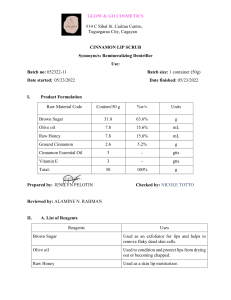

GLOW & GO COSMETICS #14 C Sibal St. Caritan Centro, Tuguegarao City, Cagayan REMINERALIZING TOOTH POWDER Synonym/s: Remineralizing Dentrifice Use: Used to eliminate plaque and other deposits from tooth surfaces Batch no: 050822-08 Batch size: 1 container (100g) Date started: 05/08/2022 I. Date finished: 05/08/2022 Product Formulation Raw Material Code Content/200 g Content/100 g %w/w Units Xylitol 70 35 35% g Bentonite Clay 70 35 35% g Sodium Bicarbonate 40 20 20% g Turmeric 10 5 5% g Activated Charcoal 10 5 5% g Total: 200 100 100% g Prepared by: JENILYN PELOTIN Checked by: NICOLE TOTTO Reviewed by: ALAMINE N. RAHMAN II. A. List of Reagents Reagents Uses Xylitol Used to reduce the levels of decay-causing bacteria in saliva. Bentonite Clay Used as an antibacterial agent. Sodium Bicarbonate Used to buffer the intraoral pH. Turmeric Used to reduce plaque. GLOW & GO COSMETICS #14 C Sibal St. Caritan Centro, Tuguegarao City, Cagayan Activated Charcoal Used to remove stains from teeth. B. List of Equipment/Materials Materials Uses Ceramic Bowl Used as a container and where all the ingredients are mixed. Ceramic Spoon Used to the powdered ingredients. Paper box Used as container for the ingredients. Weighing scale Used to determine the weight of the ingredients. Clean container Used as a container for the final product. Prepared by: JENILYN PELOTIN Checked by: NICOLE TOTTO Reviewed by: ALAMINE N. RAHMAN III. Standard Operating Procedures 1. Wearing of lab gown, gloves, mask, and lab shoes. 1.1 Restrain loose clothing and wear laboratory gown properly. Fasten all the buttons. 1.2 Tie back long hair and wear hair net. 1.3 Wear gloves, face mask, and flat shoes (as needed). 2. Cleaning of utensils. 2.1 Wash glassware with soap solution. 2.2 Remove product debris by hand or by tools such as scraper. 2.3 Rinse thoroughly with warm potable water and dry. GLOW & GO COSMETICS #14 C Sibal St. Caritan Centro, Tuguegarao City, Cagayan 3. Cleaning and sanitizing of formulation area. 3.1 Clear the working area from all the laboratory materials and equipment. Return them in their proper storage area. 3.2 Clean up debris and discard properly. 3.3 Wipe chemical spills, rinse surface with warm potable water and dry. 4. Packaging materials: bottles, tins, jars, tubes, etc. 4.1 Label containers properly. Labels must be clear and visible. 4.2 Keep containers in proper storage area. Prepared by: JENILYN PELOTIN Checked by: NICOLE TOTTO Reviewed by: ALAMINE N. RAHMAN IV. Precautionary Measures 1. Check the expiration of reagents. 2. Check if the materials are in good condition, it is functioning and properly calibrated. 3. Check if the packaging materials are properly sanitized or sterilized. 4. Check if the glassware has no cracks and the calibration can be seen or visible. Prepared by: JENILYN PELOTIN Reviewed by: ALAMINE N. RAHMAN V. Processing Procedures 1. Dispensing Procedures 1.1. Measure 35 g Xylitol 1.2. Measure 35 g Bentonite Clay Checked by: NICOLE TOTTO GLOW & GO COSMETICS #14 C Sibal St. Caritan Centro, Tuguegarao City, Cagayan 1.3. Measure 20 g Sodium Bicarbonate 1.4. Measure 1 tsp (5 g) Turmeric powder 1.5. Measure 1 tsp (5 g) Activated charcoal 2. Compounding Procedures Note: Do not use any materials which is metallic because it would deactivate the benefits of the Bentonite clay upon interaction. Use of glass, wooden, and ceramics materials are highly recommended. 2.1. Take a glass, wooden, or ceramic bowl. 2.2. Add the ingredients (Xylitol, Bentonite clay, Sodium bicarbonate, Turmeric and Activated charcoal in order). 2.3. Mix thoroughly with a use of wooden, ceramic, or glass spoon. 3. Packaging Procedures 3.1. The finished product shall be packed in a clean container and closed tightly. 3.2. Label it properly. The following mandatory information shall appear in the label of the finished product. 3.2.1 Name of product, Identity/product type, Indication, Net quantity of content, Directions for safe use/Application, Warnings, Manufacturer’s name and address including logo, Batch No./Lot No., Manufacturing Date, Expiration Date, & Any other required information such as logo, icons or symbols, barcode. Prepared by: JENILYN PELOTIN Reviewed by: ALAMINE N. RAHMAN Checked by: NICOLE TOTTO GLOW & GO COSMETICS #14 C Sibal St. Caritan Centro, Tuguegarao City, Cagayan 2 Packaging 1. Bottles Cleansed and Sanitized by: JENILYN PELOTIN 2. Labels Prepared by: VALERI SHEI MORILLO Checked by: NICOLE TOTTO GLOW & GO COSMETICS #14 C Sibal St. Caritan Centro, Tuguegarao City, Cagayan Reviewed by: ALAMINE N. RAHMAN 3 Product Evaluation & Quality Control Parameters Organoleptic Test Specifications Actual Result of Evaluation Color must be checked visually and varies in color formed through The color of the used ingredients. The odor, must be pleasant to smell or a little product is greyish. aromatic. The smell of the product is aromatic. Determination of Mix 1/2 or 1 tsp of toothpowder in a glass of water. Determine the pH by The pH level of the pH dipping the end of the pH strip into the mixture or by using pH meter. product is neutral. After a couple of seconds, remove the paper and compare the color of the pH strip to the color chart provided with the pH paper kit. pH level must be in 8-9. Flow Property Test This helps in easy application of powder to skin. In this method, angle of repose of powder is measured by allowing the powder product to fall on a plate through a funnel. Then the height and the radius of heap formed is measured, and even the time taken for the powder to fall is noted. The height and the diameter of the resulting cone are measured and the angle repose is calculated from this equation: Angle of repose= tan-1 (h/r) Where: h= height of the pile r= radius of the pile The angle of repose must be more than 40 degrees but NMT 45 degrees since powders have passable flowability. The angle of repose is more than 40 degrees and NMT is 45 degrees since powders have passable flowability. GLOW & GO COSMETICS #14 C Sibal St. Caritan Centro, Tuguegarao City, Cagayan Colour In this test, a sample of powder is spread on a white paper. The The color of the Dispersion Test segregation or bleeding of the color is observed. The color of the powder is properly distributed in the powder should be properly distributed in the formulation. formulation. Stability Test 4 Stability test is prepared by storing the prepared formulation at different temperature for 5-7 days. The product is left at room temperature or left at 35°C temperature. There should be no microbial growth upon storage. The color, odor and texture of product must still be the same. The color, odor and texture of product must still be the same after storing the product in a room temperature for 7 days. There’s no microbial growth upon storage. Marketing 1. Flyers Prepared by: HAYDEE ANGELIE SIBAL Checked by: NICOLE TOTTO GLOW & GO COSMETICS #14 C Sibal St. Caritan Centro, Tuguegarao City, Cagayan Reviewed by: ALAMINE N. RAHMAN 2. Billboard Prepared by: HAYDEE ANGELIE SIBAL Checked by: NICOLE TOTTO Reviewed by: ALAMINE N. RAHMAN Noted by: MRS. CARMEN B. VALERA, RPh, MPA, MBA