Geometrical Tolerancing Exercises: PP7305:1991 Standards

advertisement

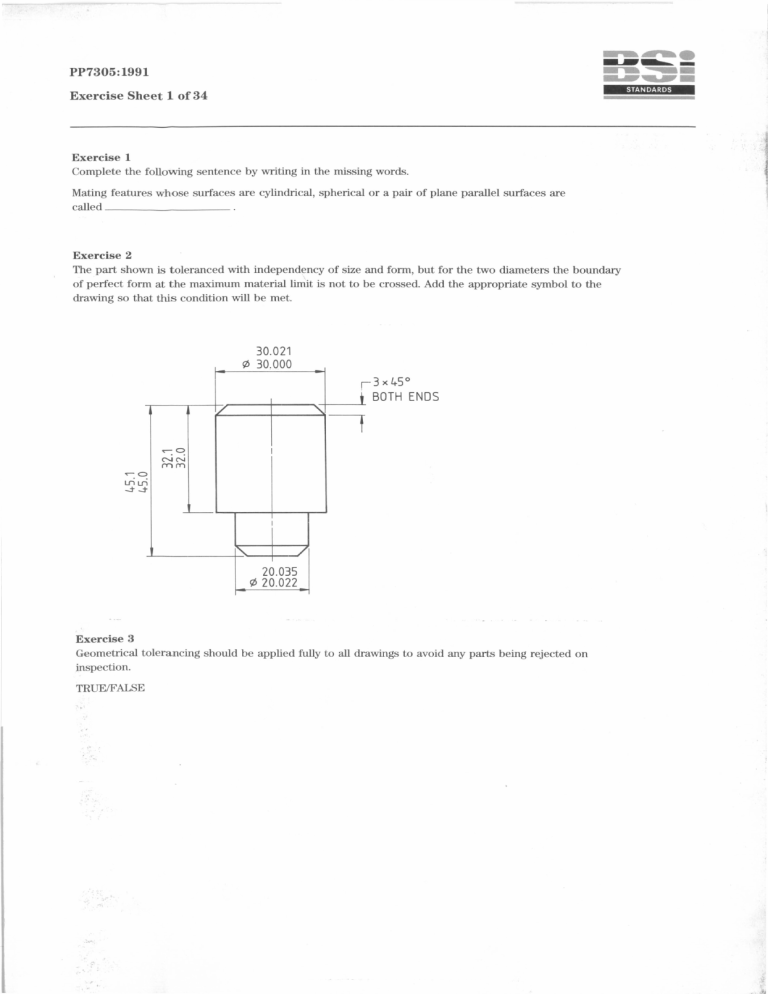

PP7305:1991

STANDARDS

Exercise Sheet 1 of 34

Exercise 1

Complete the following sentence by writing in the missing words.

Mating features whose suifaces are cylindrical, spherical or a pair of plane parallel suifaces are

calle<l~~~~~~~~~

Exercise 2

The part shown is toleranced with independency of size and forro, but for the two diameters the boundary

of perfect forro at the maximum material limit is not to be crossed. Add the appropriate symbol to the

drawing so that this condition will be met.

~

30.021

30 000

¡3 X 45º

BOTH ENOS

/

"!

..-- o

'

1

C'JN

rn rn

•

1

1

1

""

~

-

/

1

20.035

20.022

Exercise 3

Geometrical tolerancing should be applied fully to all drawings to avoid any parts being rejected on

inspection.

TRUE/FALSE

PP7305: 1991

-

Exercise Sheet 2 of 34

Exercise 4

Complete the table by writing the number of each feature against its description.

Description

Feature number

Face

Axis

Edge

Median plane

External cylindrical surlace

Internal cylindrical surlace

Exercise 5

In the right-hand column of the table write the letter F if the characteristic refers to the form of single

features, the letter O if it refers to the orientation of related features and the letter L if it refers to the location

of related fe atures.

Characteristic

Letter

Characteristic

Angularity

Perpendicularity

Flatness

Coaxiality

Parallelism

Circularity

Position

Symmetry

Straightness

Pro:file of a surlace

Pro:file of a line

Cylindricity

Letter

STANDARD$

PP7305:1991

STANDARDS

Exercise Sheet 3 of 34

Exercise 6

A run-out tolerance can only be applied to related features.

TRUE/FALSE

Exercise 7

Write against each symbol in the table the letter for the characteristic that it represents.

Symbol

Letter

Characteristic

o

A

Perpendicularity

L_

B

Position

o

e

Circular run-out

/:/

11

D

Straightness

E

Coaxiality

-

F

Profile of a line

J_

G

Cylindricity

o

H

Angularity

I

J

Flatness

@

K

Circularity

-$-

L

Total run-out

(\

M

Symmetry

ti

N

Parallelism

p

Profile of a surface

-

-

-

Exercise 8

A geometrical tolerance applied to a feature defines the size and shape of a tolerance zone within which

the feature is to lle.

TRUE/FALSE

PP7305: 1991

STANDARDS

Exercise Sheet 4: of 34

Exercise 9

Place a tick by those dimensions on the drawing that are theoretically exact.

NO

cO a:i

l.()l.()

R 10.5

10.0

80.2

80.0

15.5

R 15.0 .

FEATURE CONTROLLED

Exercise 10

Place a tick in the box that describes the feature controlled by each leader line.

!ll

Qi

;§

""'

d)

-==

Qi

~

a)

/

A•

B~

A

l

1

1

1

~

o

i---

e

-$

1

1

~

-

..__

e

~---

1

1---- - -

1

1

1

___

B

D

E

-

E

b)

A

1

1

•O

e

B

-~1

~

~

-

'

-

1

.~

++-7L-++

t

-~

l

~

B

e

D

E

F

·~

o=

~o

o

!ll

·~

e,¡

:e

~

Qi

~

rJJ.

Qi

Qi

3

=~

=

o~~

o e

o

Qi

3

Qi

~

~~

Qi

Qi

~e

Qi

~

Qi

'OC

-=

~

~

rJJ.

=e,¡

.e~i

!ll

~

=

FEATURE CONTROLLED

Exercise 1 O ( continued)

Place a tick in the box that describes the feature controlled by each leader line.

]

""'

Q.I

"CI

~

Q.I

~

1

c)

l

o

1(

~~)

E

~

•B

1

'A

1

-

1

1

1

A

1

1

B

e

\__0J'

1

D

E

t

F

r

d)

1

-

E

\

-~ -

--'---

t

1

-+\,

/

A

/

\{

_O

e

B

1

r

1

B

e

1

._

D

E

F

·~

o=

~

o

u

Q.I

Q.I

fil

Q.I

'!Elª

~

CJ

Q.I

~

rxi

=

=

~

o =

o~~

u e

~

..$

Q.I

~

~~

Q.I

Q.I

~=

Q.I

"1

Q.I

'O«>

"CI

~

~

rxi

=

Q.I

~i

.5

~

"1

fil

~

PP7305: 1991

STANDARDS

Exercise Sheet 7 of 34

Exercise 11

(a) A face of a component is required to be parallel witlún 0.2 to a second face wlúch is identified as datum

feature D. Make a sketch of the tolerance frame for tlús requirement.

(b) Datum feature D is to be flat witlún O. l. Make a sketch of the tolerance frame for tlús requirement.

(c) The axis of a bore is required to be square to datum feature D witlún a cylindrical tolerance zone

0.05 diameter. Make a sketch of the tolerance frame for tlús requirement.

Exercise 12

Complete the following sentence by writing in the missing words.

A _ _ _ _ _ _ _ _ _ _ _ _ _ is indicated by a leader from the tolerance frame terminating in an

equilateral triangle.

Exercise 13

Complete where necessary the tolerance frames for the drawing shown.

i..no

NO

ºº

'°'°

(T) (T)

'&

11 0.1

Exercise 14

In the right hand column of the table write the letter for the correct description of the datum designation.

Letter

Datum

1

1

1DE 1

íl

1D1E1

1 1

1 D-E

1

Description

A A single datum established by two datum features

B A multiple datum ~ system consisting of two datums

C Multiple datums, the datums to be applied in a

particular order.

Exercise 15

Place a tick in the box that describes the datum feature denoted by each datum triangle.

DATUM FEATURE

~

'Q

l'll

·a

ª

'.S

o=

io

ª

~

u

~

1

a)

1

~/

1

A

B

~//////)

B

~

r

-

1

O.a.

-

LJ

---

%/~((////

_/

-

e

D

E

.

,...e

1

b)

F

.4 ..

F

1

1

1

1

A

/

%1

-------

J~F

'~ J

A

~

-------______

,___

-------

--------

,

~~

.n

B

-

1

1\

'J

1

-

e

D

--

,.

-$1

B

E

)

F

1

~

l'll

·a

~

3

~

==

!S

o

~

o

~

~

r.r.i

i~

~

u=

~

ª

....~

~~

~ ~

:e

~

~

~

~

'b()

"'CI

~

]

r.r.i

=~

~]

·=

~

l'll

=:!

PP7305:1991

STANDARDS

Exercise Sheet 9 of 34

Exercise 16

Make dimensioned sketcbes of the geometrical reference frame for:

(a) the axes of the four 10.0/10.1 diameter boles;

(b) the axes of the group of two boles 12.0/12.1 diameter and the 20.0/20.1 diameter bole;

ee)

the axes of the six 8. 0/8.1 diameter boles.

196.0

195.5

20.1

115.0

114.5

1X~20.0

12.1

10.1

4x ~ 10.0

2x~12.0

-$-

50.0

49.5

250

249

~ 0.2 M

8.1

6 X ~ 8.0 1 EQU 1 SP

1

PP7305:1991

Exercise Sheet 10 of 34

Exercise 17

A feature of a component is to be toleranced for straightness. Over the whole length of the feature the

tolerance is to be 0.05. Over any length of 50 the tolerance is to be reduced to 0.02. Make a sketch of the

tolerance frame.

Exercise 18

A feature of a component is 700 long and is to be toleranced for parallelism with reference to a datum

surface A. The functional requirements will be satisfied if any line 100 long on the fe ature is parallel to

datum A within 0.03.

(a) Make a sketch of the tolerance frame.

(b) To what maximum value could the parallelism tolerance accumulate over the whole length of

the feature?

In exercises 19 to 35, add to the drawings tolerance frames, leaders, datums and notes as necessary so that

the toleranced features will comply with the stated requirements. The geometrical tolerances are to apply

regardless of feature size (RFS) except where stated otherwise.

Exercise 19

The three scribed lines are to be straight within a tolerance of 0.02.

STANDARDS

PP7305:1991

STANDARDS

Exercise Sheet 11 of 34

In exercises 19 to 35, add to the drawings tolerance frames, leaders, datums and notes as 'necessary so that

the toleranced features will comply with the stated requirements. The geometrical tolerances are to apply

regardless of feature size (RFS) except where stated otherwise.

Exercise 20

The axis of the central hole is to be contained within a cylindrical tolerance zone of 0.03 diameter.

LnC>

OC>

c:) c:)

NN

'&

Exercise 21

The surface of the washer face on the blanking plug is to be flat within a tolerance of 0.04 and is not to

be concave.

.....---

1

"

J

r

l

l.

J

'

j

1

PP7305:1991

STANDARDS

Exercise Sheet 12 of 34

In exercises 19 to 35, add to the drawings tolerance frames, leaders, daturns and notes as necessary so that

the toleranced features will comply with the stated requirements. The geometrical tolerances are to apply

regardless of feature size (RFS) except where stated otherwise.

Exercise 22

The conical surface of the needle valve is to be circular within a tolerance of 0.01 and the right-hand

cylindrical surface is to be circular within a tolerance of 0.05.

Exercise 23

The profile of the component in any section parallel to the plane of projection of the drawing is to be

contained within a bilateral tolerance zone 0.4 wide.

3 PLACES

PP7305:1991

STANDARDS

Exercise Sheet 13 of 34

In exercises 19 to 35, add to the drawings tolerance frarnes, leaders, datums and notes as necessary so that

the toleranced features will comply with the stated requirements. The geometrical tolerances are to apply

regardless of feature size (RFS) except where stated otherwise.

Exercise 24

The bore of the bearing block is 25.00/25.02 diarneter. Its axis is to be contained between two planes

0.01 apart that are parallel to the plane that contains the bottom surface of the component.

Bore

PP7305:1991

STANDARDS

Exercise Sheet 14 of34

In exercises 19 to 35, add to the drawings tolerance frames, leaders, datums and notes as necessary so that

the toleranced features will comply with the stated requirements. The geometrical tolerances are to apply

regardless of feature size (RFS) except where stated otherwise.

Exercise 25

In the sectional view, the axis of the upper hole is to lie between two horizontal planes 0.2 apart that are

parallel to the cornmon axis of the two lower holes. In the other view, the axis of the upper hole is to lie

between two vertical planes 0.1 apart that again are parallel to the cornmon axis of the two lower holes.

1

coo

~o

00

~

PP7305:1991

STANDARD$

Exercise Sheet 15 of 34

11) exercises 19 to 35, add to the drawings tolerance frames, leaders, datums and notes as necessary so that

the toleranced features wi1l comply with the stated requirements. The geometrical tolerances are to apply

regardless of feature size (RFS) except where stated otherwise.

Exercise 26

(a) Each side of the slot is to be square to the chamfered face within 0.2.

(b) The maximum material principle could, if desired, be applied to the datum feature.

TRUE/FALSE

01.I'l

~o

cri cri

NN

_____l/

Exercise 27

The common axis of the branch pipe is to lie between two straight lines 0.12 apart that are inclined ata

true angle of 60º to the common axis of the main pipe.

I'\

/

/

'

"

/

I

--

~~

l..i'

r

PP7305:1991

Exercise Sheet 16of34

In exercises 19 to 35, add to the drawings tolerance frames, leaders, datums and notes as necessary so that

the toleranced features will comply with the stated requirements. The geometrical tolerances are to apply

regardless of feature size (RFS) except where stated otherwise.

Exercise 28

The angled face is to lie between two parallel planes 0.1 apart that are inclined ata true angle of 30º to the

axis of the 8.0/7.9 diameter hole.

STANDARDS

PP7305:1991

Exercise Sheet 17 of 34

In exercises 19 to 35, add to the drawings tolerance frames, leaders, daturns and notes as necessary so that

the toleranced features will cornply with the stated requirernents. The geornetrical tolerances are to apply

regardless of feature size (RFS) except where stated otherwise.

Exercise 29

The eight holes are 5.00/5.02 diameter and are equally spaced on a 60 pitch circle diameter. Their axes are

to be contained in cylindrical tolerance zones of 0.05 diameter. The cylindrical tolerance zones are to be

square to the face of the flange adjacent to the spigot. Apply the rnaxirnurn material principle to this

geornetrical tolerance.

STANDARD$

PP7305:1991

STANDARDS

Exercise Sheet 18 of 34

In exercises 19 to 35, add to the drawings tolerance frames, leaders, daturns and notes as necessary so that

the toleranced features will comply with the stated requirements. The geometrical tolerances are to apply

regardless of feature size (RFS) except where stated otherwise.

Exercise 30

The functional requirements for the component are as follows.

(a) The axis of the 16.00/16.02 diameter bore is to be contained in a cylindrical tolerance zone of

0.01 diameter that is coaxial with the outside diameter.

(b) The axis of the 25.00/25.03 diameter counterbore is to be contained in a cylindrical tolerance zone of

0.02 diameter that is coaxial with the 16.00/16.02 diameter bore.

( c) The maximum material principle is to be applied wherever possible to the geometrical tolerances of

features and to daturn features.

rno

~~

NO

OC>

'S.

'°'°

'S.

LrH.n

NN

NO

OC>

o...:t...:t

o

~~

'S.

Exercise 31

(a) The axes ofthe three grooves are to be contained within one cylindrical tolerance zone of 0.03 diameter.

(b) Can the maximum material principle be applied to this geometrical tolerance?

.__

-

YES/NO

['\

l/)

UJ

>

o

o

--

~

'---'--

~

rn

I/

-

-

-

PP7305:1991

STANDARDS

Exercise Sheet 19 of 34

In exercises 19 to 35, add to the drawings tolerance frames, leaders, datums and notes as necessary so that

the toleranced features will comply with the stated requirements. The geometrical tolerances are to apply

regardless of feature size (RFS) except where stated otherwise.

Exercise 32

The median plane of the slot is to lle between two parallel planes 0.03 apart that are symmetrically disposed

about the common median plane of the 15.00/14.97 wide tongues.

OC--

~~

lf"l...:t-

lf"IO

~~

OOCO

Exercise 33

The median planes of each of the two widths of the tee slot and the median plane of the dovetail are all

to lie between two parallel planes 0.05 apart that are equally disposed about the median plane of the

45.00/44.98 block width. Apply the maximum material principle to the geometrical tolerances and to the

datum feature.

20.1

20.0

10.1

1·

10.0

---~~~~-;-~~

-1

-~--~~~~---.

25.00

24.98

45.00

44.98

PP7305:1991

STANDARD$

Exercise Sheet 20 of 34

In exercises 19 to 35, add to the drawings tolerance frames, leaders, datums and notes as necessary so that

the toleranced features will comply with the stated requirements. The geometrical tolerances are to apply

regardless of feature size (RFS) except where stated otherwise.

Exercise 34

During one complete revolution of the component about the mean axis of the 30.00/29.98 and 38.00/37.98

diameters, the circular run-out of the 42.00/41.98 diameter is not to exceed 0.08 and the radial run-out of

the right-hand face of the 50.00/49.98 diameter collar is not to exceed 0.02.

Ln

-:t-:t

'$.

'$.

---

oco

º"'

crir.-:

(Y)(Y)

'$.

•

-

Exercise 35

While the component is revolving about the axis of the 35.018/35.002 diameter:

(a) the total radial run-out of the surface of the 54.970/54.930 diameter is not to exceed 0.05;

(b) the total axial nm-out of the right-hand face of the 54.970/54.930 diameter is not to exceed 0.08.

CON

~o

ºº

u-\L.ri

(Y) (Y)

Q

-

..__ - - - - - - - - f - + - -

PP7305:1991

STANDARDS

Exercise Sheet 21 of 34

Exercise 36

Place ticks in the appropriate places in the YES and NO colunms.

Toleranced characteristic

Maximum material principie may be applied

YES

Flatness of a face

Pet"pendicularity of a bore axis to a datum plane

Angularity of a surface to a datum plane

Parallelism of a bore axis to a datum axis

Roundness of a conical surface

Position of a spigot axis

Cylindricity of a bore

Axial run-out of a face

Straightness of the generator of a cylinder

Symmetry of the median plane of a slot

Profile of a surface

Squareness of a face to a datum plane

Coaxiality of a bore axis to a datum axis

Parallelism of a surface to a datum surface

Profile of a line

Angularity of a bore axis to a datum plane

NO

PP7305:1991

STANDARDS

Exercise Sheet 22 of 34

Exercise 37

The drawings show two mating components of an assembly.

(a) For component 1 write down:

(1) the MMC size of the tenon;

(2) the virtual size of the tenon.

(b) For component 2 write down:

(1) the MMC size of the mating slot for the tenon;

(2) the virtual size of the mating slot for the tenon.

ee)

What is the maximum permitted v~lue of the symmetry tolerance:

e1) on the tenon;

(2) on the mating slot for the tenon?

49.97

49.95

-r~

...---~~~~--~~~~~~

Component 1

24.95

24 93

- --·----------.ij

50.02

50.00

= O. O5 @ A@

1

~~~~~~~~~~--------1B

25.02

25.00

Component 2

1

1

PP7305:1991

STANDARDS

Exercise Sheet 23 of 34

Exercise 38

For the component shown:

(a) What are the MMC sizes of the two holes?

(b) When both holes are at their MMC sizes what is the diameter of the coaxiality tolerance zone for the

16.06/16.00 diameter hole?

(e) What is the diameter of the coaxiality tolerance zone when the hole diameters are:

(1) 20.00 and 16.01

(2) 20.02 and 16.03

(3) 20.04 and 16.06?

1

1

1

1

1

1

1

1

1

$--

1

1

-$-

1

1

1

1

1

1

1

1

1

1

1

1

1

1

l

1

1

1

PP7305:1991

STANDARDS

Exercise Sheet 24 of 34

Exercise 39

(a) What is the MMC size of datum bore C?

(b) What is the MMC size of the four holes?

( c) A cornponent is inspected and the individual diarneters of the four holes are found to be:

(1) 12.00

(2) 12.01

(3) 12.02

(4) 12.03

Complete the following table.

Hole diameter

Positional tolerance zone diameter

12.00

12.01

12.02

12.03

( d) Place a tick in the box against a correct staternent and a cross in the box against an incorrect staternent.

D

D

D

D

Datum axis

e is to be perpendicular to datum face D.

The axes of the four holes are to be perpendicular to datum face D.

Datum face D is to be flat.

The axes of the tolerance zones for the four holes are to be perpendicular to datum face D.

e

e) If datum bore e is 40.02 diarneter, by what rnaxirnurn arnount rnay its axis be displaced frorn the centre

of the geornetrical reference frarne of the four holes?

-.:to

00

ºº

-.:t-.:t

'&

PP7305:1991

STANDARDS

Exercise Sheet 25 of 34

Exercise 40

(a) Write down the sizes of the four diameters at which they are all to be perfectly coaxial and have their

axes perfectly square to datum face E.

(b) Write down the virtual size of the bore.

(e) The larger outside diameter is measured and found to be 44.99. What is the diarneter of the cylindrical

tolerance zone within which its axis is required to lie?

º'°

º"'

LI1 _j

,.,,,.,,

rno

00

CX)CX)

(Y'l (Y'l

'S.

'S.

~~

~~

~o

NN

º'°

º"'

LI1

_j

'S.

'S.

...:t...:t

E

PP7305:1991

STANDARDS

Exercise Sheet 26 of 34

Exercise 41

The four holes are 12.000/12.062 diameter equally spaced on the 70 diameter pitch circle. The posicional

tolerance zone for their axes is to be 0.08 diameter, posicioned relacive to datums F and G. The median plane

of the pair of flats is to have a posicional tolerance of 0.04 relacive to the centre of the geometrical reference

frame of the four holes and datum F. Complete the drawing showing these requirements, applying the

maximum material principle wherever possible.

®

0

l.

!

G

lrr--

80.0

79.9

(

1

I

39.975

~ 39.950

1

1

~

PP7305: 1991

STANDARDS

Exercise Sheet 27 of34

Exercise 42

(a) The six 12 diameter holes are to carry an H7 size tolerance. Relative to datums R, S and T their axes

are to be contained within 0.25 diameter tolerance zones. In addition, each hole axis is to lie within a

0.08 diameter tolerance zone, the axis of which is within the 0.25 diameter tolerance zone and perpendicular

to the primary datum. Complete the tolerance frame to indicate these requirements.

(b) What is the shape, size and position of the virtual condition for each hole?

Cb

$

1

1

~

~

~[ill

1

1

1

1

$

~

$

[ill

HTI

PP7305:1991

STANDARDS

Exercise Sheet 28 of 34

Exercise 43

The positional tolerance zone for the axes of the four M16-6H tappings is to be 0.08 diameter relative to

datums D and E. The tolerance zone is to be projected a distance of 50 from the primary datum. Show these

requirements on the drawing, without using the maximum material principle.

¡-n--r--rg-¡t----J

1"7"'""TT"""r;]

_I

1

-+----!

1

..

-0.025

1

~so -o.oso_~

.

PP7305:1991

STANDARDS

Exercise Sheet 29of34

Exercise 44

~a) Components A and B are to be fastened together using the stud shown at figure (b). A projected

tolerance zone is required for the axis of the tapping in component A. What length should be specified for

the projected tolerance zone?

(b) If the design is changed and the set bolt at figure ee) is substituted for the stud, what length should now

be specified for the projected tolerance zone?

(o)

.,.

so :t 0.1

Component

7S:t0.1

A_/

Component B

(b)

'

65 :t 0.2

letal end

11S:t0.2

-

-

160:t0.2

, (e)

11S:t0.2

--,

~

¡---1

j

[

50 ±0.2

_¡

-

'

PP7305:1991

Exercise Sheet 30 of 34

Exercise 45

Three datum target indications are shown. Write down the meaning of each of them.

(a)

GD

\F9

(b)

~

~

(e)

Q

(2

Exercise 46

Pairs of pipe flanges, as shown, are assembled by bolting together with M8 bolts and nuts. The limits of size

for the diameter of the unthreaded shank of an M8 bolt are 8.00 and 7.78.

Complete the tolerance frame on the drawing by inserting the maximum value of the positional tolerance

for the hole axes.

STANDARDS

PP7305:1991

STANDARDS

Exercise Sheet 31 of34

Exercise 47

The cover is assembled to the housing using M8 hexagon nuts. The limits of size for the plain portion of an

M8 stud are 8.00 and 7.85.

Complete the drawings for the cover and housing by inserting in the tolerance frames suitable maximum

yalues for the positional tolerances for the hole and stud axes.

70 PCO

COVER

3xMBx1.25-6g 1 EQUI SPI

~~

70 PCO

00

+

lf'I

o

HOUSING

w

PP7305:1991

STANDARDS

Exercise Sheet 32 of 34

Exercise 48

The block is secured to the slideway by two M8 screws which pass through the slots in the flange of

the block.

Complete the drawings for the slideway and block by inserting in the tolerance frames suitable maximum

yalues for the symmetry tolerances for the median planes of the slideway slot and the tongue of the block.

t-1

A

SLIDEWAY

r---------¡

1

1

1

1

1

1

1

1

B

BLOCK

PP7305:1991

STANDARDS

Exercise Sheet 33 of 34

Exercise 49

The canister is pushed into the bore in the body so that its flange seats in the counterbore below the thread.

The canister is retained in the body by a screwed plug.

Complete the drawings for the canister and body by inserting in the tolerance frames suitable maximum

values for the coaxiality tolerances for the canister flange and its mating counterbore.

MA@

A

CANISTER

BOOY

PP7305:1991

STANDARDS

Exercise Sheet 34 of 34

Exercise 50

The lever is secured to the spindle by an M12 hexagon nut and a plain washer.

Complete the drawings for the lever and spindle by inserting in the tolerance :frames suitable maximum

values for the positional tolerances for the median planes of the pairs of flats.

@X M

y

</>

19.980

19. 959

pp 7305

Solutions to Exercises in

Geometrical Tolerancing

1991 edition

........

___....,._

...

....._.

---~­

STANDARDS

PP7305: 1991

First published 1983 as PD 7305

First revision 1991

BSI Catalogue number PP 7305

ISBN 0-580-20393-X

UDC 744:003.63:621.753.1:514

STANDARDS

STANDARDS

PP7305:1991

Foreword

PP 7305 consists of this booklet and 34 exercise sheets.

The exercises are designed for students taking courses in

engineering drawing and design that require a knowledge

of geornetrical tolerancing, to give practice in the

principies of the subject. The principies are those set out

in BS 308 Engineering drawing practice:Part 3:1990

Geometrical tolerancing and PP 7304: 1991 Introduction

to geometrical tolerancing. This is a cornpanion

publication to PP 7305.

In this edition the nurnber of exercises has been increased

to take account of the changes in the subject introduced

in BS 308:Part 3: 1990. It is intended that students will

work the exercises directly on the exercise sheets, and

with this in rnind the sheets have been designed for

easy reproduction. Perrnission is given for educational

establishrnents to reproduce thern for the use of lecturers

and their students within the one establishment.

The solutions in this booklet rnay not be photocopied

or otherwise reproduced without the prior perrnission

in writing of BSI. The booklet is not included in any

national licence scherne nor in BSI's special scherne

for educational establishrnents which relates to

British Standards.

©

British Standards Institution 1991

STANDARDS

PP7305:1991

Introduction

Linear dimensions and tolerances on the drawings are in

rnillimetres. They are examples only and are not quoted

as recornmended practices.

The drawings are in first angle projection. They are not

to be considered as design examples and are complete

only in so far as is necessary to enable the question to

which they refer to be answered.

STANDARDS

PP7305:1991

Solution 5 continued

Solution 1

'features of size'

Characteristic

Letter

Perpendicularity

o

Coaxiality

L

Circularity

F

Syrnrnetcy

L

Pro:file of a surface

F

Cylindricity

F

Solution 2

30 .021

(1130000

®

r

3 x45°

BOTH ENOS

/

"¡

1

1

~o

NN

,..,..,,..,..,

Solution 6

TRUE. The toleranced surface needs to be related to a

datum axis.

1

1

"-

1

1

/

20.035

(1120.000

®

Solution 3

FALSE

Solution 7

Symbol

Solution 4

Description

Feature number

Face

1, 9

Axis

2, 7

Edge

4

Median plane

3

Externa! cylindrical surface

5

Interna! cylindrical surface

6, 8

Solution 5

Letter

o

J

L

H

o

K

jj

G

11

N

-

D

J_

A

o

p

!

e

@

E

~

B

Characteristic

Letter

(\

F

Angularity

o

ti

L

Flatness

F

---

M

Parallelisrn

o

Position

L

Straightness

F

Pro:file of a surface

F

Solution 8

TRUE

1

STANDARDS

PP7305:1991

Solution 9

Solution 10 continued

FEATURE CONTROLLED

Cll

Q,l

;§

·~

= !S

~

o

o

""'

"CI

Q,l

=

Q,l

(e)

NO

Cll

·~

~

~

Q,l

¡..;:¡

u

A

v

=rl:i

Q,l

u

e

D

Q,)

"CI

rl:i

s

Q,l

s

Q,l

Q,l

Q,l

Q,l

'b«I

"CI

~

R 15.5

15.0

80 .2

80.0

F

(d)

A

e

D

FEATURE CONTROLLED

Cll

Q,l

;§

""'Q,l

"CI

=

Q,l

¡..;:¡

(a)

·~

Cll

·~

= !S

~

o

o

~

u

rl:i

~

Q,l

=-

Q,l

E

Q,l

....=

=

o ;=-

=

'a

~ =

~:9

~:e

o

u s :s

Q,l

Q,l

Q,l

v

v

v

Q,l

'btl

"CI

~

Solution 11

v

(a)

v

D

v

E

v

v

(b)

v

v

e

D

E

F

¡..;:¡

v

e

B

v

Cll

·rr.i

v

A

A

=~

v

v

v

~ .$~~=

~

B

(b)

F

Q,l

Q,l

¡..;:¡

v

B

Solution 10

Cll

rl:i

v

v

E

R 10.5

10.0

=~

~ .$~~=

~

v

B

cx:icx:i

LJ"lLJ"l

Q,l

.3 .3==

=o =

~ :9 ~.3

o

=-

1010.1 I

v

v

(e)

l_Ll!ZSo.oslol

Solution 12

'datum feature'

2

'I

\,

STANDARDS

PP7305:1991

Solution 13

Solution 15

DATUM FEATURE

-Q

=

:s

Cl.l

ª

~

=

= !E

C.I

i

Q

u

C.I

Q,l

~

Q,l

=

'a

=

i~ ~~ t

u e :e -=

Q

00

Q

Q,l

C.I

Q,l

Q,l

~

.¡

E

.¡

A

.¡

B

Solution 14

.¡

e

Letter

Datum

E

B

1 1

1DE1

1 1

1D1E1

e

1 1

1D-E1

A

.¡

D

1

.¡

.¡

F

Solution 16

{al

{b)

1

o

rn

o

rn

30

1

30

f--+---1

L_~ºLJ

{e)

~

3

1

p;o~T-!

70

C.I

Cl.l

00

.¡

D

Q,l

~ .5...;:¡~~=

.¡

e

(b)

=

.¡

B

11 0.1 L

Q,l

C.I

.¡

A

(a)

=

='a

=

·~

Q

~

Q,l

Cl.l

·~

lfl

rn

r

1

j

1

lfl

rn

1

1

+

STANDARD$

PP7305:1991

Solution 17

Solution 20

0.05

0.02/ 50

Solution 18

o

o o

c::ic::i

IJ)

NN

(a)

'&

l//I0.03/1001

Al

(b) Since the feature is 700 long, the maximum value to

which the parallelism tolerance could accumulate over

its whole length will be 7 x 0.03 = 0.21.

-

f/}Q.03

Care should be taken in checking the solutions to

exercises 19 to 35 to ensure that:

e

a) the leader from the tolerance frame always carries

an arrowhead that touches the toleranced feature in

such a direction that the orie.:;i.tation of the tolerance zone

is correct;

Solution 21

(b) the arrowhead is positioned correctly in relation to

the dimension lines depending on whether the tolerance

refers to a surface, face, edge or line; or to the axis or

median plane of the dimensioned feature only; or to the

common axis or common median plane;

ec) datum triangles are positioned correctly using the

same criteria as in (b);

ed)

where the tolerance zone is circular or cylindrical,

0 appears on the tolerance frame before the tolerance

valu e.

Solution 19

Solution 22

Note that the leader from the left-hand tolerance frame

is to be normal to the axis and not normal to the

conical surface.

4

STANDARDS

PP7305:1991

Solution 25

Solution 23

+

1

Solution 24

11 0.01 A

Solution 26

NO

OC>

LrÍU"Í

NN

"Q

(a)

..l 0.02 A

The dimension line for the bore diameter is to be

positioned as shown so that the direction of the

arrowhead on the leader frorn the tolerance frame

o~entates the tolerance zone parallel to the daturn

surface.

Note that the arrowheads on the leaders frorn the

tolerance frame are not to be in line with the

dimension line.

(b) FALSE. Since the daturn feature is aplane surface,

the rnaximurn material principle cannot be applied to it.

5

STANDARD$

PP7305:1991

Solution 27

Solution 29

L 0.12 A

A positional tolerance could be used instead of an

angularity tolerance.

;

Solution 28

1

Solution 30

B

NO

00

00

...t...t

"Q

A

A

A positional tolerance could be used instead of an

angularity tolerance.

6

PP7305:1991

Solution 31

Solution 33

(a)

20 .1

20 .0

10.1

10.0

25 .00

24.98

45 .00

____ _ _ _4_4_.9_8_ __ _ _ _ __,A

(b) YES. The rnaximum material principle rnay be applied

to the geornetrical tolerance because the fe ature to which

the tolerance applies incorporates an axis.

Solution 34

Solution 32

O<D

--++---

º"'

---tt- a:i,....:

rnrn

Q

-::- 0.03 A-B

B

or-

º"'

0i

UlO

00

cricri

Solution 35

B

U 0.05 A

CDN

~o

ºº

uiui

rnrn

Q

A

U 0.08 A

7

STANDARDS

PP7305: 1991

Solution 36

Toleranced characteristic

Maximum material principie may be applied

YES

NO

v

Flatness of a face

Squareness of a bore axis to a datum plane

v

v

Angularity of a surface to a datum plane

Parallelism of a bore axis to datum axis

v

v

Roundness of a conical surface

Position of a spigot axis

v

v

v

v

Cylindricity of a bore

Axial run-out of a face

Straightness of the generator of a cylinder

Symmetry of the median plane of a slot

v

v

v

Profile of a surface

Squareness of a face to a datum plane

'

Coaxiality of a bore axis to a datum axis

v

v

v

Parallelism of a surface to a datum surface

Profile of a line

Angularity of a bore axis to a datum plane

v

Solution 37

(e) ( 1) Be cause the maximum material principle is

applied to the geometrical tolerance on the tenon

and to the datum to which this geometrical tolerance

is referred, the maximum permitted value of the

symmetry tolerance on the tenon is the stated

symmetry tolerance plus the size tolerance on the

tenon plus the size tolerance on datum feature A.

(a) (1) 24.95

(2) Virtual size of tenon

MMC size + stated geometrical tolerance

24.95 + 0.05

25.00

Therefore, the maximum permitted value of the

symmetry tolerance on the tenon is 0.05 + 0.02 + 0.02

= 0.09.

(b) (1) 25.00

(2) Virtual size of slot

MMC size - stated geometrical tolerance

25.00 - 0.03

24.97

(2) Similarly, the maximum permitted value of the

symmetry tolerance on the slot is 0.03 + 0.02 + 0.02

= 0.07.

8

STANDARD$

PP7305:1991

Solution 38

(a) 20.00 and 16.00

Solution 40

(a) Since the geometrical tolerances are speci:fied as zero

at MMC, the sizes of the four diameters at which they are

all to be perfectly coaxial and have their axes perfectly

square to datum face E are the MMC sizes:

(1) 35.00

(2) 18.00

(3) 32.00

(4) 45.00

(b) 0.02

ec) The diameter of the coaxiality tolerance zone is the

sum of the stated coaxiality tolerance and the departures

of the hole diameters from their maximum material limits

of size.

Therefore, coaxiality tolerance zone diameters are:

(1) 0.02 +

o+

0.01

=

(b) The virtual size of the bore

0.03

(2) 0.02

+ 0.02 + 0.03 = 0.07

(3) 0.02

+ 0.04 + 0.06

=

MMC size - stated geometrical tolerance

18.00 - o

18.00

0.12.

ec) The diameter of the cylindrical tolerance zone for the

larger outside diameter is the departure of the feature

from its maximum material limit of size.

Solution 39

(a) 40.00

Cylindrical tolerance zone diameter

MMC size - actual finished size

45.00 - 44.99

0.01

(b) 12.00

ec) The diameter of the positional tolerance zone is the

sum of the stated positional tolerance and the departure

of the hole from its maximum material limit of size.

Solution 41

Hole diameter

Positional tolerance

zone diameter

12.00

0.01

12.01

0.01

+ 0.01 = 0.02

12.02

0.01

+ 0.02 = 0.03

12.03

0.01

+ 0.03 = 0.04

( d) [8) Datum axis C is to be perpendicular to datum

face D.

[8] The axes of the four holes are to be perpendicular

to datum face D.

[8] Datum face D is to be flat.

[2] The axes of the positional tolerance zones are to

be perpendicular to datum face D.

ee) The axis of datum bore e is required to lie in a

cylindrical tolerance zone whose diameter is the

departure of the bore from its maximum material limit

of size and whose axis coincides with the centre of the

geometrical reference frame of the four holes. When

the datum bore is 40.02 diameter the tolerance zone

for its axis is 0.02 diameter. Therefore the maximum

displacement of the datum bore axis from the centre of

the geometrical reference frame for the four holes is 0.01,

that is, the radius of the tolerance zone.

39 .975

G ~-91~39~.9::....:5=0-.J

9

STANDARDS

PP7305:1991

Solution 44

(a) The mínimum specified length of the projected

tolerance zone for the tapping in component A when the

stud is used is the maximum projection of the stud from

the joint face of component A.

Solution 42

(a)

12 .018

6 X 12.000

-$-

9l O. 25 T S R

9l 0.08 T

Therefore, the mínimum specified length should be 115.2.

(b) The mínimum specified length when the set bolt is

used is the maximum thickness of component B.

~

cD

ED

1

1

1

i

1

1

1

1

-$---$--

@]

~

[l9J

Therefore, the mínimum specified length should be 75.1.

Solution 45

(a) The datum target is circular with a diameter of 6. It

is the third target for establishing datum A.

$

[§]

R

hTI

(b) The datum target is square with a side of 5. It is the

first target for establishing datum B.

(b) The virtual condition for each hole is a geometrically

perfect cylinder whose axis is at the theoretically exact

position of the hole axis.

(c) The datum target is square with a side of 20. lt is the

second target for establishing datum C.

The size of the virtual condition is the maximum material

size of the hole miuus the stated positional tolerance for

its axis.

Solution 46

This is an example of the 'floating fastener' case. The

maximum value of the positional tolerance for the hole

axes is the difference between the maximum material

limits of size of the holes and the unthreaded shanks of

the holes. Therefore, the maximum positional tolerance

for the hole axes is 8.40 - 8.00 = 0.4.

12.000 - 0.25 diameter

11.975 diameter

That is, virtual size

Solution 43

~

[

@

n:

1

1

Solution 47

This is an example of the 'fixed fastener' case. The sum

of the positional tolerances for the hole axes and the

stud axes should not exceed the difference between the

maximum material limits of size of the holes and the plain

portions of the studs. Therefore, the sum of the positional

tolerances for the hole and stud axes is 8.40 - 8.00 = 0.4.

1

iii

~!I

-0.025

9' 50 -0.050

1

1

~

_l

m

This sum can be shared in· any proportion between the

positional tolerances for the hole and stud axes, say as

0.2 for each.

Note that the studs and holes are groups of three features.

Therefore the clearance at MMC between the datums V

and W cannot be used as additional positional tolerance

for the hole axes and stud axes.

Since the whole of the positional tolerance which is

theoretically available has been allocated between

the hole ancr stud axes, it follows that in the most

unfavourable assembly conditions the hole and stud will

touch, giving a 'size-to-size' assembly. In the light of

measurement uncertainty this could be considered

10

STANDARD$

PP7305:1991

Solution 49

This is an example of the 'fixed fastener' case. The sum

of the coaxiality tolerances for the canister flange and its

mating counterbore should not exceed the sum of the

clearances at MMC between datums A and B and between

the canister flange and the counterbore.

undesirable. A size-to-size assembly can be avoided by

reducing the tolerance zone diameter for either the hole

or the stud axes, which will give clearance between the

studs and holes under all assembly conditions.

Note. This also applies to the symmetry, coaxiality

and positional tolerances in exercises 48, 49 and 50

respectively.

Clearance

Solution 48

This is an example of the 'fixed fastener' case. The sum

of the symmetry tolerances for the median planes of the

slideway slot and the tongue of the block should not

exceed the clearances at MMC between the slot and the

tongue and between the slideway datum and the block

datum. Since the slot and tongue are single features the

clearance at MMC between the datums A and B can be

used as part of the symmetry tolerance for the median

planes of slot and tongue. This also applies to the

coaxiality tolerance in exercise 49 and the positional

tolerance in exercise 50.

MMC of slideway datum

MMC of block datum

75.00

74.95

Clearance

0.05

MMC of slideway slot

MMC of block tongue

MMC of counterbore

MMC of canister flange

Clearance

Total clearance

0.1

Total clearance

0.05

0.15

0.08

51.00

50.95

0.05

0.08 + 0.05

0.13

This total clearance can be shared in any proportion

between the coaxiality tolerances, sayas 0.07 for the

canister flange and 0.06 for the mating counterbore.

Note. See also solution 4 7.

Solution 50

This is an example of the 'fixed fastener' case. The sum

of the positional tolerances for the median planes of the

pairs of flats should not exceed the sum of the clearance

at MMC of the spindle and lever bore and the clearance

at MMC of the pairs of flats.

40.1

40.0

Clearance

41.00

40.92

MMC of datum B

MMC of datum A

MMC of lever bore

MMC of spindle

+ 0.1

Clearance

This total clearance can be shared in any proportion

between the symmetry tolerances, sayas 0.08 for the

median plane of the slideway slot and 0.07 for the median

plane of the tongue of the block.

Note. See also solution 47.

20.00

19.98

0.02

MMC across flats on lever

MMC across flats on spindle

15.000

14.984

Clearance

0.016

Total clearance

0.02 + 0.016

0.036

This total clearance can be shared in any proportion

between the positional tolerances, sayas 0.02 for the

median plane of the flats in the lever and 0.016 for the

median plane of the flats on the spindle.

Note. See also solution 47.

11