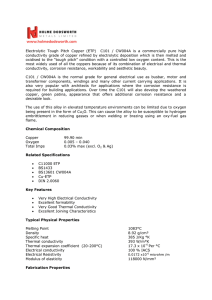

Novel Metal-Carbon Materials called Covetics Iwona Jasiuk Department of Mechanical Science and Engineering University of Illinois at Urbana-Champaign Contact: ijasiuk@Illinois.edu Industry Session “Enablers for Transportation Electrification” 34th Annual IEEE Applied Power Electronics Conference and Exposition Anaheim, CA, March 20, 2019 Introduction • Covetics are novel metal-carbon materials • Carbon is infused into metal using a unique electrical process. • Cross-cutting process: copper, aluminum, iron, silver, and others. • Carbon amounts far higher than predicted by phase diagrams. • Notable increases in mechanical properties, electrical and thermal conductivities, oxidation resistance. Invented by Roger Scherer in 1997 Shugart & Scherer US 8541335 2013 Shugart & Scherer US 20100327233 2010 Knych et al. Archives of Metallurgy and Materials 2014 Salamanca-Riba et al. Advanced Functional Materials 2015 Bakir and Jasiuk (2017) “Novel metal-carbon nanomaterials: A review on covetics,” Advanced Materials Letters 8(9), 884-890. 2 Covetics - Definition and Concept • Term Covetic = Covalent and Metallic bonding. Terms based on a hypothesis that a covalent bond forms between C and metal. • Carbon in Metals – low solubility • Conventional methods – formation of carbides (e.g., Al4C3). • Alternative methods • electrochemical deposition • solid state processing - mixing in expensive nano-carbon fillers (CNTs, GNPs). Metal-carbon bonding is weak. Cu-C phase diagram • Covetics – nano-carbon phase is formed, strongly bonded to a metal. • Carbon does not separate after remelting, laser ablation, and magnetron sputtering. • Covetics can be remelted, diluted, alloyed, and post-processed. Alternating graphene layers within a metallic lattice forming in a covetic Knych et al., Met Trans B (2014) 3 Industrial Relevance • Covetics are cost effective • Raw material cost is low • Carbon added is in the form of a low cost amorphous activated carbon • Conventional furnaces and equipment can be used for the manufacture • Covetics can be processed using traditional methods (remelting, extrusion) • Covetics process is scalable • More economical than infusing metal with carbon nanotubes or graphene nanoplatelets • Covetics are excellent candidates for various industrial applications • Replacement for aluminum, copper and other metals. • Many energy applications 4 Industrial relevance Potential applications and benefits of covetics: Applications Benefits Heat exchangers Higher efficiency for a $12B annual market High-voltage power transmission cable 40% higher strength; 40% higher electrical conductivity -> $10B annual savings for US power grid Substitution of covetic aluminum for copper in electrical wiring Weight reduction and improved efficiency (aircraft and automotive); cu: 50lbs/car, Al: 20lbs/car Nuclear fuel rods Reduce thermal gradients to improve service performance Fuel cell and supercapacitor electrodes Higher efficiency electrodes Thermal management in microelectronics Higher currents, faster switching at higher temperatures U. Balu Balachandran, Covetic Materials CPS Agreement Number 28418, Argonne National Laboratory, May 2015 5 Industrial relevance Replacing Cu with Al Covetics Enables Significant Vehicle Lightweighting Uses Copper 50 lbs/car Uses Aluminum Covetics 20 lbs/car • DOE seeks target of 30% vehicle lightweighting by 2022 • Covetics is a new metallurgical pathway for alloy development and offer OEMs the design freedom to extend range by increasing battery pack size 6 Industrial relevance Covetics can not only enable lightweighting, but also enhance performance DC/DC Converters & AC/DC Chargers Interconnects, Bus Bars, & Enclosures for Inverters Chassis Cabling Battery Pack Heat Exchanger Electric Motor Housing • All of these subsystems benefit from the weight savings, 40% higher strength, higher electrical conductivity, and high thermal conductivity, offered by covetics. Department of Energy Goals for Plug-In Electric Vehicles by 2022, https://www.nrel.gov/transportation/vehicle-tech-targets.html 7 Covetics – Manufacture Invented by Roger Scherer in 1997 Combined plastic and aluminum, and added electric current First independent verification of the covetics process • How are covetics made? • • • • Melt metal in an induction furnace Add carbon and stir Apply electric current while stirring Conventional equipment: furnaces, stirring; infrastructure is available Experimental set-up for covetics synthesis Knych et al., Met Trans B (2014) 8 Properties of Covetics • Covetics exhibit enhanced properties. • Based on data published so far: • • • • Higher strength (40%), hardness (40%), and toughness (in aluminum and copper), Higher thermal conductivities (13% increase in copper), Higher electrical conductivities (28-37% increase in copper), Increased oxidation resistance in thin copper films. • Challenges • Properties are highly dependent on processing parameters. • No guaranteed improvements => Processing is the focus of current research. 9 Thermal/Electrical Properties • Thermal conductivity: 13% increase in copper (earlier data 50%) • Electrical conductivity (28-37% increase in copper) • Increased oxidation resistance in thin copper films (Isaacs et al. 2015) ASTM E1461 @ 22.1°C Sheet resistance 782.7 mΩ, 137% IACS Balu Balachandran, Argonne National Laboratory 10 Mechanical Properties Ultimate Tensile Strength (UTS) 7075 Al covetics (warm rolled) 0 wt%C 3 wt%C 5wt%C Iftekhar Jaim et al. Carbon (2016) • UTS increased for covetics as compared to base 7075 Al • Similar results for 0.2% yield strength Tests done at the University of Illinois 11 Mechanical Properties Ultimate Tensile Strength (UTS) 10200 Cu covetics (as cast) 0.2% Yield Strength • UTS increased for covetics as compared to base copper • Similar results for 0.2% yield strength Tests done at the University of Illinois 12 Mechanical Properties 10200 Cu covetics (as cast) 3 wt% C Before 0 wt% C After (0 wt%C) After (3wt% C) Strain (mm/mm) • Stress-strain curve comparison • Increase in strength and toughness for 3 wt%C covetics as compared to 0 wt%C. 0 wt %C 3wt %C SEM images of Cu 10200 covetics Tests done at the University of Illinois 13 Mechanical Properties Comparison with 10200 Cu covetics (as cast) with 3 wt%C 10200 Cu Tensile Strength (MPa) Elongation (%) Vickers Hardness (HV) Maximum Energy (J) Annealed 210 40 55 max 61 (Izod) Half Hard 245 10 75 - 90 - Hard 310 7 90 - 115 34 (Izod) Our Data (for 3 wt%C Cu covetic) 223 ± 9 33.5 ± 3 70 ± 3.1 43 ± 2.1 (Charpy) Mechanical properties of 10200 Cu (MatWeb Materials Property Data) 14 Properties - Summary • Increase in ultimate tensile strength, 0.2% yield strength, energy absorption and hardness in aluminum- and copper-based covetics • Increase in both strength and toughness (copper covetics) • The increased electrical and thermal conductivity of copper covetics Challenges • • • • Reliably achieve improved properties Covetics exhibit porosity due to high surface tension Heterogeneous distribution of carbon Measurement of carbon content (e.g., combustion techniques do not work due to a strong metal-carbon bond) 15 Industrial relevance Covetics not only enable lightweighting, but also enhance performance Vehicle Sub-System Design Benefit of Covetics Heat Exchanger Higher efficiency, weight savings & high thermal conductivity Chassis Weight savings, corrosion resistance Battery Pack Case Weight savings, high electrical conductivity, high thermal conductivity, reduced integration cost Interconnects & Bus Bars Weight savings, high electrical conductivity, high thermal conductivity Cabling Weight savings, 40% higher strength, 40% higher electrical conductivity, high thermal conductivity Enclosures for Inverter & Chargers Weight savings & high thermal conductivity Note: Integration opportunities could facilitate final reduced system level cost at scale Department of Energy Goals for Plug-In Electric Vehicles by 2022, https://www.nrel.gov/transportation/vehicle-tech-targets.html 16 Concluding Remarks Covetics have multiple benefits: • A scalable process, low cost of raw materials • Low cost carbon used => nano-carbon (instead of expensive CNTs, GNPs) • Carbon strongly bonds to metal, difficult to achieve with conventional processes • Increase in mechanical, thermal and electrical properties • The process should be applicable to a wide range of metals and alloys • Novel materials – multiple research opportunities • Open field for materials exploration. 17 References Bakir M, Jasiuk I (2017) Novel metal-carbon nanomaterials: A Review on covetics, Advanced Materials Letters 8(9), 884-890. Balachandran BU (2015) Covetic Materials CPS Agreement Number 28418, Argonne National Laboratory, May 2015 Iftekhar Jaim H, Isaacs RA, Rashkeev SN, Cole DP, LeMieux M, Jasiuk I, Nilufar S, Salamanca-Riba LG (2016) Sp2 carbon in Al6061 and Al-7075 alloys in the form of crystalline graphene nanoribbons, Carbon 107, 56-66. Isaacs RA, Zhu H, Preston C, Mansour A, LeMieux M, Zavalij PY, Iftekhar Jaim HM, Rabin O, Ku L, Salamanca-Riba LG (2015) Nanocarbon-copper thin film as transparent electrode, Applied Physics Letters 106, 193108-1-5. Knych T, Kwasniewski P, Kiesiewicz G, Mamala A, Kawecki A, and Smyrak B (2014) Characterization of nanocarbon copper composites manufactured in metallurgical synthesis process, Metallurgical and Materials Transactions 45B, 1196-2000. Salamanca-Riba LG, Isaacs RA, LeMieux MC, Wan J, Gaskell K, Jiang Y, Wuttig M, Mansour AN, Rashkeev SN, Kuklja MM, Zavalij PY, Santiago JR, Hu L (2015) Synthetic crystals of silver with carbon: 3D epitaxy of carbon nanostructures in the silver lattice, Advanced Functional Materials 25, 4768-4777. Varnell JA, Bakir M, DiAscro MA, Chen X, Nilufar S, Jasiuk I, Gewirth AA (2019) Understanding the influence of carbon addition on the corrosion behavior and mechanical properties of Al alloy “covetics,” J. Materials Science 54 (3), 2668–2679. 18 Thank you! Questions? Acknowledgments • • • • National Science Foundation (NSF) Department of Energy (Dr. David Forrest) Air Conditioning and Refrigeration Center at University of Illinois NSF Industry/University Cooperative Research Center on Novel High Voltage and Temperature Materials and Structures Contact: Dr. Iwona Jasiuk, e-mail: ijasiuk@Illinois.edu 19