January 2011

Calculation of tanks and apparatus

made of thermoplastics

DVS – DEUTSCHER VERBAND

FÜR SCHWEISSEN UND

Vertical round, non-pressurised tanks

VERWANDTE VERFAHREN E.V.

R&D INTAKE MANIFOLDS

Technical Code

DVS 2205-2

Replaces January 2010 edition

Reprinting and copying, even in the form of excerpts, only with the consent of the publisher

Contents:

1

2

3

3.1

3.1.1

3.1.2

3.1.3

3.2

3.2.1

3.2.2

3.3

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

3.3.6

3.4

4

4.1

4.1.1

4.1.2

4.1.3

4.1.4

4.1.5

4.1.6

4.1.7

4.1.8

4.1.9

4.2

4.2.1

4.2.2

4.2.3

5

5.1

5.2

5.3

5.4

5.5

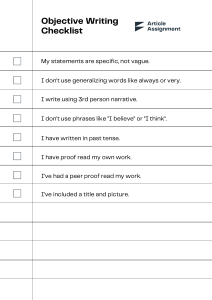

1

Scope of application

Calculation variables

Loading

Continuously effective loads

Total dead load

Load of the filling material

Internal and external pressures

Loads effective for a medium-long time

Snow load

Summer temperature

Loads effective for a short time

Internal and external pressures

Moving loads on the roof

Wind loads

Radially symmetrical equivalent loading caused by wind

pressure

Partial vacuum due to wind suction

Assembly loads

Temperature

Proof of the steadiness

Proof of the strength

Effects

Superimposition of the effects

Shell

Bottom

Welded joint between the bottom and the shell

Conical roof

Nozzles

Anchoring

Lifting lugs

Proof of the stability

Superimposition of the effects

Shell

Conical roof

Appendix

Explanations

Standards and technical codes

Literature

Temperature-dependent and time-dependent elastic moduli for stability and deformation calculations

Design-related details

Scope of application

The following design and calculation rules apply to vertical, cylindrical flat-bottom tanks which are fabricated from thermoplastics

in the factory, in particular:

–

–

–

–

polyvinyl chloride (PVC)

polypropylene (PP)

polyethylene (PE)

polyvinylidene fluoride (PVDF)

The cylindrical shell with an identical wall thickness throughout or

with a graduated wall thickness can be welded together from

panels or may consist of a wound pipe or an extruded pipe.

Consideration must be given not only to the hydrostatic loading but

also to pressures effective for short and long times. The following

minimum values are stipulated:

Overpressure: 0.0005 N/mm2 (0.005 bar)

Partial vacuum: 0.0003 N/mm2 (0.003 bar)

The pressures effective for a long time may only be applied if

they can also take effect.

Restriction on the main dimensions:

Tank diameter:

d4m

Ratio:

h/d 6

Minimum wall thicknesses: s = 4 mm

Attention must be paid to the responsibilities of certain legal fields

(e.g. building law, water law, occupational health and safety law

etc.).

2 Calculation variables

a

A1

mm

–

A2

–

A2I

–

AB

AD

Aj

AZ

bPr

bÖ

c

C

C1

C2

C*

m2

m2

m2

m2

mm

mm

–

–

–

–

–

d

dA

dL

dmax

dmin

dSch

mm

mm

mm

mm

mm

mm

ETC

K

N/mm2 Elastic modulus in the case of short-time

loading for T°C

N/mm2 Elastic modulus in the case of short-time

loading for 20°C

N/mm2 Elastic modulus in the case of long-time loading

for 20°C

–

Long-time welding factor

E K20C

E20C

L

fs

Weld thickness

Reduction factor for the influence of the specific

toughness (corresponds to A4 according to the

DVS 2205-1 technical code)

Reduction factor for the medium in the case of

the proof of the strength

Reduction factor for the medium in the case of

the proof of the stability and the deformation

Area of the bottom

Area of the roof

Area exposed to the wind (partial area)

Shell area of the cylinder

Width of the claw

Width of the lifting lug

Force coefficient according to DIN 1055-4

C1 C 2

Stress-increasing factor

Material-specific design factor

Coefficient for the circular cylinder subjected to

external pressure loads

Nominal inside diameter

Outside diameter of the nozzle

Hole diameter in the lifting lug

Maximum cylinder diameter

Minimum cylinder diameter

Diameter of the shackle

This publication has been drawn up by a group of experienced specialists working in an honorary capacity and its consideration as an important source of information

is recommended. The user should always check to what extent the contents are applicable to his particular case and whether the version on hand is still valid. No

liability can be accepted by the Deutscher Verband für Schweißen und verwandte Verfahren e.V., and those participating in the drawing up of the document.

DVS, Technical Committee, Working Group "Joining of Plastics"

Orders to: DVS Media GmbH, P. O. Box 10 19 65, 40010 Düsseldorf, Germany, Phone: + 49(0)211/1591- 0, Telefax: + 49(0)211/1591-150

216

Page 2 to DVS 2205-2

fsD

fz

fzD

g

gA

–

–

–

m/s2

N/mm2

Long-time welding factor for the roof

Short-time welding factor

Short-time welding factor for the roof

Acceleration due to gravity (9.81 m/s2)

Equivalent area load for the nozzles and similar

items on the roof

2

N/mm Area-related weight of the roof

N

Dead load of the bottom

N

Dead load of the roof

N

Total dead load

kN

Load of the filling material

N

Snow load

N

Dead load of the cylinder

mm

Height of the tank

mm

Filling height

mm

Filling height of the course i

mm

Residual filling height

mm

Height of the course i

mm

Cylindrical height

mm

Height of the lowest course

gD

GB

GD

GE

GF

GS

GZ

h

hF

hF,i

hRF

hZ,i

hZ

hZF

vorh

N/mm2 Stresses effective for a short time

KK,d

vorh

N/mm2 Dimensioning value of stresses effective for a

short time

N/mm2 Dimensioning value of stresses effective for a

long time

N/mm2 Dimensioning value of stresses with a medium

effective duration

N/mm2 Creep strength for 10-1 hours

vorh

vorh

K M,d

K*

K

K *K,d

pü

püK

pus

pw,d

p1

p,d

N/mm2 Dimensioning value of the creep strength for

10-1 hours

N/mm2 Dimensioning value of the creep strength for the

computational working life at the mean effective

temperature

2

N/mm Dimensioning value of the creep strength for the

medium effective duration (e.g. in the case of

snow for three months at 0°C)

mm

Length of the upper course of the equivalent

cylinder

Nm

Bending moment in the case of a wind load

N/mm Dimensioning value of the tensile force on the

diaphragm at the lower edge of the cylinder

N/mm2 Short-time dimensioning value of the effects on

the roof according to Table 5 or 6

N/mm2 Dimensioning value of the effects on the roof

according to Tables 5 and 6

N/mm2 Radially symmetrical equivalent loading caused

by wind pressure

N/mm2 Dimensioning value of the critical shell buckling

pressure

N/mm2 Auxiliary variable

N/mm2 Snow load on the roof

N/mm2 Overpressure at the tank bottom due to the

filling medium

N/mm2 Overpressure per lower edge of the graduation

due to the filling medium

N/mm2 Continuously effective external pressure

(or internal partial vacuum)

N/mm2 External pressure (or internal partial vacuum)

effective for a short time

N/mm2 Continuously effective internal pressure

2

N/mm Internal pressure effective for a short time

N/mm2 Partial vacuum due to wind suction

N/mm2 Auxiliary variable

N/mm2 Auxiliary variable

N/mm2 Auxiliary variable

qj

kN/m2 Impact pressure on the partial area Aj

K *L,d

K *M,d

lo

MW

nZ,d

pvorh

D

K, d

vorh

pD

L,M,d

peu

pkM,d

pmax

pS

pstat

pstat,i

pu

puK

kN/m2

mm

N/mm2

mm

mm

mm

mm

N/mm2

mm

mm

mm

mm

sZm

sZ,1

sZ,i

so

mm

mm

mm

mm

TA

°C

TAK

TD

TDK

°C

°C

°C

T*D

°C

TM

°C

Maximum impact pressure effective at the tank

Radius of the cylinder

Dimensioning value of the stressability

Minimum wall thickness

Executed wall thickness of the basic component

Wall thickness of the bottom

Wall thickness of the roof

Dimensioning value of the stresses

Wall thickness of the lifting lug

Wall thickness of the cylinder

Wall thickness of the lowest course

Statically required wall thickness of the lowest

course

Mean wall thickness of the cylinder

Wall thickness of the highest course

Wall thickness of the course i

Wall thickness of the upper course of the

equivalent cylinder

Mean ambient temperature (according to Miner,

see DVS 2205-1)

Highest ambient temperature

Mean roof temperature

Highest roof temperature in the case of indoor

installation

Mean roof temperature for the summer load case

R&D INTAKE MANIFOLDS

KK

KL,d

qmax

r

Rd

s

sa

sB

sD

Sd

sÖ

sZ

sZF

s*ZF

TMK

TZ

TZK

u

V

vA

wgr

Wj

z

D

B

w

s

F

I

M

A,i

M

F

vorh

d

k,d

vorh

i,d

k,i,d

W

Mean media temperature (according to Miner,

see DVS 2205-1)

Highest media temperature

Mean temperature of the cylinder wall

Highest temperature of the cylinder wall

Permissible out-of-roundness

Filling volume

Weakening coefficient

Tolerable lifting path

Wind load

Number of anchors

Auxiliary variable

Pitch of the roof

Coefficient

Coefficient

Coefficient for the calculation of the bottom

Coefficient

Coefficient

Tolerable edge fibre expansion

Partial safety coefficient of the effect/stresses

Weighting coefficient depending on the loading

type

Partial safety coefficient of the resistance/

stressability

–

Utilisation of the axial stability in the course i

–

Utilisation of the shell pressure stability

°

Angle of the roof in relation to the perpendicular

3

Density of the material ( = g)

g/cm

3

g/cm

Density of the filling medium

N/mm2 Dimensioning value of the crucial compressive

stress in the conical roof

N/mm2 Dimensioning value of the critical buckling

stress in the conical roof

N/mm2 Dimensioning value of the crucial axial

compressive stress in the course i

°C

°C

°C

%

m3

–

mm

kN

–

–

°

–

–

–

–

–

%

N/mm2 Dimensioning value of the critical axial buckling

stress in the course i

N/mm2 Compressive stress on the diaphragm resulting

from the wind load

217

Page 3 to DVS 2205-2

R&D INTAKE MANIFOLDS

S ZF = SZ

S ZF = SZ

Figure 1.

Open flat-bottom tank with a non-graduated wall thickness.

Figure 2.

Open flat-bottom tank with a graduated wall thickness.

Figure 3.

Flat-bottom tank with a conical roof and a non-graduated wall

thickness.

Figure 4.

Flat-bottom tank with a conical roof and a graduated wall thickness.

3 Loading

3.1.1 Total dead load GE

3.1 Continuously effective loads

Dead load of the roof GD:

Depending on the application, tanks are designed for a computational operating time of up to 25 years (2 105 hours). The computational filling height hF is determined by the existing operating

conditions.

GD= AD sD g

218

GE = G D + GZ + GB

N

(1)

N

(2)

N

(3)

Dead load of the cylinder GZ:

G Z = AZ s Z g

Page 4 to DVS 2205-2

3.3.2 Moving loads on the roof

Dead load of the bottom GB:

GB = AB sB g

N

(4)

Ladders, platforms, pedestals and similar items must be set up

and fastened independently of the tank since the free expansion

of the tank (e.g. during filling and emptying and in the case of

temperature changes) would otherwise be hindered. These hindrances cause considerable stress peaks which are difficult to record computationally and, if they are taken into account, lead to

uneconomic designs. If there is any deviation from this, corresponding proof must be provided.

It is not allowed to walk on the roofs without taking any loaddistributing measures. Corresponding precautions must be taken

during assembly and inspection work.

R&D INTAKE MANIFOLDS

The wind loads Wj must be estimated as follows:

Wj = cf ∙ q ∙ Aj

kN

(6)

where:

Wj wind load of the partial area Aj.

3.1.2 Load of the filling material GF

GF = V F g

3.3.3 Wind loads

kN

(5)

3.1.3 Internal and external pressures pü and pu

Higher pressures than indicated in the scope of application must

be taken into account at the level set by the operator.

If any safety fittings which cause higher pressures (such as overfilling protection devices or ventilation and venting facilities) are

connected, only these pressures must be taken into consideration. These pressures must not be effective when the tank has

been emptied completely since the bottom would otherwise be in

danger or the tank would be lifted.

3.2 Loads effective for a medium-long time

The effective time is three months.

3.2.1 Snow load GS

The snow load according to DIN 1055-5 must be estimated

cumulatively over the computational service life at a roof wall

temperature of 0°C. The computational snow load is calculated

from the shape coefficient and the characteristic value of the

snow load sk according to the snow load zone map and the

height above sea level.

cf Force coefficient for the circular cylinder and the roof.

cf1 = 0.8 may be estimated according to DIN 1055-4, Section

10.2. Installation in a series has already been taken into consideration in this respect. Extensions cf2 = 1.6.

q Kinematic pressure according to DIN 1055-4, Table 2 depending on the wind zone and the height above the ground h

(h = hBehälter + hGebäude when the tank is located on a building, otherwise h = hG = hBehälter).

Aj Relevant exposed area in m² (for the tank: diameter times

total height hG including the roof)

The stress resulting from the wind moment MW may be calculated

using the following simplified method:

3

4 M W,x 10

W,i = ---------------------------------2

d s Z,i

N/mm2

(7)

Mw,x at the height x above the tank bottom can be calculated on

a clamped equivalent bar.

2

hG – x

- + c f2 q

M W, x = c f1 q d ---------------------2

Aj aj

Nm

(8)

where aj is the lever arm of the area exposed to the wind Aj of the

superstructures and extensions in relation to the height x.

The following value may be estimated for conical and flat roofs:

= 0.8.

3.3.4 Radially symmetrical equivalent loading caused by

wind pressure

3.2.2 Summer temperature

The compressive loading due to the inflow of the wind on to the

cylindrical shell is recorded by the equivalent load peu.

The roofs may be heated up considerably in summer. It is necessary to take account of a wall temperature of 50°C.

3.3 Loads effective for a short time

The effective duration of loads effective for a short time is stipulated as 10-1 hours.

Any water hammers which may arise during filling operations

must be prevented by taking suitable measures.

3.3.1 Internal and external pressures püK and puK

Pressure

As far as no higher pressures can occur as a result of the operating method, the minimum pressures indicated in Section 1 must

be taken into consideration. The definition of püK results in

püK pü (see Fig. 5). The same applies analogously to puK.

peu = qmax 10-3

N/mm²

(9)

r

r

= 0.46 1 + 0.1 C * ------ ---------- 0.6

h Z s Zm

(10)

where:

C* = 1.0 for the closed tank

C* = 0.6 for the open tank

h Z,i s Z,i

s Zm = ---------------------------------hZ

(11)

3.3.5 Partial vacuum due to wind suction

In the case of ventilated tanks, an internal partial vacuum results

from a suction effect.

pus = 0.6 qmax 10-3

N/mm²

(12)

pus = 0.48 10-3 N/mm² is applicable in the case of ventilation

through a pipe leading to the outside.

3.3.6 Assembly loads

Time

Figure 5.

Definition of püK.

The tank must be designed for the loading conditions arising

during the transport and the assembly. In this respect, the calculation is made with 1.5 times the assembly loads (surge factor).

F1 is estimated as the partial safety coefficient. The short-time

welding factor according to DVS 2205-1 must be taken into con-

219

Page 5 to DVS 2205-2

sideration.

In this respect, the characteristic effects or the stresses are multiplied by the partial safety coefficients F according to Table 1.

3.4 Temperature

The effective wall temperature is decisive for the dimensioning of

the components. For parts wetted with the media, proof must be

provided at the mean media temperature TM in the case of longtime effects and at the highest media temperature T MK in the

case of short-time effects. The mean temperature is the temperature which, according to Miner, causes the same damage to the

material as the changing temperatures in real operation (e.g. according to Miner, a 10 % time proportion at 30°C and 90 % at

20°C result in TM = 26.3°C; TMK = 30°C). For non-wetted parts,

the mean of the two neighbouring air temperatures may be estimated as the wall temperature using a simplifying method. The

media temperature is assumed to be the air temperature in the

tank. As far as the ambient temperature is concerned, a differentiation is made according to the installation location and the effective duration. The following minimum values are applicable:

Table 1. Partial safety coefficients of the effects.

R&D INTAKE MANIFOLDS

Minimum values

For a short time

Indoor installation

TAK = 20°C

For a long time

TA = 20°C

Outdoor installation

TAK = 35°C

TA = 20°C

In the case of outdoor installation, the wall temperature of the

roof must be estimated at min. 50°C as a result of the solar radiation. A decreased ambient temperature TAK - 5°C applies to the

proof of the stability in the cylinder in the case of outdoor installation (wind effect).

Effect

Partial safety coefficient

Dead weight, filling and assembly

F1 = 1.35

Pressures, wind and snow

F2 = 1.5

Stress-reducing dead weight

F3 = 0.9

The dimensioning value of the existing stresses results from F

times the characteristic value of the stresses existing in the component.

vorh

vorh

K K,d = F K K

The dimensioning values of the existing stresses must be multiplied by the weighting coefficient I which takes account of the

loading cases in Table 2.

Table 2. Weighting coefficient.

Loading type

I

Loading Case I

1.0

Static loading at the room temperature and in constant

conditions. Cases of damage cannot lead to any danger to people, things or the environment.

Loading Case II

1.2

Loading in changing conditions (e.g. temperature and

filling height). Cases of damage may lead to danger to

people, things or the environment, e.g. installations or

installation parts which must be monitored and tested.

The characteristic resistances or the stressabilities are divided by

the partial safety coefficient M = 1.1.

For example, the dimensioning value of the short-time strength

K *K,d results from the characteristic short-time strength value K *K

divided by M according to the creep strength diagrams in

DVS 2205-1.

*

K=

K,d

Without

collecting device

With

collecting device

Without collecting device

With collecting device

TD = (TM+TA)/2

TD = (TM+TA)/2

TZ = (TM+TA)/2

TZ = (3 ∙ TM+TA)/4

Analogously, this is followed by TDK and TZK with TMK and TAK.

Figure 6.

Definition of the effective temperatures.

4 Proof of the steadiness

The proof of the steadiness is provided according to the concept

of the partial safety coefficients. In general, the following is applicable:

K *K

--------M

The dimensioning coefficients of the stressability must be divided

by the reduction coefficients A1 and A2 and, in the case of proof

in the weld, multiplied by the welding factor. In contrast, because

of the shorter representation, the dimensioning values of the

existing stresses are below multiplied by the reduction coefficients A1 and A2 and divided by the welding factor. This leads to

the same result.

4.1 Proof of the strength

4.1.1 Effects

Any loads caused by connected nozzles and pipelines are not

covered by this calculation and must be taken into consideration

separately by means of design-related measures (e.g. compensators).

It is always necessary to look for the most unfavourable combination of the overall effects for every component. Two cases must

be investigated for the effects of wind and snow:

1. The full snow load

2. 0.7 times the snow load + the full wind load

S

------d- 1

Rd

Load cases effective for a short time do not have to be combined

with each other.

with Sd dimensioning value of the stresses

Rd dimensioning value of the stressability

4.1.2 Superimposition of the effects

220

Page 6 to DVS 2205-2

Corresponding to the effective duration, a distinction must be

made between three loading categories:

– Loading effective for a short time (K)

e.g. puK, püK, pus, peu or wind

4.1.3.1 Proof in the circumferential direction

For every course i, it must be proven that the ring tensile stresses

due to the filling and the overpressures can be accommodated at

its lower edge. According to Section 4.1.2, it is necessary to provide double proof with:

R&D INTAKE MANIFOLDS

– Effects with a medium effective duration (M)

e.g. snow ps or summer temperatures

vorh

K L,d

– Loading effective for a long time (L)

e.g. dead weight, filling, pu or pü

If the filling is not constant with regard to the filling height and the

temperature during the computational working life of the tank,

representative equivalent loading can be determined for such

intermittent loading with Miner's rule. In contrast, the application

of Miner's rule is not very practicable for the superimposition of

the loading in the three loading categories.

Therefore, it is always necessary to provide double proof.

vorh

(13)

N/mm2

(14)

and

vorh

L,M,d = dimensioning value of the existing stresses

= dimensioning value of the creep strength for the computational working life at the mean effective temperature

K*M,d = dimensioning value of the creep strength for the medium effective duration (e.g. in the case of snow for

three months at 0°C for the roof)

2. It must be proven that, if the other effects are superimposed

on the stresses resulting from short-time loading, the stresses

do not exceed the residual strength of the material at the end

of the computational working life. In this respect, the creep

strength for 10-1 hours is estimated as the residual strength.

vorh

K K,d

----------------------------- 1

(15)

K*K,d

with

=

A1 at the effective wall temperature TM

and

K K,d

vorh

F1 p stat,i + F2 p üK d A 1 A 2 I

= ------------------------------------------------------------------ -------------------------- N/mm2

2 s Z,i

fz

(17)

A1 at the effective wall temperature TMK

p stat,i = F g h F,i 10

–6

N/mm2

(18)

where hF,i means the height of the liquid level above the lower

edge of the course i.

Stresses resulting from effects with a medium effective duration

do not arise in the case of this proof:

vorh

A1 A2 I

vorh

vorh

K L,M,d = L,M,d -------------------------fs

vorh

K K,d

(16)

(K M,d = 0) .

with

K*L,d

N/mm2

with

1. It must be proven that, if the effects with a medium effective

duration are superimposed on the stresses resulting from

loads effective for a long time but without any short-time loading, the stresses do not exceed the creep strength.

vorh

K M,d

K L,d

-1

------------------- + -------------------K*M,d

K*L,d

F1 p stat,i + F2 p ü d A 1 A 2 I

= --------------------------------------------------------------- -------------------------2 s Z,i

fs

vorh

K, d

A1 A2 I

-------------------------fz

N/mm2

The welding factor of the shell weld fs or fz is taken into account

in the case of cylinders manufactured from plates. According to

today's state of the art, preference should be given to heated tool

butt welding. fs = 1 and fz = 1 apply to wound tanks.

The residual stresses resulting from the bending of the panels at

the room temperature can be neglected if the edge fibre expansion = s/d 100 [%] according to Table 3 is not exceeded.

Table 3. Tolerable edge fibre expansion.

Material

Edge fibre expansion

PE-HD

1.00

PP-H

0.50

PP-B

0.75

PP-R

1.00

PVDF

0.50

PVC-U

0.20

PVC-C

0.10

Remark: The value for PE-HD may be used for PE 63, PE 80

and PE 100.

(15a)

and

*

= dimensioning value of the creep strength for 10-1

K K,d

hours at the temperature belonging to this loading

combination.

The more unfavourable of both the cases of proof is always

crucial for the dimensioning of the components.

Remark:

For the proof of the strength of the roof, it must be checked

whether the consideration of the snow load leads to a more

unfavourable result since, although the loading total is increased, the creep strength also becomes greater because of

the effective wall temperature of 0°C.

4.1.3.2 Proof in the longitudinal direction

The greatest tensile stresses must be validated. In this respect,

just 90 % of relieving, continuously effective compressive stresses may be taken into consideration.

Only the lowest course at the interface to the bottom must be

investigated for the proof of the stresses in the longitudinal direction. The stresses arising here are caused by the bending fault

moment and the stresses in the longitudinal direction resulting

from the dead weight, the pressures and the wind must be superimposed on them.

The double proof according to Section 4.1.2 must be provided with:

d

d

vorh

K L,d = C F1 p stat + F2 p ü --- + F2 p ü --4

2

F3 G D + G Z A 1 A 2 I

– -------------------------------------- -------------------------s ZF

d

4.1.3 Shell

The height of the lowest course hZF must be min. 1.4 d s ZF .

In the case of graduated tanks, neighbouring courses may have

a wall thickness ratio of max. 3 without any further proof. In the

case of sudden thickness changes with a wall thickness ratio

greater than 2, it is necessary to use the shell seam formation according to DVS 2205-3, Fig. 2.2 a), 2.2 c) or 2.2 c1).

N/mm2

(19)

A1 at the effective wall temperature TM.

with

vorh

K M,d=

p stat = F g h F 10

–6

N/mm

(20)

0

221

Page 7 to DVS 2205-2

and

*

= sB / S ZF

vorh

K K,d =

d

d

C F1 p stat + F2 p üK --- + F2 p üK --4

2

3

Permissible range for C = 1.2

R&D INTAKE MANIFOLDS

F2 4 M W 10 F3 G D + G Z A 1 A 2 I

+ ------------------------------------------- – --------------------------------------- -------------------------- N/mm2

2

s ZF

d

d

(21)

A1 at the effective wall temperature TMK.

The factor C for the welded interface of the bond between the

bottom and the shell is the product of the stress-increasing factor

C1 = 1.2 and a material-specific design factor C2 according to

Table 4.

Table 4. The material-specific design factor C2 and the factor C for

thermoplastics.

Material

PE-HD

PP-H (Type 1)

PP-B (Type 2)

PP-R (Type 3)

PVC-NI (normal impact strength)

PVC-RI (increased impact strength)

PVC-HI (high impact strength)

PVC-C

PVDF

C2

1.00

1.17

1.00

1.00

1.25

1.08

1.00

1.33

1.17

C = C 1 C2

1.20

1.40

1.20

1.20

1.50

1.30

1.20

1.60

1.40

Remark: The values for PE-HD may be used for PE 63, PE 80

and PE 100.

It is not necessary to provide any proof of the stresses in the weld

if the conditions according to Section 4.1.5 are fulfilled.

One prerequisite for the stress-increasing factor C1 = 1.2 is that

the bottom is not executed with a thickness greater than the wall

thickness of the lowest course (sB sZF).

4.1.4 Bottom

4.1.4.1 Proof for the load case of the filling

If the bottom and the cylinder are joined with fillet welds (Fig. 11

in Section 5.5), the required thickness of the bottom may be determined as follows:

*

Figure 7.

Diagram for the determination of the thickness of the bottom,

derived for PE-HD (for C > 1.2, this diagram is on the safe side).

4.1.4.2 Proof for unanchored tanks with overpressure

If an unanchored tank (e.g. a tank in a collecting device) is loaded with overpressure, the bottom of the tank arches outwards.

This leads to the lifting of the whole tank and to bending stresses

in the bottom. A filling residue to be guaranteed with the filling

height hRF must be taken into consideration during the calculation of this lifting.

Pressures effective for short and long times are treated in the

same way since it may be postulated that the condition with a

long-time pressure and a residual filling height exists for a limited

time only. The effective pressure is therefore:

N/mm2

p1 = max (pü, püK)

(23)

Proof must be provided not only of the strength but also of the

limitation of the lifting path subjected to nominal loads to

wgr = 10 mm.

Proof of the strength

–6

p B,k – p 1 – g s B 10

h RF, = ----------------------------------------------------------------–6

F g 10

mm

p 1 d G D + G Z

1,5 ------------– --------------------- 4

d

with p B,k = -----------------------------------------------------------lB

N/mm2

B s *ZF s B s ZF

2

K *K + K *M

sB

1

- -------------------------- ---------------------------with l B = -------------------------- n Z,d l

2

A1 A2 M

with

sZF

executed wall thickness

A1 at the effective wall temperature TMK.

B

according to Fig. 7 and

GD + GZ

p1 d

– F3 ---------------------with n Z,d = F2 ------------d

4

*

s *ZF = max s*ZF,L , s ZF,K

mm

(22)

mm

(24c)

mm

(25)

–6

p B – p 1 – 0.9 g s B 10

h RF,w = -------------------------------------------------------------------------–6

0.9 F g 10

1.5 nZ

------------------lB

N/mm2

(25a)

wgr 0.75 E K

with l B = s B 3 -------------------------------------------- w A 2l n Z

mm

(25b)

GD + GZ

p1 d

– 0.9 ---------------------with n Z = ------------4

d

N/mm

(25c)

ToC

(22b)

A1 and K *K,d at the effective wall temperature TM

In the case of other structural shapes, it is necessary to provide

proof of the bottom due to the cylinder clamping moment.

222

N/mm

and = 1.5 for indoor installation

=

pB

with

d

d

and s *ZF,K= C F1 p stat + F2 p üK --- + F2 p üK --4

2

mm

(24b)

Limitation of the lifting path

(22a)

A1 and K*L,d at the effective wall temperature TM

F3 G D + G Z A 1 A 2 I

– --------------------------------------- -------------------------*

d

K K,d

(24a)

= 2.12 for outdoor installation

d

d

with s *ZF,L= C F1 p stat + F2 p ü --- + F2 p ü --4

2

F3 G D + G Z A 1 A 2 I

– --------------------------------------- -------------------------*

d

K L,d

mm

(24)

and = 0.56 for indoor installation

= 1.12 for outdoor installation

Page 8 to DVS 2205-2

The crucial residual filling height results from:

h RF = max h RF, , h RF,w

Remarks:

mm

(26)

vorh

vorh

K L,d = pD L,d

e

s

A ln -

r + B

A1 A2 I

-------------------------f sD

A ln s

--- + B

r

R&D INTAKE MANIFOLDS

K *K + K *M /2 is used in the calculation for the proof of the

strength. A loading duration of approx. 12 hours is taken into

account in this respect.

ToC

ToC

0.75 E K

is used instead of E K

(see Section 5.4) in the

calculation for the proof of the limitation of the lifting path since a

higher stress level and thus a lower modulus must be taken into

consideration during this deformation calculation than in the case

of stability problems.

4.1.4.3 Proof for an internal partial vacuum

vorh

vorh

K M,d = pD M,d e

A1 A2 I

-------------------------f sD

N/mm2

(27)

N/mm2

(28)

N/mm2

(29)

and

vorh

K K,d =

vorh

e

pDK,d

A ln s

---

r + B

A1 A2 I

-------------------------f zD

2

– 0.000103 D + 0.007825 D – 1.7771

with A =

2

B =

– 0.000433 D + 0.008115 D – 0.1870

The combinations in Table 5 must be investigated. A1 must be

determined on the basis of the temperatures in Table 5. An effecIt is not necessary to provide any proof of the bottom for an intertive mean wall temperature which is determined according to

nal partial vacuum if a residual filling remains in the tank. In this

Miner

respect, the residual filling height must be stipulated in such a

way that the total resulting from F3 times the dead load of the

T D + 50

oC

=

------------------TD*

(30)

bottom is greater than F3 times the F2 partial vacuum.

2

and takes account of a roof temperature of 50°C over three

4.1.5 Welded joint between the bottom and the shell

months (TD according to Fig. 6) is used for the summer load

case.

It is not necessary to provide any explicit proof of the stresses on

the weld if the following conditions are fulfilled:

–6

g s D 10

- + gA

N/mm2

g D = ------------------------------------(31)

– weld thickness a 0.7 sB

sin

– long-time welding factor fs 0.6 (according to DVS 2203-4)

gA equivalent area load for nozzles and similar items

If one of these conditions is not fulfilled, it is necessary to provide

The welding factor is oriented to the quality of the longitudinal

detailed proof of the stresses in the weld (e.g. FE calculation).

weld of the conical roof.

In the case of one-shell tanks with capacities up to 1,000 l and

wall thicknesses up to 10 mm, this also applies to long-time welding factors fs 0.4.

4.1.6 Conical roof

The pitch of the roof must not be less than D = 15° ( = 75°).

4.1.6.2 Loads directed outwards

The double proof according to Section 4.1.2 must be provided

with:

vorh

vorh

K L,d = pDL,d e

--s-

C ln r + D

A1 A2 I

N/mm2

(32)

and

4.1.6.1 Loads directed inwards

pDK,d

vorh

C ln s--- + D

r

The crucial combination of the dead weight gD, the partial vacuums pu and puK, the snow load ps and the partial vacuum resulting from the wind pus must be investigated. In this respect, pu,

puK and pus do not have to be combined with each other and, if

the wind is estimated, the snow load may be reduced to 70 %.

with C = 0.000013 D – 0.00097 D – 1.4054

It is necessary to prove the stresses resulting from the ring tension at the edge of the roof.

A welding factor does not have to be taken into consideration

since the weld in the roof runs parallel to the stresses.

The double proof according to Section 4.1.2 must be provided

with:

It is necessary to investigate the combinations in Table 6.

vorh

K K,d =

e

A1 A2 I

N/mm2 (33)

2

2

D = 0.000265 D – 0.04574 D + 1.5622

A1 must be determined on the basis of the temperatures in Table 6.

Table 5. Combinations of load cases for the calculation of the roof for loads directed inwards..

Installation

location

Combination

Proof according to (13)

vorh

p DL,d

Temp.

Proof according to (15)

vorh

p DM,d

Temp.

pD

–

max (F1 ∙ gD + F2 ∙ puK, F1 ∙ gD + F2 ∙ pus)

vorh

Temp.

K,d

Winter

F1 ∙ gD + F2 ∙ pu TD

F1 ∙ gD + F2 ∙ pu TD

0

Outdoors

F2 ∙ pS 0°C

max (F1 ∙ gD + F2 ∙ (ps + puK), F1 ∙ gD + F2 ∙ (0.7 ∙ pS +pus)) 0°C

Outdoors

*

Summer F1 ∙ gD + F2 ∙ pu T D

0

max (F1 ∙ gD + F2 ∙ puK, F1 ∙ gD + F2 ∙ pus)

Indoors

–

TDK

50°C

Table 6. Combinations of load cases for the calculation of the stength of the roof for loads directed outwards.

Installation

location

Indoors

Outdoors

Combination

Proof according to (13)

Proof according to (15)

vorh

pDM,d

Temp.

pDvorh

Temp.

F2 ∙ pü – F3 ∙ gD TD

0

–

F2 ∙ püK – F3 ∙ gD

TDK

*

Summer F2 ∙ pü – F3 ∙ gD T D

0

–

F2 ∙ püK – F3 ∙ gD

50°C

vorh

pDL,d

Temp.

K,d

223

Page 9 to DVS 2205-2

4.1.7 Nozzles

The nozzles must generally be attached to the roof. If nozzles are

attached to the cylinder, the maximum diameter must be limited

to dA = 160 mm. The distance between the centres of the

nozzles and the edges, the course boundaries or the welds in the

basic component must be min. dA/2 + 100 mm. However, the distance between the centres of the nozzles and the bottom and a

neighbouring course with a lower wall thickness must be min. dA.

While paying attention to the lever arms, the required anchor

force (e.g. for the plugs) must be calculated from the maximum

claw force (maximum of the three numerators).

Fig. 9 in Section 5.5 shows the execution of an anchoring

element.

R&D INTAKE MANIFOLDS

It must be proven that it is possible to accommodate the stresses

on the basic component which are increased as a result of the

stress concentration close to the opening.

The stresses in the undisturbed basic component are increased

by dividing them by the weakening value vA.

The following applies to nozzles in the cylinder and in the conical

roof:

0.75

vA = ---------------------------------------------------dA

1 + ----------------------------------------2 d + sa sa

with

dA

d

sa

(34)

outside diameter of the opening

cylinder diameter

executed wall thickness of the basic component

For the proof of the nozzles in the roof, it is necessary to provide

proof only for the largest nozzle situated near the edge of the

roof. In this respect, the dimensioning values for the existing

vorh

stresses K L,M,K,d may be determined for loads directed both inwards and outwards from the following equation:

vorh

K L,M,K,d

with p D

pD

d A1 A2 I

L,M,K,d

- ------ ------------------------= --------------------vA

2 cos s D

L,M,K,d

(35)

In the case of nozzles in the cylinder, it is necessary to provide

proof for ring tensile loads in analogy to Section 4.1.3.1, paying

attention to the height position of the nozzle. The structural

designing must be carried out according to Fig. 8, Section 5.5

(push-through nozzle). The wall thickness must correspond to

min. SDR11 (formerly pressure stage PN 10).

4.1.8 Anchoring

If anchoring becomes necessary, at least four anchors must be

arranged (z 4).

With regard to the proof of the anchoring, a distinction must be

made between three cases:

Case 1: Short-time overpressure at the media temperature T MK:

2

(36)

2

(37)

Case 3: Wind load at 20°C (only in the case of outdoor installation):

2

4 F2 M w

F2 p ü d

1

----------------------------- 10 3 + ------------------------------------ – F3 G D + G Z --d

z

4

-------------------------------------------------------------------------------------------------------------------------------------------------- 1 (38)

K *K,d

b Pr + s B s B ----------------------2 A1 I

The numerator indicates the claw force to be accommodated and

the denominator the claw force which can be accommodated and

results from the shearing stress in the weld. In this respect, half

the creep strength is estimated as the shearing stress.

224

In order to be able to dispense with any proof of the load introduction into the highest course, it must be ensured that the lifting

lug is not thicker than three times the wall thickness of the

highest course. The hole diameter (dL) must be adapted to the

diameter of the shackle (dSch).

The following equations are applicable:

sZ,1 erf sÖ 3 sZ,1

(39)

dSch dL 1.1 dsch

(40)

It must be proven that 1.5 times the loading (surge factor) can be

borne for a short time at 20°C. I = 1.2 must be set in this respect

since the transport of the tank constitutes a danger to people

irrespective of the subsequent utilisation.

The required wall thickness (sÖ) of the lifting lug results from the

proof for the face of the hole:

GE

1.5 F1 ------- A 1 I

2

s Ö = ----------------------------------------------------d Sch 2 K *K,d

mm

(41)

bÖ = max (bÖ,1, bÖ,2)

Proof of the shearing stress for the transverse weld during the

lifting of the lying tank:

GE A1 I

1.5 F1 ------- --------------fz

4

b Ö,1 = ----------------------------------------------------K *K,d

0.7 s Z,1 ------------2

Eye bar:

mm

(42)

GE

1.5 F1 ------- A 1 I

7

2

b Ö,2 = ----------------------------------------------------- + --- d L mm

3

s Ö K *K,d

(43)

4.2 Proof of the stability

Case 2: Long-time overpressure at the media temperature T M:

F2 p ü d

1

------------------------------------ – F3 G D + G Z --z

4

------------------------------------------------------------------------------------------------ 1

K *L,d

b Pr + s B s B ----------------------2 A1 I

One of the possible lifting lug shapes is shown on Fig. 10 (Section 5.5). The prerequisites for the use of these lifting lugs are

that only two lifting lugs are used per tank and that one parallel

hanger is utilised.

The maximum of both the following cases of proof is crucial for

the width of the lifting lug (bÖ).

effects according to Section 4.1.6.1 or 4.1.6.2.

F2 p üK d

1

---------------------------------------- – F3 G D + G Z --z

4

--------------------------------------------------------------------------------------------------- 1

K *K,d

b Pr + s B s B ----------------------2 A1 I

4.1.9 Lifting lugs

4.2.1 Superimposition of the effects

The crucial elastic moduli are needed for the stability calculations.

The buckling of shells is a sudden occurrence which is essentially

dependent on the imperfections, i.e. on the size of the previous

bulges. The size of the previous bulges increases along with the

loading duration because of the creep behaviour of the material.

In contrast, the elastic resistance during the beating-out is predominantly determined by the short-time elastic modulus at the temperature at that moment. The critical buckling stress k is therefore

o

calculated with the temperature-dependent moduli E TK C .

For the essential thermoplastics, the temperature-dependent and

time-dependent elastic moduli are included in Tables 8 and 9

(Section 5.4).

It is necessary to investigate the most unfavourable combination

of loads taking account of the temperature behaviour of the thermoplastics.

4.2.2 Shell

Sufficient safety against axial and shell pressure stabilities as

well as against the interaction of both must be proven for the

shell of the tank. It is not necessary to prove the stability next to

the nozzles because of the limitation of the nozzle diameters.

Page 10 to DVS 2205-2

The prerequisite is that the out-of-roundness of the cylinder

remains limited in the following form:

2 d max – d min

u = ------------------------------------------ 100 0.5

d max + d min

%

(44)

In the case of outdoor installation:

w

- ,

= max F1 G + F2 max pu pus + 0.7 s + ------i,d

vorh

1.2

N/mm2

----- F1 G + F2 puK + s

(45)

(51)

The critical shell pressure of the graduated cylinder may be

calculated on a three-course equivalent cylinder according to

DIN 18800-4:

ToC

EK

r s o 2.5

p kM,d = 0.67 C * ---------------- ---- -----

M

lo r

= F1 G + F2 max puK pus

(46)

The stress resulting from the wind moment W may be divided by

1.2 because the buckling stress should be increased by 20 % in

the event of global bending.

Using a simplifying method, the buckling stress may be determined according to the following formula:

ToC

s Z,i

EK

*

- KK,d

- ------ k,i,d = i 0.62 f ,i --------------M

r

N/mm2

0.70

with i = -----------------------------------------------------------------20 o C

EK

r

----------------- 1 + ----------------------

20 o C

100 s Z,i

EL

(47)

(48a)

The interaction between the axial and shell pressure stabilities

must be proven for every course:

1.25

1

(53)

The longitudinal stresses caused by a partial vacuum do not

have to be taken into consideration during the calculation of A,i

for the interaction since their effect is already included in M.

4.2.3 Conical roof

The most unfavourable combination of the compressive stresses

in the circumferential direction in the centre of the shell line of the

conical roof (d/4):

d

vorh

vorh

pd

d

= ------------------------ -----4 cos s D

N/mm2

ToC

(48b)

(54)

is validated with the critical stresses:

s 1.5

EK

- sin cos -----D-

k,d = 2.68 -------------- d

M

ei

1.5 – -------- 1.0

s Z,i

(52)

4.2.2.3 Interaction

1.25

N/mm2

N/mm2

The ß values are indicated on Figs. 20a to 20c in DIN 18800-4.

A,i + M

In the case of indoor installation:

and=

f ,i

N/mm2

with C * = 1.0 for tanks with solid roofs

with C * = 0.6 for the open tanks

For every course i, the axial compressive stress which exists at

the lower edge and consists of the dead weight, the partial

vacuums pu, puK and pus as well as the snow and wind loads is

determined in the most unfavourable combination in each case

and is validated with the buckling stress k,i,d.

ToC

EK

s Z 2.5

r

p kM,d = 0.67 C * ---------------- ------ -----

M

hZ r

R&D INTAKE MANIFOLDS

4.2.2.1 Axial stability

vorh

i,d

lated from:

N/mm2

with

vorh

where ei is the eccentricity in relation to the thicker of the two

neighbouring courses in the case of a graduated cylinder if this is

itself thicker than the course i under consideration.

d

A 2l l

= --------------------------------------------- 1

k,d

It is necessary to comply with the following condition for every

course i:

It is necessary to investigate the combinations in Table 7.

5

vorh

A 2l I

i,d

A,i = ------------------------------------------------ 1

k,i,d

(49)

4.2.2.2 Shell pressure stability

The crucial partial vacuum resulting from the most unfavourable

combination of the partial vacuums pu, puK, pus and peu is validated with the critical shell pressure pkM,d.

The following condition must be fulflled:

vorh

A 2l l

pd

M = -------------------------------------------- 1

p kM,d

(50)

The critical shell pressure of the non-graduated cylinder is calcu-

(55)

(56)

Appendix

5.1 Explanations

This technical code was elaborated by DVS-AG W4.3b ("Structural designing / apparatus engineering") together with the committee of experts "Plastic tanks and pipes" (project group "Calculation").

During the revision, a distinction was made as to whether the

tanks had to be dimensioned exclusively with regard to the loads

resulting from the internal pressure due to the filling material and

the filling height (this corresponds to the viewpoint of the 1974

edition) or whether any additional loading cases (e.g. wind or

snow loads) had to be taken into consideration during the dimensioning. The latter approach was chosen for the new edition of

this technical code.

Table 7. Load combinations for the stability calculation of the roof.

Installation

Combination

pd

Temp.

max F1 g D + F2 p uK F1 g D + F2 p us

TDK

Outdoors

Winter

max F1 g D + F2 p S + p uK F1 g D + F2 0.7 p S + p us

0°C

Outdoors

Summer

max F1 g D + F2 p uK F1 g D + F2 p us

50°C

Indoors

vorh

225

Page 11 to DVS 2205-2

The application relating to the "installation and operation of tanks

within buildings" is dealt with in Supplement 1.

pr EN ISO 15014

Extruded panels made of polyvinylidene fluoride (PVDF); requirements and test procedures

Supplement 2 includes the dimensioning for collecting devices

(collecting tanks).

5.2.4 Pipes and fittings

Supplement 3 includes the dimensioning for flat roofs.

DIN 8061

Pipes made of unplasticised polyvinyl chloride –

General quality requirements

DIN 8062

Pipes made of unplasticised polyvinyl chloride

(PVC-U and PVC-HI); dimensions

DIN 8074

Pipes made of polyethylene (PE) – PE 63, PE 80,

PE 100 and PE-HD – Dimensions

DIN 8075

Pipes made of polyethylene (PE) – PE 63, PE 80,

PE 100 and PE-HD – General quality requirements and tests

DIN 8077

Pipes made of polypropylene (PP) – PP-H 100,

PP-B 80 and PP-R 80 – Dimensions

DIN 8078

Pipes made of polypropylene (PP) – PP-H (Type

1), PP-B (Type 2) and PP-R (Type 3) – General

quality requirements and testing

DIN 8079

Pipes made of chlorinated polyvinyl chloride

(PVC-C) – PVC-C 250 – Dimensions

DIN 8080

Pipes made of chlorinated polyvinyl chloride

(PVC-C) – General quality requirements and testing

DIN 4740-1

Ventilation and air conditioning installations; pipes

made of unplasticised polyvinyl chloride (PVC-U)

– Calculation of the minimum wall thicknesses

R&D INTAKE MANIFOLDS

5.2 Standards and technical codes

5.2.1 Fundamentals of calculation

DIN 1055-3

Effects on load-bearing structures – Dead and

useful loads for high-rise structures

DIN 1055-4

Effects on load-bearing structures – Wind loads

DIN 1055-5

Effects on load-bearing structures – Snow and ice

loads

DIN 4119-1

Above-ground cylindrical flat-bottom tank structures made of metallic materials; fundamentals,

execution and tests

DIN 4119-2

Above-ground cylindrical flat-bottom tank structures made of metallic materials; calculation

DIN 18800-4

Steel structures; stability cases; shell bulges

DIN EN 1778 Characteristic parameters for welded thermoplastic structures; determination of the permissible

stresses and moduli for the calculation of thermoplastic components

5.2.2 Moulding materials

DIN EN ISO

1872-1

Polyethylene (PE) moulding materials

Part 1: Designation system and basis for specifications

DIN EN ISO

1872-2

Polyethylene (PE) moulding materials

Part 2: Manufacture of test specimens and determination of properties

DIN EN ISO

1873-1

Polypropylene (PP) moulding materials

Part 1: Designation system and basis for specifications

DIN EN ISO

1873-2

Polypropylene (PP) moulding materials

Part 2: Manufacture of test specimens and determination of properties

Unplasticised polyvinyl chloride (PVC-U) moulding

materials

Part 1: Designation system and basis for specifications

DIN EN ISO

1163-1

DIN EN ISO

1163-2

Unplasticised polyvinyl chloride (PVC-U) moulding

materials

Part 2: Manufacture of test specimens and determination of properties

DIN EN ISO

12086-1

Fluoropolymer dispersions, moulding materials and

extrusion materials

Part 1: Designation system and basis for specifications

DIN 16 961-1 Pipes and fittings made of thermoplastics with

profiled walls and smooth inside pipe surfaces –

Part 1: Dimensions

DIN 16 961-2 Pipes and fittings made of thermoplastics with

profiled walls and smooth inside pipe surfaces –

Part 2: Technical terms of delivery

DIN EN ISO

15494

Plastic piping systems for industrial applications –

Polybutene (PB), polyethylene (PE) and polypropylene (PP) – Part 1: Requirements on piping

parts and piping systems – Metric series

DIN EN ISO

15493

Plastic piping systems for industrial applications –

Acrylonitrile butadiene styrene (ABS), unplasticised polyvinyl chloride (PVC-U) and PVC-C –

Requirements on piping parts and piping systems

5.2.5 DVS technical bulletins and technical codes

DVS 2205

Calculation of tanks and apparatus made of thermoplastics;

Part 1 -; characteristic values

Part 3 -; welded joints

Part 4 -; flanged joints; as well as supplement

DVS 2201

Testing of semi-finished products made of thermoplastics

Part 1: Fundamentals – Remarks

Part 2: Weldability and test procedures – Requirements

DVS 2206

Testing of components and structures made of

thermoplastics

DIBt

Media list for tanks, collecting devices and pipes

made of plastic

5.2.3 Panels and welding filler materials

DIN EN 12943

Welding filler materials for thermoplastics;

scope of application, identification, requirements and testing

DIN EN ISO

14632

Extruded panels made of polyethylene

(PE-HD); requirements and test procedures

E-DIN EN ISO

15527

Pressed panels made of polyethylene

(PE-UHMW, PE-HMW and PE-HD); requirements and test procedures

DIN EN ISO

15013

Extruded panels made of polypropylene (PP);

requirements and test procedures

DIN 16927

Panels made of unplasticised polyvinyl chloride; technical terms of delivery

E-DIN EN ISO

11833-1

Plastics, panels made of unplasticised polyvinyl

chloride; delivery forms, dimensions and properties; Part 1: Panels with thicknesses > 1 mm

226

5.3 Literature

[1] Timoshenko, S.: Theory of plates and shells. McGraw Hill

Book Comp, New York / London 1959.

[2] Kempe, B.: Deformation measurements on a tank made of

high-density polyethylene in the case of a temperature

change. Schw. Schn. 42 (1990), No. 4, p. 173.

[3] Tuercke, H.: On the stability of tanks made of thermoplastics, DIBt Communications, No. 5/1995.

Page 12 to DVS 2205-2

5.4 Temperature-dependent and time-dependent elastic

moduli for stability and deformation calculations

5.5 Design-related details

T oC

Table 8. Temperature-dependent short-time elastic moduli E K

N/mm2.

in

The following design examples are indicated in this section:

– nozzle in the cylinder shell, Fig. 8

– anchoring of the bottom, Fig. 9

– lifting lug, Fig. 10

– connection between the shell and the bottom, Fig. 11

– connection between the shell and the roof, Fig. 12

– edge of open tanks, Fig. 13

R&D INTAKE MANIFOLDS

Material 10°C 20°C 30°C 40°C 50°C

60°C 70°C 80°C

PE-HD

1,100

800

550

390

270

190

–

–

PP-H

1,400 1,200

960

770

620

500

400

320

PP-B

1,200 1,000

790

630

500

400

320

250

PP-R

1,000

620

490

380

300

230

180

3,200 3,000 2,710 2,450 2,210 2,000

–

–

10°C 20°C 40°C 60°C 80°C 100°C

–

–

–

–

PVC-NI

PVDF

800

1,900 1,700 1,330 1,050

820

650

20 oC

Table 9. Time-dependent long-time elastic moduli E L

in N/mm2.

Material 1 year 5 years 10 years 15 years 20 years 25 years

PE-HD

308

269

254

245

239

235

PP-H

464

393

365

350

340

330

PP-B

405

334

307

293

283

275

PP-R

322

298

288

283

279

276

PVC-NI 1,800

1,695

1,652

1,627

1,609

1,600

763

744

733

725

720

PVDF

810

Remark: The elastic moduli for PE-HD may also be used for

PE 63, PE 80 and PE 100. The long-time elastic moduli

for PE apply to stresses 0.5 N/mm² and those for

PP to 1 N/mm². The stress dependence of the elastic moduli for PVC-NI and PVDF can be neglected.

Figure 8.

Nozzle in the cylinder shell.

Without a gap and without pressing

Anchor bolt

Claw: steel

PE sheet 2 mm

Spacer plates

Minimum number

of claws: 4

Figure 9.

Anchoring of the bottom.

227

Page 13 to DVS 2205-2

Use a cross-beam for the lifting

of the tank

R&D INTAKE MANIFOLDS

Bei

von

bÖ aauch

eckiger

If

bÖEinhaltung

is complied

with,

square

Anschluss möglich

connection

is also possible.

Figure 10.

Lifting lug.

ü without anchoring

ü with anchoring

Figure 11. Connection between the shell and the bottom.

Figure 13. Edge of open tanks.

228

Extruder weld

Figure 12. Connection between the shell and the roof.

File:

Erstellt am:

Zuletzt geändert am:

D:\Eigene Dateien\Kunden\DVS\Ri+Me\2205\Teil 2 englisch\e2205-2bb1.fm

07.10.2008

08.10.2008

December 2008

DVS – DEUTSCHER VERBAND

FÜR SCHWEISSEN UND

VERWANDTE VERFAHREN E.V.

Calculation of tanks and apparatus made

of thermoplastics

Welded stationary tanks in the case

of installation in buildings

Technical Code

DVS 2205-2

R&D INTAKE MANIFOLDS

Supplement 1

Translation of the German edition from November 2003

Reprinting and copying, even in the form of excerpts, only with the consent of the publisher

Contents:

1

2

3

3.1

3.1.1

3.1.2

3.1.3

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.3

4

4.1

4.1.1

4.1.2

4.1.3

4.1.4

4.2

4.2.1

4.2.2

5

5.1

5.2

5.3

5.4

5.5

1

Restriction on the main dimensions:

Scope of application

Calculation variables

Loading

Continuously effective loads

Total dead load

Load of the filling material

Internal and external pressures

Loads effective for a short time

Internal and external pressures

Partial vacuum due to wind suction

Moving loads on the roof

Assembly loads

Temperature

Proof of the steadiness

Proof of the strength

Shell

Bottom

Nozzles

Lifting lugs

Proof of the stability

Shell

Conical roof

Appendix

Explanations

Standards and technical codes

Literature

Computational elastic moduli for stability calculations

Design-related details

Scope of application

The following design and calculation rules apply to vertical, cylindrical flat-bottom tanks which are fabricated from thermoplastics

in the factory, in particular:

– polyethylene (PE)

– polypropylene (PP)

– polyvinyl chloride (PVC)

– polyvinylidene fluoride (PVDF)

This part of the technical code is only applicable to the installation

of the tanks in buildings.

The cylindrical shell with an identical wall thickness throughout or

with a graduated wall thickness can be welded together from

panels or may consist of a wound pipe or an extruded pipe.

Consideration must be given not only to the hydrostatic loading

but also to pressures effective for short and long times. The

following minimum values are stipulated:

Overpressure:

Partial vacuum:

0.0005 N/mm² (0.005 bar)

0.0003 N/mm² (0.003 bar)

The pressures effective for a long time may only be applied if

they can also take effect.

Tank diameter:

d≤4m

Ratio:

h/d ≤ 6

Minimum wall thicknesses: s = 4 mm

Attention must be paid to the responsibilities of certain legal fields

(e. g. building law, water law, occupational health and safety law

etc.).

2 Calculation variables

a

AB

AD

AZ

A1

mm

m²

m²

m²

–

A2

–

A2l

–

bÖ

C

C1

C2

d

dA

dL

dmax

dmin

dSch

mm

–

–

–

mm

mm

mm

mm

mm

mm

N/mm²

E

fs

fsD

fz

g

GB

GD

GE

GF

GZ

h

hF

hF,i

hZ

–

–

–

m/s²

N

N

N

kN

N

mm

mm

mm

mm

Weld thickness

Area of the bottom

Area of the roof

Shell area of the cylinder

Reduction factor for the influence of the specific

toughness (corresponds to A4 according to the

DVS 2205-1 technical code)

Reduction factor for the medium in the case of

the proof of the strength

Reduction factor for the medium in the case of

the proof of the stability

Width of the lifting lug

C1 ⋅ C2

Stress-increasing factor

Material-specific design factor

Nominal inside diameter

Outside diameter of the nozzle

Hole diameter in the lifting lug

Maximum cylinder diameter

Minimum cylinder diameter

Diameter of the shackle

Elastic modulus in the case of short-time loading for T°C

Long-time welding factor

Long-time welding factor for the roof

Short-time welding factor

Acceleration due to gravity (9.81 m/s²)

Dead load of the bottom

Dead load of the roof

Total dead load

Load of the filling material

Dead load of the cylinder

Height of the tank

Filling height

Filling height of the course i

Cylindrical height

This publication has been drawn up by a group of experienced specialists working in an honorary capacity and its consideration as an important source of information

is recommended. The user should always check to what extent the contents are applicable to his particular case and whether the version on hand is still valid. No

liability can be accepted by the Deutscher Verband für Schweißen und verwandte Verfahren e.V., and those participating in the drawing up of the document.

DVS, Technical Committee, Working Group "Joining of Plastics"

Orders to: DVS Media GmbH, P. O. Box 10 19 65, 40010 Düsseldorf, Germany, Phone: + 49(0)211/1591- 0, Telefax: + 49(0)211/1591-150

229

Page 2 to DVS 2205-2 Supplement 1

hZ,i

hZF

K

mm

mm

N/mm²

Height of the course i

Height of the lower course

Creep strength for 10-1 hours

K

N/mm²

lo

mm

lm

mm

lu

mm

pstat

N/mm²

pstat,i

N/mm²

pu

N/mm²

puK

N/mm²

pus

pü

püK

sa

sB

sD

sM

N/mm²

N/mm²

N/mm²

mm

mm

mm

mm

sÖ

sZ

sZF

sZFC

mm

mm

mm

mm

sZFR

–

sZ,1

sZ,i

TA

TD

TM

TW

TZ

u

V

vA

αD

βF

βS

δB

δF

δS

ε

γF

γI

–

mm

–

–

mm

–

°C

%

m³

–

°

–

–

–

mm

mm

%

Creep strength for the computational working

life at the mean effective temperature

Length of the upper course of the equivalent

cylinder

Length of the central course of the equivalent

cylinder

Length of the lower course of the equivalent

cylinder

Overpressure at the tank bottom due to the filling medium

Overpressure per lower edge of the graduation

due to the filling medium

Continuously effective external pressure (or internal partial vacuum)

External pressure (or internal partial vacuum)

effective for a short time

Partial vacuum due to wind suction

Continuously effective internal pressure

Internal pressure effective for a short time

Executed wall thickness of the basic component

Wall thickness of the bottom

Wall thickness of the roof

Wall thickness of a one-course cylinder

resulting from the partial vacuum stability

Wall thickness of the lifting lug

Wall thickness of the cylinder

Wall thickness of the lowest course

Statically required wall thickness resulting from

the longitudinal stress

Statically required wall thickness resulting from

the ring tension

Wall thickness of the highest course

Wall thickness of the course i

Outdoor air temperature

Temperature of the roof

Media temperature

Wall temperature of the collecting device

Temperature of the tank wall

Permissible out-of-roundness

Filling volume

Weakening coefficient

Pitch of the roof

Coefficient for the calculation of the roof

Coefficient for the calculation of the roof

Coefficient for calculation of the bottom

Coefficient for the calculation of the roof

Coefficient for the calculation of the roof

Tolerable edge fibre expansion

Partial safety coefficient of the effect/stresses

Weighting factor depending on the loading type

(see DVS 2205-2)

Partial safety coefficient of the resistance/

stressability

Angle of the roof in relation to the perpendicular

Coefficient for the shell pressure stability

Density of the material (γ = ρ ⋅ g)

Density of the filling medium

γM

κ

λ

ρ

ρF

230

°

–

g/cm³

g/cm³

R&D INTAKE MANIFOLDS

Figure 1.

Open flat-bottom tank with a non-graduated wall thickness.

Figure 2.

Open flat-bottom tank with a graduated wall thickness.

Figure 3.

Flat-bottom tank with a conical roof and a non-graduated wall

thickness.

Page 3 to DVS 2205-2 Supplement 1

3.2.1 Internal and external pressures püK and puK

As far as no higher pressures can occur as a result of the

operating method, the minimum pressures indicated in Section 1

must be taken into consideration. The definition of püK results in

püK ≥ pü (see Figure 5). The same applies analogously to puK.

The following conditions must be complied with for the pressures

effective for a short time:

R&D INTAKE MANIFOLDS

K*

≤ ---------- ⋅ p

K*

K*

≤ ---------- ⋅ p

K*

and p

Pressure

p

Time

Figure 4.

Flat-bottom tank with a conical roof and a graduated wall thickness.

Figure 5.

Definition of p

.

3.2.2 Partial vacuum due to wind suction

3

Loading

In the case of ventilated tanks, an internal partial vacuum results

from a suction effect (on this subject, see the DVS 2205-2

technical code, Section 3.3.5).

3.1 Continuously effective loads

Depending on the application, tanks are designed for a computational operating time of up to 25 years (2 ⋅ 105 hours). The computational filling height hF is determined by the existing operating

conditions.

3.1.1 Total dead load GE

GE = G D + G Z + G B

N

(1)

N

(2)

N

(3)

N

(4)

Dead load of the cylinder GZ:

GZ = AZ ⋅ sZ ⋅ ρ ⋅ g

Dead load of the bottom GB:

GB = A B ⋅ s B ⋅ ρ ⋅ g

3.2.3 Moving loads on the roof

It is not allowed to walk on the roofs without taking any loaddistributing measures. Corresponding precautions must be taken

during assembly and inspection work.

3.2.4 Assembly loads

Dead load of the roof GD:

GD = A D ⋅ s D ⋅ ρ ⋅ g

pus = 0.48 ⋅ 10-3 N/mm² is applicable if the ventilation is carried

out through a pipe leading to the outside.

Ladders, platforms, pedestals and similar items must be set up

and fastened independently of the tank since the free expansion

of the tank (e. g. during filling and emptying and in the case of

temperature changes) would otherwise be hindered. These

hindrances cause considerable stress peaks which are difficult to

record computationally and, if they are taken into account, lead to

uneconomic designs. If there is any deviation from this, corresponding proof must be provided.

The tank must be designed for the loading conditions arising

during the transport and the assembly. In this respect, the

calculation is made with 1.5 times the assembly loads (surge

factor). γF1 is estimated as the partial safety coefficient. The

short-time welding factor according to DVS 2205-1 must be taken

into consideration.

3.3 Temperature

The effective wall temperature is decisive for the dimensioning of

the components. Wetted parts must always be designed for the

media temperature TM. For non-wetted parts, the mean of the two

neighbouring air temperatures may be estimated as the wall temperature using a simplifying method. The media temperature is

assumed to be the air temperature in the tank and TA = 20°C the

mean outdoor air temperature over a long time in the case of indoor installation. The wall temperatures are indicated on Figure 6.

3.1.2 Load of the filling material GF

GF = V ⋅ ρ F ⋅ g

kN

(5)

3.1.3 Internal and external pressures pü and pu

Higher pressures than indicated in the scope of application must

be taken into account at the level set by the operator.

If any safety fittings which cause higher pressures (such as overfilling protection devices or ventilation and venting facilities) are

connected, these pressures must be taken into consideration.

These pressures must not be effective when the tank has been

emptied since the bottom would otherwise be in danger or the

tank would be lifted.

3.2 Loads effective for a short time

The effective duration of loads effective for a short time is stipulated as 10-1 hours (e. g. assembly loads).

Any water hammers which may arise during filling operations

must be prevented by taking suitable measures.

Without

collecting device

Figure 6.

With

collecting device

Definition of the effective temperatures.

231

Page 4 to DVS 2205-2 Supplement 1

Outdoor air temperature: TA = 20°C in the case of indoor installation

Without collecting device

Material

Edge fibre expansion ε

PE-HD

1.00

TD = (TM + TA)/2

PP-H

0.50

TZ = (3 ⋅ TM +TA)/4

PP-B

0.75

PP-R

1.00

PVDF

0.50

PVC-U

0.20

PVC-C

0.10

With collecting device

R&D INTAKE MANIFOLDS

TD = (TM + TA)/2

TZ = (TM + TA)/2

4

Table 1. Tolerable edge fibre expansion.

Proof of the steadiness

The proof of the steadiness is provided according to the concept

of the partial safety coefficients. In this respect, the characteristic

effects or the stresses are multiplied by the partial safety

coefficients γF according to the following table:

Effect

Partial safety coefficient

Dead weight, filling and assembly

γF1 = 1.35

Pressures

γF2 = 1.5

Remark: The value for PE-HD may be used for PE 63, PE 80

and PE 100.

The factor C for the welded interface of the bond between the

bottom and the shell is the product of the stress-increasing factor

C1 = 1.2 and a material-specific design factor C2 according to

Table 2.

Moreover, the effects are multiplied by the reduction factors A1

and A2 as well as by the weighting coefficent γI.

The characteristic resistances or the stressabilities are divided by

the partial safety coefficient γM = 1.1.

Table 2. The material-specific design factor C and the factor C for

thermoplastics.

Material

C2

C = C1 ⋅ C2

4.1 Proof of the strength

PE-HD

1.00

1.20

4.1.1 Shell

PP-H (Type 1)

1.17

1.40

The height of the lowest course hZF must be min. 1.4 ⋅ d ⋅ s

PP-B (Type 2)

1.00

1.20

In the case of graduated tanks, neighbouring courses may have

a wall thickness ratio of max. 3 without any further proof. In the