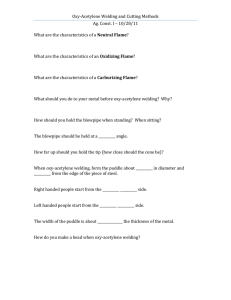

FLEXIBLE OXY-ACETYLENE GAS CUTTER DEPARTMENT OF MECHANICAL ENGINEERING TOMS COLLEGE OF ENGINEERING FOR STARTUPS KOTTAYAM, MATTAKARA Project Guide, SUMEER S. Assistant Professor Dept. of Mechanical Engineering Project Team, MATHEW THOMAS JIBIN GEORGE JITHIN VARGHESE CONTENT • • • • • • • • • • • • • Introduction Literature survey Theory Conventional oxy-acetylene gas cutting Problem definition Flexible oxy-acetylene gas cutter Project scope Proposed design Degrees of freedom Components used Specification Conclusion Reference INTRODUCTION • Oxy-fuel welding (commonly called oxyacetylene welding, oxy welding, or gas welding in the U.S.) and oxy-fuel cutting are processes that use fuel gases and oxygen to weld and cut metals, respectively. LITERATURE SURVEY Paper Author Year Conclusion Design of an autonomous Wall painting robot Mohammed abdellatif 2012 Automated painting need for automobile industry and decrease painting time Robotic arm wireless controlled Ashish singh 2013 To control the robot with an android application 2015 How temperature affect and study of strength of test piece Study and development of inert oxy acetylene gas welding S K Gupta ,et.al Design and manufacturing of automatic gas profile cutting Ajay M Patel ,et.al 2015 To reduce the human effort and making automated profile cutter Design and development of mechanism of robotic arm for lifting part K.L Voon 2015 How to lift part with robotic arm and forces required Design and structural analysis of robotic arm Gurudu rishank reddy 2016 Making different type of robotic arms CONVENTIONAL OXY-FUEL CUTTING • In oxy-fuel cutting, a torch is used to heat metal to its kindling temperature. • A stream of oxygen is then trained on the metal, burning it into a metal oxide that flows out of the kerf as slag. THEORY • Pure oxygen, instead of air, is used to increase the flame temperature to allow localized melting of the workpiece material (e.g. steel) in a room environment. – A common propane/air flame burns at about 2,250 K (1,980 °C; 3,590 °F), – a propane/oxygen flame burns at about 2,526 K (2,253 °C; 4,087 °F), – an oxy-hydrogen flame burns at 3,073 K (2,800 °C; 5,072 °F), and – an acetylene/oxygen flame burns at about 3,773 K (3,500 °C; 6,332 °F). TYPES OF FLAMES PROBLEM DEFINITION • Suitable for cutting mild steel only. • High heat input, large heat-affected zone. • Material warpage when cutting thin materials; straightening work required. • Low dimensional accuracy when cutting repeat cuts due to heat influence. • Low cutting speed. • Skilled labour. FLEXIBLE OXY-ACETYLENE GAS CUTTER (FOAGC) • This unique machine uses robotic arm to move the flame torch for the cutting operation. • The robotic arm could be controlled using a Smartphone powered by android operating system. • The cutting operation of the machine could be changed to welding operation simply by changing the tip of the flame torch and changing the temperature intensity of the flame. • A continuous track drive system is used and so this machine could be moved to other places easily. PROJECT SCOPE • • • • • • • Flexible, can cut any direction any angle. More complicated profiles can be cut No skilled labour required. More dimensional accuracy. No Alignment problems. Increased cutting speed Problem in carrying the conventional equipment has been solved. PROPOSED DESIGN DEGREES OF FREEDOM • Axis 1: Let your arm hang down. Raise it in front of you, turning only at the shoulder. • Axis 2: Let your arm hang down. Raise it out away from your body like you’re doing jumping jacks. • Axis 3: Bend your elbow. • Axis 4: Wave like the Queen of England by twisting at the wrist. It’s a twist between the wrist and the elbow. • Axis 5: Make a fist, then make it nod up and down. Bonus points if you draw eyes on the first knuckle of your index finger. • Axis 6: Imagine holding a big dial in your fingers. Turn the dial without moving the rest of your hand. COMPONENTS USED • Robotic arm • Continuous track wheel • Arduino robot arm control chip • Displacement sensor SPECIFICATIONS Type of Gas Max. Inlet Pressure (Bar) Max. Outlet Pressure (Bar) Max. Flow (LPM) Inlet Connection Outlet Connection Oxygen 230 10 1000 5/8” BSP R/H (Male) 3/8” BSP R/H (Male) Acetylene 20 1.5 250 5/8” BSP R/H (Male) 3/8” BSP R/H (Male) Nozzle Size MS Plate Thickness (mm) 1/32" 6 3/64" 12 1/16" 50, 75, 100 1/8" 300 REGULATORS (i) Double Stage Regulators conforming to IS 6901‐2009 with ISI Certification mark (ii) For use in indoor, as well as, outdoor conditions (iii) Stainless steel diaphragm in first stage to absorb shock of inlet pressure and flexible rubber diaphragm in second stage for fine gas control (iv) Shall have two pressure gauges – one to indicate the Inlet Pressure and the other to indicate the Outlet Pressure (v) Shall have Pressure Adjusting Knob for adjusting working pressure (vi) Second stage plenum chamber volume shall be at least five times than first stage for stable flow characteristics (vii) Forged brass body and cap spring (viii) Valve shall be made of fire retardant material (ix) Shall have safety valve and inlet filter CUTTING BLOWPIPE (i) Injector type hand cutting blowpipe for use with dissolved Acetylene Cylinders (ii) Conform to IS 7653‐1975 with ISI Certification mark (iii) Body and head made of forged brass (iv) Swaged nozzles to ensure parallel beam of heating flame (v) Shall consist of Blowpipe‐1 no., Cutting Nozzle (3/64")‐1 no., Nut & Nipple for hose connection of both Oxygen and Acetylene gas HOSES WITH CONNECTORS Two hoses, for Oxygen and Acetylene gas, each of 10m length, factory fitted with necessary nut and nipples at both ends with any other necessary adaptors required for gas connection of Blow pipe (Sl. No. 1) or Cutting Machine (Sl. No. 5) with regulator through the flashback arrestors shall be supplied. SMATPHONE INTERFACE CONCLUSION The flexible oxy-acetylene gas cutter would be so useful in large industries. The FOAGC enable a person to cut a metal sheet with atmost accuracy with less effort. Since it could be operated using a smartphone it no longer requires highly skilled labour. REFERENCES [1] Mohamed Abdellatif, “Design of an Autonomous Wall Painting Robot”, Mechatronics and Robotics Dept. Egypt-Japan University of Science and Technology, Alexandria, Egypt, 2012 [2] Ashish Singh, Mrs.M.V. Patil, “Robotic Arm Wirelessly Controlled” IJSR Android Application, 2013 [3] S K Gupta, Md.Ehsan Asgar, “Study and Development of Inert OxyAcetylene Gas Welding, IJETT journal, Aug 2014 [4] Ajay M Patel,Dhaval Shah,Mudit Kothari, “Design and Manufacturing of Automated Gas profile Cutting Machine using PLC” ,IJSRD vol.3, 2015 [5] A.N.W.QI, K.L.VOON, M.A.ISMAIL, N.MUSTAFFA, M.H.ISMAIL “Design and Development of a Mechanism of Robotic Arm for Lifting Part1” Faculty of Mechanical Engineering, University Malaysia Pahang, 2015 [6] Gurudu Rishank Reddy, Venkata Krishna Prashanth Eranki, “Design and Structural Analysis of a Robotic Arm”, 2016 THANK YOU