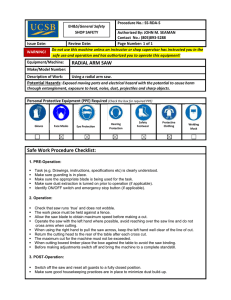

Journal of Food Engineering 70 (2005) 165–170 www.elsevier.com/locate/jfoodeng Cutting forces in foods: experimental measurements Tim Brown *, Stephen J. James, Graham L. Purnell FRPERC, University of Bristol, Churchill Building, Langford, North Somerset BS40 5DU, UK Received 26 May 2004; accepted 20 September 2004 Abstract Investigations into parameters affecting cutting forces in foods were undertaken to identify basic trends such as the relationship of cutting forces to cutting speeds and food temperatures. A simple plain blade was used to cut three typical foodstuffs (cheese, bacon and beef) at three feed speeds and three temperatures. After each cut the blade was passed through the product a second time to measure forces indicative of friction on the sides of the blade. Cutting forces for cheese decreased with increasing temperature and increased with cutting speed. The relatively homogeneous nature of the samples resulted in consistent and repeatable measurements. For bacon, variable salt content gave rise to different ice contents and thus hardnesses in samples at the same ÔfrozenÕ temperatures. Layers of fat and muscle boundaries also produced marked deviations from the average forces. Force results were therefore scattered but increased with decreasing temperature. The effect of cutting speed was not consistent for all forces, but higher speeds generally produced higher forces. For beef, there was a marked difference between frozen and unfrozen samples but little difference between samples at different unfrozen temperatures. In unfrozen samples, cutting speed had little effect on forces, whereas faster cutting speeds produced higher forces in frozen samples. The proportion of total cutting forces made up by friction was found to be consistent over all temperatures and speeds for cheese and bacon, but markedly higher in the frozen beef samples compared to the unfrozen samples. 2004 Elsevier Ltd. All rights reserved. Keywords: Cutting force; Friction; Cutting speed; Temperature; Food 1. Introduction The design and operation of food cutting equipment and associated processes such as tempering to achieve suitable physical properties have traditionally been based on adaptations of systems used for processing materials such as metal or wood (Brown, James, Purnell, & Swain, 2000). Developments have been empirical and in an environment of commercial competitiveness, the sharing and publication of knowledge and fundamental science has been limited. In the meat industry, cutting is * Corresponding author. Tel.: +44 117 928 9239; fax: +44 117 928 9314. E-mail address: tim.brown@bris.ac.uk (T. Brown). 0260-8774/$ - see front matter 2004 Elsevier Ltd. All rights reserved. doi:10.1016/j.jfoodeng.2004.09.022 known to have a direct effect on profitability. Cevger, Sariozkan, & Guler (2003) showed that cutting broilers into joints could increase the profits of a poultry plant by up to 15.6% and there was an improvement of almost 2% when manual cutting was replaced by a machine operation. Literature searches for information on cutting forces, which could be used for design or optimisation, have revealed few published data. As stated by McGorry, Dowd, & Dempsey (2003), even for hand cutting operations ÔThe force exposure associated with meat cutting operations and the effect of knife sharpness on performance and productivity have not been well documentedÕ. The same authors developed specialised hardware which allowed them to measure peak cutting moments of up to 17.2 Nm in manual lamb shoulder boning. 166 T. Brown et al. / Journal of Food Engineering 70 (2005) 165–170 To develop optimal cutting and slicing systems, data are required on cutting forces for different food types and how they vary with such factors as cutting temperature, speed, type of cutting device e.g. blade profile and edge angle. King (1999) measured the forces, and hence fracture energies, required to cut frozen meat. A knife oscillating in a slicing action was used to cut horse M. semimembranosus and M. longissimus dorsi over a range of temperatures ( 1.5 C to 30 C) and vibration frequencies (0–1000 Hz). The blade required less force to cut when slicing than when not slicing; the decrease in force was proportional to the velocity of the slicing motion. These data can be applied to cutting and dicing operations with frozen meat. However, many meat cutting operations take place at temperatures above the initial freezing point of 1.5 C. Cheese, bacon and beef are three common foods that are cut and sliced at many times from production to consumption. This paper details the construction of a simple apparatus for cutting force measurement and presents cutting force data for cheese, bacon and beef. The temperatures investigated cover most of the range of interest for industrial processing. Fig. 1. Schematic of product, holders, blade and cut path. 2. Materials and methods chamber, positioned and immediately cut to minimise any temperature gain. The centre temperatures of three samples in each test group (food–temperature–speed combination) were measured before and after cutting and friction force measurement using a handheld temperature probe (T2006, Digitron) to check that no appreciable sample warming had occurred. 2.1. Food products 2.3. Equipment Three products were selected for the measurements: • cheese (mature cheddar sourced from a single local manufacturer), • beef (cut from lean muscles from topside primals sourced from an on-site abattoir), • bacon (cut from back joints sourced from a single commercial supplier). 2.2. Sample preparation and fixturing Samples of each product were band-sawed or manually cut to fit into rectangular section plastic holders of inside dimensions 110 mm long · 50 mm wide · 48 mm high. The holders fitted tightly into a slightly larger, rectangular supporting socket mounted on a support fixture. Narrow slots in the sides of the socket and holder allowed the passage of the blade for the trials (Fig. 1). This method of fixturing provided both restraint for the samples and ensured that they had repeatable dimensions to an accuracy of approximately ±1 mm. Once cut to size and placed in holders, all the samples were wrapped to avoid moisture loss and conditioned to their required cutting temperatures in a refrigerated chamber adjacent to the experimental cutting rig. For each cutting trial, a sample was removed from the The cutting tool (Stanley heavy duty trimming blade type 1992) was held in a non-retractable knife handle, modified slightly to allow rigid attachment to an instrumented support plate. The support plate was mounted on a horizontal traverse platform driven by a ballscrew rotated at controlled speeds by an electric motor (M42004-01A-200, AEG). This allowed fixed and repeatable speeds of cutting. For each parameter combination, a new blade was chosen at random from a single batch of blades to minimise blunting from repeated cutting. The relative positions of the product holders and the blade were set to give a constant cut depth of 16 mm vertically into the sample, i.e. not through the full thickness of the sample. This resulted in a cut area of 16 mm deep by 50 mm long = 800 mm2. Cutter position was recorded using the output from a draw-wire sensor (WDS-1000P60-CR-P, Micro Epsilon). The edge of the blade was orientated at 45 to the feed direction (Fig. 1) to minimise any build-up of force before the blade entered the sample, and give a more Ôsteady-stateÕ cutting force through the sample. This resulted in horizontal and vertical force components, which were measured through the instrumented support plate using a configuration of four strain gauges. The strain gauge signals were conditioned (2120A, 2110B, Measurements Group Inc.) and recorded at a frequency T. Brown et al. / Journal of Food Engineering 70 (2005) 165–170 of approximately 100 Hz using PC-based logging software developed in-house for the trials. 2.5. Data measured and its interpretation For all parameter combinations, six replicate cuts were made. After each cut, the sample was removed and the blade returned to its start position. The sample was then replaced for a second traverse of the blade to measure forces attributable to friction between the side of the blade and the sample. The recorded force data during the cutting and the friction traverses were plotted and analysed for maximum and average horizontal and vertical forces for the duration of the Ôsteady-stateÕ cutting, i.e. when the blade was fully inserted to its intended depth (16 mm). The horizontal and vertical force data were then processed to give the ÔtotalÕ resultant forces (the square root of the sum of squares for horizontal and vertical forces). The data were statistically analysed using Analysis of Variance to test for the significance of parameter effects at the 5% probability level (P < 0.05). 3. Results 3.1. Raw data profiles The force profiles of a typical set of replicate measurements (horizontal cutting forces in cheese in this case) are shown in Fig. 2. The forces ramped up as the blade entered the product (with its cutting edge at 45 to the edge of the sample), levelled out during fully developed cutting where the cut depth was constant, and finally ramped down as the blade left the sample. Friction forces generally exhibited profiles which were very similar in shape to those for cutting forces but lower in magnitude. In the example shown there was good repeatability, due to the fairly homogeneous nature of cheese. For the less homogeneous meat tissues in bacon and beef, Cutting Force (N) Three cutting speeds typifying the relatively low speeds found in manual and slow machine cutting were used for each set of trials (30 mm s 1, 100 mm s 1 and 250 mm s 1). Product temperatures of 5 C, +5 C and +15 C were selected for cheese and beef. For bacon, cutting at higher temperatures proved difficult due to deformation of the samples, so lower temperatures at which more ice was present in the meat were used ( 15 C, 10 C and 5 C). These are closer to the ÔtemperedÕ conditions used for bacon slicing (Brown, Gigiel, Swain, & James, 2003; James & James, 2002). 30 20 10 0 510 530 550 570 590 -10 Position (mm) Fig. 2. Horizontal cutting forces for cheese at 15 C and 30 mm s 1. 30 Cutting Force (N) 2.4. Experimental conditions 167 20 10 0 510 530 550 570 590 -10 Position (mm) Fig. 3. Horizontal cutting forces for beef at 5 C and 30 mm s 1. greater variability and irregularity was found, as shown in Fig. 3. 3.2. Maximum and average forces The mean and standard deviation values of forces from the replicate cutting traverses at each parameter combination are shown for the three products in Tables 1–3, together with derived resultant forces (the square root of the sum of squares of horizontal and vertical). As the proportion of the total cutting forces made up by friction was found to be relatively constant for each product, friction forces are expressed as averaged percentages of the total cutting forces to avoid excessive data presentation. The statistical analysis confirmed that for all three of the products, the effect of sample temperature on horizontal, vertical and resultant forces was significant. Cheese and bacon exhibited the expected trend that lower temperatures produced higher cutting forces. The temperatures used for beef included one below the initial freezing point, and this produced far higher forces than those above the initial freezing point. However, the effect of cutting speed was more variable. For cheese, its effect was significant for all forces. Forces increased with cutting speed as would be expected. For beef and bacon, only its effect on the maximum and average horizontal forces, and the average 168 T. Brown et al. / Journal of Food Engineering 70 (2005) 165–170 Table 1 Cutting forces measured in cheese Temp. (C) Speed (mm/s) Horizontal force (N) Maximum 5 5 15 30 100 250 30 100 250 30 100 250 Vertical force (N) Average Maximum Resultant force (N) Average Maximum Average Mean SD Mean SD Mean SD Mean SD Mean SD Mean SD 39.8 55.3 61.2 26.7 34.8 43.2 15.7 22.3 26.8 4.4 5.0 4.5 6.3 2.6 4.8 1.2 2.9 4.5 30.9 45.6 54.6 21.4 29.8 36.6 12.6 18.3 23.9 5.7 2.6 2.5 5.6 2.7 3.8 1.0 2.6 2.3 9.5 9.5 11.2 5.3 5.8 7.3 3.8 4.0 5.2 1.6 1.0 2.5 1.8 1.2 2.3 0.8 0.9 2.4 6.5 6.5 9.1 2.6 3.7 5.0 1.5 1.3 2.2 1.4 1.2 2.5 1.7 1.1 2.4 0.6 1.2 1.0 41.0 56.2 62.2 27.2 35.3 43.8 16.1 22.7 27.4 4.1 4.8 4.8 6.3 2.5 4.9 1.2 2.9 4.7 31.6 46.0 55.4 21.6 30.0 37.0 12.7 18.3 24.0 5.6 2.4 2.7 5.7 2.7 3.9 1.0 2.6 2.3 Table 2 Cutting forces measured in beef Temp. (C) 5 5 15 Speed (mm/s) 30 100 250 30 100 250 30 100 250 Horizontal force (N) Vertical force (N) Resultant force (N) Maximum Average Maximum Average Maximum Average Mean SD Mean SD Mean SD Mean SD Mean SD Mean SD 121.8 156.3 170.3 21.7 15.8 19.8 21.2 17.8 15.0 10.8 13.3 31.5 5.1 9.2 4.1 6.4 6.2 4.3 111.8 148.1 155.7 14.3 11.5 14.1 13.8 13.1 12.6 9.7 14.9 27.9 3.3 6.2 1.1 3.2 4.1 2.2 61.3 83.5 77.3 19.5 13.7 13.3 18.5 17.3 15.7 13.8 40.8 13.1 5.0 7.8 3.3 7.2 9.5 9.9 53.8 64.5 56.8 11.1 8.0 9.9 11.5 10.6 11.5 13.7 39.1 18.2 2.7 3.7 2.0 3.0 3.9 6.6 137.1 179.6 187.5 29.2 21.0 24.0 28.2 24.9 22.4 9.0 28.6 30.9 6.9 12.0 5.0 9.4 10.9 9.0 124.8 164.3 167.0 18.1 14.0 17.2 18.0 16.9 17.5 8.7 25.4 24.2 4.2 7.1 1.9 4.2 5.5 5.4 Table 3 Cutting forces measured in bacon Temp. (C) 15 10 5 Speed (mm/s) 30 100 250 30 100 250 30 100 250 Horizontal force (N) Vertical force (N) Resultant force (N) Maximum Average Maximum Average Maximum Average Mean SD Mean SD Mean SD Mean SD Mean SD Mean SD 77.0 82.3 88.7 30.7 34.5 52.2 20.3 12.5 16.5 13.8 8.1 19.7 7.1 11.7 12.3 8.5 5.4 4.1 62.3 64.2 74.4 22.4 27.7 43.7 12.4 8.8 13.1 9.2 5.0 17.6 4.8 11.8 10.8 3.3 4.6 4.8 50.0 50.3 44.2 22.2 29.0 38.7 14.8 10.8 14.2 12.2 20.2 13.3 4.4 13.6 13.8 6.6 1.2 1.6 39.4 37.0 37.2 16.6 22.9 31.8 9.7 9.1 11.5 12.1 16.8 11.9 3.2 10.2 9.8 4.3 0.9 2.7 92.8 97.2 99.6 38.0 45.2 65.4 25.3 16.8 21.9 9.8 16.4 20.7 7.6 17.5 16.4 10.3 4.5 3.6 74.6 75.1 83.8 27.9 36.0 54.3 16.0 12.9 17.6 7.1 9.4 18.2 5.4 15.2 13.2 4.6 3.9 4.7 resultant forces was significant. For the beef samples below the initial freezing point, the effect of cutting speed was more marked than for those above the freezing point, with the latter being similar in magnitude and inconsistent in order. There were also some significant interactions between the effects of temperature and speed for cheese and beef (for maximum and average horizontal and resultant cutting forces), but not for bacon. To illustrate some of the trends in the data, the values for the maximum resultant forces for the three products are presented in Figs. 4–6, which include both cutting and friction results. Friction forces averaged 46% of the total cutting forces for cheese, with this proportion being relatively constant across all temperatures and speeds. For bacon, the average was 43%. There was a marked difference between friction forces in the frozen and unfrozen beef T. Brown et al. / Journal of Food Engineering 70 (2005) 165–170 Fig. 4. Maximum and average resultant cutting forces (total and friction) in cheese. Fig. 5. Maximum and average resultant cutting forces (total and friction) in beef. Fig. 6. Maximum and average resultant cutting forces (total and friction) in bacon. 169 170 T. Brown et al. / Journal of Food Engineering 70 (2005) 165–170 samples, with the frozen values averaging 28% and the unfrozen only 23%, both considerably lower than the other products. 4. Discussion In general, the data for the three products followed expected trends. Decreasing temperature produced higher cutting and friction forces. In the case of cheese, the relationship between forces at the different temperatures was substantially linear. Where freezing was introduced for one set of samples of beef, significantly higher forces resulted. Freezing to some degree was present in all of the bacon samples, and this was reflected by another linear relationship. Increased cutting speeds generally resulted in higher forces, except in the case of the unfrozen beef samples where forces remained similar. However, an attempt at repetition with bacon at temperatures in the chilled range resulted in bunching up of the material rather than cutting, with subsequent failure of the blades. The relatively homogeneous nature of cheese resulted in steady, repeatable force plateaus during cutting. The variable physical and chemical composition of the beef and bacon samples produced less steady and more variable forces. Although care was taken to cut the samples from lean areas of original material, the samples contained different amounts of fat and occasional muscle boundaries and connective tissue. Cutting through such boundaries resulted in pronounced maximum forces. In the case of bacon, additional variability most probably resulted from differences in salt and moisture content introduced during the curing process. Such differences give rise to varying amounts of ice at any given Ôsemi-frozenÕ temperature, and consequently variable hardness. Further sources of variability other than those inherent in the products may have impacted on the results. The method of product fixturing imposed more control than is usually present in commercial cutting operations, but nevertheless still allowed some movement and in the case of some chilled samples, bunching up of material. Blunting of the blades was not evident in the cheese and bacon trials, but could have played a part in producing some of the variability in the beef trials, particularly where large forces were produced in cutting frozen samples. The method used to indicate the proportion of force due to friction produced consistent results over all temperatures and speeds for cheese and bacon. For beef however, friction forces in the frozen samples were proportionately higher than those in the chilled samples. This could be attributed to the greater rigidity of the material exerting a stronger ÔclampingÕ effect on the blade. For the faster cutting speeds, the relatively slow logging rate meant that the numbers of data points captured during traverse of the fairly short cut path were limited. To better characterise cutting force profiles with peaks and troughs such as those found for beef and bacon, these trials re-affirmed the need for rapid data capture and ideally larger samples to allow greater length of cut path. The use of systems capable of measuring and recording at frequencies up to 1000 Hz has subsequently been adopted. 5. Conclusions The cutting trials generally confirmed expected trends, such as increased forces resulting from higher speeds and lower temperatures. They also revealed sources of variability due to inherent product characteristics and movement and distortion of samples. Although some reduction in blade sharpness most probably occurred during cutting of the six replicates in each sample set, its effects were not readily apparent as a progressive increase in forces. The introduction of much more rapid data capture, improved product fixturing and use of larger samples for future trials will help to minimise or better capture the effects of such sources. Acknowledgement The authors would like to thank DEFRA for supporting this work under the Advanced Food Manufacturing LINK scheme. References Brown, T., Gigiel, A. J., Swain, M. V., & James, C. (2003). Practical investigations of two-stage bacon tempering. International Journal of Refrigeration, 26, 690–697. Brown, T., James, S. J., Purnell, G., & Swain, M. J. (2000). Improving food cutting systems. In Proceedings of IChemE Food and Drink 2000 (pp. 103–106). ISBN 0 85295 438 7. Cevger, Y., Sariozkan, S., & Guler, H. (2003). Impact of manual and mechanical cut-up of broiler carcasses on the enterprise income. Veterinarni Medicina, 48(9), 248–253. James, S. J., & James, C. (2002). In Meat refrigeration (pp. 150–153). Woodhead Publishing, ISBN 1 85573 442 7. King, M. J. (1999). Slicing frozen meat with an oscillating knife. Meat Science, 51(3), 261–269. McGorry, R. W., Dowd, P. C., & Dempsey, P. G. (2003). Cutting moments and grip forces in meat cutting operations and the effect of knife sharpness. Applied Ergonomics, 34(4), 375–382.