circuits shown are the effective circuits that contribute to the testing. Components not having an effect on the current flow are not shown. Dotted lines in the polarity-test circuit are test leads. 19 SERVICE PARTS LIST The service parts and hardware listed and illustrated include only those parts and assemblies usually furnished for repair or involved in the maintenance procedures described in this manual. Further breakdown of listed assemblies is not recommended. Dimensions of all common hardware parts have been carefully checked so that they may be locally acquired. The suffix letter of the 14 character catalog number for common hardware parts codes the plating of the part: A - No plating; raw material H - Silver M -Black oxide Q - Cadmium + zinc + chromate Y - Zinc + chromate Z - Electro zinc + bronze irridite Figure 30 Bushing parts - exploded view. 20 A hardware kit, Catalog No. KA849R1, contains an assortment of roll pins, cotter pins, retaining rings, stop nuts, etc.— common hardware parts used in Cooper Power System reclosers that may not be readily locally available. To assure correct receipt of any part order, always include recloser type and serial number. Because of Cooper Power System's continuous improvement policy, there may be instances where the parts furnished may not look extactly the same as the parts ordered. However, they will be completely interchangeable without any rework of the recloser. All parts carry the same warranty as any whole item of switchgear, i.e. against defects in material or workmanship within a period of one year from date of shipment. S280-40-6 Bushing Parts (Figure 30) Qty. Item No. 1 2 3 4 5 6 7 8 9 10 11 12 Catalog Description Bushing assembly - Type VWE Standard creepage Standard creepage with BCT accy 17-inch extra-creepage 17-inch extra-creepage with BCT accy Bushing assembly-Type VWVE Standard creepage Standard creepage with BCT accy 26-1/2-inch extra-creepage 26-1/2-inch extra-creepage with BCT accy Hex jam nut, 1/2—20, brass For Type VWE For Type VWVE Flat washer Split lockwasher, med, 1/2, bronze Capscrew, hex hd, 3/8—16x2-1/4, stl Bushing clamp Clamping ring Lower bushing gasket Terminal Upper bushing gasket Bushing ceramic-Type VWE Standard creepage Standard creepage with BCT accy 17-inch extra-creepage 17-inch extra-creepage with BCT accy Per Number Assy. Item No. 13 KA717R25 6 KA717R26 KA717R27 6 6 14 KA717R28 6 15 KA717R29 6 16 KA717R30 KA717R31 6 6 KA717R32 6 17 K880725320050H K880725320050H KP2028A3 6 12 12 K900830050000A 6 K730101137225Q KP1109R KP1111R KP2090A66 KA17W901 KP2090A57 3 3 1 1 1 1 KP1110R 1 19 20 21 22 1 1 KP186W 1 Bushing rod assembly Type VWE Standard & 17-inch creepage Standard & 17-inch creepage with BCT accy Roll pin, 1/8x15/16 (included in Item 13) Flat washer (included in item 13) Insulating tube (included in item 13) Standard & 17-inch creepage Standard & 17-inch creepage with BCT accy Shock absorber (included in item 13) Qty. Per Assy. KA716R20 1 KA716R21 1 K970801125093M 1 KP2028A39 1 KP3230A49 1 KP3230A46 1 KP2090A2 1 The following parts are applicable to the bushing current transformer accessory only 18 KP171W KP1578R Description Catalog Number 23 24 25 26 Capscrew, hex hd, 3/8—16x2, stl Transformer clamping flange Flange gasket Replacement current transformer 600:5, multi-ratio 1200:5, multi-ratio Capscrew, hex hed, 3/8—16x1-1/4, stl Transformer clamping sleeve Hex nut, 3/8—16, stl Stud Bushing spacer K730101137200Q KP170W KP2090A73 3 1 2 KA159W KA132W 1 1 K730101137125Q KP169W K880201116037Q KP3149A40 KP275W 3 1 3 3 1 21 Figure 31 Head and tank assemblies - exploded view. 22 S280-40-6 Head and Tank Assemblies (Figure 31) Item No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 Description Receptacle and wiring bundle assembly Gasket Capscrew, hex hd, 1/4—20x3/4, stl Split lockwasher, med., 1/4, stl Oil level dipstick O-ring gasket Closing oil instruction plate All Type VWE and Type VWVE serial 1304 and above Type VWVE below serial 1304 Self-tapping screw, Type Z, #2x3/16, sst Capscrew, hex hd, 1/4—20x5/8 stl Manual closing tool access cover plate Cover plate gasket Capscrew, hex hd, 5/8—11x1-1/2, stl Split lockwasher, med, 5/8, stl Lifting lug Capscrew, hex hd, 1/4—20x5/8, stl Split lockwasher, med, 1/4, stl Auxiliary switch cover plate Cover plate gasket Ground connector Head casting, includes control shaft bushings Head gasket Cable clamp Cable clamp Machine screw, rd hd, 8—32x5/16, stl Split lockwasher, med No. 8, stl Current transformer support Spacer Current transformer Flat washer, 14S, brass Split lockwasher, med, 1/4, stl Machine screw, rd hd, 1/4—30x2, stl Hex nut, 10—24, stl Split lockwasher, med, No. 10, stl Resistor, wirewound, 100 ohm, 25 watt Bracket Machine Screw, rd hd, 10—24x2-1/4, stl Self-tapping screw, Type Z, #4x3/16, sst Voltage data plate Nameplate Type VWE Type VWVE Catalog Number Qty Per Assy. Item No. 40 KA33RE1 K P611R 1 1 K730101125075Q K900801025000Z KA363R KP2000A9 4 4 1 1 43 44 KP2312R KP1225R 1 1 K721515102031Z 2 45 46 47 48 49 50 51 K730101125062Q 2 KP246R1 KP2000A12 1 1 K730101162150Q K900801062000Z KP456H2 2 2 2 K730101125062Q K900801025000Z KP609R KP611R KA392R 4 4 1 1 1 KA840R KP2103A8 KP2006A1 KP2006A2 1 1 2 4 K721501108031Z K900801008000Z KP145RE KP3009A38 KA86RE1 K900525025056A K900801025000Z 6 6 6 6 3 12 9 K721501125200Z K881001124010Z 6 3 K900801010000Z 3 KP4022A31 KP238RE 3 3 K721501110225Z 3 K801515004018A KP567R 4 1 KRW271V1 KRW307V1 1 1 41 42 52 53 54 55 56 57 58 59 60 61 62 63 64 Description Self-tapping screw, rd hd. No. 12x1/2, sst Cover plate Manual operating handle assembly Spacer Retaining ring, Type C, 5/16 in, sst (WA516) Roll pin, 1/8x3/4, stl Shaft and lever assembly Spacer Flat washer, 14S, brass Cotter pin, 3/32x1/2, brass Roll pin, 3/32x1/2, stl Retaining ring, Type C, 3/16 in, sst (WA510) Groove pin Spacer Retaining ring, Type C, 3/8 in, sst (WA518) Indicator and support assembly Spacer Groove pin Spacer Capscrew, hex hd, 1/2—13x1/4, stl Flat washer Pipe plug, 1 in, sq hd Tank Oil sampling and drain valve Pipe plug, 1/2 in sq hd Catalog Number Qty. Per Assy. K801515012050A KP283R 5 1 KA477R KP3009A39 1 1 K970915302000A K970801125075M KA18RE KP3007A8 K900525026056A K970525093050A K970801093050M 1 1 1 1 1 1 1 K970915188000A KP3123A12 KP3006A9 2 1 1 K970915375000A KA19RE KP301 3A38 KP3126A4 KP301 3A11 2 1 3 1 1 K730101150325Q KP2028A23 KP2007A4 KRW116FA KA809R KP2007A3 10 10 1 1 1 1 The following parts are applicable to the CT-type battery charger power source. It is standard on the Type VWE below serial 2100 and VWVE below serial 1500; it is an optional accessory on later units. 65 66 67 68 69 70 71 72 73 74 75 76 77 78 Capacitor, 0.2 mfd, 2500 wvdc Split lockwasher, med, No. 6, stl Machine screw, rd hd, 6— 32x5/16, stl Hex nut, 10—24, stl Split lockwasher, med, No. 10, stl Flat washer, 14S, brass Resistor, wirewound, 1000 ohms, 25 w Bracket Machine screw, rd hd 10—24x2-1 /4, stl Current transformer support Spacer Current transformer Split lockwasher, med, 1/4, stl Machine screw, rd hd, 1/4—20x2, stl KP4004A8 K900801006000Z 1 2 K721501106031Z K881001124010Z 2 1 K900801010000Z K900525026056A 3 2 KP4022A36 KP238E 1 1 K721501110225Z KP145RE KP3009A38 KA86RE1 K900801025000Z 1 2 2 1 2 K721501125200Z 2 23 Figure 32 Closing coil mechanism - exploded view. 24 S280-40-6 Closing Coil Mechanism (Figure 32) Item No. 1 2 3 4 5 6 7 8 9A 9B 10 11 12 13 14 15 Description Capscrew, skt hd, 1/2—13x4-1/2, stl Split lockwasher, med, 1/2, stl Spacer Operating lever coupler Indicator shaft coupler Contactor toggle spring Groove pin Retaining ring WA514, Type C, 1/4, stl Closing solenoid contactor, below 30 kv Closing solenoid contactor, above 30 kv Capscrew with preassembled split lockwasher, 1/4—20x1/2, stl Machine screw, rd hd, 1/4—30x1/2, brass Split lockwasher, med, 1/4, bronze Hex nut, 1/4—20, brass Fuse retainer clip Closing coil fuse assembly (also included in closing coil replacement kit, item 27) 2.4-3.3 kv (2 red color bands) 4.15-6 kv (black color band) 7.2 to 11 kv (yellow color band) 12 to 24.9 kv (red color band) Catalog Number Qt Per Assy. 21 22 23 24 25 26 Fuse mounting bracket Lead assembly Flat washer, 3/8 SAE, stl Groove pin Retaining ring WA518, Type C, 3/8, stl Plunger and link assembly Upper stringer assembly Hex nut, 3/8—16, stl Split lockwasher, med, 3/8, stl Capscrew, hex hd, 3/8—16x1 -1/4, stl Solenoid frame Description Catalog Number Closing coil replacement kit (includes closing coil, lower coil gasket, 28, two fuse assemblies, 15, and voltage data plate, 36 Figure 31) 60 Hertz 50 Hertz 2.4 kv KA834R1 KA861R1 3.3 kv KA834R10 KA861R10 4.16-4.8 kv KA834R2 KA861R2 6.0 kv KA834R6 KA861R6 7.2-8.32 kv KA834R3 KA861R3 11.0 kv KA834R9 KA861R9 12.0-13.2 kv KA834R4 KA861R4 14,0 kv KA834R5 KA861R5 17.0 kv KA834R12 KA861R12 20.0 kv KA834R11 KA861R11 23.0-24.9 kv KA834R13 KA861R13 125 vdc* KA834R7 250 vdc* KA834R8 *No fuses required with low- voltage dc coils Qty. Per Assy. 27 KP2036A3 K900801050000M KP3182A1 KP1177R KP1056R1 KP141R1 KP1306R 6 6 6 1 1 2 1 KP970901250000M 4 KA430R3 1 KA1143R 1 K830101125050A 3 K721525125050A 6 K900830025000A K881025120025A KP2006A16 6 8 2 28 29 30 31 2 32 33 34 35 36 KA259R904 KA259R901 37 38 39 40 41 KA259R902 KA259R903 NOTE: Only one fuse assembly is required on reclosers with closing coils connected phase to ground (type VWVE below serial 1304) 16 17 18 19 20 Item No. KP257L KA28W1 K900201037000A KP3126A2 2 2 2 1 K970901375000M KA50R KA62R K880201116037A K900801037000Z 2 1 4 4 12 K730101137125A KP100R1 12 1 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Lower solenoid gasket Solenoid bridge plate assembly Solenoid frame post Machine screw, rd hd, 8—32x3/4, stl Cable clip Split lockwasher, med, No. 8, stl Hex nut, 8—32, stl Trip solenoid assembly Capscrew, hex hd, 1/4—30x1/2, stl Flat washer, 1/4 SAE, stl Hex nut, 1/4—20, stl Insulator Terminal block Machine screw, fil hd, 6—32x5/8, stl Lead wire assembly Hex nut, 6—32, brass Machine screw, rd hd, 6—32x1/2, brass Mercury switch (SW-3) Mounting clip Machine screw, rd hd, 8—32x7/16, stl Machine screw, rd hd, 6—32x1, brass Internal tooth lockwasher, No. 6, brz Hex nut, 6—32, brass Microswitch (SW-1) Rotary solenoid assembly Type VWE below serial 3900 and Type VWVE below serial 2850 Type VWE above serial 3900 and Type VWVE above serial 2850 Hex nut, 1/4—28, stl Flat washer, No. 14S, brass Split lockwasher, med, 1/4, stl Groove pin Retaining ring WA510, Type C, 3/16, stl Spring Spacer Cotter pin, 3/32x1, brass 1 KP389R KA644R1 KP1669R 1 1 4 K721501108075Z KP2006A8 K900801008000Z K881001132008Z KA11RVE 5 7 4 5 1 K730101125050Y K900201025000Z K880201120025Y KP2101A209 KP2101A9 1 2 1 1 1 K721801106062Z KA62RE K881025132006A 2 1 1 K721525106050A KP134RE1 KP2006A19 1 1 4 K721501108043Z 4 K721525106100A 2 K901032006000A K881025132006A K999904130008A 4 2 1 KA12RE1 1 KA61WE K881001328025Z K900525025056Z K900801025000Z KP3123A3 1 4 2 2 1 K970901188000M KP98L KP3007A30 K970525093100A 2 1 1 1 25 Figure 33 Interrupter mechanism - exploded view. 26 S280-40-6 Interrupter Mechanism (Figure 33) Item No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Description Insulating barrier Wire tie Contact rod assembly replacement kit Groove pin Retaining ring, Type C, 1/4” stl Spring Upper current exchange assembly Phases A and B Phase C Upper stringer assembly Capscrew, hex hd, 3/8 16x1-3/4 brass Flat washer, No. 24S, brass Short bushing lead (6 per phase) Phases A and B Phase C Short lead insulation Phases A and B Phase C Spacer Split lockwasher, mea, 3/8 si brz Hex nut, 3/8 16, brass Interrupter clamp Qty Per Assy. Item No. KRW125N1 K994904170004A 3 12 17 18 KRW706VA KP3124A50 K970901250000M KP1066VWS 3 3 6 6 KRW115FB KRW115FA KA62R 2 1 9 K730125137175A K900525039087H 3 6 KP3250A13 KP3250A14 12 6 KP2106A72 KP2106A71 KP3013A63 K900833037000A K881025116037A KP1036VS 2 1 3 6 6 12 Catalog Number 19 20 21 22 23 24 25 26 27 28 29 Description Capscrew, skt hd, 1/4—20x1, stl Vacuum interrupter VWE below S/N 7305 VWVE below S/N 7295 Phases A and B Phase C VWE above S/N 7305 VWVE/VWVE27 above S/N 7295 VWVE38 Lower stringer assembly Spacer Flat washer, 3/8 AN, stl Elastic stop nut, 3/8—16 Flat washer, 3/8 SAE, stl Split lockwasher, med, 3/8, stl Hex nut, 3/8—16, stl Lower current exchange assembly Phases A and B Phase C Long bushing lead (6 per phase) Long lead insulation (6 per phase) Capscrew, hex hd, 3/8—16x1, brass Catalog Number Qty. Per Assy. KP2036A10 12 KRW710V1 KRW710V2 KA327VS2 2 1 3 KA327VS2 KA338VS1 KA107VS KP3009A121 K900201039062Z KP2020A21 K900201037000A K900801037000A K880201116037A 3 3 9 3 3 3 9 9 9 KA127VWS2 KA127VWS1 KP3250A15 2 1 18 KP2106A77 3 K730125137100A 3 27 Cooper Power Systems Quality from Cooper Industries ©1991 Cooper Power Systems, Inc. Kyle® is a registered trademark of Cooper Industries, Inc. P.O. Box 2850 • Pittsburgh, PA 15230 Printed on Recycled Paper KBP 5/95