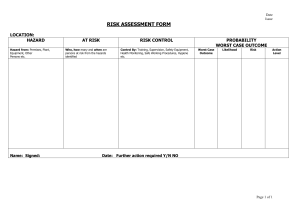

TOPIC 2 JOB SAFETY ANALYSIS & HIRARC •Classes of Hazards •Get Analysis •Job Safety Analysis •Hazard Identification, Risk Assessment and Risk Control •Hierarchy of Control Identify classes of hazard Describe Get analyses, Job Safety Analysis (JSA), HIRARC Perform a simple Hazard Identification and Risk Asssessment List and differentiate the Hierarchy Of Prevention Control http://www.dosh.gov.my/index.php/en/legisl ation/guidelines http://www.dosh.gov.my/index.php/en/mainservices/enforcement Hazard: Risk: anything that can caused probability of harm Risk Assessment: Evaluating the severity/consequences and possibility/chance hazard being done Risk Management: a decision making process which is based upon certain factual information and findings. THE 6-STEP RISK MANAGEMENT PROCESS THE PROCESS OF RISK MANAGEMENT Start 6. Supervise and Review 1. Identify the Hazards Classify Activities (Work, Product, Services, Activities) Identify Hazards 5. Risk Control Implementation 4. Make Control Decisions 2. Assess the Risks 3. Analyze Risk Control Measures Determine Risk*/Impact Decide if Risk is Tolerable Decide if Impact is Significant Prepare Risk Control Action Plan Review Adequacy of Action Plan is anything that has the potential to cause HARM to people, asset, environment and reputation. Hazard by itself cannot produce harm or danger unless we are EXPOSED to the hazard EXPOSURE is the main mechanism or pathway that release the dangers from hazard source 1. Obvious Hazards: which is apparent to the senses 2. Concealed Hazards: which is not-apparent to the senses 3. Developing Hazards: which cannot be recognised immediately but will develop over time 4. Transient Hazards: which is intermittent or temporary hazards Hazard is originated from Arabic -AZZAHR, means chance, luck. Hazards is anything that has potential to cause HARM or DANGER to people/human’s health and safety, asset/property, environment and reputation. Two groups of Hazard: HAZARDS can be a. Safety Hazard and a. Continuous (inherited in the system) or b. Health Hazard b. Non-Continuous (due to system failure). Health hazards Biological agent / hazards Chemical agent / hazards Ergonomics hazards Physical Agent / hazards Psychosocial / Pyscological hazards Viruses Bacteria Fungus Insects Rodents Animals Etc. Smoke Detergent Dust Glues Vapour Insecticides Fumes Paint Thinner Heavy metals Organic Solvent Cleansing agent etc. Manual handling Computer work Workspace Work layout Task design Etc. Fit the task to the man Electrical Space Slippery floor Vent Uneven surfaces Machines Holes Tools Noise Fire Heat Radiation Pressure Vibration Sexual harassment Gender issues Socialization Stress, shift work Financial burden Marital problems Family problems Safety Hazards Mechanical / machinery Height/Gravity Electrical Fire/ Explosion Violence Confine Space RISK: Is the chance or probability of harm actually being done = Hazard x Exposure = Consequences x Probability DANGER: Is the relative exposure to hazard It shows the magnitude (size) of the hazard and the risk There are 3 traditional OR basic hazard analysis Get Analysis (GA) Job Safety Analysis (JSA) Hazard Identificatio n, Risk Assessment and Risk Control (HIRARC) Preliminary Hazards Analysis (PHA) Failure Modes and Effects Analysis (FMEA) Failure Modes and Effects Criticality Analysis (FMECA) Hazard and Operability Analysis (HAZOP) Event Tree Analysis (ETA) Fault Tree Analysis (FTA) Energy Trace and Barrier Analysis Operating and Support Hazard Analysis System/subsystem Hazard Analysis Hazard Evaluation Human Reliability Analysis (HRA). Physical inspection Document reviews Accident Reports Audit Report Law review Exposure Monitoring Reports OSH Publications Biological / Medical Surveillance Report Workers knowledge & experiences Brain Storming Inspection worksheet Contact/ Industry/ Association Ask “5 W” A physical examination of the workplace requires; • an inquiring mind, • lateral thinking, and • the ability to be and remain open minded. • Reports of accidents, accident investigation and audits • Information from publications – Regulations and Codes of Practice – Statistics – Handbooks, etc. – CSDS (MSDS). – Excessive noise – Excessive heat – Inadequate ventilation – Radiation exposure – Excessive air contaminants – Ergonomic hazards – Substance is used in workplace – Substance is hazardous – Evidence or reason to suspect injury – Atmospheric monitoring insufficient – Techniques available – Will benefit those at risk Employees Requiring Health Surveillance and are exposed to hazard for which there is: (i) identifiable health effect/disease (ii) likelihood that it could occur (iii) valid techniques for detecting effect (iv) valid biological monitoring method and reason to believe values might be exceeded. • This is a process of conducting group meetings with people who are familiar with the operation of the area under review, recording all ideas and thoughts relating to possible hazards and then sorting the results into some sort of priority order. • Employees should be encouraged to report any hazards they are aware of. • Location • Machine • Person • Age of Person • Time of Day • Day of Week • Part of Body • Severity of Injury • Occupation These publications can be of particular benefit as they concentrate on reporting issues relating to safety and health A counter-part in another subsidiary of the company or even a contact in a competitive company could be a good source of information as they probably share similar safety problems. Safety and health is often brought up at industry association meetings or during informal discussions before or after meetings. Its important to try to anticipate how human behaviour, equipment, and system failures could combine to create a hazardous situation. Constantly ask yourself "What if?...." • Checklist and inspection worksheet (standard approach and record). • Safety Audit Worksheet. (Involve supervisors, managers and employees) Is an accident prevention technique which seeks to; b. Develop precautions that will eliminate or guard against these hazard a. Identify the hazard associated with each stage of a job c. Provide a safe work procedure to be used in job training or the development of a safe system of work. A briefing guide for infrequent jobs Teaching aid for initial job training To assist in completing accident investigation As standard for safety inspections Formulation of a safe work procedure KEY ELEMENTS IN JOB SAFETY ANALYSIS (JSA) 1. Select the type / scope of the job. 2. Break each main action or steps from the start / beginning till the completion of the job. 3. Use action ‘verb’ used to in each step to describe the job. 4. Normally the job is described in less than 10 steps. 5. List all the possibility of things that can go wrong or causing harm or injuries. An instrument to identify hazard, analyze and assess its associated risk and then apply the suitable control measures HIRARC C = CONTROLS. R = RISK A = ASSESSMENT H = HAZARD I = IDENTIFICATION R = RISK • • Risk is the combination of the likelihood and severity of a specified hazardous event occurring. In mathematical term, risk can be calculated by the equation: RISK = LIKELIHOOD X SEVERITY • • • Likelihood is an event likely to occur within the specific period or circumstances Severity is outcome from an event eg. of outcomes: • • • • • severity of injury or health of people, or damage to property, or insult to environment, or any combination of those caused by the event. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Classify Work Activities Identify Hazard Identify The Risk Conduct Risk Controls Identify Likelihood /Probability of Occurrence Identify Severity / Consequence of Hazard Decide Risk Score/ Risk Level Rank the Risk According to the Score Identification of Control Measures Construct the Safety Work Procedures Very Likely -- Could happen frequently Likely -- Could happen occasionally Unlikely -- Could happen, but only rarely Highly Unlikely -- Could happen but probably never will Very Rare -- Once per year or less Rare -- A few times per year Unusual -- Once per month Occasional -- Once per week Frequent -- Daily Continuous -- Constant Severity can be divided into four or five categories. Severity are based upon an increasing level of severity to; an individual’s health, the environment, or to property. FATAL—Death MAJOR INJURIES—Normally irreversible injury or damage to health requiring extended time off work to effect best recovery. MINOR INJURIES—Typically a reversible injury or damage to health needing several days away from work to recover. Recovery would be full and permanent. NEGLIGIBLE INJURIES— Would require first aid and may need the remainder of the work period or shift off before being able to return to work. The HAZARD CONSEQUENCES/HARM can be rated as: 1 - Slight Health Effects : Not affecting work performance or causing disability 2 - Minor Health Effects : Hazards capable to cause minor health effects which are REVERSIBLE for instance: Irritant Chemical 3 - Major Health Effects : Hazards capable of causing IRREVERSIBLE health damage without loss of life. Examples: Noise which can cause Hearing loss and impairment 4 - PERMANENT TOTAL DISABILITY or One to 3 Fatalities : Hazards capable of causing IRREVERSIBLE DAMAGE with SERIOUS disability or Death. Examples : Corrosive chemicals, Psychological Stress, Carcinogens 5 - Multiple FATALITIES : Hazard that has potential to cause multiple fatalities. Example: Chemicals with Acute Toxic Effects - Carbon Monoxide Poisoning Risk can be presented in variety of ways. Risk analysis uses likelihood and severity in qualitative method, presenting its result in a risk matrix Risk can be calculated using the following formula: Relative Risk = L x S where L = Likelihood S = Severity • • • To use this matrix, first find the severity column that best describes the outcome of risk. Then follow the likelihood row to find the description that best suits the likelihood that the severity will occur. The risk level is given in the box where the row and column meet. The relative risk value can be used to prioritize necessary actions to effectively manage work place hazards. Probability/likelihood Severity/Consequences Highly likely Very likely Likely Less Likely 5 4 3 2 1 5 25 20 15 10 5 4 20 16 12 8 4 3 15 12 9 6 3 2 10 8 6 4 2 Value Fatal Major Minor Near Miss Unlikely 25 20 15 10 5 20 16 12 8 4 15 12 9 6 3 10 8 6 4 2 Risk Level Risk Value Extremely High 20 - 25 High Risk 12 - 16 Medium Risk 8-10 Low Risk 2-6 Multi Entry Risk Assessment Form (MERA Form) Activities/ process/ facilities/ equipments Hazard Effect Current Risk Control Legal Reqmnt Action & Recommend ation Risk Sev Prob Risk Rating Definition: • Control is the elimination or inactivation of a hazard • the hazard does not pose a risk to workers who have • to enter into an area or work • on equipment 1. Elimination - Getting rid of a hazardous job, tool, process, machine or substance is perhaps the best way of protecting workers. For example, a salvage firm might decide to stop buying and cutting up scrapped bulk fuel tanks due to explosion hazards. 2. Substitution - Sometimes doing the same work in a less hazardous way is possible. For example, a hazardous chemical can be replaced with a less hazardous one. Controls must protect workers from any new hazards that are created. a. Redesign - Jobs and processes can be reworked to make them safer. For example, containers can be made easier to hold and lift. b. Isolation - If a hazard cannot be eliminated or replaced, it can some times be isolated, contained or otherwise kept away from workers. For example, an insulated and air-conditioned control room can protect operators from a toxic chemical. c. Automation - Dangerous processes can be automated or mechanized. For example, computercontrolled robots can handle spot welding operations d. Barriers - A hazard can be blocked before it reaches workers. For example, special curtains can prevent eye injuries from welding arc radiation. Proper equipment guarding will protect workers from con tacting moving parts. e. Absorption - Baffles can block or absorb noise. Lockout systems can isolate energy sources during repair and maintenance. Usually, the further a control keeps a hazard away from workers, the more effective it is. f. Dilution - Some hazards can be diluted or dissipated. For example, ventilation systems can dilute toxic gasses before they reach operators. a. Safe work procedures - Workers can be required to use standardized safety practices. The employer is expected to ensure that workers follow these practices. Work procedures must be periodically reviewed with workers and updated. b. Supervision and training – Initial training on safe work procedures and refresher training should be offered. Appropriate supervision to assist workers in identifying possible hazards and evaluating work procedures. c. Job rotations and other procedures can reduce the time that workers are exposed to a hazard. For example, workers can be rotated through jobs requiring repetitive tendon and muscle movements to prevent cumulative trauma injuries. Noisy processes can be scheduled when no one is in the workplace. d. Housekeeping, repair and maintenance programs Housekeeping includes cleaning, waste disposal and spill cleanup. Tools, equipment and machinery are less likely to cause injury if they are kept clean and well maintained. e. Hygiene - Hygiene practices can reduce the risk of toxic materials being absorbed by workers or carried home to their families. Street clothing should be kept in separate lockers to avoid being contaminated by work clothing. Eating areas must be segregated from toxic hazards. Eating should be forbidden in toxic work areas. Where applicable, workers should be required to shower and change clothes at the end of the shift. PPE refers to protective clothing, helmets, goggles, or other garments or equipment designed to protect the wearer's body from injury or infection: head, eyes, ears, fingers, foot, limb, body The hazards addressed by protective equipment include physical, electrical, heat, chemicals, biohazards, and airborne particulate matter. Safe Work Procedures are step by step instructions that allow workers to conduct their work safety when hazards are present. A Safe Work Procedure identifies the materials and equipment needed, and how and when to use them safety. a. regulatory requirements b. necessary PPE c. required training d. worker responsibilities e. specific sequence of steps to follow to complete the work safely f. required permits g. emergency procedures