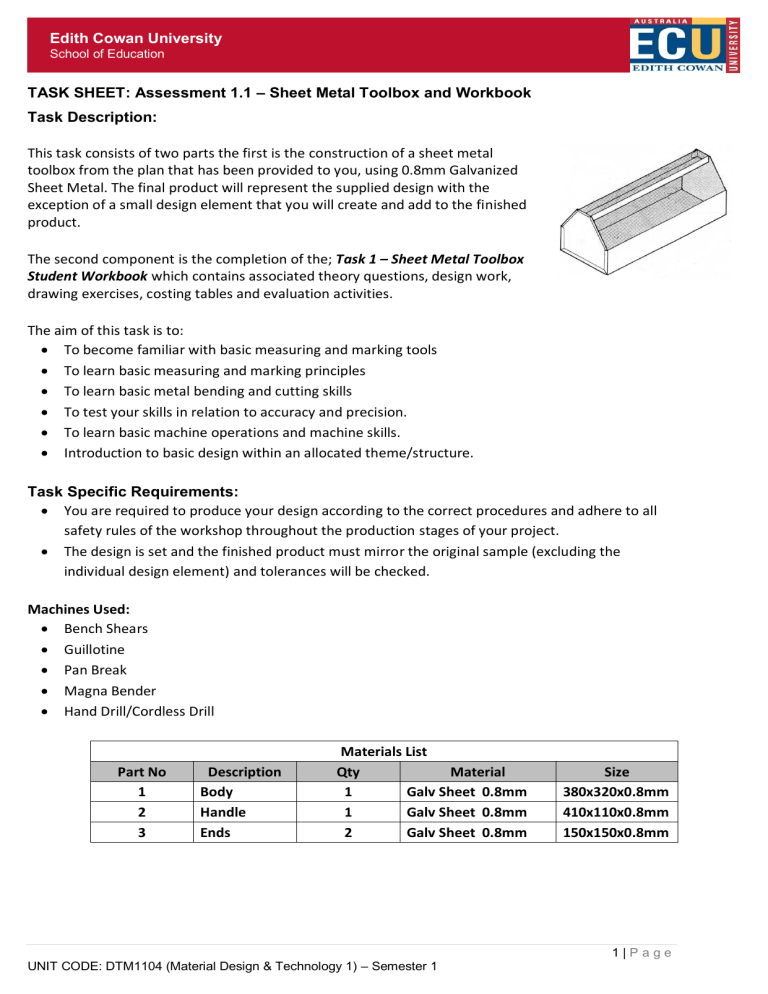

Edith Cowan University School of Education TASK SHEET: Assessment 1.1 – Sheet Metal Toolbox and Workbook Task Description: This task consists of two parts the first is the construction of a sheet metal toolbox from the plan that has been provided to you, using 0.8mm Galvanized Sheet Metal. The final product will represent the supplied design with the exception of a small design element that you will create and add to the finished product. The second component is the completion of the; Task 1 – Sheet Metal Toolbox Student Workbook which contains associated theory questions, design work, drawing exercises, costing tables and evaluation activities. The aim of this task is to: To become familiar with basic measuring and marking tools To learn basic measuring and marking principles To learn basic metal bending and cutting skills To test your skills in relation to accuracy and precision. To learn basic machine operations and machine skills. Introduction to basic design within an allocated theme/structure. Task Specific Requirements: You are required to produce your design according to the correct procedures and adhere to all safety rules of the workshop throughout the production stages of your project. The design is set and the finished product must mirror the original sample (excluding the individual design element) and tolerances will be checked. Machines Used: Bench Shears Guillotine Pan Break Magna Bender Hand Drill/Cordless Drill Part No 1 2 3 Description Body Handle Ends Materials List Qty Material 1 Galv Sheet 0.8mm 1 Galv Sheet 0.8mm 2 Galv Sheet 0.8mm Size 380x320x0.8mm 410x110x0.8mm 150x150x0.8mm 1|Page UNIT CODE: DTM1104 (Material Design & Technology 1) – Semester 1 Edith Cowan University School of Education 2|Page UNIT CODE: DTM1104 (Material Design & Technology 1) – Semester 1 Edith Cowan University School of Education Task 1 - Production Procedure 1. Collect the provided materials for the task (pre-cut sheet 410x570x0.8mm) 2. On the allocated material mark out the detail as per below and indicate the waste. 3. 4. Body 5. 6. 7. 8. Ends 9. Show your lecturer for confirmation of accuracy. Cut to shape using the Guilotine Mark out the detail of the body and indicate any waste. Cut to shape Bend the 10mm safe edge, then the 15mm lap joint using the magna bender and the pan break. Bend the two sides. Check the width between the sides (150mm) and adjust the measurements if required before marking out the ends. 10. Mark out the detail and indicate the waste. 11. Cut to shape, fit to the body and bend the safe edges. 12. Spot weld one end into place, rivet the other to the body. Handle 13. Check the length between the ends (380mm) and adjust the measurements if required before marking out the handle. 14. Mark out the detail and indicate the waste. 15. Cut to shape and bend the safe edges. 16. Bend the shape of the handle Design Elements 17. Using the design proforma in the Task 1.1 Sheet Metal Tool Boox Workbook design a small element that could be fitted to or slide along the tool box to enhance the design and add indivudal creative flare. 18. Source material, mark, measure and cut. Make any nesscary bends and cuts Assembly 19. Fit and rivet the handle to the body. 20. Fit Design Element to the toolbox. 21. Apply a surface finish. 3|Page UNIT CODE: DTM1104 (Material Design & Technology 1) – Semester 1 Edith Cowan University School of Education Assessment 1.1 – Sheet Metal Toolbox and Workbook Measurement Accuracy: The marking out and the measurement accuracy of the individual components are completed independently and to a high degree of accuracy. /3 Does the assembled toolbox meet the tolerances stipulated for this task and is it accurate in regards to the overall dimensions of the design. /3 Construction: The construction and assembly of the toolbox was completed independently and according to the task procedure. Have the quality of cuts, bends and fixing techniques all been completed to a high standard. /3 /3 Presentation and Finish: Does the completed project display a high level of execution and presentation in regards to the overall visual aesthetic. /3 Workshop Safety and Interactions: The project has been completed according to the correct workshop procedures and guidelines. Have the students workshop interactions between their peers and with staff been positive and followed workshop guidelines. /3 /3 Design Element The degree of difficulty in regards to the chosen design element. /3 /3 /3 Does the execution of the completed element resemble the documented idea. Does the completed element function as intended. Toolbox Workbook Have all the questions and activities been attempted and completed /3 /3 /3 Have all the questions and activities been completed to a high degree of accuracy. Have the drawing activities been completed to a high level, showing care in line work, accuracy, shading, dimensioning and presentation. Comment: TOTALS /39 Teacher Signature: Date: 4|Page UNIT CODE: DTM1104 (Material Design & Technology 1) – Semester 1 5|Page UNIT CODE: DTM1104 (Material Design & Technology 1) – Semester 1