Wang et al. - 1999 - Application of Taguchi Method to Robust Design of BLDC Motor Performance

advertisement

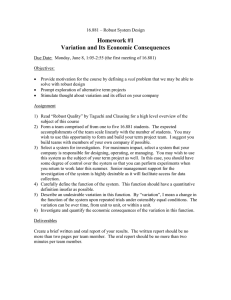

IEEE TRANSACTIONS ON MAONRT‘ICS. VOI. 35 NO 5. SEFTEMBER 1999 37110 Application of Taguchi Method to Robust Design of BLDC Motor Performance H.T. Wang, Z.J. Liu, S.X.Chen and J.P. Yang Data Storage Institute, National University of Singapore 10 Kent Ridge Crescent, Singapore 119260 Abstract-This paper describes an approach to design of brushless de motors considering the cogging torque reduction and running torque optimization to enhance the product robustness. The approach is based on Tawchi method and utilizes the orthogonal array for design of ‘experiments’, i.e. the scheme for numerical simulations using a finite element method. The concept of sienal-to-noise (SN)ratio is aDDlied to evaluate the mot& performance. A comparison is made between the robust solution and the result obtained using a conventional optimization procedure to demonstrate the effectiveness of the rohnst design approach. Index Terns-Electrical Machine, FEM, Robust Design, Taguchi Method I. INTRODUCTION With recent advances in high-speed magnetic recording technology, the robustness of the spindle motor performance becomes an increasingly critical issue. As the design constraints are more stringent, the spindle motor is to be designed to perform in accordance with design specifications despite the variability in operating conditions. For instance, the effect of cogging and unbalanced magnetic pull developed in brushless DC (BLDC) motors [l], which may cause vibration and acoustic noises, must be controlled to the minimum possible level even when the operating condition is subject to variability in thermal condition, material properties, and other noises. It should be noted that in practice the motor performance is controlled by quality inspection means during production process, and excessive cogging/UMP remains as the main cause responsible for a high product failure or re-work rate. Finite element methods ( E M ) are routinely used in evaluation of engineering product performance. Owing to rapid advancement in computer power and CAE tools, development of FEM based design and optimization techniques are gaining pace [Z]. Some commercial FEM software has been implemented with preliminary optimization tools such as those based on fullfactorial or fractional-factorial Design of ‘Experiments’ (DOE). However, it is known that DOE based optimization is not suitable for handling the non-linearity or the effects of noise factors. In this paper, an optimization technique based on Taguchi method is applied to a robust design problem concerning spindle motor performance. Taguchi method is a system of cost-driven quality engineering that emphasizes the effective application of engineering strategies rather than advanced statistical techniques. It can reduce variability and find cost-effective, robust designs of engineering products using a comparatively small number experiments. It essentially aims at achieving the optimal design target while keeping the product performance insensitive to the effects of noise factors that may be due to variability in manufacturing process or environmental conditions, The effectiveness of the technique was demonstrated In the design examples presented below. 11. CONCEPTSANDMETHOD A . Taguchi Method As simulation of product performance using FEM invariably takes considerable computing resources and time, the major challenge encountered in FEM based optimization process for a practical problem is that the designer can only perform a limited number of design trials before reaching the optimal. The concept of Taguchi method that is proven to be effective in the quality engineering involving an efficient planning of experiments on physical prototypes, is now employed for computer simulation based optimization procedure. Application of Taguchi method to robust design problems involves three main stages, (a) Selection of the performance characteristics to be optimized, the control factors that can be adjusted in the optimization exercise, and noise factors; (b) Design and execution of the experiments based on orthogonal array to obtain information on the product performance and its variability; and (c) Using analysis of mean (ANOM) and variance (ANOVA) techniques to obtain optimal setting of parameters for robust. design. Then, verification of the robust design result shall be performed. One of the key features of the Taguchi method is the use of signal-to-noise ratio (SN Ratio) to transform the performance characteristic in the optimization process [3]. For the design problem under investigation, the cogging torque to running torque ratio is chosen as the performance characteristic and the S N ratio can be expressed as follows, B. Simulation of Product Response To evaluate a design performance, a parametric description for a BLDC motor is made. Fig. I shows one pole pitch of the cross-sectional view of BLDC motor. The electromagnetic field in the motor can be analyzed by using finite element method, and the electromagnetically induced forces and torque can also be computed with various techniques [l]. 0018-9464/99$10,00 0 1999 IEEE 3701 Rg.1. Cross-sectional view of BLDC motor showing 112 Stator tooth and 1 magnet pole referred to as product performance characteristics, is to be simulated using FEM. Simulation and Results The FEM simulation of the electromagnetic field in the spindle motor is straightforward, however particular care must he taken in the computation of electromagnetic forces using FEM based techniques. It will be noted that since the effect of the noise factors is to be examined in the optimization process, the accuracy of the numerical simulation is of great concern. Therefore, a very detailed modeling of the physical problems is usually necessary. A typical mesh of FEM analysis for the spindle motor optimization problem is shown in Fig. 2, and the magnetic flux distribution in Fig. 3, respectively. The cogging torque-to-running torque ratio is computed according to the following equation where T,i and Tri are cogging torque and running torque of the ith run. Fig.2. Mesh for FEM analysis Computation and Analysis The mean, standard deviation, mean square deviation (MSD) and S/N ratio based on the numerical simulation of the responses are computed, and the results are given in TABLE I. TABLE I COMPUTATION ANDANALYSIS FOREACH RUNS Run 1 2 ' 3 4 5 6 7 R g 3 Plux Distnbution 8 9 mean 45.141% 49.266% 53.878% 59.785% 63.482% 65.195% 39.306% 42.668% 47.750% Std. De". 0.029843 0.031780 0.033317 0,016776 0.017890 0.017403 0.024648 0.025757 0.0~4038 MSD S/NRatio 0.204566 6.891657 0.243616 6.132947 0.291273 5.356992 0.357677 4.465089 0,403283 ,3.943902 0.425313 .3.712914 .0.155037 8.095657 0.182648 7.383841 0.228523 ' 6.410703 111.DESIGN OF EXPERMENTS ANALYSIS Design of Experiments In this paper, An 8-pole & 6-slot external rotor BLDC motor was considered. The design objective is to achieve the optimal cogging torque-to-running torque ratio, and in the mean time the deviation due to the effects of all noise factors should be maintained minimal. Three design parameters were considered as the control factors. They are Tooth Face Angle (TFA), Tooth Body Height (HTB), and Magnet Thickness (HM). Other three factors are considered as the noise factors, they are Magnet Material (MM), Tooth Face Angle (TFA), and Air-Gap Length (LA). Fig. 1 shows a partial cross-sectional view with some parameter specified. Two L9 orthogonal arrays (OA) were utilized to structure the settings of the design parameters (control factors) and noise factors, respectively. At each design parameter setting the response, or otherwise may be The sensitivity analysis for each control factor can then be performed by calculating the average S/N ratio for each factor at the same level. Additionally, the effects of factors on the performance of the spindle motor can also be found according to the S/N ratio. The results are given in TABLE 11. At the same time, the percentage contribution (PC) for all control factors can be computed and presented using the ratio of factor SS to TSS, as shown in TABLE 111. It can be observed that the tooth face angle has larger Contribution and more pronounced influence on the performance. Prediction and verification Based on the above analyses of control factors and sensitivity, an optimal setting of the design parameters can be determined. Predictions of the mean and deviation of response can be obtained. TABLE I1 COMPUTATION ANDANALYSISFORFACTORS Factor Level WN) ~~ 1 TFA 2 3 HTB 2 3 LM 2 3 I 1 6,127199 4.040635 7.296734 6.484134 5.820230 5.I60203 5.996137 5.669580 5.798850 TABLE III ANOVAFORCONTROL FACTORS SS D . 0 . F Meansq. F PC'(%) Factor TFA 16.324 2 HTB 2.6292 2 LM 0.1623 2 'PC-percentage contribution 8.1619 1.3146 0.0811 TABLE IV PREDICTION ANDVERIPICATION Prediction Verification Mean 39.13% 38.57% STD.DEV 0.02321 0.02389 8.13396 CriuyTaw Vdiden 0045 ,""U" 143.18 84.89 23.061 13.67 1.4233 0.842 For the optimization problem under investigation, the optimal setting is From: TFA is on level 3, HTB is on level 1, and LM is on level 1. That is, TFA is 51", HTB is 3.8 mm, and LM is 1.155 mm. This is also referred to as the robust solution in the following. Figure 4 compares the cogging torque profiles developed in the BLDC spindle motor before and after robust design procedure being applied. The percentage contribution of each control factor to the performance characteristic can. also be evaluated during the course of optimization using Taguchi method. The variance of the cogging torque at different settings of design parameters is plotted in Fig. 5. The robust design point is also indicated in these figures. It can be seen that the robust design process yields smaller cogging torque and larger running torque, and in the meantime the performance is less sensitive to noise factors at the settings of control factors corresponding to the robust design point. Table IV shows the prediction and verification on robust point. SIN Fig.4. A Cogging Torque Comparison between Normal Design and Robust Design 8.26064 From these figures, it can be concluded that by applying the robust design technique an improved product performance, in this case reduced cogging torque or cogging to running torque ratio, can be achieved. At the robust design point the sensitivity level of the performance to the noise factors, as reflected by the variance of the performance, is also significantly reduced. Fig.5. A Cornperison about Cogging Torque Variation between Normal Design and Robust Design IV. CONCLUSION Design optimization of HDD spindle motors using a Taguchi method is discussed. The robust solution that is insensitive to the effects of noise factors is achieved. It is shown that the technique is effective in the cases where FEM simulation or other computationally expensive technique is to be used to evaluate the product performance as against each setting of design parameters. It is especially true when a robust solution is to be found and therefore a very detailed analysis of the physical problem is necessary to account for the noise effects in numerical simulation process. The technique is also seen to be suitable for use in optimization problems involving discrete design parameters. REFERENCES Z. J. Liu. S. X. Chen, Q. D. Zhang, 'Design of Brushless DC spindle motors for high speed HDD Recording', IEEE Trans. on Magnetics, vol. 34,No. 2,pp 483-485.1998. K.Preis, C.Magele, and O.Biro, "FEM and evolution strategies m the optimal-design of electromagnetic devices", B E E Trans. an Maen.. Val. 26.No.9.~~2181-2183. 1990. W.?.Fuwlkes 'et al. "Engineering .Methods for Robust Pmduct Design': Addison-Wesley, 1995.