Assignment No. 2 – due oct. 18 (in class)

CIVL 358 – fall 2017

1. Select required joist size (in suites, and corridor) for the 3rd floor of the

office bldg shown below. Assume all material is spf #2 light framing,

and:

Floor Assembly: 12mm gyproc ceiling, joists @ 16” o.c., 0.25 kpa

M&E, 15mm plywood, 19mm concrete topping, carpet.

Use 2x4 interior bearing walls and 2x6 exterior bearing walls

*read clause 4.1.5.4 carefully for corridor live load.

2. Design the drop beam on the far east side of the McCann building as separate simple span

beam. Pick the lightest option that works for each of the 4 beam types covered in class

(built-up, engineered, sawn timber –assume D.Fir grade 1, glulam-assume Spruce-pine).

Refer to the drawings for all required dimensions, but also assume the following:

a. The building will be used for a billiards hall.

b. Floor assembly includes TJI joists(assume same weight as a 2x12) and osb as listed

on drawings, plus hardwood flooring, 0.25 kpa Mech., and ½” drywall ceiling.

c. Assume that the telepost provides 4” long bearing to beams on either side of it (8”

total) and is the same width of the beam.

d. Arch. has limited the depth of the beam to be no more than 356mm deep.

3. Which beam option from question would be most economical? Which one do you think

looks best?

4. Sketch a cross-section of a drop beam supporting joists, vs a flush mount beam. Indicate

joist hangers if required.

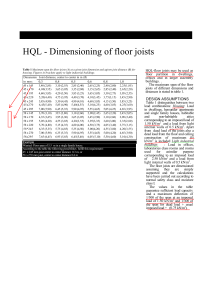

�(FORTE�

MEMBER REPORT

Level, Floor: Joist

PASSED

/

2 piece(s) 11 7/8" TJI® 560 @ 305mm OC

Overall Length: 16942mm

+

0

+

l

I)

WWW

.....

�;7�mm -f,

.:..:....___--¥

-t<-"----��==------,r

=m

=m"'-�""1J<"------'6"-'7=-7=-1..:..m

,r1-t<-�---=3-=0-=0'-'0"'m

1

1

[i]

All locations are measured from the outside face of left support(or left cantilever end).AII dimensions are horizontal.

Deslan Results

Actual GI Location

Member Reaction(kN)

Shear(kN)

Moment(kN-m)

Live Load Defl. (mm)

Total Load Deft (mm)

TJ-Pro ™ Rating

System Vibration Control

Bare Joist Deflection (mm)

/

I

19.08 @ 10016mnf

10.63 @ 10060mm

-12.09 @ 10016mm

8.222 @ 13673mm

10.847 @ 3262mm

55

0.582

3.840

Allowed

42.12(89mm)

31.67

42.83

19.003

19.002

55

1.000

19.003

LDF

Result

Load: Combination (Pattern)

1.00 1.25 D + 1.5 L {Adj Spans)

Passed(45%)

1.00 1.25 D + 1.5 L {Adj Spans)

Passed {34%)

1.00 1.25 D + 1.5 L(Adj Spans)

Passed(28%)

Passed(l/832)

1.0 D + 1.0 L (Alt Spans)

Passed(l/631)

1.0 D + 1.0 L(Alt Spans)

-- -Passed

Passed (58%)

-Passed(l/999+)

.

System : Floor

Member Type : Joist

Budding Use : Residential

Building Code ; NBCC 2015

---

'

Design Methodology : LSD

-- ---

• Deflection criteria: LL (1./360) and TL (l/360).

• The Importance category considered for this design Is normal.

• Top Edge Bracing (Lu): Top compression edge must be braced at 2972mm o/c unless detailed otherwise.

• Bottom Edge Bracing (Lu): Bottom compression edge must be braced at 2946mm o/c unless detailed otherwise.

• A structural analysis of the deck has not been performed.

• The moment, shear, and member reaction values are based on factored loads (strength). Support reactions and deflections are based on unfactored loads

(service).

• Deflection analysis Is based on composite action with a single layer of 19/32" Weyerhaeuser Edge Gold'" Panel (20" Span Rating) that is glued and nailed

down.

• Additional considerations for then-Pro'" Rating Include: 1/2" Gypsum ceiling.

Loads ID Supports

Bearing Length

(lcN)

Floor

live

4.38/(11m� � 82mm

44mm

1 - Stud wall - SPF

1.44

0.03

10.48/89mm

89mm

89mm

2.69

2 - Stud wall - SPF

0.07

10.48/89mm

89mm

89mm

2.69

3 - Stud wall - SPF

0.07

4.38/·

44mm

/11;;,, ,- 82mm

1.44

4 - Stud wall - SPF

0.03

• Rim Board is assumed to carry all loads ilmi[ied directly above It, bypassing the member being designed.

Supports

Loads

1 - Uniform (kPa)

Total

JAvallable

,.

Required

Dead

Location (Side)

Spacing

Dead

Floor Uve

0mm to 16942mm

305mm

1.6

4.8

Ac:cessortes

1 1/8" Rim Board

None

None

1 1/8" Rim Board

I

(

I

Comments

Residential • Living Areas

Weyerhaeuser Notes

� SUSTAINABLE f-ORESTRY INITIATIVE

Weyerhaeuser warrants that the sizing of its products will be in accordance with Weyerhaeuser product design critena and published design values.

Weyerhaeuser expressly disclaims any other warranties related to the software. Use of this software is not intended to circumvent the need for a design

professional as determined by the authority having Jurisdiction. The designer of record, builder or framer is responsible to assure that this calculation is

compatible with the overall project. Accessories (Rim Board, Blocking Panels and Squash Blocks) are not designed by this software. Products manufactured at

Weyerhaeuser facilities are third-party certified to sustainable forestry standards. For current code evaluation reports, Weyerhaeuser product literature and

Installation details refer to www.weyerhaeuser.com/woodproducts/document-library.

The product application, Input design loads, dimensions and support information have been provided by Forte software Operator

Forte Software Oparator

Job Nola&

11/612017 6:37 56 PM

Forte vS 3, Design Engine· V7 0 0.5

Page 1 of 1

Assignment No. 3 – due nov. 8 (in class)

CIVL 358 – fall 2017

May hand in as groups of 3 people max.

1. Select required joist size (in suites, and corridor) using TJI as a

continuous 3 span for the 2nd floor of the building below.

Floor Dead: 1.6 kpa, Floor Live: 4.8 kpa.

Use a 55 TJ pro rating, assuming 19/32” decking, glued and nailed, no

strapping or blocking, and ½” gypsum ceiling.

Use 2x4 interior bearing walls and 2x6 exterior bearing walls and 11

/8” rimboard.

Limit joist depth to 12” max.

Provide printout of report (one page is fine) from forte.

7m

7m

2. Design the interior bearing walls for the building, assuming joist depth as selected in

question 1. Use a separate stud spacing for all levels.

Assume interior walls do not support the roof trusses.

Ignore self-weight of the walls.

Use 2x4 spf #2, assuming adequate lateral bracing from drywall.

3. A door opening at the main floor along the interior wall is 4’0” wide, clear span. Select

the built-up lumber door header, and required jack studs on each side, assuming the same

opening occurs directly above on the 2nd and 3rd floors. Select the required number of king

studs required at each side, and sketch final solution showing header, jacks , and kings.

1. Dead=.85kpa, live = 2.4kpa

a. 2ply 2x8 @ 16” o.c. using a span of 4.15m. solution shown in class

b. P.21 floors of 2.4kpa or less live load – with 400 spacing, use 1F16

I know we usually round up (but in this table 400mm implies 16” o.c., 300 = 12”,

500=19.2” )

c.

i. Left span = 10’6” – 3.5”/2 bearing on right side – 4.5” concrete on left side

(beyond beam pocket) – 3.5”/2 bearing on left side

=3.0m

Wf = 4.15m x [1.25(.85kpa)+1.5(2.4kpa)] = 19.34 kn/m

Mf = 19.34kn/m x (3m)2 / 8 = 21.8 kNm

Vf = 19.34 x 3m / 2 = 29 kN

EIreq = 360 x (4.15m x 2.4kpa) x (5/384) x (3m) 3

=1260 x 109 Nmm2 ---GOVERNS

Or

=180 x (4.15m x 3.25kpa) x (5/384) x (3m) 3

=853 x 109 Nmm2

Pick 4ply 2x12 or 5ply 2x10 – either good without height or width restrictions

If 4ply 2x12

Mr = 24.2 > 21.8

Vr = 43 kN > 29 kN

EI = 2820 > 1260

Check bearing….qf = 29 kN/ 3.5” = 0.326KN/mm

qr = 0.161 kN/mm x 4ply = 0.644 kN/mm > 0.326 so its OK!

ii. Right span = 10’3.75” – 3.5”/2 bearing on left side = 3.1m (assumes telepost is

centered on bearing on the right side)

Same equations as above , but 3.1m span

Wf = 19.34 kN/m

Mf = 23.2 kNm

Vf = 30 kN

EIreq = 1390 x109 Nmm2

Pick 4ply 2x12. Mr = 24.2 >23.2 , Vr = 43 kN > 30 kN, EI = 2820 > 1390

Bearing qr = 0.644 kN/mm > qf = 30 kN / 3.5” = 0.337 kN/mm

OK!

d. Sawn timber span = 13’2.25” – 3.5”/2 bearing on right side = 3.98m

(assumes telepost centered on bearing on the left side)

Use all the same equations as for part c) but span is 3.98m

Wf = 19.34 kN/m

Mf = 38.3 kNm

Vf = 38.5kN

EIreq = 2943 x109 Nmm2

Pick 140 x 292 or 191 x 292

140x292 d.fir select

Mr = 38.4 > 38.3

Vr = 40.5 > 38.5

EI = 3490 > 2943

all Ok

Check bearing

qr = 0.784 kN/mm > qf = 38.5 kN / 3.5” = 0.433 kN/mm true so OK!

2. Wood shrinks because of moisture loss. When initially cut down its considered “green” and is

full of moisture, over time it slowly dries out until it reaches equilibrium with its environment

(the building its used for). Shrinkage is much more severe perpendicular to grain. Generally

shrinkage parallel to grain (eg. A wall stud) is so minimal its considered neglible.

3. Softwood is coniferous, hardwood is deciduous . Softwood is cheaper, more plentiful, easier to

work with so its used for structures.

4. Wood is stronger parallel to grain.

5. Sketch shown in class. Bending failure occurs at midspan, shear and bearing failure would occur

at the either end

6. Dimensional lumber, I-joists, parachord trusses, engineered wood (lsl, psl, lvl)

7. Nails, screws, bolts, simpson connectors

8. Stick frame – made up for many, repetitive smaller members.

Platform – the floor is built first, and the walls sit on top of the floor.

1.

2.

3.

4.

5.

6.

7.

Assignment No. 1 – due sep. 27 (in class)

CIVL 358 – fall 2017

May be handed in in groups of up to 3 people max.

Choose osb decking and required joist size (in suites, and corridor) for

the 3rd floor of the condominium shown below. Assuming:

all material is spf #2 light framing, joists @ 16” o.c.

“building area” is less than 600m2

No concrete topping on floors.

Joists have no bridging, but have drywall ceiling attached below.

Foundation wall is 8” thick.

2x4 interior bearing walls and 2x6 exterior bearing walls

Calculate the total vertical shrinkage that will occur between top of

foundation wall and u/s of trusses. (assume same joist depths will be

used on main and 2nd floor as you selected in question 1, rimboard is

of the same material as the joists) EMC = 7%

Select osb roof decking if roof supports 1.1 kpa snow (trusses @ 24”)

and h-clips are not used.

Select the minimum required wall stud size and spacing for the main

floor exterior wall, and interior wall(those that are shown in sketch

below). Assume the attic is not accessible by a stairway. Assume the

interior walls support the floors and roof trusses.

When is a single wall top plate permitted? Reference the code.

What is the required size and spacing of common nails if used to

fasten the floor sheathing to the joists.

Per part 9, what is the permissible deflection limit for the roof trusses

if a drywall ceiling is attached to them. Is that limit for live load, dead,

or total?

4.5m

4.5 m

Assignment No. 1 – Due Oct. 18 at beginning of class

CIVL 358 - Fall 2016

Assignments may be handed in as groups of 3 people max.

Instructor - Corwin Neufeld

Use the McCann house dwgs for this assignment.

1. Assume the house will be converted into a church with fixed seating. Floor assembly

consists of 5/8” drywall ceiling, 0.3 kPa M+E, dimensional lumber joists, 5/8” thick osb

subfloor, 20mm hardwood.

a. Contractor wants to use SPF #2 2x8 joists – select a joist spacing that will work to

satisfy uls and sls conditions. (options are 19.2”, 16”, 12”, or 2ply 19.2”, 2ply

16”, 2ply 12” – since these all work with standard 4x8’ osb panels)

b. Select the minimum required osb decking and its thickness.

c. Select a built-up sawn lumber beam for the drop beam on the two far left spans

(west side). Use the most cost effective beam for each span, but keep beam depths

the same. Assume 3.5” bearing length at the telepost

d. Select a sawn timber beam (douglas fir select) for the drop beam with the largest

span, East of the stairs. Assume 3.5” bearing length at the teleposts. Pick lightest

size possible.

2. Describe why would shrinks. Which direction relative to grain is shrinkage the most

severe?

3. Describe difference between softwood and hardwood –which one do we use for building

structure and why?

4. Which direction with respect to grain is wood strongest in compression?

5. Draw a side view of a joist from question 1 and sketch where it might fail in bending, shear,

and bearing.

6. List 4 different types(not sizes or species, but types) of wood products that could be used

for the joists or beams in a floor system.

7. List 4 types of connectors used in wood construction

8. Is the McCann house a stick frame building or timber frame? Is it platform framed or

balloon framed? How can we know?

I Ass;enfY\iP{I+ #ct

i

1)

C:i: V L � S c5

)

I

':J j

I DC-+, l � H- , d,V ( 7

(l

- 0, I CI

Jr.P�

Q,o7

- l

l/

---.'--lj9

� ,._,._

j,____

S :v +_es

(

L

c,m, ocs�-;·

-5..,;�_e

-s�--,,

Jt---6-o-�---J.OM -"---

6.ofW---J'

Su;+es

I)

J<-P�

Xcorridoc

I, C-/ D - L y. /.

$

L(. 973

:::