Computer-Aided Design 45 (2013) 875–886

Contents lists available at SciVerse ScienceDirect

Computer-Aided Design

journal homepage: www.elsevier.com/locate/cad

Efficient parts nesting schemes for improving stereolithography utilization

Vassilios Canellidis, John Giannatsis, Vassilis Dedoussis ∗

Center for Product Development and Rapid Prototyping, Laboratory of Advanced Manufacturing Technologies & Testing, Department of Industrial Management & Technology,

University of Piraeus, 80 Karaoli & Dimitriou str., 18534 Piraeus, Greece

article

info

Article history:

Received 24 April 2012

Accepted 4 December 2012

Keywords:

Stereolithography

Nesting problem

2D packing

Genetic algorithm

Additive manufacturing

abstract

In the present paper, the platform layout optimization problem for the simultaneous fabrication of

different parts, which is addressed in the batch planning of Stereolithography Additive Manufacturing

technology, is studied. The methodology proposed in the paper employs a Genetic Algorithm technique

for the 2D nesting of parts on the platform of the stereolithography machine. The build orientation

of the parts is assumed fixed and is decided prior to layout optimization, according to part-specific

quality and cost requirements. Three placement schemes, appropriately adapted to the problem, are

considered for the parts nesting and fabrication layout definition. The algorithms and placement schemes

developed are evaluated in several test cases/benchmarks involving parts with both simple and complex

geometries. The computational results included in the paper indicate that the proposed methodology can

lead to satisfactory layout/packing–nesting arrangements in a time efficient manner, leading, therefore,

to substantial improvement of stereolithography machine utilization.

© 2012 Elsevier Ltd. All rights reserved.

1. Introduction

Since their introduction, Additive Manufacturing (AM) technologies have been mainly employed as methods for the production of models and prototypes for new product development;

hence the term Rapid Prototyping has been associated to them.

In AM, parts are fabricated by the controlled addition of material,

usually in the form of thin layers. Some of the most well known

AM technologies are Stereolithography (SL), Selective Laser Sintering, 3D Printing (3DP), Multi-jet Modeling (MJM) and Fused Deposition Modeling (FDM). In recent years the capabilities of AM

technologies with respect to reliability and materials have significantly improved, to the point that they are increasingly employed

for the production of actual end-use products or their components

[1,2]. The main applications of this sort include the production

of geometrically complex and/or highly customized or specialized

products in small numbers. Compared with other manufacturing

methods, AM methods have significant advantages, namely the

capability to fabricate parts of almost any geometry in relatively

short times. On the other hand, the cost per part associated with

AM methods is relatively high. For the successful implementation

of AM in the industrial manufacturing setting, therefore, it is crucial

to achieve cost-effective utilization of the associated equipment

and full exploitation of their capabilities in terms of time and geometrical flexibility. Under this new perspective, the study of process planning problems in AM gains further importance, because

∗

Corresponding author. Tel.: +30 210 414 2320; fax: +30 210 414 2454.

E-mail address: vdedo@unipi.gr (V. Dedoussis).

0010-4485/$ – see front matter © 2012 Elsevier Ltd. All rights reserved.

doi:10.1016/j.cad.2012.12.002

the corresponding decisions of the user/operator of the AM system

significantly affect the perceived production time, cost and quality.

From the applications point of view, the selection of build parameters such as build orientation and layer thickness/pattern, and

the efficient utilization of the machine time and workspace have

been recognized as two of the most important problems in AM process planning [3]. The selection of build parameters concerns the

fabrication of a single part and it is essentially a multi-objective optimization problem, in which the optimum compromise between

fabrication cost and quality under specific constraints is sought. In

this context, several tools have been proposed during the last few

years, in order to aid the operator in the selection of build orientation and layering strategy [4–6]. Efficient utilization of the machine

time and workspace, on the other hand, concerns the simultaneous

production of different (or geometrically similar/identical) parts, in

a time and cost-efficient manner. AM equipment is capable of fabricating various different parts concurrently, in the so-called fabrication jobs, without human supervision. Job setup is performed by

the operator, who chooses and places the parts/products to be built

in a manner that will efficiently utilize the machine workspace,

usually through the maximization of the number of parts per job

or of the corresponding build volume. This way significant cost and

time savings may be gained, because the number of labor intensive and time consuming job setups is reduced, and in some cases

a more efficient use of the AM machine is achieved. The machine

utilization is relatively more important in technologies like SL or

SLS, where the ‘dead’ time associated with the necessary layer recoating or material spreading step, is allocated in as many parts as

possible. Further gains can also be expected in some cases through

876

V. Canellidis et al. / Computer-Aided Design 45 (2013) 875–886

the minimization of the amount of unused or secondary raw material that is discarded after production (e.g. supports and/or trapped

material).

In this paper we concentrate on SL, which is perhaps the most

mature and widely used of all AM technologies. The relevant

problem of raising the degree of utilization of the SL machine is

addressed by determining the optimum placement layout of different parts on the SL machine platform/workspace. The problem is

tackled employing a Genetic Algorithm (GA) approach in conjunction with three different placement schemes, which are based on

established nesting and 2D packing methodologies appropriately

adapted to the SL case. The feasibility and efficiency of the developed schemes is investigated via a series of case studies involving standard benchmark tests and a representative test case with

‘‘real-world’’ parts of quite general free-form geometry.

2. Proposed methodology and problem formulation

The packing or layout planning problem in SL has been the

subject of relatively few studies. Most of the works reported in the

literature concern other AM technologies and address in most of

the cases the fully 3D packing problem using heuristic optimization

schemes, mainly different variations of GA [7–10]. Contrary to

most of the problems investigated in the previous literature, where

the placement of parts to be fabricated on top of others is permitted

(as is the case in powder-based technologies like SLS), in the case

of SL this is not generally advisable because of the adverse effects

of support structures.

In order to be effective, in any optimization approach the specific characteristics and constraints of the particular technology

under investigation should be first considered. These characteristics should then be reflected in the problem formulation and the

construction of the optimization objective function. The most basic

relevant ‘‘constraint’’ in the context of SL seems to be the requirement for support structures which are fabricated concurrently and

by the same material as the part and which are necessary in order

to prevent part/layer drifting and deformations. If a part is placed

over another (along the build direction) the support structure of

the top part will interfere with or ‘‘touch’’ the geometry of the

bottom part, at its top surfaces. This interference can significantly

deteriorate the surface quality (increase the corresponding roughness) and possibly the dimensional accuracy of the bottom part,

as well as increase the required post-processing time (manual polishing/finishing). Due to this, parts in SL are usually placed alongside each other, after of course a proper build orientation for each

one is chosen; hence the packing problem essentially becomes

two-dimensional (2D packing). An alternative approach to resolving this issue and formulating a more holistic approach can be to

construct a weighted multi-criteria objective function that incorporates the technology specific constraints [11], but this approach

seems to be sensitive to the selection of criteria weight values.

Another methodological concern is the apparent trade-off between the quality of the optimization solution and the required

computational time, which is a very important parameter in the

manufacturing environment. For the problem under investigation

significant parameters that affect the quality/time trade-off, besides the choice of a specific optimization technique, are the number of orientations allowed per part and the selection/construction

of a specific placement and interference checking strategy. The

choice of a free orientation scheme, that considers rotations of the

parts about all three axes, will probably lead to significantly better results in terms of packing density than those obtained with a

fixed build orientation per part, where only rotations about the Z

axis are permitted. This approach, on the other hand, significantly

increases the associated complexity and does not guarantee that

specific part quality/cost constraints are satisfied. This is the reason that the middle road, i.e. the examination of a limited set of

acceptable orientations, is proposed in several studies [12,11,13].

Due to the possible adverse effects of support structures in SL

and the need for relatively low computational times, the approach

followed in the present paper examines placement layouts with

parts alongside each other (no part is placed beneath another)

and assumes a fixed build orientation/direction per part. The build

orientation of a part is selected according to part-specific quality, cost and time requirements and constraints, which are defined

by the SL machine operator according to the part’s geometry and

its intended use. Casting patterns and final products, for example,

require high dimensional accuracy and surface finish, while for

concept models low fabrication cost is more significant. For the

purposes of the present study, orientation evaluation is performed

automatically following a methodology proposed by the authors

in [6]. The adopted methodology incorporates a multi-objective

function for the representation of the SL operator’s preferences

regarding the relative importance of build quality, as expressed

by mean part surface roughness due to stair-stepping and contact with supports, and build-time/-cost. According to these preferences, as well as constraints regarding the minimum acceptable

quality and maximum acceptable cost, a GA technique is employed

for the automatic identification of the optimum build orientation

among the many possible. Build-time/-cost and part surface roughness per orientation are evaluated from the STL file according to

experimentally derived formulas described in [14]. Following the

orientation selection for each part and if it is quite obvious that

the parts cannot be fitted in one fabrication job, a sub-grouping

of parts may take place. In this case the operator should try and

group parts by their respective build height (Z dimension) in order

to avoid inefficient packing solutions where ‘‘high’’ parts, with a

relatively high number of layers, are fabricated concurrently with

‘‘low’’ parts, with relatively lower numbers of layers, which sometimes require considerably lower fabrication times.

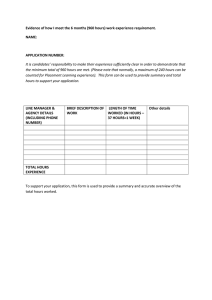

Subsequently the layout planning or platform packing phase

takes place, where the already oriented parts are positioned on

the platform of the machine alongside each other, trying to fit as

many as possible and exploit the available area. In this step the

problem could be said to reside in the dense packing/nesting of

the parts’ projections on the platform plane. The latter polygonal

projection of each part can be computed from the Boolean union of

all the slices that are obtained after slicing the corresponding STL

file (Fig. 1). Having derived the parts projections on the platform

of the SL machine, the sole optimization objective can be defined,

therefore, as that of maximizing the area of the platform that is

covered by the non-overlapping projections of, say n, parts:

n

f =

Projection_Area_of_the_ith_part

i =1

Fabrication_Platform_Area

.

(1)

Under this definition of the objective function, the packing

problem in SL can be considered as a 2D nesting problem [15]. The

2D irregular parts nesting problem is a widely-addressed subject in

various manufacturing sectors such as that of metal products, textiles, footwear and furniture, as well as ship building. Particularly

in the field of metal processing and manufacturing, and especially

in the area of sheet-metal cutting, shearing and stamping, various

problem-solving approaches have been proposed in order to minimize waste material and efficiently automate the part layout planning process.

One of the earliest proposed approaches is that of employing a

sliding algorithm for the optimum nesting of two blanks in sheet

metal stamping [16]. Another approach is proposed by Lamousin

and Waggenspack [17] who employ a heuristic technique for

the progressive nesting of parts through the matching between

V. Canellidis et al. / Computer-Aided Design 45 (2013) 875–886

90

80

70

60

Z 50

40

30

20

10

0

80

60

Y

40

20

0 10

20

30

40

50

60

70

80

90

X

Fig. 1. STL model and its projection on the build platform (XY plane).

complementary features of the parts and the stock material. A

similar boundary nesting approach that employs evolutionary

heuristic techniques is adopted in a study by Tay et al. [18]. In

order to increase the efficiency of the heuristic employed for the

nesting of irregular-shaped polygons a hybrid approach has also

been proposed by Mahanty et al. [19].

Algorithms that optimize the orientation and layout of identical polygonal blanks in a strip for minimum material usage have

been also proposed by Nye [20], Cui and Huang [21], and Licari and

Valvo [22]. The problem of optimum nesting of a large number of

copies of an irregularly shaped part in a limited sheet is investigated by Costa et al. in [23], as well as in a study by Martins and

Tsuzuki [24]. The problem of optimum part layout arrangement in

multiple sheets is addressed in studies by Babu and Babu [25] and

Lee et al. [26]. The nesting problem has also been investigated in

the context of combined manufacturing processes such as sheet

metal cutting and punching [27,28], laser cutting and bending [29]

and the design of progressive dies [30,31]. Integrated computeraided systems that employ nesting algorithms have also been proposed by Rao et al. [32] and Xie et al. [33].

The study of the relevant literature shows that there are two

important methodological decisions that have to be made in order

to address any specific instance of the 2D nesting problem, namely

the selection of an optimization scheme, i.e. how an exploration of

the space of all possible layouts/solutions is performed, and that

of a placement scheme, i.e. how a specific layout is constructed

through the placement of the various parts. The characteristics

and details regarding the optimization and placement schemes

adopted in the present study are given in the following sections.

2.1. Optimization scheme

From an optimization point of view the parts nesting or layout planning problem in SL seems to share the most similarities

with the knapsack problem, according to the typology proposed

in [34]. In this context, the problem is considered as NP-complete

and its complexity is related to the size/shape variety of the parts

and the number of feasible placement positions for each part;

hence heuristic optimization algorithms, like Genetic Algorithms

(GA) and Simulated Annealing (SA), are often applied for solving it.

Heuristic approaches do not guarantee that the global optimum is

877

found, but they can provide ‘‘acceptably good’’ solutions, i.e. solutions close to the global optimum, with low computational effort.

For the problem under investigation GA, which is based on genetics

and evolution theory, has been adopted as the optimization technique. The basic concept behind GA is that the ‘‘genetic pool’’ of a

given set of problem solutions potentially contains traces of the

optimum solution, which can be discovered by controlled ‘‘evolution’’ of the initial population. GA maintains, therefore, a set of

potential solutions (population) that ‘‘evolves’’ in subsequent

‘generations’ towards hopefully better solutions, according to the

principles of ‘‘natural selection’’ and ‘‘survival of the fittest’’. This

evolution is carried out as potential solutions (individuals), represented by chromosomes, are combined in pairs (parents) in order

to produce new chromosomes (offsprings) thus providing a new

generation of individuals. Random changes in individuals (mutations) add a stochastic element to the evolution procedure in order to avoid premature convergence to a local optimum solution.

For a more detailed presentation of the various GA approaches/

variations the reader is referred to [35].

In the context of the present problem employing the GA approach means that a set of randomly-constructed packing layouts/solutions is allowed to ‘‘evolve’’ towards a set that contains

the optimum and/or near-optimum packing layouts. The chromosomal representation (genotype) of packing layouts/solutions utilizes a permutation coding scheme, for which individual solutions

are coded as sequences of integers (genes) that correspond to the

placement sequence of a set of parts. The packing layout π for the

jth chromosome, for example, πj = {5, 3, 7, 1, 2, 4, 6} can be interpreted as the consecutive placement of the projections of seven

parts on the fabrication platform, beginning with the projection of

part no. 5 then that of part no. 3, etc. The placement of each projection is carried out according to a prescribed placement strategy,

which is explained in the next section, thus constructing the corresponding nesting layout (phenotype).

The population evolution is performed following the generally applied GA process presented in Fig. 2. The first step in this

process consists of defining the initial population, i.e. a set of

possible packing layouts/solutions, which is constructed either at

random or by the operator. Then, an evaluation of the ‘‘fitness’’

value for each individual takes place. The fitness value of an individual/chromosome j corresponds to the respective value of the

objective function fj derived from Eq. (1), thus the higher the area

utilization percentage of a solution the higher its fitness. Subsequently, a test of convergence is performed, namely the evaluation

of the difference between the mean fitness value of the population and the fitness value of the best solution. If there is no difference between the two values (the population is homogeneous), it

is assumed that an optimum or near-optimum solution has been

reached and the algorithm terminates, otherwise the population is

allowed to evolve further. The next step in the algorithmic ‘‘evolution’’ involves the selection of layouts/solutions for reproduction,

through the use of specific selection operators. In the present paper the proportional selection approach proposed in [36] has been

adopted. According to this approach, the probability pi of an individual i to be selected for reproduction is proportional to its relative

fitness, as expressed by the following:

pi =

fi

>0

m

(2)

fj

j =1

where m is the number of chromosome/solutions of the population. Following the computation of the reproduction selection

probability for all chromosomes, the interval I = [0, 1) is divided into m sub-intervals, one for each chromosome, denoted by

878

V. Canellidis et al. / Computer-Aided Design 45 (2013) 875–886

for example, that the father-string is π1 = {1, 2, 3, 4, 5, 6, 7}, the

mother-string is π2 = {6, 4, 2, 5, 3, 1, 7}, p = 2 and q = 3. In

this case, the first three genes of the first offspring are selected

from the father-string (2, 3, 4) while the next four empty gene-slots

are filled by the remaining mother-genes, thus producing offspring

π3 = {2, 3, 4, 6, 5, 1, 7}. Similarly, for the construction of the second offspring, q consecutive genes, starting from the p-th gene, are

first selected from the mother-string, while the remaining empty

gene-slots are filled by the corresponding father-genes. The second

offspring, therefore, is π4 = {4, 2, 5, 1, 3, 6, 7}.

The mutation operator, on the other hand, aims at adding diversity to the population through the introduction of new traits that

are not present in the individuals/chromosomes. This operation reduces the probability of converging to a local optimum solution too

fast and before a sufficient amount of the solution space has been

searched, especially when several local optima may be expected. In

the present GA application, mutation is performed by simply swapping the location of two genes in a chromosome, which has been

selected randomly from the population according to the specified

mutation rate.

Following reproduction, the evolution strategy is applied. In this

step, the removal of a number of individuals from the population

is required in order to keep the population size constant. This is

performed by ranking the old and new individuals/chromosomes

according to their fitness value and removing the less-fit excessive

part of the list. The final step of the algorithm is to perform the

convergence test on the newly-created generation in order to

determine whether the termination criterion is satisfied or the

algorithmic evolution will continue.

Fig. 2. Flowchart of the GA employed in the study.

2.2. Placement scheme

Ai (πi , fi ), as follows:

A1 (π1 , f1 ) ↔ I1 = [0, p1 )

A2 (π2 , f2 ) ↔ I2 = [p1 , p1 + p2 )

Aj (πj , fj ) ↔ Ij = [p1 + · · · + pi−1 , p1 + · · · + pi )

Am (πm , fm ) ↔ Im = [1 − pm , 1).

After the association of each individual chromosome Ai (πi , fi ) to

a sub-interval, two random numbers αi ∈ [0, 1), i = 1, 2 are generated. The different intervals, in which the two random numbers

lie, represent the individual chromosomes on which crossover or

mutation operates. If the generated numbers lie within the same

interval, additional random numbers are considered.

In the following reproduction step, new children chromosomes

(‘‘offspring’’) representing new packing layouts/solutions are

‘‘bred’’. Breeding and offspring generation are carried out via two

operators, the crossover and the mutation operator. The crossover

operator aims at the preservation and improvement of promising

genetic material from one generation to the next by selecting two

chromosomes from the population (according to their respective

selection probability) and producing a new, possibly better, chromosome that combines features of both its parents. Currently there

are quite a few rules that could be followed in crossover operation,

but there is not a unique operator that performs well in all cases,

as its performance is usually problem specific [35]. For the permutation type of problems such as the present one, the SJX operator,

introduced by Jakobs [37], has been found to perform quite well

and has been adopted in this work. Given a father and a mother

string/permutation, as well as two integers p and q, the SJX operator produces two offspring. For the construction of the offspring the

operator selects q consecutive genes, starting from the pth gene,

from the first parent, and fills in the remaining offspring genes with

the corresponding different genes of the second. In order to clarify

the function of the operator an example is given in Fig. 3. Suppose,

The issue of placement strategies/rules and interference checks

in nesting is quite important, because it influences not only the

quality of the solution but also the required computational effort. Various part placement methods, such as the Left-Bottom, the

Pixel–Raster, the Direct Trigonometry, the No-fit polygon and the

Phi function methods, have been proposed in the nesting problems literature [15]. Each one of them has certain advantages and

disadvantages that make it appropriate for addressing different

variants of the nesting problem. Variations of the Left-Bottom

heuristic technique are usually easy to implement and provide

fast solutions, but are considered to be better suited for simple orthogonal geometries rather than for geometrically complex

arbitrary shapes. Raster/pixel methods are also relatively easily

implemented and are usually employed for non-convex pieces of

moderate geometrical complexity. For geometries of higher complexity and levels of detail, however, the memory requirements increase significantly and this may also lead to significantly higher

computational effort [15,38]. Direct trigonometry methods cope

better with geometrical complexity and highly irregular shapes

but they are also computational expensive [39]. The No-Fit Polygon technique is an efficient and commonly utilized method for

conducting intersection tests between pairs of polygons, but it has

not been widely applied in the context of nesting problems due

to the large number of degenerate cases, which can arise when

various forms of shapes are considered [15,38]. Finally, the phifunction method, which aims at the representation of all mutual

positions of two shapes through mathematical expressions, has not

been broadly adopted, as there is not currently any algorithmic

procedure for generating the required phi-function for arbitrary

shapes [40]. In the context of the present study, three different

placement schemes were examined, the first employing the LeftBottom/Down-Bottom (LBDB) method and the Ray Casting technique, the second employing the No-Fit Polygon method, while the

V. Canellidis et al. / Computer-Aided Design 45 (2013) 875–886

879

Fig. 3. Example of the SJX crossover operator.

18

16

14

12

10

8

6

4

2

0

0

2

4

6

8

10

12

14

16

18

Fig. 4. Schematic representation of the MBR of an arbitrary object.

third is a hybrid one, employing a combination of the previous two

methods.

The LBDB method incorporates rules that aim at placing objects

as close as possible to the platform origins, i.e. the left bottom

corner. In order to reduce the required computational effort, the

Minimum Bounding Rectangle (MBR) of the polygon that should

be placed and the corresponding MBRs of the already placed parts

are initially determined. The MBR is defined as the minimum area

rectangle that encapsulates the convex hull of a polygonal object

as illustrated in the example of Fig. 4.

The Left-Bottom/Down-Bottom rule, which employs vertical

and horizontal insertion lines defined by the borders of the platform and previous MBRs, are then applied in order to evaluate different placement positions for the incoming object. An example of

the LBDB method is presented in Fig. 5, where two possible placement positions for rectangle B are evaluated. The position chosen

for placement is the one that minimizes the distance of the MBR

origin to the platform origin (Fig. 5(c) or (d)). In this position, two

possible MBR orientations, the initial one and its 90° rotation about

the Z axis, are evaluated and the one that leads to the minimum

‘‘height’’ along the Y dimension is chosen.

In order to enhance further the nesting of the incoming polygon

to the previously placed adjacent polygons, a second densification

step involving horizontal and vertical movements is employed. The

extent of possible movements is determined employing casting

of rays from the vertices of the incoming polygon and evaluating

the corresponding distances until another polygon or the platform

boundaries are met (Fig. 6(a)). This procedure is also followed for

selected vertices of previously placed polygons (Fig. 6(b)) and the

minimum of the examined distances is determined. The evaluated

minimum distance and the corresponding vertex define the vector

of translation for the incoming polygon towards the already

placed polygons without interference. The ray-casting process is

performed for both the previously chosen MBR orientation, as well

as its mirror orientation (rotated 180° about the Z axis), and the

one leading to the closest to the platform origin placement is

chosen. In order to further illustrate the ray-casting densification

operation an animated example is presented in Animation 1 (see

the Appendix).

The second placement method is based on the concept of the

No-Fit Polygon (NFP) [15], which can be used to determine all

arrangements that two arbitrary polygons of standard orientation

may assume so that the two shapes touch. These arrangements are

the closest possible that can be defined between the two polygons

without intersection. An intuitively simple method to construct

the NFP of two polygons, say A and B, is to keep one (e.g. A) fixed

in position, while the other traverses around the fixed polygon’s

edges, ensuring that the polygons always touch but never intersect

(see Fig. 7). The corresponding NFP (NFPAB ) is thereby drawn as the

route trajectory of a chosen reference point of polygon B.

In previous studies, robust analytical methods for the construction of the NFP of two convex shapes have been presented [41,42].

However, in the case of concave shapes similar methods or algorithms are still under development. In order to overcome this difficulty in the case of concave shapes a method for obtaining an

estimation (as a point cloud) of the actual NFP boundary of two

highly irregular shapes has been devised. The method initially

computes the convex hull of the corresponding original concave

geometry, thus covering concave regions with dummy lines, as

presented in Fig. 8. An initial rough approximation of the NFP is

then constructed based on the convex hulls of the original polygons. The resulting NFPCONVEX shares common edges with the actual NFP, i.e. all edges that are determined employing the actual

880

V. Canellidis et al. / Computer-Aided Design 45 (2013) 875–886

Fig. 5. Schematic representation of the LBDB placement procedure.

a

b

Fig. 6. The ray-casting densification process.

edges of the original polygons, but differs from the actual one in the

areas composed of dummy edges, where a tighter arrangement of

the two polygons is possible. The dummy edges are then replaced

by approximations of the corresponding actual edges, which are

created by successive sliding moves of polygon B as close as possible towards the fixed polygon. The sliding movement is performed

at points on the dummy edge which are determined by a user

selected threshold value and the traveling distance is computed

through ray casting. The resulting points form an approximation of

the corresponding areas of the actual NFP, the accuracy of which is

determined by the threshold value.

In order to find the best possible arrangement between the two

polygons, polygon B is allowed to ‘‘slide’’ along the edges of the

approximated NFP (NFPESTIMATOR ), following a procedure similar to

that employed for the construction of the NFPESTIMATOR . The best

of the possible arrangements is the one that minimizes the ratio r

(Eq. (3)), which is defined as the sum of the areas of A and B divided

by the area of the convex hull of the A and B Boolean union (A ∪ B):

r =

Area of A + Area of B

Area of the A ∪ B Convex hull

.

(3)

Having placed the first two polygons their Boolean union is

constructed. This new polygon is then employed as the fixed

polygon for the insertion of the next polygon from the permutation

order and the NFP construction and placement process is repeated.

Compared with the LBDB method which gradually packs the

objects following the permutation sequence and filling the

platform from the bottom-left corner, the NFP method fills the

platform following a pattern from the platform center towards

its periphery. In order to better illustrate the NFP placement

process an animated example is presented in Animation 2 (see the

Appendix).

The required computational effort for the construction of the

NFP approximation of two polygonal objects can be quite big, and

increases significantly as the complexity of the polygons, i.e. the

V. Canellidis et al. / Computer-Aided Design 45 (2013) 875–886

881

Fig. 7. Illustration of the NFP construction process.

Fig. 9. Schematic representation of the combined LBDB/NFP placement process.

2.3. 2D packing/layout optimization process

Fig. 8. Schematic representation of the NFP estimation process for non-convex

polygons.

number of their edges, increases. In an effort to decrease the

computational time and exploit the advantages of both previous

methods a third placement scheme has been examined. In this

scheme the LBDB strategy is followed but instead of employing

the ray-casting technique in order to pack the nesting placement,

the NFP is employed. To better illustrate the placement process an

example is presented in Fig. 9, where the incoming object, polygon

B, has already been placed based on the MBRs of the objects and

following the LBDB rules.

In the specific arrangement there is unutilized space between

the two objects that can be minimized by a leftward movement of

polygon B. The corresponding travel distance is computed by casting a ray from a reference point of object B to the approximate NFP

of the two objects (NFPAB ), thus reducing the computational time

associated with ray-casting in the standard LBDB scheme. In order

to accelerate the packing process the NFPs of all pair combinations

of the available objects are computed prior to the initiation of the

GA heuristic process. An animated example illustrating the combined LBDB and NFP placement scheme is presented in Animation

3 (see the Appendix).

The 2D nesting/layout optimization process for all three

placement schemes follows three basic phases presented in Fig. 10.

In the first phase the orientation of each one of the parts to be

fabricated is defined according to the associated quality and cost

requirements and the corresponding projection on the platform

plane is evaluated. Next comes the initialization phase where preprocessing data operations that reduce the computational effort

associated with optimization are performed. The most basic of

these operations is that of simplifying the geometry of projections

by reducing the associated number of points of the parts employing

the Douglas–Peucker algorithm [43]. In order to avoid possible

intersections between parts due to this geometry simplification

a small offset of the original geometry by a certain threshold is

first applied. In the combined LBDB and NFP scheme a database

containing the NFPs or NFP estimates of all possible combinations

of parts in pairs is also constructed during the initialization phase.

Finally, in the third phase the GA is employed in order to search

the solution space and identify the optimum or near-optimum

parts layout arrangement on the platform of the machine. The

evaluated layouts are constructed employing one of the three

schemes presented in previous paragraphs.

3. Computational results and discussion

The efficiency of the proposed methodology and placement

strategies was investigated using four case studies; three involving

882

V. Canellidis et al. / Computer-Aided Design 45 (2013) 875–886

Fig. 10. Flowcharts of the packing optimization process for the three placement schemes under investigation.

sets of relatively simple 2D shapes presented in previous studies and one involving ‘‘real-world’’ SL parts. The software implementation of the proposed methodology has been carried out

employing Matlab R2008a. The parameters of the implemented

GA algorithm in all test cases were: population size of 50 chromosomes, crossover rate of 100% and mutation rate of 1.25%. The

GA terminated when the population became fully homogeneous,

i.e. the mean value of the fitness function (mean percentage of

platform area coverage) of the population reached the corresponding maximum fitness value (maximum percentage of platform area

coverage obtained by the best layout arrangement in a generation).

All test cases were run on a PC equipped with a Pentium 4 processor at 3.4 GHz and 2 GB of RAM.

Table 1

Results of benchmark test cases.

Platform area coverage (%)

No. parts packed

Albano set

Mean comput. time per packing

arrangement/generation (s)

Total computational time (s)

Mao set

Blaz set

3.1. Benchmark test cases

A series of three test cases was examined first. The data sets

for the three test cases were obtained from the ESICUP web site

(http://paginas.fe.up.pt/~esicup/tiki-index.php) which contains a

publicly available archive of data sets employed in previous

packing/nesting problem studies. The first data set (Albano set) has

been examined in a study by Albano and Sapuppo [44] and contains

24 instances of the shapes presented in Fig. 11(a), the second (Mao

set) has been proposed by Bounsaythip and Maouche in [45] and

contains 20 instances of the shapes presented in Fig. 11(b), while

the third (Blaz set) contains 20 instances of the shapes presented

in Fig. 11(c) that have been used by Blazewicz et al. in [46]. The

specific test cases were selected because of the irregular geometry

of the associated polygons which corresponds to what should be

expected for parts projections in SL practice.

The results of the test cases in terms of packing/nesting

efficiency, as measured by the percentage of platform area coverage and the number of parts placed, as well as the associated required time per placement scheme are presented in Table 1. The

corresponding layout arrangements of the shapes per placement

scheme and case are presented in Fig. 12. It should be noted that

Platform area coverage (%)

No. parts packed

Mean comput. time per packing

arrangement/generation (s)

Total computational time (s)

Platform area coverage (%)

No. parts packed

Mean comput. time per packing

arrangement/generation (s)

Total computational time (s)

LBDB

NFP

LBDB and NFP

82.2

24

1.30

71.6

23

6.00

82.2

24

0.60

11,554 19,017 5760

71

20

1.18

71

20

7.70

71

20

0.39

3115

19,455 928

71.4

20

0.98

71.4

20

5.23

71.4

20

0.40

2652

5230

1372

the three test cases were examined following the testing methodology proposed by the corresponding authors for comparative reasons; hence the packing areas are not square as is the case with the

SL platform. The obtained results do not show any significant differences between the three placement schemes in terms of packing

efficiency, since all three methods lead to the placement of all parts

and identical values of platform coverage, with the exception of the

results obtained by applying the NFP scheme in the Albano case.

The observed values of area coverage are also comparable to that

reported in the relevant literature. In terms of computational time,

however, it is evident that the combined use of LBDB and NFP techniques leads to significant time savings compared to the placement

schemes employing solely LBDB or NFP. This conclusion becomes

more evident if the mean computational time per layout arrangement or generation is examined, where the sole application of the

NFP or LBDB schemes leads to quite high computational time requirements compared to the corresponding ones, when the combination of both schemes is applied.

V. Canellidis et al. / Computer-Aided Design 45 (2013) 875–886

(a) Albano set.

883

(b) Mao set.

(c) Blaz set.

Fig. 11. Polygonal shapes examined in benchmark test cases.

3.2. ‘‘Real-world’’ stereolithography parts test case

Fig. 12. ‘‘Optimum’’/best layout arrangements for the benchmark cases using

different part placement schemes.

In order to further investigate the proposed approaches another

test case, comprising of 20 parts fabricated by SL in the context

of past projects and partnerships of the Center for Product

Development and Rapid Prototyping at the University of Piraeus,

was computed. The corresponding parts are of variable size and

geometrical complexity, as could be expected for a representative

‘‘real-world’’ case of a stereolithography build job in a RP/RM

service bureau (see Table 2 and Fig. 13). The orientation of the parts

was selected according to part-specific quality/cost requirements

following the procedure proposed by the present authors and

presented in detail in [6]. The platform dimensions were set at

250 mm × 250 mm, equal to that of the SL machine used for their

fabrication.

The projections of the parts on the platform were computed

after slicing the STL files and carrying out the Boolean union of

the corresponding slices. Due to the relatively high level of detail

and complexity of the STL files the obtained 2D projections had

a significantly higher number of points per polygon compared to

the benchmark test cases (see Table 2). A preliminary application

of the developed algorithms employing these original projections

showed that significant computational effort was required; hence

a reduction of the level of detail of the projected polygons was applied. Geometry simplification was achieved through the reduction

of the number of polygon points employing the Douglas–Peucker

algorithm [43], following an initial offset of the original geometry by a certain threshold, to avoid possible intersections between

parts due to the simplification procedure. The test case results are

884

V. Canellidis et al. / Computer-Aided Design 45 (2013) 875–886

Fig. 13. Parts examined in the SL test case.

z

y

y

z

x

x

y

z

x

Fig. 14. ‘‘Optimum’’/best layout arrangements for the SL test case using different part placement schemes.

presented in Table 3 while the corresponding packing/nesting arrangements are illustrated in Fig. 14.

From Table 3 it can be observed that the best layout arrangements are obtained employing the LBDB and NFP placement

schemes. In both cases only one part, the human jaw medical

model, is not present in the layout arrangement (see Fig. 14) probably due to the size and highly non-convex nature of the corresponding polygonal projection. To further illustrate the layout

construction process employing the LBDB and NFP scheme for a

single solution/individual an animated example is presented in Animation 4 (see the Appendix).

Employing solely the NFP technique, on the other hand, leads

to relatively worse results in terms of both packing efficiency and

computational time, as is also observed in the first test case. The

relatively high computational time of the NFP approach can be

attributed to the relatively high mean time that is required per

packing arrangement/generation (16 s) as well as to the relatively

high number of generations (700 generations) required for convergence, as can be seen in Fig. 14. The LBDB and NFP schemes on

the other hand converged significantly faster, in about 200 generations. Examining further the mean and best fitness plots (Fig. 15)

also shows that the optimum solution for all three schemes is discovered well before converging, in the range of 100–150 generations, an indication that, perhaps, the computational time can be

significantly reduced if another termination criterion, such as the

maximum number of generations or the average change in fitness

value, is applied. The computational results presented above indicate that the combined application of the LBDB packing procedure

and the NFP technique for pair-wise part arrangement is overall

superior.

Part name and

number

Hinge (16 & 19)

Washing machine

arm–left

component

(17 & 20)

Bishop (9)

Distributor (14)

Fliptop (1 & 2)

Gear (5 & 6)

Knight (8)

Washing machine

arm–central

component

(12 & 18)

Ship model (7)

Engine

model (11 & 15)

Jaw (4)

Caliper

model (3 & 13)

Cover (10)

STL

STL

triangles volume

(cm3 )

4,860 10.95

10,394 20.55

30,171 8.21

4,028 7.15

6,552 2.07

1,420 0.54

75,934 9.78

17,718 28.55

Projection’s Projection’s Projection

NoPoints

NoPoints

area

after

(mm2 )

reduction

157

340

439

39

450

256

430

120

20

25

519.5

4958.9

16

7

14

9

16

13

937.45

1893.06

1346.4

114.2

937.4

6236.5

828

0.23

4,427 38.60

231

292

27

19

255.8

3141.7

100,948 64.37

49,682 38.36

4119

894

43

25

3447.5

2105.9

12,300 19.78

735

13

7808.1

4.8

4.6

LBDB

4.4

4.2

4

3.8

0

78

19

1.95

15,493

LBDB and NFP

73

18

16

22,313

78

19

0.4

2600

4. Concluding remarks

In the present paper an investigation of the parts placement

problem encountered during the job process planning phase of the

SL fabrication procedure is presented. Taking into account the specific characteristics of the SL technology, maximization of the platform area coverage has been chosen as the primary optimization

objective that needs to be achieved, in order to reduce the number of machine setups and increase its utilization. A GA heuristic

technique and three distinct part placement schemes were applied

for the nesting of parts on the platform and the optimization of

their layout arrangement. In order to evaluate the efficiency of the

proposed methodology, algorithm and placement schemes, four

case studies were examined; the first three concerning relatively

simple geometrical forms whilst the fourth one had actual/‘‘realworld’’ parts fabricated using the SL technique. The test results indicate that employing the combined LBDB and NFP scheme for the

placement of parts and the associated layout arrangement in conjunction with the GA optimization technique leads to ‘‘good’’ 2D

packing/nesting solutions. Also, taking into account that the process planning in SL is performed on dedicated process-planning

computers and in parallel with SL machine operation, as is quite

often the case in actual practice, the computational time involved

is considered to be acceptable. Furthermore, the combined LBDB

and NFP approach seems to be able to handle 2D polygonal forms

of variable complexity, similar to those expected in SL fabrication

jobs, without significant problems in terms of part intersections

and degenerate cases. From the applications point of view it is

concluded, therefore, that the proposed methodology presents a

valuable tool for the automation of the job/layout planning task,

thereby reducing the cost and time of process planning and increasing the utilization of the SL systems. Obviously, the present

methodology could be also applied to any other AM technology

100

150

200

250

0.74

0.72

0.7

0.68

NFP

0.66

0.64

0.62

0.6

0.58

0

NFP

50

Number of Generations

Utilized Area of Manufacturing Platform (mm2)

Platform area coverage (%)

No. parts packed

Mean computational time per packing

arrangement/generation (s)

Total computational time (s)

× 104

5

Table 3

Results of the SL test case.

LBDB

885

3.6

Utilized Area of Manufacturing Platform (%)

Table 2

Data of parts examined in the SL test case.

Utilized Area of Manufacturing Platform (mm2)

V. Canellidis et al. / Computer-Aided Design 45 (2013) 875–886

5

100

200

300

400

500

600

700

800

Number of Generations

× 104

4.8

LBDB

&NFP

4.6

4.4

4.2

4

3.8

3.6

0

50

100

150

200

250

Number of Generations

Fig. 15. Convergence plots of mean and best fitness values per generation for the

SL test case using different parts placement schemes.

that shows the same predominant fabrication characteristic, i.e. requirement of support structures, such as the FDM process.

Appendix. Supplementary data

Supplementary material related to this article can be found

online at http://dx.doi.org/10.1016/j.cad.2012.12.002.

References

[1] Wohlers T. Wohlers report 2011—additive manufacturing and 3D printing

state of the industry. Oak Ridge-Colorado, USA: Wohlers Assoc. Inc.; 2011.

[2] The Economist 3D printing: the printed world. February 12th issue. Available

at: http://www.economist.com/node/18114221 (last accessed 07.02.11).

[3] Munguia J. Pursuing successful rapid manufacturing: a user’s best practices

approach. Rapid Prototyping J 2008;14(3):173–9.

[4] Pandey PM, Reddy NV, Dhande SG. Part deposition orientation studies in

layered manufacturing. J Mater Process Technol 2007;185:125–31.

[5] Byun HS, Lee KH. Determination of the optimal build direction for different

rapid prototyping processes using multi-criterion decision making. Robot

CIM-Int Manuf 2006;22(1):69–80.

[6] Canellidis V, Giannatsis J, Dedoussis V. Genetic algorithm based multiobjective optimization of the build orientation in stereolithography. Int J Adv

Manuf Technol 2009;45(7–8):714–30.

[7] Wodziak JR, Fadel GM, Kirschman C. A genetic algorithm for optimizing

multiple part placement to reduce build time. In: Proc. of the 5th international

conference on rapid prototyping. June 12–15, 1994, p. 201–10.

886

V. Canellidis et al. / Computer-Aided Design 45 (2013) 875–886

[8] Zhang X, Zhou B, Zeng Y, Gu P. Model layout optimization for solid ground

curing rapid prototyping processes. Robot CIM-Int Manuf 2002;18:41–51.

[9] Lewis JE, Ragade RK, Kumar A, Biles WE. A distributed chromosome genetic

algorithm for bin-packing. Robot CIM-Int Manuf 2005;21(4–5):486–95.

[10] Hur SM, Choi KH, Lee SH, Chang PK. Determination of fabricating orientation

and packing in SLS process. J Mater Process Technol 2001;112:236–43.

[11] Gogate S, Pande SS. Intelligent layout planning for rapid prototyping. Int J Prod

Res 2008;46(20):5607–31.

[12] Ikonen I, Biles W, Kumar A, Ragade RK, Wissel JC. A genetic algorithm for

packing three-dimensional non-convex objects having cavities and holes. In:

Proc. of 7th international conference on genetic algorithms, 1997, p. 591–98.

[13] Canellidis V, Dedoussis V, Mantzouratos N, Sofianopoulou S. Pre-processing

methodology for optimizing stereolithography apparatus build performance.

Comput Ind 2006;57:424–36.

[14] Giannatsis J, Dedoussis V. Decision support tool for selecting fabrication

parameters in Stereolithography. Int J Adv Manuf Technol 2007;33:706–18.

[15] Bennell J, Oliveira JF. The geometry of nesting problems: a tutorial. European J

Oper Res 2006;184:397–415.

[16] Prasad YKDV, Somasundaram S, Rao KP. A sliding algorithm for optimal nesting

of arbitrarily shaped sheet metal blanks. Int J Prod Res 1995;33(6):1505–20.

[17] Lamousin H, Waggenspack Jr WN. Nesting of two-dimensional irregular parts

using a shape reasoning heuristic. Comput Aided Des 1997;29(3):221–38.

[18] Tay FEH, Chong TY, Lee FC. Pattern nesting on irregular-shaped stock using

genetic algorithms. Eng Appl Artif Intell 2002;15(6):551–8.

[19] Mahanty B, Agrawal RK, Shrin S, Chakravarty S. Hybrid approach to optimal

packing using genetic algorithm and coulomb potential algorithm. Mater

Manuf Process 2007;22(5):668–77.

[20] Nye TJ. Optimal nesting of irregular convex blanks in strips via an exact

algorithm. Int J Mach Tools Manuf 2001;41(7):991–1002.

[21] Cui Y, Huang L. Dynamic programming algorithms for generating optimal strip

layouts. Comput Optim Appl 2006;33(2–3):287–301.

[22] Licari R, Lo Valvo E. Optimal positioning of irregular shapes in stamping die

strip. Int J Adv Manuf Technol 2011;52(5):497–505.

[23] Costa MT, Gomes AM, Oliveira JF. Heuristic approaches to large-scale periodic

packing of irregular shapes on a rectangular sheet. European J Oper Res 2009;

192(1):29–40.

[24] Martins TC, Tsuzuki MSG. Simulated annealing applied to the irregular

rotational placement of shapes over containers with fixed dimensions. Expert

Syst Appl 2010;37(3):1955–72.

[25] Babu R, Babu NR. A generic approach for nesting of 2-D parts in 2-D sheets

using genetic and heuristic algorithms. Comput Aided Des 2001;33(12):

879–91.

[26] Lee W-C, Ma H, Cheng B-W. A heuristic for nesting problems of irregular

shapes. Comput Aided Des 2008;40(5):625–33.

[27] Xie SQ, Tu YL, Liu JQ, Zhou ZD. Integrated and concurrent approach for

compound sheet metal cutting and punching. Int J Prod Res 2001;39(6):

1095–112.

[28] Pan M, Rao Y. An integrated knowledge based system for sheet metal cuttingpunching combination processing. Knowl -Based Syst 2009;22(5):368–75.

[29] Verlinden B, Cattrysse D, Van Oudheusden D. Integrated sheet-metal

production planning for laser cutting and bending. Int J Prod Res 2007;45(2):

369–83.

[30] Kumar S, Singh R. Automation of strip-layout design for sheet metal work on

progressive die. J Mater Process Technol 2008;195(1–3):94–100.

[31] Ghatrehnaby M, Arezoo B. A fully automated nesting and piloting system for

progressive dies. J Mater Process Technol 2009;209(1):525–35.

[32] Rao Y, Huang G, Li P, Shao X, Yu D. An integrated manufacturing information

system for mass sheet metal cutting. Int J Adv Manuf Technol 2007;33(5):

436–48.

[33] Xie SQ, Wang GG, Liu Y. Nesting of two-dimensional irregular parts: an

integrated approach. Int J Computer Integr Manuf 2007;20(8):741–56.

[34] Wäscher G, Haußner H, Schumann H. An improved typology of cutting and

packing problems. European J Oper Res 2007;183:1109–30.

[35] Dréo J, Pétrowski A, Siarry P, Taillard E. Metaheuristics for hard optimization.

Berlin, Heidelberg: Springer-Verlag; 2006.

[36] Holland JH. Adaptation in natural and artificial systems. 2nd ed. MIT Press;

1992.

[37] Jakobs S. On genetic algorithms for the packing of polygons. European J Oper

Res 1996;88:165–81.

[38] Whitwell G. Novel heuristic and metaheuristic approaches to cutting

and packing. Ph.D. Thesis. School of Computer Science and Information

Technology. Univ. of Nottingham. 2004.

[39] Hopper E. Two dimensional packing utilising evolutionary algorithms and

other meta-heuristic methods. Ph.D. Thesis. School of Engineering, Univ. of

Wales, Cardiff, 2000.

[40] Chernov N, Stoyan Yu, Romanova T. Mathematical model and efficient

algorithms for object packing problem. Comput Geom Theory Appl 2010;

43(5):535–53.

[41] Burke E, Hellier R, Kendall G, Whitwell G. Complete and robust no-fit polygon

generation for the irregular stock cutting problem. European J Oper Res 2007;

179(1):27–49.

[42] Bennell JA, Dowsland KA, Dowsland WB. The irregular cutting-stock problem a new procedure for deriving the no-fit polygon. Comput Oper Res 2001;28(3):

271–87.

[43] Douglas D, Peucker T. Algorithms for the reduction of the number of points

required to represent a digitized line or its caricature. Cartographica 1973;

10(2):112–22.

[44] Albano A, Sapuppo G. Optimal allocation of two-dimensional irregular shapes

using heuristic search methods. IEEE Trans Syst Man Cybern 1980;10(5):

242–8.

[45] Bounsaythip C, Maouche S. Irregular shape nesting and placing with

evolutionary approach. IEEE Trans Syst Man Cybern 1997;4:3425–30.

[46] Blazewicz J, Hawryluk P, Walkowiak R. Using a tabu search approach for

solving the two-dimensional irregular cutting problem. Ann Oper Res 1993;

41:313–25.

Vassilios Canellidis received his undergraduate degree

(ptychion) in industrial management and technology

(2002) from the Department of Industrial Management &

Technology in the University of Piraeus. He carried out

postgraduate studies at the School of Electrical and Computer Engineering in the National Technical University

of Athens and at the Department of Industrial Management & Technology in the University of Piraeus, where

he received the M.Sc. (2006) and Ph.D. (2011) degrees in

techno-economic systems and optimization methods for

advanced manufacturing systems respectively. He is the

author or co-author of 15 papers published in refereed journals and scientific conference proceedings. His published work focuses on the solution of combinatorial

optimization problems in the fields of Additive Fabrication and Rapid Prototyping

technologies. Current research interests also include Combinatorial Geometry, the

application of meta-heuristic algorithms for optimizing industrial processes as well

as applications of Additive Fabrication Technologies. He is a reviewer for the International Journal of Advanced Manufacturing Technology and speaks both Greek and

English.

John (Ioannis) Giannatsis received his undergraduate degree (ptychion) in industrial management and technology (1995) and the Ph.D. degree in CAD/CAM and rapid

prototyping/manufacturing systems (2005) from the Department of Industrial Management & Technology in the

University of Piraeus. During his Ph.D. studies he worked

as a Research Assistant at the Department of Industrial

Management & Technology, which he joined in 2005 as a

Teaching Assistant. In 2008 he was elected Lecturer and

he is currently teaching courses in the areas of Advanced

Manufacturing technologies, CAD/CAM systems, Industrial

& Operations Management and Product Development. He is the author or co-author

of more than 20 papers published in refereed journals and scientific conference proceedings. His published work focuses on Additive Manufacturing and Rapid Prototyping technologies, as well as their applications in product design/development

and the medical sector. His current research interests include also Computer Integrated Manufacturing, Virtual Modeling and Ergonomic Design.

Vassilis Dedoussis, is Professor in Industrial Systems

Techniques and Director of the Laboratory of Advanced

Manufacturing Technologies & Testing at the Department

of Industrial Management & Technology, University of

Piraeus. He has received the Dipl. Ing. degree from the National Technical University of Athens (Mechanical Engineering, 1981), and the M.Sc. (with distinction) and Ph.D.

degrees in computational aerodynamics from Imperial

College, London (Aeronautics 1983, 1988). He is a member

of the Technical Chamber of Greece and the Greek Association of Computational Mechanics. His published work focuses on computer aided engineering of aircraft, industrial and power installations

as well as commercial product components. His current research interests include

CAD and rapid prototyping applications for product design and development.