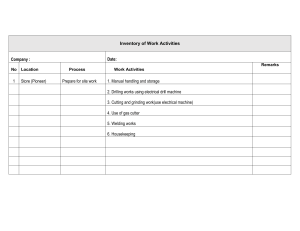

Inventory of Work Activities Company : HYDRO ONE PTE LTD Date:27-08-2021 Remarks No 1 Location Store (Pioneer) Process Prepare for site work Work Activities 1. Manual handling and storage 2. Drilling works using electrical drill machine 3. Cutting and grinding work(use electrical machine) 4. Use of gas cutter 5. Welding works 6. Housekeeping RISK ASSESSMENT Company: Hydro one pte ltd RA Leader: Anandnan Dhinesh Approved By: Process: Prepare for site work RA Members 1: Lu Xingang Signature: Activity Location: Store (Pioneer) RA Members 2: Original Assessment Date: 27-08-2021 RA Members 3: Name: Last Review Date: 27-08-2021 RA Members 4: Designation: Next Review Date: 26-08-2024 RA Members 5: Date: 1. Hazard Identification No 1 Activity Manual handling and storage Hazard Improper handling of materials Revision No. 00 2. Risk Evaluation Possible Accident / Ill Health & Persons-at-Risk Cuts 3. Risk Control Initial Risk Index Existing Risk Control Use trolley. secure material before transport Buddy system for long or heavy materials (max. 25kg) Slow down when approaching blind spots. Pre Task Briefing. Wear hand gloves and safety shoes properly. Bodily Injuries Likelihoo d Severity Catastrophic (5) Document No.00 S L R 3 3 9 Additional Risk Control Measures Close supervising. Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 5 10 15 20 25 Major (4) 4 8 12 16 20 Moderate (3) 3 6 9 12 15 Minor (2) Negligible (1) 2 1 4 2 6 3 8 4 10 5 Residual Risk Index S L R 3 2 6 Action by: Designation (Follow up-date) Supervisor 1. Hazard Identification No Activity Hazard Improper storage 2 Drilling works using electrical drill machine Moving machine parts 2. Risk Evaluation Possible Accident / Ill Health & Persons-at-Risk Bodily Injuries Bodily Injuries 3. Risk Control Initial Risk Index Existing Risk Control Barricade and install warning signage Materials stored should not exceed 1.5m height. Do not store materials close to the opening or edge of building All materials shall be raised above floor level in store. Maintain good housekeeping. Chemical and gas don’t put inside the store. Machine guard and emergency switch in place. No loose clothing / jewelry. Disconnect and remove power source when not in use. Do not modify. Wear proper hand gloves. Cuts Likelihoo d Severity Catastrophic (5) S L R 3 2 6 3 2 6 Additional Risk Control Measures Residual Risk Index Action by: Designation (Follow up-date) S L R Refresher training to workforce to remind on RA/SWP control measures. 3 1 3 Supervisor Refresher training to workforce to remind on RA/SWP control measures. 3 1 3 Supervisor : Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 5 10 15 20 25 Major (4) 4 8 12 16 20 Moderate (3) 3 6 9 12 15 Minor (2) Negligible (1) 2 1 4 2 6 3 8 4 10 5 1. Hazard Identification No Activity Hazard Equipment Handling - Improper Use - Damaged 2. Risk Evaluation Possible Accident / Ill Health & Persons-at-Risk Bodily Injury 3. Risk Control Initial Risk Index Existing Risk Control Cordon work area (Barricade, warning signage). Machine guard and emergency switch in place. Monthly maintenance. Physical checks on equipment. Pre use checks. Competent LEW monthly inspection for electrical tools/machine. Perform by trained, experienced and competent person. Follow speed recommended by manufacturer Disconnect and remove power source when not in use or before changing bits. Wear proper PPE(hand gloves, shoes,) Cut. Likelihoo d Severity Catastrophic (5) S L R 4 2 8 Additional Risk Control Measures Full time supervision Damaged equipment store one place provide “not in use” signage. Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 5 10 15 20 25 Major (4) 4 8 12 16 20 Moderate (3) 3 6 9 12 15 Minor (2) Negligible (1) 2 1 4 2 6 3 8 4 10 5 Residual Risk Index S L R 4 1 4 Action by: Designation (Follow up-date) Supervisor 1. Hazard Identification No Activity Hazard Electrical hazards Dust 2. Risk Evaluation Possible Accident / Ill Health & Persons-at-Risk 3. Risk Control Initial Risk Index Existing Risk Control Cables to be hung clear of wet ground. Full time supervision Disconnect and remove power source when not in use or before changing bits No modification of tools / equipment. Monthly maintenance. Competent LEW monthly inspection for electrical tools/machine. Wear proper PPE. Eye Irritation Respiratory problem Sweep or vacuum the work area after work. Wetting of workplace. Briefing during toolbox meeting Wear dust mask, safety googles. Electric Shock Likelihoo d Severity Catastrophic (5) S L R 4 2 8 3 2 6 Additional Risk Control Measures Residual Risk Index Action by: Designation (Follow up-date) S L R Refresher training to workforce to remind on RA/SWP control measures. 4 1 4 Supervisor Refresher training to workforce to remind on RA/SWP control measures. 3 1 3 Supervisor Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 5 10 15 20 25 Major (4) 4 8 12 16 20 Moderate (3) 3 6 9 12 15 Minor (2) Negligible (1) 2 1 4 2 6 3 8 4 10 5 1. Hazard Identification No Activity Hazard Noise 3 Cutting and grinding works. Fire (Sparks from cutter) 2. Risk Evaluation Possible Accident / Ill Health & Persons-at-Risk 3. Risk Control Initial Risk Index Existing Risk Control Hearing discomfort. Noise barrier to be installed at noisy work area if possible. Deafness Noise level to be monitored. Noise pollution Machineries to be maintained properly. Job rotation. Double hearing protection (for noise exceeding 85dB) Briefing during toolbox meeting Ensure PPE is worn. (ear plug) Burns, bodily injuries/death Fire blankets to be set up to shield workers from fire hazards Property damage Fire watchman to be present when grinding/cutting is going on Explosion Only Competent person to carried angle cutting work. Flammable of combustible materials shall be stored away from the work area. Likelihoo d Severity Catastrophic (5) Additional Risk Control Measures S L R 3 2 6 Close supervision 5 2 10 Residual Risk Index Action by: Designation (Follow up-date) S L R 3 1 3 Supervisor : Engage fire watch 5 with proper training at the time of cutting and grinding work. 1 5 Supervisor After completion of hot work standby the firewatcher for min of 30 Mins. Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 5 10 15 20 25 Major (4) 4 8 12 16 20 Moderate (3) 3 6 9 12 15 Minor (2) Negligible (1) 2 1 4 2 6 3 8 4 10 5 1. Hazard Identification No Activity Hazard Poisonous fumes Noise 2. Risk Evaluation Possible Accident / Ill Health & Persons-at-Risk Initial Risk Index Existing Risk Control Respiratory illness/unconscio usness Deafness 3. Risk Control Fire extinguisher must be readily available and in good condition at the work area Wear face shield and welding gloves. Provide localized mechanical ventilation. Close supervision Specific briefing on hot works to be given during toolbox meeting Wear mask properly. Noise barrier to be installed at noisy work area (where possible). Machineries to be maintained properly Job rotation Double hearing protection (for noise exceeding 85dB) Noise pollution Likelihoo d Severity Catastrophic (5) S L R 3 2 6 3 2 6 Additional Risk Control Measures Residual Risk Index Action by: Designation (Follow up-date) S L R Refresher training to workforce to remind on RA/SWP control measures. 3 1 3 Supervisor Refresher training to workforce to remind on RA/SWP control measures. 3 1 3 Supervisor Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 5 10 15 20 25 Major (4) 4 8 12 16 20 Moderate (3) 3 6 9 12 15 Minor (2) Negligible (1) 2 1 4 2 6 3 8 4 10 5 1. Hazard Identification No Activity Hazard Poor Cable Management Equipment / Tools Handling - Improper Use - Damaged 2. Risk Evaluation Possible Accident / Ill Health & Persons-at-Risk Bodily Injury due to Slip/Trip/Fall Electric Shock Initial Risk Index Existing Risk Control Close supervision Briefing during toolbox meeting Ensure PPE is worn. (ear plug Elevate cables above ground using cable stand Cables to be hung on nonconductive supports Cables to be hung clear of wet ground Briefing during toolbox meeting Cordon work area (Barricade, warning signage) Bodily Injury Cuts 3. Risk Control Ensure machine guards and emergency switch in place Ensure that the cutting disc, guard and attachments (including handle) are secure and correctly fitted. Likelihoo d Severity Catastrophic (5) S L R 3 2 6 4 2 8 Additional Risk Control Measures Residual Risk Index Action by: Designation (Follow up-date) S L R Refresher training to workforce to remind on RA/SWP control measures. 3 1 3 Supervisor Full time supervision 4 1 4 Supervisor Refresher training to workforce to remind on RA/SWP control measures. Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 5 10 15 20 25 Major (4) 4 8 12 16 20 Moderate (3) 3 6 9 12 15 Minor (2) Negligible (1) 2 1 4 2 6 3 8 4 10 5 1. Hazard Identification No 4 Activity Gas cutting Work Hazard Fire 2. Risk Evaluation Possible Accident / Ill Health & Persons-at-Risk Initial Risk Index Existing Risk Control Burns, bodily injuries/death Inspect the cutting disc for damage. Do not use damaged grinding disc. Pre Task briefing Pre use checks Perform by trained, experienced and competent person Monthly LEW Checks Disconnect and remove power source when not in use or before changing bits No modification of tools / equipment Fire watchman and fire extinguisher to be present when gas cutting going on. Inspect the work area before start work. Remove flammable material. Property damage Explosion 3. Risk Control Perform by trained, experienced and competent person. Full time supervision Likelihoo d Severity Catastrophic (5) S L R 5 2 10 Additional Risk Control Measures Residual Risk Index S L R Engage fire watch 5 with proper training at the time of gas cutting work. 1 5 After completion of hot work standby the firewatcher for min of 30 Mins. Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 5 10 15 20 25 Major (4) 4 8 12 16 20 Moderate (3) 3 6 9 12 15 Minor (2) Negligible (1) 2 1 4 2 6 3 8 4 10 5 Action by: Designation (Follow up-date) Supervisor 1. Hazard Identification No Activity Hazard Poor hose management Hose Improper use 2. Risk Evaluation Possible Accident / Ill Health & Persons-at-Risk 3. Risk Control Initial Risk Index Existing Risk Control Gas cylinder must be stand and secure. Use cylinder stand. Wear proper PPE. Elevate hose above ground Hose do not put sharp edge. Pre task briefing Burns Do not use damaged hose. Bodily Injuries Ensure flashback arrester and pressure regulator fix properly. Before start work must check full hose and every joint part of hose. Must use soap oil. Full time supervision Pre Task briefing Don’t do any modification Bodily Injuries Likelihoo d Severity Catastrophic (5) S L R 4 2 8 4 2 8 Additional Risk Control Measures Residual Risk Index Action by: Designation (Follow up-date) S L R Refresher training to workforce to remind on RA/SWP control measures. 4 1 4 Supervisor Refresher training to workforce to remind on RA/SWP control measures. 4 1 4 Supervisor Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 5 10 15 20 25 Major (4) 4 8 12 16 20 Moderate (3) 3 6 9 12 15 Minor (2) Negligible (1) 2 1 4 2 6 3 8 4 10 5 1. Hazard Identification No 5 Activity Welding work Hazard Electrical hazards Fire 2. Risk Evaluation Possible Accident / Ill Health & Persons-at-Risk Initial Risk Index Existing Risk Control Electric Shock Check connection of earth cable. Connect properly Pre Task briefing Pre use checks Perform by trained, experienced and competent person Monthly LEW Checks No modification of tools / equipment Use welding gloves. Fire watchman and fire extinguisher to be present when gas cutting going on. Inspect the work area before start work. Remove flammable material. Perform by trained, experienced and competent person. Full time supervision Bodily Injury Burns, bodily injuries/death Property damage Explosion 3. Risk Control Likelihoo d Severity Catastrophic (5) Additional Risk Control Measures S L R 4 2 8 Refresher training to workforce to remind on RA/SWP control measures. 5 2 10 Residual Risk Index Action by: Designation (Follow up-date) S L R 4 1 4 Supervisor Engage fire watch 5 with proper training at the time of Welding work. 1 5 Supervisor After completion of hot work standby the firewatcher for min of 30 Mins. Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 5 10 15 20 25 Major (4) 4 8 12 16 20 Moderate (3) 3 6 9 12 15 Minor (2) Negligible (1) 2 1 4 2 6 3 8 4 10 5 1. Hazard Identification No Activity Hazard Poisonous fumes 6 Houseke eping. Trip & fall 2. Risk Evaluation Possible Accident / Ill Health & Persons-at-Risk Initial Risk Index Existing Risk Control Respiratory illness/unconscio usness Physical Injuries 3. Risk Control Provide localized mechanical ventilation. Close supervision Specific briefing on hot works to be given during toolbox meeting Wear mask properly. Do not leave any tools or materials unattended. Ensure tools are kept in tool box and stored in storage yard. Unwanted materials and rubbish to be disposed should be throw in a container bin or thrash bag after work. Likelihoo d Severity Catastrophic (5) S L R 3 2 6 3 1 3 Additional Risk Control Measures Refresher training to workforce to remind on RA/SWP control measures. Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 5 10 15 20 25 Major (4) 4 8 12 16 20 Moderate (3) 3 6 9 12 15 Minor (2) Negligible (1) 2 1 4 2 6 3 8 4 10 5 Residual Risk Index Action by: Designation (Follow up-date) S L R 3 1 3 Supervisor - - - Supervisor 5 x 5 Risk Matrix Risk Category Rare (1) Remote (2) Catastrophic (5) Medium (5) Major (4) Moderate (3) Minor (2) Negligible (1) Medium (4) Low (3) Low (2) Low (1) Medium (10) Medium (8) Medium (6) Medium (4) Low (2) Accident Severity Level 5 4 Severity Catastrophic Major 3 Moderate 2 Minor 1 Negligible Likelihood Of Accident Occasional (3) High (15) Medium (12) Medium (9) Medium (6) Low (3) Frequent (4) High (20) High (16) Medium (12) Medium (8) Medium (4) Description Fatality, diseases or multiple major injuries. Serious injuries or life-threatening occupational disease (includes amputations, major fractures, multiple injuries, occupational cancer, acute poisoning). Injury requiring medical treatment or ill-health leading to disability (includes lacerations, burns, sprains, minor fractures, dermatitis, deafness, work-related upper limb disorders). Injury or ill-health requiring first-aid only (includes minor cuts and bruises, irritation, ill-health with temporary discomfort). Not likely to cause injury or ill-health. Level 1 2 3 4 5 Likelihood Rare Remote Occasional Frequent Almost Certain Description Not expected to occur but still possible. Not likely to occur under normal circumstances. Possible or known to occur Common occurrence. Continual or repeating experience Level 1-3 4-12 Risk Low Medium High Description Acceptable Additional control measure will be added Management will not allow job to be done when there is high risk level 15-25 Almost Certain (5) High (25) High (20) High (15) Medium (10) Medium (5) Likelihoo d Severity Catastrophic (5) Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) 5 10 15 20 25 Major (4) 4 8 12 16 20 Moderate (3) 3 6 9 12 15 Minor (2) Negligible (1) 2 1 4 2 6 3 8 4 10 5