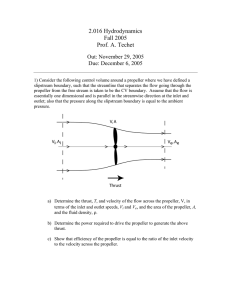

i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 3 7 ( 2 0 1 2 ) 1 4 6 0 3 e1 4 6 1 1 Available online at www.sciencedirect.com journal homepage: www.elsevier.com/locate/he Hydrogen tube vehicle for supersonic transport: 4. Hydrogen propeller Arnold R. Miller* Supersonic Institute, 200 Violet St, Suite 100, Golden, CO 80401, USA article info abstract Article history: A hydrogen propeller is the method of propulsion of a conceptual supersonic vehicle that Received 6 April 2012 operates within a hydrogen-filled tube at cruise speed of 1 km/s. Because Mach number Received in revised form governs formation of shock waves at the blade tips, the high sonic speed of hydrogen 19 June 2012 allows a rotational frequency 3.85 times faster than the same propeller operating in air Accepted 19 June 2012 immediately outside the tube. RankineeFroude propulsive efficiency and e for a given Available online 11 August 2012 vehicle Mach numberepropeller pitch and helix angle are invariant with respect to the atmosphere. To achieve constant efficiency at a given thrust and for adequate acceleration, Keywords: the low density of hydrogen requires some combination of higher frequency, more blades, Hydrogen or larger diameter. The hydrogen propeller conceptual design employs 14 contra-rotating Propeller blades, 4.11 m diameter, and rotational frequency of 40.4 s1 at translational velocity of RankineeFroude theory 970 m/s. Supersonic transport Copyright ª 2012, Hydrogen Energy Publications, LLC. Published by Elsevier Ltd. All rights Tube vehicle 1. Introduction Tube vehicles, for example, subway trains, provide benefits that include operation independent of the weather, shortestdistance travel, avoidance of surface traffic, and groundlevel noise abatement. A large literature exists on the aerodynamics of vehicles operating in air-filled tubes [1e6]. Because of flow restriction in the gap between tube and vehicle, a tube vehicle experiences higher drag than the same vehicle operating in an open atmosphere [4]; to lower drag, evacuated tubes with air pressure of 9 kPa have been proposed [7]. One factor in realizing the potential of a tube vehicle is to maximize tube cross-sectional area while minimizing infrastructure cost. Such a method has been proposed as “conjoined tubes” [8]. Because a practical tube system must allow parallel or bidirectional transit, the idea is to join a bundle of circular-section tubes to form a single, fluted tube reserved. with grooves or waists along its length. Fig. 1 illustrates the idea for three conjoined tubes. Another new idea is to use hydrogen as the tube atmosphere [9e11]. The conceptual supersonic hydrogen vehicle operates within an enclosed, hydrogen-filled tube at cruise speed of 1 km/ s. To prevent leakage of air into the tube, hydrogen pressure is minimally above outside air pressure, and the tube serves as a phase separator rather than a pressure vessel. Within the tube, a vehicle levitates above a guideway on a magnetic field or gas film and uses propeller propulsion; it breathes fuel for fuelcell power from the tube, stores liquid oxygen onboard, and collects the product water as it operates [9]. Parameters associated with sonic speed and aerodynamic drag can be very different inside the tube than outside. The hydrogen vehicle has two Mach numbers: one with respect to hydrogen inside the tube and one with respect to air outside. A speed of Mach 0.74 inside (970 m/s) corresponds to Mach 2.8 for a land vehicle immediately outside the tube and to Mach 3.3 * Corresponding author. Tel.: þ1 303 296 4218; fax: þ1 303 296 4219. E-mail address: arnold.miller@vehicleprojects.com. 0360-3199/$ e see front matter Copyright ª 2012, Hydrogen Energy Publications, LLC. Published by Elsevier Ltd. All rights reserved. http://dx.doi.org/10.1016/j.ijhydene.2012.06.079 14604 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 3 7 ( 2 0 1 2 ) 1 4 6 0 3 e1 4 6 1 1 Fig. 1 e Schematic of conjoined tubes: Three circularsection tubes joined along their lengths form a fluted tube having three waists. Shown are the propeller disk of one vehicle and the possible positions of two others (dashed). for the same body hypothetically at 11,000 m, a typical cruise altitude of transport airplanes. Thus, the vehicle can be strongly supersonic outside while subsonic inside. For laminar flow over a flat plate, skin-friction drag varies inversely with the square root of the Reynolds number [11,12]. Assuming the same speed and same characteristic length [4,5], the Reynolds number for the hydrogen vehicle is half the number for the land vehicle but twice that of the body at altitude. A gas-filled tube, vis-à-vis an evacuated tube, offers the potential efficiency, simplicity, and low infrastructure cost of propeller propulsion. Propeller propulsion has been studied for air-filled tube vehicles [3]. However, a hydrogen propeller has not been studied or built, and no propeller-driven vehicle in air could achieve a speed of 1 km/s. The high sonic speed and low density of hydrogen make the design of a hydrogen propeller distinct from that of air propellers; the linear nature of a tube constrains multiple propellers to be contra-rotating pairs or tandem pairs, one at either end of the vehicle. In this paper, we investigate contra-rotating, tandem propellers driving a hydrogen tube vehicle and propose a conceptual propeller design based on the results. 2. Thrust and power We assume the main features of RankineeFroude momentum theory [13,14] but apply it to contra-rotating, tandem propellers in a tube. A propeller is modeled as an ideal actuator disk, equivalent to a propeller with an infinite number of blades [14], which exhibits no resistance to gas flow, transfers all mechanical energy to the gas, and experiences a uniform distribution of gas pressure and velocity over its surface. As an ideal actuator disk, a contra-rotating propeller has twice the area of an actuator disk representing a single propeller. RankineeFroude theory assumes isentropic, incompressible, irrotational flow in an ideal gas. By the assumption of isentropic flow, the theory ignores presence of the vehicle in the propeller flows. In the case of a tube vehicle, by continuity, propeller flow accelerates as it enters the gap between vehicle and tube, but it equally decelerates as it exits. Thus, by the isentropic assumption, we also ignore presence of the vehicle in the tube. Flow velocity Vf through front disk Df (see Fig. 2) is derived from the Bernoulli equation. To avoid violating the Bernoulli assumption of adiabatic flow, the equation is separately applied before the disk and after the disk. It can thus be shown [13] that Vf equals the mean 1 Vf ¼ ðV þ Vs Þ 2 (1) where V is flow velocity far ahead of the disk (i.e., vehicle velocity, or initial inflow velocity, within the vehicle-fixed frame of reference) and Vs is the fully-developed slipstream velocity far behind the disk. The analysis based on the Bernoulli equation is not changed by the fact that the flows occur within a tube e as long as they are isentropic and incompressible e and Eq. (1) applies equally to an actuator disk within a finite-diameter, infinite-length tube as to one in an open atmosphere. The tube may have any cross-sectional geometry; e.g., it may be circular-section or fluted. Following the RankineeFroude theory for a single disk, the thrust and power of the front disk derives from Newton’s second law. In unit time increment, mass flow mf ¼ rAVf, where r is gas density and A is the area of the disk. Substitution of Eq. (1) into this expression gives 1 mf ¼ rAðV þ Vs Þ 2 (2) for the mass flow through the front disk. Since thrust Tf ¼ mf(VsV), substitution of Eq. (2) for mf gives 1 Tf ¼ rA Vs2 V2 ; 2 Vs V (3) as the thrust provided by the front disk of the tandem pair. In unit time, power is the kinetic energy to change V to Vs, that is, 1 1 Pf ¼ mf Vs2 mf V2 . Substituting Eq. (2) into this expression 2 2 yields Fig. 2 e Propulsion in a tube: Front disk Df and rear disk Dr are identical up to location. Possible streamline velocities are vehicle velocity V, velocity through front disk Vf, and slipstream velocity from front disk Vs. Mean inflow velocity to rear disk, V0 (not shown), is the weighted mean of V and Vs. The tube has unbounded length. i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 3 7 ( 2 0 1 2 ) 1 4 6 0 3 e1 4 6 1 1 1 Pf ¼ rA Vs2 V2 ðVs þ VÞ; 4 Vs V (4) as the slipstream power required by the front disk of the tandem pair. Thrust Tr and power Pr for the rear disk Dr differ from the front disk because the initial inflow velocity V0 may be greater than V, and its final slipstream velocity Vs0 may be greater than Vs. Possible velocities of streamlines entering the rear disk are illustrated in Fig. 2. Because the vehicle length is large, before the rear disk is reached, we assume (a) the slipstream from the front disk achieves its final velocity Vs and (b) complete mixing of the flows occurs. By continuity, if a streamline with velocity Vs misses the rear disk, a streamline of velocity V must replace it. Hence, the initial inflow velocity to the rear disk is the weighted mean V0 ¼ ð1 wÞV þ wVs ; 0w1 (5) where w is the probability that a streamline in the slipstream from the front disk will intersect the rear disk. Weight w¼ A At (6) where A is the area of the rear actuator disk and At is the cross-sectional area of the tube. We assume that Vs0 =Vs ¼ V0 =V and hence the final slipstream velocity from the rear disk is Vs0 ¼ V0 Vs V (7) This assumption is equivalent to the standard Rankinee Froude assumption of an inflow factor a [13,15], defined as Vs ¼ V(1þ2a), a 0, where a is a constant1 positive real number. If a is the same for the front and rear disks, we have Vs0 ¼ V0 ð1 þ 2aÞ and Vs0 =Vs ¼ V0 (1þ2a)/V(1þ2a) ¼ V0 /V, which is equivalent to (7). Substitution of V0 for V and substitution of Vs0 for Vs into Eqs. (3) and (4) give ð1 wÞV þ wVs 2 1 ; Tr ¼ rA Vs2 V2 V 2 0 w 1; 0 < V Vs (8) 3 1 ð1 wÞV þ wVs ; 0 w 1; 0 < V Vs Pr ¼ rA Vs2 V2 ðVs þVÞ V 4 (9) for the thrust and power, respectively, for rear disk Dr. 1 The standard assumption is that a is constant for all V. However, because of the large speed range and the cubic dependency of slipstream power on V, a constant a is not realistic for the hydrogen vehicle. For example, taking h ¼ 0.90, the Rankinee Froude expression [13] for propulsive efficiency h ¼ 1/(1 þ a) yields constant a ¼ 0.111. With an actuator disk area A ¼ Re ¼ 81.2 m2, as developed in the section Calculations for Design, Eq. (4) calculates 1.7 GW for slipstream power at 970 m/s; even if we reduce A to that of the airplane, 13.27 m2, the power is 270 MW. Rather than being a constant, the inflow factor must be a decreasing function of V, which amounts to Vs being a nonlinear function g of V, with monotone decreasing slope. Derivation of Eq. (7) is valid because it only assumes that each tandem propeller has the same function g and same argument V. 3. 14605 Propulsive efficiency The RankineeFroude propulsive efficiency h establishes an upper bound on efficiency of propeller propulsion. Extension of the definition to tandem propellers gives the following equation for propulsive efficiency h¼ V Tf þ Tr Pf þ Pr (10) where Tf and Tr are the thrust provided by the front and rear disks, respectively, and Pf and Pr are the slipstream power required by the front and rear disks, respectively. Substitution into Eq. (10) of Eqs. (3), (4), (8) and (9) gives h¼ 2V V3 þ V½ð1 wÞV þ wVs 2 ; Vs þ V V3 þ ½ð1 wÞV þ wVs 3 0 w 1; 0 < V Vs (11) as the propulsive efficiency for tandem disks in a tube; V can validly assume the value zero in (11), but V and Vs cannot simultaneously be zero. By inspection, because h is a continuous function of Vs and w, with V fixed, h converges to its maximum value of unity as Vs / V and w ¼ 0. Proposition: Efficiency h as described by (11) is a monotone decreasing function of w (with fixed V and Vs), and independently, h is a monotone decreasing function of Vs (fixed V and w). Proof: For brevity, using the V0 notation as defined by Eq. (5), Eq. (11) may be written as h ¼ 41 $42 ¼ 2V V3 þ VV02 $ Vs þ V V3 þ V03 (12) where 41 and 42 are positive real numbers for all values of the independent variables. It is obvious that 41 is a monotone decreasing function of Vs (fixed V and w), and it is not false that 41 is a monotone decreasing function of w (fixed V and Vs). For factor 42, consider that V0 is a weighted mean and hence V V0 Vs. It follows that, for fixed V, a non-negative 0 real number c exists such that V ¼ cV0 , c 1. Therefore, the VV 2 term in (12) becomes VV02 ¼ ðcV0 ÞV02 ¼ cV03 ; c 1 (13) and the second factor becomes 42 ¼ V3 þ cV03 ; c1 V3 þ V03 (14) Consider the continued inequality 0 V V0 Vs, with V constant: With Vs fixed, by the properties of a weighted mean, c decreases monotonically as w increases; with w fixed, c decreases monotonically as Vs increases. Hence, noting that the numerator of 42 is a monotone increasing function of c, it follows that 42 is a monotone decreasing function of w, and 42 is a monotone decreasing function of Vs. Because positive real numbers 41 and 42 each obey the conditions of the Proposition, their product h does also. Corollary: With V and w fixed, h converges monotonically to unity as Vs converges to V. Proof: Let V and w be fixed. By the Proposition, if Vs decreases monotonically, h increases monotonically. Since Vs 14606 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 3 7 ( 2 0 1 2 ) 1 4 6 0 3 e1 4 6 1 1 is bounded below by V, and h is bounded above by unity, it follows that h/1 monotonically as Vs/V. Efficiency as defined by Eq. (11) is not explicitly a function of r or A; however, for efficiency to increase and thrust to remain constant, either r or A (or both) must also increase. It is sufficient to show this by considering only the front disk: Because efficiency is increased by the convergence Vs/V, the factor ðVs2 V2 Þ in Eq. (3) simultaneously converges monotonically to zero; hence, for thrust to remain constant, the product rA must increase as efficiency increases. Likewise, for given thrust, speed, and density, efficiency is an increasing function of A, and for given thrust, speed, and area, it is an increasing function of r. Fig. 3 compares h from Eq. (11), as a function of Vs, with the standard RankineeFroude propulsive efficiency h0 ¼ 2V/ (VsþV) for a single disk [13]. With vehicle velocity fixed at V ¼ 970 m/s and weight w ¼ 0.3, a reasonable value of w for a fluted tube, Vs is varied from 970 m/s to 1020 m/s. Because w > 0, the efficiency of the tandem disks is lower than that of a single disk; however, the maximum absolute difference in efficiency, over the range examined, is less than 1%. Because propulsive efficiency is maximized when Vs is near V, we can derive an approximation from the limit of Eq. (11) as Vs/V. Define DV ¼ Vs V; Vs V (15) then, substitution into Eq. (11) of Vs as thus defined gives, after dropping terms containing DV2 and DV3, an expression for lim h from which we establish the approximation DV/0 2V V þ wDV hy ; 2V þ DV V þ 3= wDV 2 0 w 1; (16) which is valid when DV is small. With V ¼ 970 m/s and w ¼ 0.3, the relative error is less than 0.25% for values of Vs up to 1120 m/s. 4. Pitch and frequency Because a propeller rotates simultaneously to translating, a fixed point B on a blade traces out a helix as the vehicle advances. Pitch p is the distance the point moves forward in one revolution. Letting r be the orthogonal distance of B from the rotational axis, the helix angle, or pitch angle, q(r) is the angle between the helix and any edge of the right sections of the cylinder, with radius r, on which the helix lies; the coarser the helix, the larger the angle. Helix angle is given as [14] qðrÞ ¼ arctan p 2pr (17) Because pitch by definition is p¼ V f (18) where V is vehicle speed and f is propeller rotational frequency, we have qðrÞ ¼ arctan V 2prf (19) for the helix angle. Ignoring angle of attack, if a blade’s nosetail line is twisted along its length according to Eq. (19), the blade will strike the atmosphere by its edge, and most of its drag will be skin-friction drag. For a given propeller diameter, rotational frequency f is limited by the formation of shock waves at the blade tips. The tips experience the highest flow velocity on the vehicle. Tip velocity Vtip is the vector sum Vtip ¼ VþVrot, where V is translational velocity and Vrot is tangential velocity of the rotating tip, and hence, tip speed is Vtip ¼ ðjVj2 þ jVrot j2 Þ1=2 . Since tangential speed is Vrot ¼ pdf, where d is propeller diameter, tip speed is Vtip ¼ qffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi 2 V2 þ ðpdf Þ (20) Because formation of shock waves is governed by Mach number, assuming the same blade shape, the acceptable Mach number of the tips in hydrogen is the same as the acceptable Mach number in air or any ideal gas. Consider two gases: (a) hydrogen or (b) any ideal gas (referred to as the “second gas”). Let fi be the rotational frequency and Vi be the speed in the second gas. If the vehicles have the same Mach number in their respective gases, then V ¼ sVi, where s is the sonic ratio. Suppose the propeller frequencies are likewise related by f ¼ sfi. Then, from (20), the ratio of tip speeds is also in the ratio of s: Vtip ¼ Vtip; i Fig. 3 e Propulsive efficiency: Efficiency h versus slipstream velocity for a RankineeFroude single disk and tandem disks. Initial inflow velocity is fixed at 970 m/s. qffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi 2ffi ðsVi Þ2 þ pdsfi qffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi 2ffi ¼ s Vi2 þ pdfi (21) where Vtip, i is the tip speed in the second gas. Eq. (21) shows that the Mach numbers of the blade tips in the two gases are identical, and for a given propeller diameter, blade shape, and vehicle Mach number, a hydrogen propeller may rotate faster than a propeller in air or any ideal gas by the sonic ratio s. Denoting the sonic ratio as s0 when the air propeller is operating in the standard atmosphere at zero altitude, we have 14607 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 3 7 ( 2 0 1 2 ) 1 4 6 0 3 e1 4 6 1 1 s0 ¼ 3.85. If the comparison is made with an air propeller operating at higher altitude than zero, then s > s0. With given vehicle Mach number and propeller diameter, the pitch and helix angle are invariant with respect to the identity of the atmosphere. Let pi be the pitch of a propeller in the second gas. Because V ¼ sVi and f ¼ sfi, the pitch p of the hydrogen propeller is V sVi Vi p¼ ¼ ¼ ¼ pi sfi fi f Calculations for design Based on the theoretical results above and recommendations for contra-rotating propeller design [16], we will develop a conceptual design by extrapolating the propeller of an airplane to operation in a hydrogen atmosphere. The Bombardier Dash 8 Q400 [9] uses the Dowty R408 propeller [17], a six-bladed, carbon-fiber composite propeller with scimitar-shaped blades. We assume that the hub diameter, blade shape, and propeller diameter of the hydrogen propeller are the same as the air propeller and that it uses two contrarotating rows of blades. To be determined are the rotational frequency and the number of blades. The blade will be twisted to satisfy Eq. (19). To accommodate the potential for higher rotational frequency, as well as adding more blades and two rows of contra-rotating blades, consider a transformation that converts the geometric rotor area Ra of the air propeller to an equivalent, hypothetical rotor area Re of the hydrogen propeller. The transformation is defined as Re ¼ ðFCNÞRa Vehicle Q400 airplane Hydrogen (22) Hence, pitch of the hydrogen propeller is the same as the pitch in any ideal gas; likewise, the helix angle is invariant. 5. Table 1 e Frequency and tip speed.a (23) where F is the ratio of thrusts obtainable (with fixed flow velocity) by increasing rotational frequency of the hydrogen rotors versus the air propeller; C is the ratio of thrusts obtainable by increasing the number of blade-rows from one to two (contra-rotating); and N is the ratio of thrusts by increasing the mean number of blades from six to (n1 þ n2)/2, where n1 is the number of blades in the first row, n2 is the number in the second, and N ¼ (n1 þ n2)/12. For a given flow velocity, each factor increases mass flow through the rotor. Analogous to airplane takeoff, rotor frequency at startup is higher than at cruise. Table 1 lists the Q400’s known frequencies at takeoff and cruise and computes the corresponding tip Mach numbers using Eq. (20). The table also displays the frequencies of the hydrogen vehicle at V ¼ 0 and V ¼ 970 m/s and the corresponding tip Mach numbers matching those of the airplane. At V ¼ 0, the hydrogen propeller can rotate at 65.5 s1 compared to 17.0 s1 for the air propeller; at cruise, it can rotate at 40.4 s1 compared to 14.17 s1. Hence, the ratio of thrusts is F ¼ 3.85 at startup and F ¼ 2.85 at cruise. The thrust provided by the two rotors could, in principle, be equal and thence C ¼ 2. However, because of gearbox requirements [16], the thrust provided by the two rotors may not be Speed m/s Frequency s1 Tip Speedb m/s Tip Speed Mach 0 185 0 970 17.0 14.17 65.5 40.4 219.8 260.3 846.9 1102 0.646 0.841c 0.646 0.841 a Propeller diameter 4.11 m for both vehicles. b From Eq. (20). c At 7620 m altitude in standard atmosphere. equal. As an empirical model for the effect on thrust of adding a second, contra-rotating row of blades, we note that the front row of the contra-rotating propellers of the Tupolev Tu-95 (n1 ¼ n2 ¼ 4) absorbs 54.4% of the power for the pair and the rear row absorbs 45.6% [18]. Therefore, we let C ¼ 100/54.4 ¼ 1.84. What remains to be determined is the ratio N. To determine ratio N that provides adequate startup thrust, set V ¼ 0 in Eq. (3), as well as in the analogous equation for thrust of the airplane propeller, and assume that ideal actuator disk area is proportional to physical rotor geometric area. Then, the ratio of thrusts yields 2 Re T0 ra0 Vsa ¼ Ra Ta0 r VsH (24) where T0 is the maximum static thrust of the hydrogen vehicle, Ta0 is the maximum static thrust of the airplane, ra0 is the density of air at zero altitude in the standard atmosphere, Vsa is the slipstream velocity of the airplane at maximum static thrust, and VsH is the slipstream velocity of the hydrogen vehicle at maximum static thrust. Assuming at V ¼ 0 that Vsa ¼ VsH, and using transformation (23), Eq. (24) reduces to FCN ¼ T0 ra0 Ta0 r (25) Static thrust of the hydrogen vehicle is computed from Newton’s second law. Because the vehicle must reach 970 m/s in a reasonable elapsed time, its mass must be similar to an airplane’s. We estimate a mass from the 74-passenger Q400 airplane [9]. Based on the weight breakdown of a similar-sized airplane [19], the Q400 without its wing and tail should weigh approximately 87% of its total takeoff mass of 29.3 t. Assuming the mass, in total, of all other components and fluids of the two vehicles is equal, the mass at V ¼ 0 of the hydrogen vehicle is taken as 26 t. If the acceleration is a decreasing linear function of time t, starting from initial value a0 ¼ 2.4 m/ s2, it can be shown2 that 970 m/s can be attained in 13.5 min, which is deemed a satisfactory elapsed time. Static thrust of the hydrogen vehicle is therefore T0 ¼ (26 103 kg)(2.4 m/ s2) ¼ 62.4 kN, or 31.2 kN per propeller. 2 Let the linear acceleration function be a0(1t/teq), where teq is the timeto reach equilibrium speed of 970 m/s. Integration gives VðtÞ ¼ a0 t 1= t2 =teq . Letting t ¼ teq, this equation yields 2 teq ¼ 808 s. 14608 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 3 7 ( 2 0 1 2 ) 1 4 6 0 3 e1 4 6 1 1 Table 2 e Data for Q400 Airplane. Parameter Value a Altitude at cruise, m Density of air at cruise,b kg/m3 Density of air at zero altitude in Std. atmosphere,c kg/m3 Mass at takeoff,a t Power, equivalent, at cruise,d MW Power, shaft, normal takeoff,e MW Power, shaft, maximum at cruise, MW Propeller diameter,a m Propeller geometric disk area, m2 Propeller rotational frequency at takeoff,f s1 (rpm) Propeller rotational frequency at cruise,f s1 (rpm) Speed of vehicle at cruise,g m/s (Mach) 7620 0.548 1.2256 29.3 7.30 6.83 5.89 4.11 13.27 17.0 (1020) Symbol ra ra0 Pa 2Pmax Ra 14.17 (850) 185 (0.60) Va a Ref [21]. b Ref [13], Appendix 2; by linear interpolation. c Ref [13], Appendix 2. d Equivalent power (shaft power plus exhaust power): maximum shaft power at cruise divided by the observed ratio 0.806 of shaft power to equivalent power [22]. e 2 3.415 MW [21]. f 1020 rpm at takeoff and 850 rpm at cruise [23]. g Cruise speed of 667 km/h [21]. We will determine that 14 blades are adequate at cruise by showing that the hydrogen propeller’s power loading, power per unit area, falls within the propfan loading limits proposed by Strack et al. [16], namely, 0.31e0.41 MW/m2. With the parameters F, C, and N discussed above and the geometrical rotor area Ra ¼ 13.27 given in Table 2, we have the equivalent rotor area Re ¼ 81.2 m2. Hence, the recommended power loadings give an acceptable power range of 27e37 MW per contra-rotating propeller for the hydrogen vehicle. The range of power estimates determined in the Appendix, 19e38 MW, falls almost entirely within or below this range, which supports a propeller design having 14 blades. The result of the analysis is a hydrogen propeller conceptual design with rotational frequency of 40.4 s1 at cruise, 14 contra-rotating blades, hub diameter of 0.375 m, and outer diameter of 4.11 m. The analysis of Strack et al. [16] found that contra-rotating propeller efficiency is maximized when rotor spacing is minimized. The minimum spacing with the R408 blade is 0.37 m, occurring when the blades are feathered; we use a rotor spacing of 0.43 m. From Eq. (18), the pitch of the hydrogen propeller is 24.0 m, which compares to 13.1 m for the Q400 airplane propeller. Fig. 4 is a CAD drawing of the hydrogen propeller conceptual design, and Table 4 collects relevant design parameters for the hydrogen vehicle and airplane. The static thrust for the airplane is estimated by a model of the maximum static thrust of a propeller as a function of its maximum shaft power [20] 2=3 Ta0 ¼ 0:90ð2ra0 Ra Þ1=3 Pmax (26) where Pmax is its maximum shaft power per rotor. From the data in Table 2, with Pmax ¼ 3.415 MW, Eq. (26) yields Ta0 ¼ 65.15 kN. With F ¼ 3.85, C ¼ 1.84, the two thrust values just computed, and hydrogen density from Table 3, we solve (25) for N to give N ¼ 1.005. Since n1 ¼ 7 and n2 ¼ 6 correspond to N ¼ 1.083, a 13-bladed propeller may be adequate. However, if the true static thrust of the airplane is lower than calculated by Eq. (26), the error would make the value of N calculated via (25) too small. With 14 blades, (25) calculates that the true thrust Ta0 could be as low as 39.3 kN. Propulsive efficiency at cruise will be higher for 14 blades than 13 because h is an increasing function of A (see Propulsive Efficiency) and likewise an increasing function of Re. Hence, for a design margin and increased efficiency, the conceptual design uses 14 blades, seven in each row. Table 3 e Data for Hydrogen Vehicle. Parameter a 3 Density of hydrogen, kg/m Mass at startup, t Speed of vehicle at cruise, m/s (Mach)b 3 Value Symbol 0.0824 26 970 (0.74) r V a At tube pressure 101.3 10 Pa and temperature 298e300 K [24]. b For 1310 m/s speed of sound [24]. Fig. 4 e Hydrogen propeller conceptual design. Fourteen contra-rotating blades of 4.11 m diameter are shown with a nose-tail helix angle q(r) designed for a cruise speed of 970 m/s at rotational frequency of 40.4 sL1. As per Eq. (19), q(0.375) [ 84.4 at the blade root, and q(2.055) [ 61.7 at the tips. Rotor spacing is 0.43 m, and the person is 1.7 m tall. i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 3 7 ( 2 0 1 2 ) 1 4 6 0 3 e1 4 6 1 1 Table 4 e Comparison of Parameters. Parameter Mass at startup, t Number of blades per propeller Number of propellers Number of passengers Pitch at cruise, m Propeller diameter, m Propeller frequency at startup, s1 Propeller frequency at cruise, s1 Vehicle speed at cruise, m/s (Mach) a b c d 6. Q400 airplane Hydrogen vehicle 29.3a 6 2 (lateral)b 74b 13.1 4.11 17.0 26 14 2 (tandem) 74c 24.0 4.11 65.5 14.17 40.4 185 (0.60)d 970 (0.74) At takeoff [21]. Ref [21]. Ref [9]. At 7620 m altitude [21]. Discussion of results For a given vehicle Mach number, the propeller pitch and helix angle are invariant with respect to the atmosphere. These parameters, the same in hydrogen as in air or any ideal gas, are invariant because both vehicle velocity and rotational frequency are multiplied by the sonic ratio, which therefore cancels. This notwithstanding, the design pitch of the hydrogen propeller, at 24.0 m, is nearly twice the 13.1 m pitch of the Q400 airplane propeller model. Higher pitch ultimately obtains because the cruise speed V of the hydrogen vehicle in Eq. (18) is much higher than that of the given airplane e 970 m/ s versus 185 m/s at 7620 m altitude e likewise, higher Mach number has the effect of lowering acceptable propeller frequency f to avoid shock waves. For constant thrust, propulsive efficiency is an increasing function of the product rA, and therefore high efficiency in the low density of hydrogen requires a relatively large actuator disk area. Our argument is based on the monotone convergence Vs/V, as described in the Corollary, and on thrust Eq. (3). (For a different argument e but from the thrust equation e that propeller efficiency increases as A increases, see Clancy [15]). When statistical weight w ¼ 0, the rear disk is equivalent to the front disk, and the efficiency equation reduces to h0 ¼ 2V/(VsþV), the standard RankineeFroude propulsive efficiency for a single disk [13]. Efficiency is given exactly by approximation (16) in the limit as DV/0, and the approximation agrees well with Eq. (11) for values of Vs reasonably near V. Efficiency in any case is slightly lower than a Rankinee Froude single disk because tandem disks increase the inflow velocity and slipstream kinetic energy for the rear disk. The Proposition and Corollary apply to tandem propellers in hydrogen, air, or any ideal gas. Because Mach number governs formation of shock waves, the sonic ratio s allows a hydrogen propeller rotational frequency 3.85 times faster than the same propeller, at the same translational speed, operating in air immediately outside the tube. The frequency of 40.4 s1 is designed for the cruise speed of 970 m/s, and as per Eq. (20), a higher frequency 14609 of 65.5 s1 is feasible at V ¼ 0. The ratio F of cruise design frequencies of the hydrogen vehicle and airplane, 40.4 s1/ 14.17 s1 ¼ 2.85, is below the sonic ratio s ¼ 4.23 for air at an altitude of 7620 m because the vehicle Mach numbers, as required by Eq. (21), are not the same, with the hydrogen vehicle’s being higher. The conceptual design of a hydrogen propeller is based on transforming the rotor area of an air propeller to a hypothetically larger rotor area that is generated by increasing the rotational frequency, the number of blade-rows, or the number of blades per row. Although the geometrical area of the two rotors is the same, each of these three factors e F, C, and N e increases thrust by increasing mass flow at a given flow velocity, and the transformed area behaves as though it were a larger geometrical area. Fourteen contra-rotating blades rotating at 65.5 s1 provide sufficient static thrust and at 40.4 s1 provide a cruise power-loading within recommended limits for propfans. 7. Conclusions To achieve satisfactory propeller static thrust, power loading, and efficiency, the low density of hydrogen requires some combination of higher frequency, more blades, or larger diameter. This conceptual design uses a standard airplane propeller diameter but uses more blades rotating at higher frequency. Tandem propellers are necessary for the tube vehicle to generate sufficient thrust. High speed of sound and low density of hydrogen play key roles in hydrogen propeller characteristics. With such a high cruise speed, propeller thrust to achieve practical vehicle acceleration may be the limiting factor in passenger carrying-capacity of a hydrogen tube vehicle. The vehicle could consist of several passenger cars in a train [9]; however, achievable acceleration may limit the number of cars or, alternatively, the maximum speed. At the maximum speed of 1 km/s, passenger carrying-capacity could be augmented by multiple discrete vehicles operating in parallel in a fluted tube. High sonic speed allows a 3.85-fold higher rotational frequency than an air propeller immediately outside the tube, and high frequency partially offsets the need for an awkwardly large-diameter propeller. A higher rotational frequency, however, requires superior dynamic balance and greater strength. This analysis discovers characteristics of a hydrogen propeller e potential high rotational frequency and invariance of pitch and helix angle e that suggest it can be developed as a practical device. As the next step of development, we propose that the work justifies implementing experiments on a physical prototype. Acknowledgements I thank my research assistant, Valerie A. Traina, for assistance with the literature references. Thanks to the technical staff of Vehicle Projects Inc for reviewing the manuscript in a series of review sessions and to Dan Lassiter for confirming the 14610 i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 3 7 ( 2 0 1 2 ) 1 4 6 0 3 e1 4 6 1 1 derivations of Eqs. (8), (9), (11) and (16). This research was supported in part by Vehicle Projects Inc. f fi mf N Appendix We estimate the power of the hydrogen vehicle by considering the Q400 fuselage as a model of the hydrogen-vehicle fuselage. When an airplane is minimized for total drag, parasitic drag equals induced drag [19], and half its cruise power Pa is due to induced drag. Hence, Pa0 ¼ ½ Pa, where Pa0 is the power with zero angle of attack, i.e., the zero-lift condition. Start by eliminating induced drag at cruise speed Va in air by instantaneously reducing the effective angle of attack to zero, and then transfer the airplane to an open hydrogen atmosphere with zero lift and new speed V. Since, in any case, the airplane’s power is directly proportional to the product rV3, we have PH0 ¼ Pa0 rV3 1 rV3 ¼ Pa ra Va3 2 ra Va3 (A.1) for the power of the transferred airplane. From the parameters in Tables 2 and 3, Eq. (A.1) yields PH0 ¼ 79 MW for the airplane at zero lift in an open hydrogen atmosphere at 970 m/s. Consider the airplane as constructed from a complete, enclosed fuselage body to which wings and tail have been added. Let Sfus be the surface area of this enclosed body, and let S be the exposed area of the entire airplane (minus propeller blades). From a commercial CAD model of the Q400, we estimate [25] Sfus/S ¼ 0.48. Assume that the hypothetical power required by the fuselage body itself, Pfus, is proportional to this ratio of surface areas, and hence Sfus Pfus yPH0 S (A.2) Eq. (A.2) computes Pfus ¼ 38 MW for the airplane fuselage as a model of the hydrogen-vehicle fuselage in the open hydrogen atmosphere at 970 m/s, which corresponds to 19 MW per contra-rotating propeller. This estimate omits power to overcome increased drag due to operation within a tube and to provide vehicle levitation; however, these adjustments should be smaller than the basic power estimate itself. The power due to operation within a tube can be made as small as desired by increasing tube cross-sectional area At; if levitation were magnetic, based on the known power of 1.7 kW/t for the Transrapid train [26], power consumption should be only 44 kW. Hence, we estimate that the hydrogen vehicle power P, per contra-rotating propeller, falls within the range 19 < P 38 MW at 970 m/s. Nomenclature A At a0 B C c F area of ideal actuator disk of hydrogen vehicle, m2 cross-sectional area of hydrogen tube, m2 initial acceleration of vehicle, m s2 fixed point on a propeller blade ratio of thrust for two contra-rotating rotors versus one rotor real constant n1 n2 P Pa Pa0 Pf Pfus PH0 Pmax Pr p pi Ra Re r S Sfus s s0 Ta0 Tf Tr T0 t teq V V V0 DV Va Vf Vi Vrot Vrot Vs Vs’ Vsa VsH Vtip Vtip Vtip, i w ratio of thrust obtainable by increasing rotational frequency of hydrogen rotor propeller rotational frequency in hydrogen, s1 propeller rotational frequency in any ideal gas, s1 mass flow through front actuator disk, kg/s ratio of thrust due to increasing the number of blades in rotors number of blades in first row number of blades in second row power per propeller of the hydrogen vehicle at cruise (equilibrium), MW power of airplane at cruise, MW power of airplane with zero-lift, zero angle of attack power required by the front actuator disk, W power attributable to airplane fuselage power of an airplane at zero lift in hydrogen maximum shaft power of airplane power required by the rear actuator disk, W pitch of propeller pitch of propeller in an ideal gas geometric rotor area of airplane, m2 transformed, equivalent rotor area in hydrogen vehicle, m2 radius, m area measure of vehicle; surface area of entire airplane surface area attributable to an airplane’s fuselage ratio of speed of sound in hydrogen to speed of sound in a specified gas, sonic ratio ratio of sonic speeds when air is the standard atmosphere at zero altitude maximum static thrust of airplane, N thrust provided to the vehicle by the front actuator disk, N thrust provided to the vehicle by the rear actuator disk, N maximum static thrust of hydrogen vehicle, N time time to reach equilibrium speed speed of vehicle, m/s; initial inflow velocity for front actuator disk, m/s velocity of vehicle, m/s initial flow velocity for rear actuator disk, m/s velocity increment imparted by actuator disk, m/s speed of airplane at cruise, m/s flow velocity through front actuator disk, m/s speed of vehicle in any ideal gas, m/s tangential speed of rotating propeller blade tips, m/s tangential velocity of rotating propeller blade tips, m/s final slipstream velocity from front actuator disk, m/s final slipstream velocity from rear actuator disk, m/s slipstream velocity of airplane at maximum static thrust, m/s slipstream velocity of hydrogen vehicle at maximum static thrust, m/s propeller blade-tip speed, m/s propeller blade-tip velocity, m/s propeller tip velocity in any ideal gas, m/s probability (statistical weight) that a streamline from front disk will intersect rear disk i n t e r n a t i o n a l j o u r n a l o f h y d r o g e n e n e r g y 3 7 ( 2 0 1 2 ) 1 4 6 0 3 e1 4 6 1 1 Greek letters a RankineeFroude inflow factor, dimensionless front actuator disk Df rear actuator disk Dr d propeller diameter, m h propulsive efficiency of tandem actuator disks in a tube, dimensionless RankineeFroude propulsive efficiency (w ¼ 0), h0 dimensionless q helix (pitch) angle, r density of hydrogen in the tube, kg m3 ra density of air at cruise altitude of airplane, kg m3 ra0 density of air at sea level, kg m3 41 positive real factor of h positive real factor of h 42 references [1] Gouse Jr SW, Noyes Jr BS, Swarden M. Aerodynamic drag on a body travelling in a tube. Washington, DC: US Department of Transportation; 1967 Oct.. Report No. DSR 76108e3. [2] Earnshaw PB. Aerodynamic resistance to long trains passing through close-fitting tunnels. Royal Aircraft Establishment; 1970 Nov. Technical Report 70199. [3] Hammitt AG. Aerodynamic analysis of tube vehicle systems. AIAA Journal 1972;10:282e90. [4] Smith LD. Experimental investigation of tube vehicle aerodynamic characteristics. Master’s thesis. Durham (NC): Duke University; 1972. [5] Davidson JV. Aerodynamic drag of tube vehicles. Master’s thesis. Durham (NC): Duke University; 1974. [6] Gralewski ZA. Aerodynamic drag of tube vehicles travelling at subsonic speeds. PhD thesis. Loughborough (UK): Loughborough University of Technology; 1979. [7] Cassat A, Espanet C, Bouquin V, Jufer M. Passive guidance forces of polarized linear motors combined with levitation actuators working in partial vacuum e application to Swissmetro. In: Proceedings of MAGLEV 2006 Sept 13e15; Dresden, Germany; 2006. p. 351e62. [8] Miller AR. Fluted tubes and waisted circles. Int J Math Sci Appl. [Internet]. 2011 Sept; [cited 2012 May 23];1:1563e1568. Available from: http://ijmsa.yolasite.com/resources/68_ Arnold_R_Miller_FINAL_%284_Dec_11%29.pdf. 14611 [9] Miller AR. Hydrogen tube vehicle for supersonic transport: analysis of the concept. Int J Hydrogen Energy 2008;33: 1995e2006. [10] Miller AR. Hydrogen tube vehicle for supersonic transport: 2. Speed and energy. Int J Hydrogen Energy 2010;35:5745e53. [11] Miller AR. Hydrogen tube vehicle for supersonic transport: 3. Atmospheric merit. Int J Hydrogen Energy 2012;37(19): 14598e602. [12] Munson BR, Young DF, Okiishi TH. Fundamentals of fluid mechanics. 5th ed. Hoboken (NJ): John Wiley; 2006. [13] Houghton EL, Carpenter PW. Aerodynamics for engineering students. 5th ed. Burlington (MA): Butterworth-Heinemann; 2003. [14] Carlton J. Marine propellers and propulsion. 2nd ed. Burlington (MA): Butterworth-Heinemann; 2007. [15] Clancy LJ. Aerodynamics. Hoboken (NJ): John Wiley; 1975. [16] Strack WC, Knip G, Weisbrich AL, Godston J, Bradley E. Technology and benefits of aircraft counter rotation propellers. NASA Technical Memorandum 82983. Available from: http://ntrs.nasa.gov/?method¼aboutntrs; 1982. [17] Gloucestershire Transport History [Internet]. [Cited 2011 Sept 20] Available from: http://glostransporthistory.visitgloucestershire.co.uk/GlosProp.htm. [18] Gordon Y, Komissarov D. Tupolev Tu-95/Tu-142 (Famous Russian aircraft). Hinkley (UK): Midland Publishing Ltd; 2009. [19] Shevell RS. Fundamentals of flight. 2nd ed. Upper Saddle (NJ): Prentice-Hall; 1989. [20] Lutze FH. Supplemental notes for AOE 3104, Vehicle Performance [Internet]. Dept. of Aerospace and Ocean Engineering, Virginia Tech. [Cited 2011 March 22]. Available from: http://www.dept.aoe.vt.edu/wlutze/AOE3104. [21] Bombardier Aerospace [Internet]. Toronto. 2010 [cited 2010 Aug 17]. Available from: http://www.q400nextgen.com/q400/ en/specifications.jsp. [22] Pratt & Whitney Canada [Internet]. [Cited 2011 April 6]. Available from: http://www.pwc.ca/en/engines/pw150a. [23] Bushell S, Jackson P, Munson K, Peacock L, editors. Jane’s all the world’s aircraft 2010e2011. 101st ed. Alexandria (VA): Jane’s Information Group; 2010. [24] Lide DR, editor. CRC Handbook of Chemistry and Physics. 88th ed. Boca Raton (FL); 2008. [25] Johnson KA, Reilly JR. Surface area of the Q400 aircraft based on Google SketchUp Pro software. Golden (CO): Supersonic Institute. Report. Sponsored by Vehicle Projects Inc. [cited 2012 April 4]. Available from: http://www. supersonicinstitute.com/tech.html; 2012 Apr. [26] Schach R, Jehle P, Naumann R. Transrapid und Rad-SchieneHochgeschwindigkeitsbahn, ein gesamtheitlicher Systemvergleich. New York: Springer; 2005.