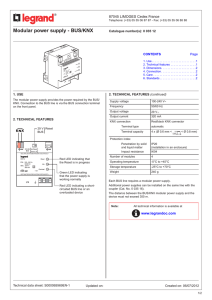

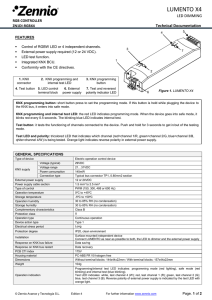

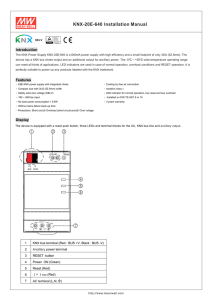

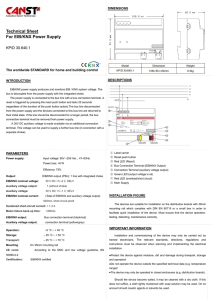

KNX Partner Training Course: System Arguments & Applications

advertisement