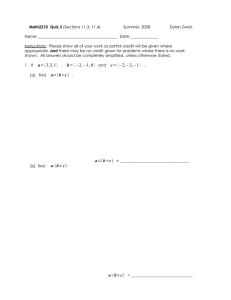

Toby Bryson 10496670 DTM1104 I intend to build a scarp metal aeroplane suited for a year 9 student. My design will include all the skills I have developed and learnt throughout the semester. My plane will be no bigger that 300mm x 500mm x 300mm and will cost no more than $30. I will make my plane look aesthetically pleasing and well suited to its functions. I will incorporate different welding process and different metals such as cast iron, steel. I want to make my plane sitting on a stand that is designed form scrap metal. I have to include minimum one piece of scrap metal, but I intend to use as much as possible in order to create rustic theme. I also must include a moving part and a tear drop made from flat bar. The plane that I want to build is a modern sea plane, I intend to build the floats of the plane out of the tear drop element required for this project. The body, wings and cockpit I want constructed out of scrap metal, in order to create the rustic theme I intend to design. My plane shouldn’t exceed the cost of $30 because majority of the metal that I will used will be scrap metal from home and the scrap metal bins in the workshop. I will design scrap metal plate for my plane to sit on. I have collected a Varity of different types of metals to achieve that side of the design brief. Aesthetically this design is very plain and simple, hence is a easy construction because it requires minimal welding and parts. The cost of the plane would be very low because it use very few parts and doesn’t create much waste. This plane design is safe because it doesn’t have nay sharp edges and wont be heavy so it would hurt if it fell on someone. This plane would suit its functions as a small desk ornament or a paper weight without getting in the way ad taking up to much room. The measurement of this plane would be no bigger than 100mm x 100mm x 50mm, I know this because the body of the plane is a spark plug and there no bigger than 100mm. This plane look aesthetically good, with the large body and engines in proportion to the rest of the plane. This would look good in my design because it allows me to incorporate more scarp metal for the engines and body. This plane would suit the function that I require for my project, because I require a moving part and this plane as two for the propellers, which I could create out of nuts a bolts. The cost of this plane design would cost more than the previous design because it requires more parts in order to build the propellers. The safety of this design would be less because it has propellers which if not designed well could be sharp, hence cut someone when there spun. The size/measurements of this plane could depending of the metal and materials available because it doesn’t, this design is a inspiration and doesn’t have a set size. Aesthetically this plane is very pleasing because it has a nice recycled/rustic theme and a nice construct in colours, from using scrap metal. This plane would suit its function as desk ornament or a paper weight well, without taking up to much room and being to heavy. This plane has a positive environmental impact because it uses scrap metal, which reduces the amount of meta going to waste. This plane wold have a low cost associated with it because it is made from majority scrap metal, which doesn’t cost much or is free. The safety of this design, is not as good as previous design because it ahs a lot of little holes were students fingers could get caught. This plane look aesthetically pleasing, because of the shiny metal finish with a clear coat. Scrap metal has been used in this design but I don’t think s well as it could have been, majority of it is design from rolled plate,. The cost of this plate would be small because it uses scrap metal and some thin sheet metal that has been rolled, which doesn’t cost much to buy. The function of this would be good, as a desk ornament or display piece, but also it using bearings as the wheels, which means the plane should move smoothly. The environmental impact of this plane would be minimal because it uses scrap metal deducing the amount of waster being produced and metal not being used. The safety of this plane is good, because there isn't to many spots for fingers to get caught and it appears that the edges aren’t sharp. Part Material Length Qty Total length Cost Total Body 50mm x 3mm galvanised pipe 240mm x 50 1 $6.5pm $1.56 $1.56 Sledges 25mm x 3mm flat bar 800mm 2 $6.8pm $8.5 $17 Fin 50mm x 3mm flat bar 65mm x75mm 1 $7.70pm $0.5 $0.5 Propeller 25mm x 3mm flat bar 25mm x30mm 1 $6.8pm $0.2 Cabin - 90mm x 40mm 1 $0 Gliders Roof sheet 120mm x 35mm 1 $0 Wings Lawn mower blades 330mm x45mm 1 $0 Sledge attaches Bike chain 50mm x 8mm 4 $0 Propeller Bearing 50mm 50mm 1 $0 Propeller Round bar 100mm x 8mm 1 Propeller Bolt 40mm x 10mm 1 $4.2pm $0.42 $0.42 $0 $19.48 Week 1, 2nd -8th Week 2, 9th - 13th Week 3, 16th – 23th Week 4 23rd-30th Designing my plane, with concept drawings and research of other planes to find inspiration, also planning my design the step that I take to build my plane I continued to cut out the pieces required to continue building my plane. Welded the cabin part (cast iron) to my plane after practicing and learning the skill. I tooked about the chain into smaller pieces and welded so they wouldn’t move Finding and gathering resources to start to build my plane I welded the wings together and then attached them to my plane. I welded the other gliders to the back of the plane I attached the guilders to the body of the plain. Cutting the flat bar for my tear drop, then welding and grinding back the weld I fushioned weld the sides of the planes onto the body I MIG welded the glider at the back of the plane to the body. Removed splatter from the plane and added a clear coat. First I cut out the flat bar needed to create my to tear drops, I did this using the cold saw. I used 25mm x 3mm flat bar in order to create my tear drops, which were used as my sledges for my plane. I also cut out the flat bar that I needed for other stages of my build. I then welded together my tear drops using the MIG welder and once that was done I then, cleaned up the welder with a grinder to smoothen them I then cut out the galvanised pipe needed for the body of my plane, using the cold saw. After I cut out the pipe I the cut and angle along the side so I could squash the then end and create a point for the end of my plane. I then cut out used some the flat bar that I cut out earlier for the sides of the body on the plane. I cut these to shape using the cutting disc on the grind and then used the final shaping to the grinding stone. I then fusioned welded this to the pipe Next I got my lawn mower blades and removed any sharp edges from when the were used, I the over lapped these and welded them to each other. I attached the wings to the plane using a MIG welder as well. The next step was one of the most difficult problems I faced in the construction of my plane, I had a scrap piece of cast iron which I wonted to weld to my plane as the cabin, the difficulty with this I I couldn’t weld it with the MIG and after talking to my a couple lectures and researching the only way I could weld this was to braze weld it, but what I was told my the lectures is it’s difficult because it often cracks because of it crystalline structure, I in order to ovoid it from cracking I had to evenly heat up the piece of cast iron and then once welded it I had to let it cool down slowly (without water). Before I welded my final piece I practice with a other scrap piece, this first result was successful and helped me learn the skills required. I then welded my final piece, which I had issues heating up evenly because of the different thicknesses, but evenly I was able to successfully weld it without it cracking. I then started to create the gliders/wings at the back of the plane. I first cut some 50mm x 3mm to create the gliders, I then cut of the corner and attach it to the bottom the create the intented shape, once I had mig welded it I ground down the weld to create a smoother finish. Once I finished the glider I the cut a section of the scrap roofing sheet, using a cutting disc, which I used to create the second wings. I then took about the chain, until I had four piece of four links. I did this through using a centre punch and a hammer. Once I had collected my four pieces I welded my chain pieces so that they couldn’t move, then to my sledges. The chain pieces are to attach the sledges to the body of the plain. Then is started to create the parts for the propeller, first I bent the round bar into a semicircle to fill the gap between bearing and the cabin. Once I had welded the round bar to the plane I welded the bearing to the plane as well, but in this process I seized up my bearing so it would move, so I had to determine a new moving part. I then created the propeller for my plane using the grinders. I then ground down my bolt so the propeller would spin, because of the bearing seizing up. I used a washer to stop the propeller of falling off, I welded the bolt to the bearing along with the washer to the bolt, I did all these with the MIG welder. The final step of my plane was removing any splatter form the welder as well as an burn smoke/burn marks for the brazing and welding processes. My final design I built a sea plane, I built most of it out of scrap metal, because my intended design was to have a scrap metal/recycled theme. I continued this idea, by not grinding or polishing my plane, but instead I cleared coat it. Overall I think my plane turned out pretty good, apart from minor issued, which came from trying to join/balance different scrap metal objects, create cause them to be slightly uneven. The biggest problem I had was trying to weld the cast iron to by plane, in order to achieved this I had to do research and talk to my lectures in order to learn how to do it. I think my project would be good for student, because it removes and creates a purpose for scrap metal which it good for the environment.