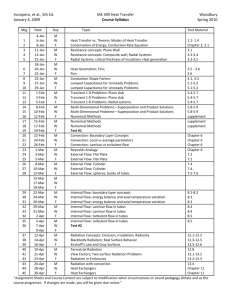

Heat Transfer Lecture Notes: Thermodynamics, Conduction, Convection

advertisement

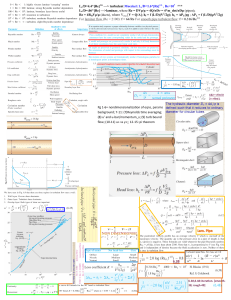

Heat Transfer – 06-92-328 The first law of thermodynamics or the energy balance for any system undergoing any process can be expressed as: Under steady conditions and in the absence of any work, the amount of net heat transfer to or from the system is given by: Fourier’s law of heat conduction: Newton’s law of cooling: ) The net rate of radiation heat transfer between two surfaces is given by: where is the surface emissivity, = 5.67 x10-8 W/m2 · K4, is the Stefan–Boltzmann constant, The one-dimensional heat conduction equation in rectangular, cylindrical, and spherical coordinate systems for the case of constant thermal conductivities are expressed as: where the property is the thermal diffusivity of the material. Under steady conditions, the surface temperature of a plane wall of thickness 2L, a cylinder of outer radius , and a sphere of radius in which heat is generated at a constant rate of per unit volume in a surrounding medium at T can be expressed as: The maximum temperature rise between the surface and the midsection of a medium is given by: One-dimensional heat transfer through a simple or composite body exposed to convection from both sides to mediums at temperatures and can be expressed as: This relation can be extended to plane walls that consist of two or more layers by adding an additional resistance for each additional layer. The elementary thermal resistance relations can be expressed as follows: Conduction resistance (plane wall): Conduction resistance (cylinder): Conduction resistance (sphere): : Convection resistance: Interface resistance: Radiation resistance: Once the rate of heat transfer is available, the temperature drop across any layer can be determined from: Heat Transfer – 06-92-328 Adding insulation to a cylindrical pipe or a spherical shell will increase the rate of heat transfer if the outer radius of the insulation is less than the critical radius of insulation, defined as: Fins: Very long fin: Adiabatic fin tip: Very long fin: Adiabatic fin tip: x=0 x=0 Fins exposed to convection at their tips can be treated as fins with insulated tips by using the corrected length instead of the actual fin length. The temperature of a fin drops along the fin, and thus the heat transfer from the fin will be less because of the decreasing temperature difference toward the fin tip. To account for the effect of this decrease in temperature on heat transfer, we define fin efficiency as: When the fin efficiency is available, the rate of heat transfer from a fin can be determined from The performance of the fins is judged on the basis of the enhancement in heat transfer relative to the no-fin case and is expressed in terms of the fin effectiveness , defined as: Here, is the cross-sectional area of the fin at the base and represents the rate of heat transfer from this area if no fins are attached to the surface. ( for uniform section fin Fin efficiency and fin effectiveness are related to each other by: The horizontal axis is : Heat Transfer – 06-92-328 Transient Heat Transfer (Chapter-4) The temperature of a lumped body of arbitrary shape of mass m, volume V, surface area , density , and specific heat initially at a uniform temperature that is exposed to convection at time t = 0 in a medium at temperature with a heat transfer coefficient h is expressed as: (characteristic length) The error involved in lumped system analysis is negligible when: The Fourier number is given by Using a one-term approximation, the solutions of one-dimensional transient heat conduction problems are expressed analytically as: (These equations are valid for Fourier number > 0.2) Plane Wall Cylinder Sphere where the constants and are functions of the Bi number only, and their values are listed in Table 4–1 against the Bi number for all three geometries. The error involved in one term solutions is less than 2% when . Heat Transfer – 06-92-328 Fundamentals of Convection (Chapter-6): (all analysis in this chapter is for laminar flow) If Ts is the surface temperature and T∞ is the free-stream temperature. The convection coefficient is expressed as: If k is the thermal conductivity of the fluid and is the characteristic length. The Nusselt number, which is the dimensionless heat transfer coefficient, is defined as: The friction force per unit area is called shear stress, and the shear stress at the wall surface is expressed as: (or) where is the dynamic viscosity, is the upstream velocity, and force over the entire surface is determined from: is the dimensionless friction coefficient. The friction The relative thickness of the velocity and the thermal boundary layers is best described by the dimensionless Prandtl number, defined as: ; The continuity, momentum, and energy equations for steady two-dimensional incompressible flow with constant properties are determined from mass, momentum, and energy balances to be: Continuity: : where the viscous dissipation function is: X-momentum: Energy: : Using the boundary layer approximations and a similarity variable, these equations can be solved for parallel steady incompressible flow over a flat plate, with the following results (laminar flow): Velocity boundary layer thickness: Local friction coefficient: Local Nusselt number: Thermal boundary layer thickness: The Nusselt number can be expressed by a simple power-law relation of the form: where m and n are constant exponents, and the value of the constant C depends on geometry. The Reynolds analogy relates the convection coefficient to the friction coefficient for fluids with Pr ≈ 1, and is expressed as: The analogy can be extended to other Pr by the modified Reynolds analogy or Chilton– Colburn analogy, expressed as: Heat Transfer – 06-92-328 External Forced Convection (Chapter-7): The drag coefficient CD is a dimensionless number that represents the drag characteristics of a body, and is defined as: where is the frontal area for blunt (bluff) bodies, and surface area for parallel flow over flat plates or thin airfoils. For flow over a flat plate, the Reynolds number is: Transition from laminar to turbulent occurs at the critical Reynolds number of: Laminar Smooth & rough Turbulent Smooth Smooth Turbulent Rough Note: The Nusselt number in this table is for uniform temperature (isothermal surface) The average friction coefficient and Nusselt number relations for parallel flow over a flat plate are Combined Laminar Turbulent Smooth Smooth & rough The local friction coefficient and Nusslet number relations for parallel flow over a flat plate are For isothermal surfaces with an unheated starting section of length ξ, the local Nusselt number and the average convection coefficient relations are: Flat plate with an unheated starting length Heat Transfer – 06-92-328 When a flat plate is subjected to uniform heat flux, the local Nusselt number is given by: For uniform heat flux surfaces with an unheated starting section of length ξ, the local Nusselt number and the average convection coefficient relations are: Flat plate with an unheated starting length The average Nusselt numbers for cross flow over a cylinder and sphere are The fluid properties are evaluated at the film temperature in the case of a cylinder, and at the free-stream temperature (except for , which is evaluated at the surface temperature ) in the case of a sphere. Although these correlations for uniform wall-temperature heating, these correlations can be used for uniform heat-flux surface to obtain an approximate solution. In tube banks, the Reynolds number is based on the maximum velocity In-line & Staggered with that is related to the approach velocity V as , Staggered with The average Nusselt number for cross flow over tube banks is expressed as: where the values of the constants C, m, and n depend on value of maximum Reynolds number. Such correlations are given in the table below. All properties except are to be evaluated at the arithmetic mean of the inlet and outlet temperatures of the fluid defined as: Heat Transfer – 06-92-328 NL : Number of pipes in longitudinal direction NT : Number of pipes in transverse direction N: Total number of tubes Use in these formulae The average Nusselt number for tube banks with less than 16 rows is expressed as correction factor whose values are given in the table below. . Where F is the The heat transfer rate to or from a tube bank is determined from: where is the logarithmic mean temperature difference defined as: The exit temperature of the fluid is: Where is the heat transfer surface area and is the mass flow rate of the fluid. The pressure drop and the pumping power required for a tube bank is expressed as: where f is the friction factor and is the correction factor, both given in the figures below. Heat Transfer – 06-92-328 Heat Transfer – 06-92-328 Internal Forced Convection (Chapter-8): The mean velocity and mean temperature for a circular tube of radius R are expressed as: The Reynolds number for internal flow and the hydraulic diameter are defined as: The flow in a tube is laminar for Re < 2300, turbulent for Re 10,000, and transitional in between. The length of the region from the tube inlet to the point at which the boundary layer merges at the centerline is the hydrodynamic entry length . The region beyond the entrance region in which the velocity profile is fully developed is the hydrodynamically fully developed region. The length of the region of flow over which the thermal boundary layer develops and reaches the tube center is the thermal entry length . The region in which the flow is both hydrodynamically and thermally developed is the fully developed flow region. The entry lengths are given by: For For where is the logarithmic mean temperature difference defined as: The pressure drop Flows) and required pumping power for a volume flow rate of are: (Laminar & Turbulent The head loss can be calculated from For fully developed laminar flow in a circular pipe, the velocity profile, friction factor and volume flow rate is given as: Heat Transfer – 06-92-328 For fully developed laminar flow, the Nusselt number is calculated from: Circular tube, laminar Circular tube, laminar ( Non-circular tube, laminar, the Nusselt number for isothermal and constant heat flux surfaces, and the friction factor are calculated from the table. For developing laminar flow in the entrance region with constant surface temperature, we have When the difference between the surface and the fluid temperatures is large All properties are evaluated at the bulk mean fluid temperature surface temperature. , except for , which is evaluated at the For fully developed turbulent flow with smooth surfaces, we have 0.023 The most common and convenient correlation that is used to evaluate the Nu in turbulent flow is: When the variation in properties is large due to a large temperature difference All properties are evaluated at the bulk mean fluid temperature surface temperature. , except for , which is evaluated at the For liquid metal flow in the range of 104 < Re < 106 we have: For fully developed turbulent flow with rough surfaces, the friction factor f is determined from the Moody chart or Heat Transfer – 06-92-328 For a concentric annulus, the hydraulic diameter is , and the Nusselt numbers are expressed as: where the values for the Nusselt numbers are given in the table below for fully-developed laminar flow with one surface isothermal and the other adiabatic : For fully developed turbulent flow, the inner and outer convection coefficients are approximately equal to each other, and the tube annulus can be treated as a noncircular duct with a hydraulic diameter of ,. The Nusselt number in this case can be determined from a suitable turbulent flow relation such as the Gnielinski equation. Heat Transfer – 06-92-328 Moody Chart Heat Transfer – 06-92-328 Heat Exchanger (Chapter-11): Heat transfer in a heat exchanger usually involves convection in each fluid and conduction through the wall separating the two fluids. In the analysis of heat exchangers, it is convenient to work with an overall heat transfer coefficient U or a total thermal resistance R, expressed as: where the subscripts i and o stand for the inner and outer surfaces of the wall that separates the two fluids, respectively. When the wall thickness of the tube is small and the thermal conductivity of the tube material is high, the last relation simplifies to: where. accounted for by: where those surfaces. . The effects of fouling on both the inner and the outer surfaces of the tubes of a heat exchanger can be are the areas of the inner and outer surfaces and and are the fouling factors at In a well-insulated heat exchanger, the rate of heat transfer from the hot fluid is equal to the rate of heat transfer to the cold one. That is, & where the subscripts c and h stand for the cold and hot fluids, respectively, and the product of the mass flow rate and the specific heat of a fluid is called the heat capacity rate. Of the two methods used in the analysis of heat exchangers, the log mean temperature difference (or LMTD) method is best suited for determining the size of a heat exchanger when all the inlet and the outlet temperatures are known. The effectiveness–NTU method is best suited to predict the outlet temperatures of the hot and cold fluid streams in a specified heat exchanger. In the LMTD method, the rate of heat transfer is determined from: is the log mean temperature difference, which is the suitable form of the average temperature difference for use in the analysis of heat exchangers. Here and represent the temperature differences between the two fluids at the two ends (inlet and outlet) of the heat exchanger. For cross-flow and multipass shell-and-tube heat exchangers, the logarithmic mean temperature difference is related to the counter-flow one as: Heat Transfer – 06-92-328 where F is the correction factor, which depends on the geometry of the heat exchanger and the inlet and outlet temperatures of the hot and cold fluid streams. (F) is calculated from the figure Heat Transfer – 06-92-328 The effectiveness of a heat exchanger is defined as Where and is the smaller of effectiveness relations or charts. and . The effectiveness of heat exchangers can be determined from Condenser or boiler (one of the streams has a constant temperature, i.e., heat exchangers reduces (regardless the type of H.E) to : As , i.e., ): The effectiveness of the , the effectiveness of the H.E approaches to a minimum value Heat Transfer – 06-92-328 Heat Transfer – 06-92-328 Radiation Heat Transfer: The view factor Fi → i represents the fraction of the radiation leaving surface i that strikes itself directly; Fi → i = 0 for plane or convex surfaces and Fi → i = 0 for concave surfaces. For view factors, the reciprocity rule is expressed as: The sum of the view factors from surface i of an enclosure to all surfaces of the enclosure, including to itself, must equal unity. This is known as the summation rule for an enclosure. The superposition rule is expressed as the view factor from a surface i to a surface j is equal to the sum of the view factors from surface i to the parts of surface j. The symmetry rule is expressed as if the surfaces j and k are symmetric about the surface i then Fi → j = Fi → k. The rate of net radiation heat transfer between two black surfaces is determined from: The net radiation heat transfer from any surface i of a black enclosure is determined by adding up the net radiation heat transfers from surface i to each of the surfaces of the enclosure: The total radiation energy leaving a surface per unit time and per unit area is called the radiosity and is denoted by J. The net rate of radiation heat transfer from a surface i of surface area Ai is expressed as is the surface resistance to radiation. The net rate of radiation heat transfer from surface i to surface j can be expressed as is the space resistance to radiation. The network method is applied to radiation enclosure problems by drawing a surface resistance associated with each surface of an enclosure and connecting them with space resistances. Then the problem is solved by treating it as an electrical network problem where the radiation heat transfer replaces the current and the radiosity replaces the potential. The direct method is based on the following two equations: The first and the second groups of equations give N linear algebraic equations for the determination of the N unknown radiosities for an N-surface enclosure. Once the radiosities J1, J2, …, JN are available, the unknown surface temperatures and heat transfer rates can be determined from the equations just shown. The net rate of radiation transfer between any two gray, diffuse, opaque surfaces that form an enclosure is given by Heat Transfer – 06-92-328