DESIGN OF ELECTRICAL MACHINES

TABLE OF CONTENTS

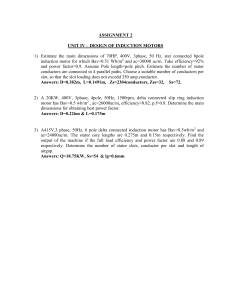

NO

I

TITLE

SYLLABUS

QUESTION BANK

CLASS WORK PROBLEMS

TWO MARKS

UNIT – I – INTRODUCTION

1.1 Design

1.2 Engineering Design

1.3 Considerations To Evolve A Good Design

1.4 Design Factors

1.4.2 Electromagnetic Fields

1.4.1 Electrostatic Fields

1.5 The Basic Structure Of An Electromagnetic

Rotating Electrical Machine

1.6 Limitations In Design

1.7 Constructional Details Of Machines

1.8 Specification Of Machines

1.8.1 Specification

1.8.2 The Standard Specifications Issued For

Electrical Machines,

1.8.3 Indian Standard Specifications Numbers

Along With Year.

1.9 Recend Trends In Design

1.10 Basic Principles

1.10.1 Faraday’s Law Of Electromagnetic

Induction

1.10.2 The Change In Flux Linkages Can Be

Caused In Three Ways

1.10.3 Biot-Savart’s Law

1.10.4 Force Between Current Carrying

Conductor

1.11 General Design Procedure

1.11.1 Main Dimension Of The Rotating

Machines

PAGE

1

1

1

1

2

4

6

8

9

11

14

1.12.Properties Of Materials Used In Electrical

Machines

1.12.1 Properties Of High Conductivity

1.12.2 Properties Of Copper

1.12.3properties Of Annealed Copper

1.12.4 Magnetic Materials

1.12.5 Soft Magnetic Materials

1.12.6 Hard Magnetic Materials

1.12.7 Electrical Properties Of Insulating

Materials

1.12.8 Applications Of Insulating Materials

1.13 Recent Trend In Design

1.13.1 Advantages Of Use Of A Digital

Computer

1.13.2 Computer Aided Design ( Cad)

1.13.2.1 Analysis Method

1.13.2.2 Synthesis Method

1.13.2.3 Hybrid Method

1.13.3 The Method Of Design Optimization

Using Computers

1.13.4 Flow Diagram For Analysis Method Of

Design.

1.13.6 Flow Diagram For Synthesis Method Of

Design.

1.13.5 Advantages Of Analysis Method

1.14 Basic Principles Of Magnetic Circuits

1.15 Difference Between Electric And Magnetic

Circuits

I

16

22

26

29

1.16 Similarities In Electric And Magnetic Circuit

30

1.17 Magnetization Curves

1.18 Reluctance Of The Airgap In Machines With

Smooth Aramture

1.18.1 Reluctance Of Airgap In Machines With

Open Armature Slot

1.18.2 Case (I) Reluctance Of Airgap Neglecting

Fringing Effect

1.18.3 Case (I) Reluctance Of Airgap Including

The Effect Of Fringing

1.18.4 The Gap Contraction Factor For Slots

1.18.5 Estimation Of Carter’s Gap Co-Efficient

For Slots

30

32

1.19 Effects Of Ventilating Ducts On Reluctance Of

Airgap

1.19.1 Gap Contraction Factor For Ducts (Kgd)

1.19.2 Total Gap Contraction Factor

1.20 Gap Contraction Factor For Induction Motor

1.20.1 Stator Slot Opening

1.20.2 Rotor Slot Pitch

1.21 Mmf For Airgap

1.21.1 Mmf For Airgap In Rotating Machines

1.21.2 Mmf Of Air Gap In Machines With Smooth

Armature.

1.22 Mmf For Teeth

1.22.1 Methods

1.22.1 .1 Graphical Method

1.22.1 .2 Three Ordinate Method (Simpson’s Rule)

1.22.1 .3 Bt1/3 Method

1.21.3 Mmf Of Air Gap In Machines With Open

Armature Slot And Radial Ventilating Ducts

1.21.4 Effect Of Salient On The Mmf For Airgap

1.23 Real And Apparent Flux Density

1.24 Magnetic Leakage

II

36

38

39

41

42

1.24.1 The Leakage Flux Affects The Following

Performance Of Various Machines

1.25 Slot Leakage Reactance (Reactive Voltage)

43

1.26 Unbalanced Magnetic Pull

45

1.27 Magnetic Loading

47

1.28 Electric Loading

1.28.1 Specific Magnetic And Electric Loading

48

1.29 Output Equation

48

PROBLEMS

48

UNIT II

DC MACHINES

2.1 Constructional Elements

66

2.2 Output Equation

67

2.3 Alternative Expression For Power Developed In

Armature

68

2.4 Separation Of D And L For Dc Machines

69

44

2.5 Choice Of Armature Diameter

II

2.6 Choice Of Specific Loading

2.7 Choice Of Specific Electric Loading

2.8 Selection Of No. Of Poles

2.8.1 Advantages Of Large Number Of Poles

2.8.2 Disadvantages Of Large Number Of Poles

2.8.3 Guiding Factor / Condition Factor For

Choice

Of Number Of Poles

2.9 Length Of Airgap

IV

72

73

75

78

PROBLEMS

79

2.10 Area of cross section of armature conductor

84

2.11 Design of commutator and brushes

85

2.12 Efficiency and losses

86

UNIT III

TRANSFORMER

3.1 Constructional Details

3.2 Output Equation Of Single Phase Transformer

3.3 Output Equation Of Three Phase Transformer

III

71

100

100

103

3.4 Emf Per Turn

3.5 Design Of Cores

3.5.1 Two Stepped Core / Cruciform Core

3.5.2 Ratio Of Area Of Core And Circumscribing

Circle

3.6 Choice Of Flux Density In The Core

3.7 Over All Dimension Of The Transformer

3.8 Design Of Windings

3.9 Cooling Of Transformers

3.9.1 Methods Of Cooling Transformer Are

3.9.2 T/F Oil As A Cooling Medium

3.9.3 Temperature Rise In Plain Walled Tanks

3.10 Design Of Tank With Cooling Tubes

105

3.11 Dimensions Of Tank

3.12 Estimation Of No Load Current Of Transformer

3.13 No Load Current Of Three Phase Transformer

115

PROBLEMS

118

UNIT - IV

105

108

109

111

112

114

128

130

INDUCTION MOTORS

4.1 Constructional Details

4.2 Separation Of D And L For Induction Motors

4.3 Choice Of Specific Loadings

132

4.4 Choice Of Specific Electric Loading

134

4.5 Choice Of Specific Magnetic Loading

134

4.6 Main Dimension

134

4.7 Stator Winding

135

4.8 Length Of Mean Turn

135

4.9 Stator Conductors

135

4.10 Stator Core

136

4.11 Choice Of Stator Slot

137

4.12 Area Of Stator Slot

138

4.13 Stator Teeth

4.14 Depth Of Stator Core

133

133

138

138

4.15 Length Of Air Gap

139

4.16 Choice Of Rotor Slots

139

4.17 Design Of Squirrel Cage Rotor

140

4.18 Design Of End Rings

141

4.19 Design Of Wound Rotor

141

4.20 Rotor Teeth

142

4.21 Rotor Core

142

4.22 Slip Rings & Brushes

4.23 Output Equation And Output Co-Efficient Of Ac

Machines (Induction Machine)

PROBLEMS

142

142

144

UNIT - IV

INDUCTION MOTORS

V

5.1 Introduction

5.1.1 (I)Salient Pole Machines

5.1.2 (Ii)Cylindrical Rotor Machines

5.2 Output Equation

159

5.3 Design Of Salient Pole Machines

159

159

5.4 Types Of Poles

5.5 Short Circuit Ratio (SCR)

5.5.1 Effect Of SCR On Machine Performance

160

161

5.5.2. Summarizing, High Value Of SCR Leads To

5.6 Choice Of Specific Magnetic Loading

161

5.7 Choice Of Specific Electric Loadings

161

5.8 Number Of Stator Slots

162

5.9 Methods Of Eliminating Harmonics

5.10 Length Of Air Gap

5.10.2 Disadvantage Of Large Air Gap

5.10.1 Advantage Of Large Air Gap Are

5.10.3 Estimation Of Air Gap Using Scr

5.11 Turbo Alternator

162

5.12 Armature Design Of Salient Pole Alternator

166

5.13 Field Design (Salient Poles)

5.14 Design Of Damper Winding

168

PROBLEMS

5.15 Dispersion Coefficient

5.15.1 Higher Value Of Dispersion Co Efficient

171

163

164

170

174

ELECTRICAL MACHINE DESIGN

UNIT I: INTRODUCTION

Principles of electrical machine design - General design considerations Specifications of machines- Limitation in design- Recent trends in design – CAD

– Flow chart methods - Review of properties of materials used in electrical machines

- Magnetic circuit calculations- Introduction

to

Finite

element

method

mathematical formulation - magnetic field calculations.

UNIT II: DC MACHINES

Constructional details- Output equation - Choice of specific electric and magnetic

loadings - Separation of D and L for rotating machines. Estimation of number of

conductors / turns - Coils - armature Slots - Conductor dimension - Slot dimension.

Choice of number of poles - Length of air gap - Design of field system, Interpoles,

Commutator and Brushes.

UNIT III: TRANSFORMERS

Constructional details-Classification – output equation - Core section - Window

dimensions - Yoke dimension - Overall dimension - Determination of number of turns

and length of mean turns of windings- Resistance of windings- Leakage reactance- No

load current calculation – Regulation, losses and efficiency.

UNIT IV: INDUCTION MOTORS

Three phase Induction Motor: Constructional details - Output equation - Choice of

specific loadings - Design of stator, squirrel cage rotor, windings and slots Calculation of circuit parameters - No load current - efficiency and temperature rise

from design data. Single phase Induction Motor: Design of running and starting

windings for capacitor start induction motor.

UNIT V: ALTERNATORS

Constructional details – Output equation – Choice of specific electric and magnetic

loadings- Estimation of D and L – Stator slots- Length of airgap- Conductors/turnStator yoke design-Design of damper windings- Design of field windings- Rotor design

of turbo alternator.

TEXT BOOKS

1. A.K. Sawhney, A.Chakrabarti, "A Course in Electrical Machine Design", Dhanpat

Rai & Company, sixth edition 2006.

2.

V.N. Mittle and A. Mittle, ‘Design of Electrical Machines’, Standard Publications

and Distributors, Delhi, 2002.

3.

S en, S.K, "Principles of E lectric Machine D esign with C omputer

Programmes", Oxford & IBH Publishing Co. Pvt. Ltd., 2001, Reprint 2004.

4. M.V.K. Chari and P.P. Silvester, "Finite Elements in Electric and Magnetic

Field Problems", John Wiley, 1980.

REFERENCE BOOKS

5.

K.G. Upadhyay, ‘Design of Electrical Machines’, New Age nternational

Publishers, 2008.

6.

R.K. Agarwal, "Principles of Electrical Machine Design", S.K.Kataria and Sons,

Delhi, 2002.

7.

Shanmugasundaram, A., Gangadharan G. and Palani R., "Electrical Machine

Design Data Book", New Age international publishers (P) ltd., First edition 17979,

Reprint 2005.

8.

H .M.Rai, "Principles of Electrical Machine Design", Sathya prakashan, Delhi.,

1988

9.

P.P. Silvester and Ferrari, "Finite

Cambridge University Press, 1984.

Element

for

Electrical

Engineers",

10. A.E.Clayton, "Performance and design of Direct Current Machines", The

English Language Book Society and sir Isaac pitman and sons Ltd., London, 1962.

UNIT - I

INTRODUCTION

Basic Principles of Machine Design

Principles of electrical machine design - General design considerations Specifications of machines- Limitation in design- Recent trends in design – CAD

– Flow chart methods - Review of properties of materials used in electrical machines

- Magnetic circuit calculations- Introduction to Finite element method mathematical formulation - magnetic field calculations.

1.1 DESIGN

Design is defined as a creative physical realization of theoretical concepts.

1.2 ENGINEERING DESIGN

Engineering Design is a application of science, technology and invention to produce

machines to perform specified tasks with optimum economy and efficiency.

1.3 Considerations to evolve a good Design

1. Cost

2. Durability

3. Compliance with performance criteria as laid down in specifications.

4. Compliance with the performance specification and consumer requirements.

A good design is one where the machine has reasonable operating life,say between 20

to 30 years and has a low initial cost. This is for motors.

Induction motors used for general purpose applications.

Large synchronous machines and transformers which are used in power system must

be designed with reliability and durability in operation as the major considerations

with less initial cost.

-------------------------------*---------------------------------

1.4 Design Factors

The mechanical force required for movement in Rotating electrical machines can be

produced both by

1. Electrostatic fields

2. Electromagnetic fields

Both the fields stores some energy .

1.4.1 Electrostatic fields

in electrostatic machines, the energy density is limited by the dielectric strength of

the medium used.

For Air dielectric medium the energy density about 40J/m3

1.4.2 Electromagnetic fields

Magnetic effects is used for production of force.

Maximum value of flux density that can be used is about 1.6wb/m2.

The energy density about 1MJ/m3 (in airgap)

Approximately energy density is 25,000

The force produced by electrostatic effects are very weak.

A small current can produce large mechanical force by electromagnetic means

and therefore all the modern electrical machines are electromagnetic type.

------------------*--------------------------

1.5 THE BASIC STRUCTURE

ELECTRICAL MACHINES

It consists of following parts

1.

2.

3.

4.

5.

Magnetic circuits

Electric circuits

Dielectric circuits

Thermal circuits

Mechanical parts

OF

AN

ELECTROMAGNETIC

ROTATING

Magnetic circuits

It provides the path for the magnetic flux and consists of airgap, stator and rotor

teeth and stator and rotor cores (yokes)

Electric circuits

It consists of stator and rotor winding.The winding of a transformer or a rotating

machine conveys electrical energy to or from the working region and is concerned with

production of emf and development of magneto mechanical force.winding are formed

from suitable insulated conductors.

Dielectric circuits

The dielectric circuit consists of insulation required to isolate one conductor from

another and also the windings from the core. The insulating materials are essentially

non-metallic and may be organic or inorganic ,natural or synthetic.

Thermal circuits

The thermal circuits is concerned with mode and media for dissipation of heat

produced inside the machine on account of losses.

Mechanical parts

Fig

(1.5

)

Basic

structure

ofrotating

machines

Main mechanical parts

1. Frame

2. Bearings

3. Shaft

A successful design brings out an economic compromise for space occupied by

iron, copper (aluminum) insulation and coolant (which may be air,hydrogen,water

or oil)

--------------------*--------------------------

1.6 LIMITATIONS IN DESIGN

Saturation

Temperature rise

Insulation

Efficiency

Mechanical parts

Commutation

Power factor

Consumers specifications

Standard specifications

Saturation

Electromagnetic machines use ferromagnetic materials

The maximum allowable flux density to be used is determined by the saturation level

of the ferromagnetic material used.

A high value of flux density results in increased excitation resulting in higher cost for

the field system.

Temperature rise

The most important parts of the machine is insulation.

The operating life of a machine depends upon the types of insulating materials used in

its construction .

The life of s insulating materials in turn depends upon the temperature rise of the

machine.

Proper cooling and ventilation techniques are required to keep the temperature rise

within safe limits.

Insulation

The insulation materials used in a machine should be able to withstand the electrical

,mechanical and thermal stresses which are produced in the machines.

The type of insulation is decided by the maximum operating temperature of the

machine parts where it is put.

And also the size of the insulation is decided by maximum voltage stress and

mechanical stresses produced.

Efficiency

The efficiency of the machine should be as high as possible to reduce the operating

costs.

In order to design a highly efficient machine, the machine and electric loadings used

should be small and this requires the use of large amount of material.

Mechanical parts

The construction of mechanical parts should be as simple as possible and also it is

technologically good.

The design of mechanical part is particularly important in case of high speed

machines.

For example

In turbo alternator ,the rotor slot dimensions are so selected that the mechanical

stresses at the bottom of rotor teeth do not exceed the maximum allowable limit.

In induction motors ,the length of airgap is kept as small as possible in order to have

a high power factor.

The length of airgap and also that of the size of the shaft are mainly decided by the

mechanical considerations.

In large machines,the size of the shaft is decided by considering the critical speed

which depends on the deflection of the shaft.

Commutation

The problem of commutation is important in the case of commutator machines.

Commutation condition limit the maximum output that can be taken from a

machine.

Power factor

Poor power factor results in larger values of current for the same power and therefore

large conductor sizes have to be used.

Power factor problem is particularly important in the case of induction motors.

The size and hence cost of induction motors can be reduced by using a high value of

flux density in the airgap but results in saturation in iron parts of machine and

consequently a poor power factor.

Thus the value of flux density depends upon the power factor.

Consumer’s specifications

The specifications as laid down in the consumer’s order have to be met and the design

evolved should be such that it satisfied all the specifications and also the economic

constraints imposed on the manufacturer.

Standard specifications

This specifications are the biggest strain on the design because both the manufacturer

as well as the consumer cannot get away from them without satisfying them.

-------------------------------*-----------------------------

1.7 CONSTRUCTIONAL DETAILS OF MACHINES

Electrical machines design involves application of science and technology to produce

cost effective, durable, quality and efficient machines.

The machines should be designed as per standard specifications.

Electrical machines classifications

1. Static (stationary) machines

Transformer (converts electrical energy from one voltage level to another

voltage level.

2. Dynamic machines

a. Motors

b. Generators

Rotating machines converts electrical energy to mechanical energy or

viceversa.

This above said conversions in any electrical machine takesplace through magnetic

field.

Required magnetic field produced by an electromagnetic which requires core and

winding.

The basic principle of operation of all electrical machine is governed by faraday’s law of

electromagnetic induction.

Constructional Elements Of Transformer

1.

2.

3.

4.

IRON CORE

PRIMARY AND SECONDARY WINDING

TRANSFORMER TANK

COOLING TUBES

Constructional Elements Of Rotating Machines

1. STATOR

2. ROTOR

3. Others.

DC machine

Stator

a. Yoke

b. Field pole

c. Pole shoe

d. Field winding

e. Inter pole

Rotor

a. Armature core

b. Armature winding

c. Commutator.

d.

Others

a. Brush

b. Brush holder

Squirrel cage induction motor

Stator

a. Frame

b. Stator core

c. Stator winding

Rotor

a. Rotor core

b. Rotor bars

c. End rings

Classification of design problems

•

1. Electromagnetic Design

•

2. Mechanical Design

•

3. Thermal Design

•

4. Dielectric Design

--------------------*-------------------------------

1.8 SPECIFICATION OF MACHINES

1.8.1 SPECIFICATION

The specification are guidelines for the manufacturers to produce economic products

without compromising quality.

The quality of the certified products will be periodically monitored by the standard

organization.

1.8.2 The standard specifications issued for electrical machines,

1. Standard ratings of machines

2. Types of enclosure

3. Standard dimensions of conductors to be used

4. Method of marking ratings and name plate details.

5. Performance specifications to be used

6. Types of insulation and permissible temperature rise

7. Permissible losses and range of efficiency

8. Procedure for testing of machine parts and machines

9. Auxiliary equipments to be provided

10.Cooling methods to be adopted

in India ,the Indian standards organization (ISO) has laid down their specification(ISI)

for various products.

Recently they have released revised standard ISO 9002.

The name plate of the rotating machine has to bear the following details as per ISI

specifications.

1. KW or KVA rating of machine

2.

3.

4.

5.

6.

7.

8.

Rated working voltage

Operating speed

Full load current

Class of insulation

Frame size

Manufacturers name

Serial number of the product.

1.8.3 INDIAN STANDARD SPECIFICATIONS NUMBERS ALONG WITH YEAR.

Standard specification of induction motor

IS 325 – 1966

: Specifications for three phase induction motor.

IS 1231 – 1974

: specifications for foot mounted induction motor

IS 4029 – 1967

: Guide for testing three phase induction motors

IS 12615 – 1986

: specifications for energy efficient induction motor

IS 13555 – 1993

: Guide for selection and application of three phase induction

Motor for different types of driven equipment.

Standard specification of Transformer

IS 1180 – 1989

: Specifications for outdoor 3 phase distribution transformer upto

100KVA

IS 2026 – 1994

: Specification of power transformer

IS 11171 – 1985

: Dry type power transformer

IS 10561 – 1983

: Application guide for power transformer

IS 13956 -1994

: Testing transformers

IS 1885 – 1993

: Specification for electric and magnetic circuits

IS 996 – 1979

: Specifications for single phase AC and universal motor.

----------------------------------* ------------------------------------------1.9 RECEND TRENDS IN DESIGN

Universally accepted classification of electrical machines based upon constructional

features and power outputs exists are

1. Small size machines

2. Medium size machines

3. Large size machines

4. Larger size machines

Small size machines

Electrical machines having a power outputs upto about 750W may be called small

machines.

Medium size machines

Electrical machines having power outputs ranging from a few kilowatt upto

approximately 250KW may be classified as medium size machines.

Large size machines

Electrical machines with power outputs in the range of 250KW upto about 5000KW

are classified as large size machines.

The machines are usually designed and manufactured as a series and have a definite

power output range.

Larger size machines

These machines are manufactured on special orders from customer to meet their

specific demands.

Therefore ,large machines are designed on individual basis .

The power outputs of these machines may be as high as hundreds of megawatts.

The process of design of a single machine may be divided into three major design

problems.

Classification of design problems

1.

2.

3.

4.

Electromagnetic design

Mechanical design

Thermal design

Dielectric design

The aspect of modern day design of electrical machines is designing a number of

machines,all of which form part of a single system.

For example

Generators ,motors and transformer form a part of an electromechanical energy

network.

The different machines of such a system are inter connected and react upon each

other ,sometimes considerably and on occasions disasteroulsy.

Therefore the machines for such a system cannot be designed in isolation and the

designs of all the machines have to be complete concurrently since the design of ine

machine depends upon that of the others.

The problem thus is that of optimization of the system.

To design a series of machines having different ratings to fit into a single frame size.

In this case ,the finished designs of machines must be produced in groups ,where all

designs with in a group are independent.

The evolution of design to meet the specified optimum criteria is a matter of long and

tedious iterations and this fact has led to the applications of fast digital computers to

the design of electrical machines and transformers.

The digital computers has completely revolutionalized the field of electrical machine

deisgn.

The computer aided design has the advantages of eliminating tedious and time

consuming hand calculations thereby releasing the designer from numerical.

---------------------------* ----------------------------------

1.10 BASIC PRINCIPLES

The action of electromagnetic machines can be related to three basic principles which

are,

1. Induction

2. Interaction

3. Alignment

1.10.1 Faraday’s law of electromagnetic induction

This law states that emf induced in a closed electric circuit is equal to the rate of

change of flux linkages.

Flux linkages Ψ = NФ

N – the number of turns in a coil

Ф – flux linking

But flux Ф does not link with all the turns or alternatively all the turns do not link

with the same link.

Total flux linkages

Ψ =N1Ф1+N2Ф2+………………..NnФn

Nk=The number of turns which link with flux ФK

In this case there is a change in the value of the flux linkages of the coil,an induced

emf is produced is given by,

e=

(volt)

(-) sign indicates that the direction of the induced emf.

1.10.2 The change in flux linkages can be caused in three ways

1. The coil is stationary with respect to flux and the flux varies in magnitude with

respect to time.

2. The flux is constant with respect to time and is stationary and the coil moves

through it.

3. Both the changes mentioned above occur together (ie)the coil moves through a

time varying field.

Method I

Where the coil is stationary and the flux is time varying an emf called transformer

or pulsational emf is produced.

There is no energy conversion takes place is energy transference.

This principles used in transformers.

Method II

The flux cutting rule can be employed to illustrate the emf generated in a

conductor moving in a constant stationary field.

The emf generated in d conductor of length moving at right angles to a uniform

,stationary,time invarying magnetic field.

e=- Blv (volt)

where

B – flux density ,wb/m2(T)

l=length of conductor ,(m)

v- linear velocity of conductors (m/s)

the generated emf in this case is called a “motioned emf”.

Emf generated due to motion of conductor ,since motion is involved in the

production of this emf,the process involves electromechanical energy conversion.

This principles is utilize in rotating machines like DC ,induction

machines,synchronous machines.

Method III

A conductor or coil is moving across a stationary time varying magnetic field

(flux)and therefore both transformer as well as motional emf are produced in the

conductor or coil.

This process involves both transformer and energy conversion.

This principles is utilized in the commutator machines.

1.10.3 Biot-Savart’s Law

This law gives the value of force produced on account of interaction between a

magnetic field and a current carrying conductor

Fe=Blisin newton

B

l

i

– Flux density, wb/m2 (T)

- length of conductor,m

- current carried by conductor,A

– Angle between the direction of current and the direction of magnetic field

The direction of force produced is perpendicular to both current and magnetic field.

Conductor and magnetic field are perpendicular to each other and thus =

90˚,sin90̊˚= 1

fe=Bli newton

1.10.4 Force between current carrying conductor

Flux density

B= μH

B=μ

Electromagnetic force

F = BI2l

F=μ

F=

I2l

I1I2 newton

------------------------------* --------------------------------------1.11 GENERAL DESIGN PROCEDURE

In general electrical machines having two windings

Two winding

Transformer

DC machines

Induction machine

&

Synchronous machines

Primary

Winding

secondary

winding

Armature winding

stator

Winding

Rotor

Winding

Field winding

The general design procedure is to relate the main dimensions of the machines to its

rated power outputs.

An electrical machine is designed to deliver a certain amount of power called rated

power.

Rated power is the maximum power that can be delivered by the machine safety.

In DC machines the power rating is expressed in KW

In AC machines the power rating is expressed in KVA

In case of motor the output power is expressed in HP

Active part

In electrical machines the core and winding of the machine are together called active

part.

Because the energy conversion takes place only in the part active part of the

machines.

For all the machines the general output equation can be developed for DC machines

which relates the power output to volume of active part (D2L),speed, magnetic and

electric loading.

Similarly a general output equation can be developed for AC machine which relates

KVA rating to volume of the active part (D2L), speed, magnetic and electric loading.

1.11.1 MAIN DIMENSION OF THE ROTATING MACHINES

In rotating machines the active part is cylindrical in shape.

The volume of the cylindrical is given by the product of area of cross-section and

length (AxL)

D – Diameter of the cylinder

L – Length of the cylinder

Then volume of cylinder =

Fig (1.11.1) Main Dimensions of Rotating Machines

In DC machines

Fig (1.11.1 ) Construction of DC machine

D – Diameter of the armature

L – Length of the armature

In AC machines

D – Inner diameter of stator

L – The length of stator core

Dr – Diameter of Rotor

lg-Length of airgap

--------------------*-----------------------

1.12.PROPERTIES OF MATERIALS USED IN ELECTRICAL MACHINES

Electrical conducting materials

1. High conductivity materials

2. High resistivity materials (Alloys)

High conductivity materials

This type of materials used for making all types of windings required in electrical

machines,apparatus and devices.

Also used for transmission and distribution of electric energy.

This materials having least (resistance) resistivity.

High resistivity materials (Alloys)

This type of materials used for making resistance and heating devices.

1.12.1 Properties of high conductivity

1. Highest possible conductivity (least resistivity)

2. Least possible temperature coefficient of resistance

3. Adequate mechanical strength in particular,high tensile strength and

elongation characteristizing to a certain degree of the flexibility .ie absence of

brittleness .

4. Rollability and drawability which is important in the manufacture of wire of

small and intricate sections.

5. Good welability and solderability which ensure high reliability and low electrical

resistance of the joints.

6. Adequate resistance to corrosion.

Materials

1. Copper

2. Aluminum

3. Iron and steel

4. Alloys of copper

Copper

Copper is the most widely used electrical conductor.

1.12.2 Properties of copper

1. High electrical conductivity with excellent mechanical properties.

2. Relative immunity from oxidation and corrosion under service condition.

3. It is highly malleable and ductile metals.

1.12.3Properties of Annealed copper

1.Density ,kg /m3 – 8900

2.Melting point, ˚C – 1083

3.Thermal conductivity , W / m ˚C – 350

4. Resistivity , Ωm – 0.01724x10-6

5.Specific strength ,MN/m2 – 220 - 250

Aluminum

Aluminum is joining ever increasing applications for a number of economic and

engineering reasons.

The high demand for conductor materials which cannot be met by copper production

alone.

Therefore ,aluminum which is the conductor materials next to copper id used.

Pure aluminum is softer than copper,therefore can be rolled into thin sheets (foils)

Table Comparison of Aluminum and copper wires

Item

Cost

Cross section

Diameter

Volume

weight

Breaking strength

Copper

1

1

1

1

1

1

Aluminum

0.49xPe / Pa

1.62

1.27

2.04

0.49

0.64

Where

Pc – unit price by weight of copper

Pe – unit price by weight of Aluminum

Iron and Steel

Steel alloyed with chromium and aluminum is used for making starters,Rheostats

where lightness combined with robustness and good heat dissipation are important

considerations.

Cast iron is used in the manufacture of resistance grids to be used in the starters of

large motors.

Alloys of copper

1. Bronze (cadmium ,beryllium)

2. Brass

3. Copper silver alloys

High resistivity materials

Conductors of high resistance are used where it is actually desired to dissipates

electrical energy as heat.

ie In starting and regulating devices for motors

1. Nickel – standard resistance and resistance boxes

2. Silver - rheostats

3. Iron - making high temperature elements for electric furnaces heating devices

and loading Rheostats.

Electrical carbon materials

Electrical carbon materials are manufactured from graphite and other forms of carbon

coal.

Used for making brushes for electrical machines.

1.12.4 Magnetic materials

1. Ferromagnetic materials

2. Paramagnetic materials

3. Diamagnetic materials

Types of magnetic materials

1. Soft magnetic materials

2. Hard magnetic materials

1.12.5 Soft magnetic materials

The hysteresis loss depends upon the area of hysteresis loop.

For this reason, magnetic cores used in alternating magnetic fields are made from

materials whose hysteresis loop are more or less narrow.

Fig (1.12.5) Soft magnetic materials

Soft magnetic materials are used in the manufacture of

1.

2.

3.

4.

Electrical machines

Transformers

Electrical apparatus

Instruments and devices

1.12.6 Hard magnetic materials

Fig (1.12.6) Hard magnetic materials

These materials are used in certain types of electrical machines of low power rating

and in all kinds of instruments and devices requiring permanent magnetic which set

up magnetic fields of their own.

Soft magnetic materials

1. Solid core materials

2. Electrical sheet and strip

3. Special purpose alloys

Solid core materials

These materials are normally used for parts of magnetic circuits carrying steady flux

such as cores of DC electromagnets, relays and field frames of DC machines.

Materials used for soft –solid core materials.

1.

2.

3.

4.

5.

Soft iron

Relay steel

Cast steel

Cast iron

Ferro cobalt

Insulating materials

It is essentially

1. Non metallic

2. Organic (or) inorganic

3. Uniform (or) heterogeneous in composition

4. Natural (or) synthetic.

Many of them are natural origin

1.

2.

3.

4.

5.

Paper

Cloth

Paraffin

Wax

Natural resins

In organic insulating materials

1. Glass

2. Ceramics

3. Mica

1.12.7 Electrical properties of insulating materials

An ideal insulating material

1.

2.

3.

4.

5.

High dielectric strength ,sustained at elevated temperatures

High resistivity or specific resistance

Low dielectric hysteresis

Good thermal conductivity

High degree of thermal stability (ie) it should not deteriorate at high

temperature.

The above said properties of insulating materials vary widely with many factors.

1.

2.

3.

4.

Dimension of test piece

RMS value ,waveform and frequency of impressed voltage

Temperature and moisture content of test piece

Mechanical pressure on test piece.

1.12.8 Applications of insulating materials

1. Wires for magnet coils and windings of machines

2. Laminations

3. Machines and transformers.

---------------------------*-----------------------------1.13 RECENT TREND IN DESIGN

The digital computer has completely revolutionalized the field of design of electrical

machines.

The computer aided design eliminates the tedious and time consuming hand

calculations thereby releasing the designer from numerical drudgery to enable time to

grapple with physical and logical ideas thereby accelerating the design process.

The use of computer makes possible more trial designs and enables sophisticated

calculations to be made without intolerable tedium and excessive time.

1.13.1 Advantages of use of a digital computer

1. It has capabilities to store amount of data,count integers ,round off results

down to integers and refer to tables,graphs and other data in advance.

2. It makes it possible to select an optimized design with a reduction in cost and

improvement in performance.

3. A large number of loops can be incorporated in the design programme and

therefore it makes it easier to compare different designs out of which the best

suited can be selected.

4. It performs all simple arithmetic operations at a high speed and makes ot

possible to produce designs in a short time.

5. It is capable of automatic operation,going from one step to another without the

attention of operator.

6. It reduces the probability of error with the result highly accurate and reliable

results are obtained.

7. Larger manufacturing savings can be obtained by optimization of design.This

optimization is economically feasible only through the use of digital computers.

8. It is capable of taking logical decisions by itself if programmed into thereby

saving the man hour of the design engineers which can be utilized for other

gainful work.

1.13.2 COMPUTER AIDED DESIGN ( CAD)

In the earlier stages ,the use of digital computers for design of transformer only.

In the year 1956,moore and Williams discussed the use of digital computer for

design of rotating machines.

A flow chart was developed giving basic procedure for design of polyphase induction

motors.

The concept of optimization in electrical machine design was introduced by godwin.

The concept of two commonly acceptable approaches to machine design

1. Analysis method

2. Synthesis method

1.13.2.1 Analysis Method

In this method the choice of dimensions, materials and types of construction are made

by the designer and these are presented to the computer as input data.

The performance is calculated by the computer and is returned to the designer for him

to examine.

The designer examines the performance and makes another choice of input,if

necessary and the performance is recalculated.

COMPUTER AIDED DESIGN OF ELECTRICAL MACHINES

The process of design any electrical may be broadly divided into three major aspects.

1. Electrical design

2. Mechanical design

3. Thermal design

ADVANTAGES OF COMPUTER AIDED DESIGN

The computer can handle large volume of data to make a number of trials designs.

Speed and accuracy of calculations are very high.

It can be programmed to satisfying take logical decisions.

An optimized design with least cost and the required performance can be easily

obtained.

Generally any design method can be

1. Analysis method

2. Synthesis method

3. Hybrid method

Analysis method

A preliminary design is made by the designer regarding the machine dimensions,

materials and other constructional features and these are given as input data to the

computer and the performance quantities are calculated.

The designer examines the performance and accordingly alters the input data and

then feed them to the computer again.

The computer calculates the new performance with the revised data.

This process is repeated till the required performance is achieved.

1.13.2.2 Synthesis Method

The required performance values are also given to the computer as input.

The computer through an iterative process alters the dimensions till the required

performance is obtained.

1.13.2.3 Hybrid Method

By some human intervention a combination of analysis and synthesis methods are

adopted.

1.13.3 The method of design optimization using computers

1.

2.

3.

4.

5.

Choice of independent variables

Variable transformation

Forming the constraint functions for the performance

Forming the objective function (OBJ)

Applying the minimization technique till the OBJ becomes with in the chosen

tolerance.

1.13.4 Flow diagram for Analysis method of design.

Start

Human decision

NO

Input

`

Performance

calculations

Performance

Is

Decision

OK?

Stop

Output

1.13.5 ADVANTAGES OF ANALYSIS METHOD

1. It is fairly easy to program to use and to understand.

2. It results in considerable time saving thereby giving quick returns on the

investments made.

3. The results of analysis method are highly acceptable by designers.

1.13.6 Flow diagram for synthesis method of design.

Start

Performance specification

Assume suitable values for

variable

Design calculations

Adjust

values of

variables

Performance calculations

Compare calculated and

desired performance

NO

IS

Performance

satisfactory

Yes

Calculate total cost

Stop

Print design values

1.14 BASIC PRINCIPLES OF MAGNETIC CIRCUITS

The magnetic circuit is the path of magnetic flux.

The various elements in the flux path of salient pole machines are

Poles

Pole shoes

Air gap

Armature teeth

Armature core

Yoke

The various elements in the flux path of non –salient pole machines are

Stator core

Stator teeth

Air gap

Rotor teeth

Rotor core

Fig (1.14) Magnetic circuits in electrical machines

In electric circuit the emf circulates current against resistance when a closed path is

provided.

In magnetic circuit the mmf creates flux in a closed path against reluctance of the

path.

The coil wound on an iron core with N turns and carrying a current I will produce an

mmf of NI Ampere turns

Mmf =NI (AT)

AT – unit of mmf

The equation which relates flux ,mmf and reluctance is given by

Flux =

Ф=

Ф = AT x Λ ,

(or)

Λ=

– permeance

Reluctance of the magnetic materials can be estimated using the following equation

Reluctance

S=

x

S=

- permeability of the magnetic materials

–

- Relative permeability

Absolute permeability of free space.

H/m

The strength of the magnetic field is measured by the term magnetizing force (H).

Flux =

H=

; mmf = Flux X Reluctance per unit length

Mmf = Flux X Reluctance

H=ФX

H=Ф

X

=Ф

(B =

,A=

,

=

)

H=

For the case of a materials of length l and carrying a uniform flux,the total mmf AT is

H=

H=

AT = H x l = at x l

In a series magnetic circuit

Total reluctance

S = S1+S2+S3+………………..

S1,S2,S3 – Reluctance of individual parts

Total mmf acting around a complete magnetic circuit is

Total mmf

AT = ФS

AT = Ф (S1+S2+S3+………………..)

= AT1+AT2+AT3+………………..

= at1l1+at2l2+at3l3+……………...

AT =

In a parallel circuit

Total flux divides between the paths in inverse proportion to their releuctances.

In parallel circuit

Total flux Ф = Ф1+ Ф2+ Ф3+………………

Divide by AT

=

=

+

+

+ +………= …………

Λ = Λ1+ Λ2+ Λ3+………….

S- Total reluctance of magnetic circuit

S1,S2,S3 – Reluctance of individual parts

Λ – Total permeance of magnetic circuit

Λ1 Λ2 Λ3 – Permeance of individual parts.

----------------------------*----------------------------------

1.15 DIFFERENCE BETWEEN ELECTRIC AND MAGNETIC CIRCUITS

ELCTRIC CIRCUIT

MAGNETIC CIRCUIT

Current actually flows in the

electric circuit.

Flux does not flow but it is only

assumed to flow.

When current flows, the

energy is spent continuously

Energy is needed only to create the

flux but not to maintain it.

Resistance of the electric

circuit is independent of

current strength.

Reluctance of the magnetic circuit

depends on total flux or flux density

in the materials.

1.16 SIMILARITIES IN ELECTRIC AND MAGNETIC CIRCUIT

ELCTRIC CIRCUIT

MAGNETIC CIRCUIT

The emf circulates the

current in a closed path.

The mmf creates flux in a closed

path.

Flow of current is opposed by

resistance of the circuit.

The creation of flux is opposed by

reluctance of the circuit.

The path of current is called

electric circuit.

The path of the flux is called

magnetic circuit.

Resistance R = ρl / A = l / σA

σ conductivity

Reluctance ,S = l / μA

Current =

Flux =

Current density

δ=

Flux density

B=

------------------------------*---------------------------------1.17 MAGNETIZATION CURVES

B- H or B-at CURVES)

SOME ESSENTIAL DIFFERENCES BETWEEN ELECTRIC CIRCUIT AND

MAGNETIC CIRCUITS.

The electric current is assumed to be the flow of free electrons but there is no flow of

magnetic flux .

In an electric circuit energy is consumed so long as the current flows while in a

practical magnetic circuit,energy is expanded in creating flux and to maintain it.

The most important difference between electric and magnetic circuits arises from the

fact that whereas the resistance of an electric circuit is not directly dependent upon

value of current flowing and may be regarded as constant.

The value of reluctance of a magnetic materials is dependent upon the value of flux

passing through it.

The relative permeability of ferro magnetic materials may vary between a flow hundred

and about five hundred thousand.

The actual values of permeability and reluctance are hardly used in magnetic circuit

calculations.

The magnetization curves of magnetic materials relating flux density B to mmf per uint

length ,H or at per mt are used for the rapid determination of necessary excitation.

The analytic relations between B and H prove more convenient

B=

B=

-

A,ao,a1,a2,b1,b2 – constants

Fig (1.17.1 )Magnetization Curves

Fig (1.17.2) B H curve for iron

For non magnetic materials (like air) have a constant value of permeability and so the

B-at curve for them is a straight line passing through the origin.

Mmf per metre

H =

H=

= 800000B

Where B – wb/m2

-------------------------*----------------------------

1.18 RELUCTANCE OF THE AIRGAP IN MACHINES WITH SMOOTH ARAMTURE

All rotating machines will have a small airgap between armature and pole surface.

Fig (1.18) Reluctance Of The Airgap In Machines With Smooth

Aramture

The flux is uniform spread over the entire slot pitch and goes straight across the

airgap

L – length of the core

lg-airgap length

ys – slot pitch

Ws – width of slot

Wt – width of teeth

Reluctance of the magnetic path is

S – l / μA

l- length of magnetic path

μ –permeability of the medium

A – Area of cross section of the magnetic path.

The area of cross section of the magnetic path over one slot of the armature.

Sg =

Sy-Reluctance of the airgap

lg-length of airgap

μo-Permeability of air

-Area of cross section of airgap over one slot (The product of the length of armature

and slot pitch)

Ys-slot pitch

1.18.1 Reluctance of airgap in machines with open armature slot

Fig (1.18.1 ) slotted armature surface

In armature with open and semi enclosed slots, the flux will flow through the teeth of

the armature.

Hence effective area of the flux path is decreased ,which results increased reluctance

of airgap.

1.18.2 Case (i) Reluctance of airgap neglecting fringing effect

Fig (1.18.2) slotted armature surface

Consider the armature with open type of slots

Flux is only confined to the teeth width.

Reluctance of the airgap in machines with open armature slots Sg =

1.18.3 Case (ii) Reluctance of airgap including the effect of fringing

In armature with open slots the flux would fringe around the tooth and this fringing

would increase the area of cross section of flux path.(δWs).

Fig (1.18.3) Reluctance of airgap including the effect of fringing

Contracted slot pitch

Ys’ = Wt+ δWs

Adding and subtracting Ws

Ys’ = Wt+Ws+ δWs-Ws

Ys’ = Ys+ δWs-Ws

Ys’ = Ys-Ws(1-δ)

Ys’ = Ys - KcsWs

Kcs – (1-δ) – carter’s gap co-efficient for slots.

Reluctance of airgap in machine with open armature slot Sg=

Sg=

Sg =

1.18.4 The gap contraction factor for slots

Kgs - Gap contraction factor for slots

Kgs =

Kgs =

Kgs =

Kgs =

Kgs =

,Kgs >unity

1.18.5 Estimation of carter’s gap co-efficient for slots

Kcs = carter’s gap co-efficient for slots

Kcs =

Kcs = Wo / lg : Wo = slot opening

Open type slots

Fig (1.18.5) carter’s airgap co efficient

parallel sided open slots

Kcs = [

Where Y =

-----------------* ---------------------------------

1.19 Effects of ventilating Ducts on Reluctance of Airgap

When the length of the armature is higher than the diameter or length is greater than

0.1metre ,radial ventilating ducts are provided for better cooling of the core.

Fig (1.19 )Effects of ventilating Ducts on Reluctance of Airgap

Ventilating ducts of width 10mm in between two stacks.

Carter’s co-efficient for ducts - Kcd

Kcd =

Contracted axial length

L’ = L – KcdndWd

Kcd – carter’s coefficient for ducts

Wd – Width of the ducts

nd-number of the ducts

1.19.1 Gap contraction factor for ducts (Kgd)

Kgd =

Kgd =

=

Kgd =

1.19.2 Total gap contraction factor

Kg =

Kg =

Kg =

X = Kgs X Kgd

Kg = Kgs x Kgd

Kgs - Gap contraction factor for slots

Kgd – Gap contraction factor for ducts

-----------------------*---------------------------------

1.20 Gap contraction factor for induction motor

In induction motor both rotor and the stator has slots.

Hence the gap contraction factor should be computed for both the stator and rotor.

Kgs = Kgss x Kgsr

Kgs – Total gap contraction factor for slots

Kgss - gap contraction factor for stator slots

Kgss =

Kgsr =

Yss – stator slot pitch

Wos – Stator slot opening

Kcss – Carter’s co-efficient for stator slots

Ysr – Rotor slot pitch

Wor – Rotor slot opening.

1.20.1 Stator slot opening

Yss =

Yss =

1.20.2 Rotor slot pitch

Ysr =

Ysr =

D –stator inner diameter

Sr – no of rotor slots

Ss – no of stator slots

---------------------------*--------------------------

1.21 MMF FOR AIRGAP

Non magnetic materials

Mmf per meter of the path in non magnetic materials =

=

~ 800000B AT/m

1.21.1 Mmf for airgap in rotating machines

In machines with open or semienclosed slots ,the flux concentrates on teeth ie the

flux is not uniformly distributed in the airgap.

These are radial ventilating ducts in the machines for cooling purposes .this results in

contraction of flux in the axial direction.

1.21.2 Mmf of air gap in machines with smooth armature.

Mmf / metre for airgap

atg=

=

= 800000Bav

Bav - Average flux density in the airgap

μ –μo-Permeability of airgap

lg-length of the airgap

mmf required for airgap of length lg in machines with smooth armature ATg =

800000Bavlg

1.21.3 Mmf of air gap in machines with open armature slot and Radial ventilating ducts

The Reluctance of airgap in machines with open armature slots

>

Smooth

Armature slots

Mmf required for airgap in machines with open armature slots and ducts =

Kg x ATg for airgap in machines with smooth armature surface

= Kg x 800000Bavlg

1.21.4 Effect of Saliency on the mmf for airgap

Fig (1.21.4) Air gap flux in salient pole machine

Mmf for airgap in salient pole machines = 800000BgKglg

Kg = Kgs Kgd Kgsal

Kg – total gap contraction factor

Field form factor

Kf =

Kf =

Bg =

,Also Kf ~Ψ =

=

-----------------------*---------------------------

1.22 MMF FOR TEETH

Fig (1.22 )Mmf For Teeth

1.22.1 METHODS

1. GRAPHICAL METHOD

2. THREE ORDINATE METHOD (SIMPSON’S RULE)

3. Bt1/3 method

1.22.1 .1 GRAPHICAL METHOD

The flux density at various sections of the tooth are determined.

Flux density at any section

Bt =

At –Area of cross section of tooth at the desired section

Bt- Flux density of tooth corresponding to At

nt-number of teeth under a pole

Ф – flux per pole

1.22.1 .2 THREE ORDINATE METHOD (SIMPSON’S RULE)

The mean value of at is given by atmean = at1+4at2+at3 / 6

At1=at for the root of teeth

At2= at for the centre of teeth

At3 – at for the tip of tooth

Mmf required for the tooth ATt = atmean *lt

ATt = atmean *ds

1.22.1 .3 Bt1/3 method

Total mmf for tooth ATt =at1/3 *lt

ATt = at1/3 *ds

ds=lt

lt –length of teeth

ds- depth of slot.

----------------------------*--------------------------

1.23 Real and Apparent flux Density

Higher flux densities the flux passing through the slots becomes large and can not be

neglected .

Apparent flux Density

Bapp = total flux in a slot pitch / tooth area

Real flux density

Breal = Actual flux in the tooth / tooth area

In machines – two parallel paths for the flux over one slot pitch

1.

Iron path of tooth

2.

Air and conductor path of slot

The apparent flux density = Bapp = total flux over a slot pitch /iron area over a slot

pitch

Bapp = Breal +BaK

Ba – flux density in air

Ba =μoH = μo atreal

Bapp = Breal +4π*10-7atreal (Ks-1)

1.24 Magnetic leakage

The flux which passes through unwanted path is called the leakage flux.

The designer has to provide a path of low reluctance so that comparatively little flux

leaks away from the desired path.

The leakage path flux affects the performance of transformer and rotating machines.

1.24.1 The leakage flux affects the following performance of various machines

1. Excitation demand of salient pole machines

2. Stray load losses

3. Forces between the windings under short circuit conditions

4. Commutation conditions in dc machines.

Fig (1.24) Magnetic leakage

Leakage co-efficient

Cl = total flux / useful flux

Cl = useful flux + leakage flux / useful flux

1.24.2 Types of leakage flux

1. Slot leakage flux

2. Tooth top leakage flux

3. Zigzag leakage flux

4. Overhang leakage flux

5. Harmonic or differential leakage flux

6. Skew leakage flux

7. Peripheral leakage flux

1.25 Slot leakage reactance (reactive voltage)

When the leakage flux is associated with a winding carrying alternating current.

This reactive voltage may be considered as a voltage drop due to a leakage reactance.

A slot consist of

Zs –conductors

Conductor carrying a current of Iz

Slot inductance = flux linkages / current

= ZsФsl / Iz ---------------(1)

Фsl –slot leakage flux

Фsl = mmf * permeance

Фsl = ZsIzΛs

- ---------------------(2)

Sub (2) in (1)

Ls =( Zs/ Iz) * Zs* Iz* Λs

Ls = Zs2Λs

Slot leakage reactance Xs = 2πf*slot inductance

Xs = 2πf Zs2Λs

Xs = 2πf Zs2Lλs [ Λs= Lλs ]

----------------*------------------------

1.26 UNBALANCED MAGNETIC PULL

Fig (1.26) Unbalanced Magnetic Pull

In rotating machines if the air gap around the armature peripheral is non uniform

then radial forces are developed in the rotor .

The radial forces will act perpendicular to rotor axis.

This force or pull is called the unbalanced magnetic pull.

Force due to a pole ,in dc machine

F= ½ B2/ μo Ap

Force due to pole in ac machine

F = Bm2 /3μo DL

Area per pole Ap = πDL / p

F – force between two poles ,N

Ap - area of each pole m2

B – flux density

μo – permeability of air H/m

Estimation of unbalanced magnetic pull

In ac machines

Magnetic pull per unit area Pm = ½ B2 / μo

Unbalanced magnetic pull due to pair of pole = Pp = 2ApPm(e / lg)

Unbalanced magnetic pull due to P number of poles UMP = pole pair *Pp

= p/2 *2Ap Pm(e/lg)

UMP = P ApPm(e/lg)

When the poles are located at an angle of θ with horizontal axis

The unbalanced magnetic pull acting downwards due to pair of poles

Unbalanced magnetic pull acting downwards due to a pair of poles = 4ApPm(e/lg)sin2θ

Effects of unbalanced magnetic pull

Saturation of magnetic materials due to reduction in air gap.

Excessive vibration and noise due to unbalanced radial forces

Design guidelines to reduce unbalanced magnetic pull

The following technique are employed

1. The length of the rotor can be kept small and diameter can be made higher

2. Ball bearings are employed and rotor is dynamically balanced

3. The combination of rotor and stator slots which produce vibrations are avoided.

…………………………………………………………………………………………………………….

1.27 Magnetic loading

•

1. Total Magnetic Loading (TML)

TML=Total flux entering and leaving the armature

.

TML=pØ

2. Specific Magnetic Loading (SML)

SML=(Flux per pole)/Area Under a pole SML=(pØ)/(¶DL)

1.28 Electric Loading

•

1. Total Electric Loading (TEL)

TEL=sum of currents in all the conductors on the armature

TEL=IzZ

3. Specific Electric Loading (SEL)

SEL=(Total Armature ampere conductors)

Armatue periphery at airgap

SEL ac =(IzZ)/¶D

1.28.1 Specific magnetic and electric loading

Machines

Specific magnetic loading Bav

in wb/m2

Dc machine

0.4 to 0.8

Induction motor

0.3 to 0.6

Synchronous machine 0.52 to 0.65

Turbo alternator

0.52 to 0.65

Specific electric loading ac in

amp.cond/m

15000 to 50000

5000 to 45000

20000 to 40000

50000 to 75000

1.29 Output Equation

•

The output of a machine can be expressed in terms of its

main dimensions, specific magnetic and electric loadings and

speed.

•

Pa=CoD2Ln

Where Output coefficient Co=¶2Bavac*10-3

PROBLEMS

P1) A 350 KW, 500V, 450rpm, 6-pole, dc generator is built with an armature

diameter of 0.87m and core length of 0.32m. The lap wound armature has 660

conductors. Calculate the specific electric and magnetic loadings.

Given data

P= 350KW

N= 450rpm = n=450 / 60 = 7.5rps

Z = 660

; p=6

D = 0.87m

V = 500V

L = 0.32m

To find

Bav and ac

Formula

Bav = pФ / πDL

ac=IzZ / πD

soln

The power output of the generator

P= VI *10-3 in KW

Full load current I = P / V*10-3 = 350 / (500*10-3)

I =700 amps

Neglecting field current Ia~ I

Current through each armature conductor Iz=

Iz = Ia / a

Iz = 700 /6

Iz = 116.67A ( a= p in lap wound)

1.Specific electric loading

ac=IzZ / πD = 116.67 *660 / (π *0.87)

ac=28173 amp.cond / m

induced emf in dc generator

E = ФZnP /a

E = ФZn ( for lap wdg p=a)

Flux / pole Ф =E /Zn

= 500 / 660*(450/60)

Ф = 0.101wb

2.specific magnetic loading

Bav = pФ / πDL

= 6*0.101/ π*0.87*0.32

Bav = 0.6929 wb/m2

…………………………………………………………………………………………………………..

P2) Calculate the MMF per meter for a flux density of 1.7wb/m and a

permeability of 23.5 x

10- 6H/m.

Given data

Flux density B = 1.7wb/m2

permeability μ = 23.5 x 10-6H/m

To find

Mmf / meter = ?

Formula used

B = μH

H=B/μ

Solution

H=B/μ

H = 72.3x103A/m

Result

Mmf / meter H =

72.3x103A/m

……………………………………………………………………………………………………

P3 ) The length of the iron path of a magnetic circuit is 50cm.the area of cross

section is 12.5cm2 µr = 800, what is the reluctance of the magnetic circuit.

Given data

l=50cm =50x10-2m

Area of cross section a=12.5cm2

a=12.5x10-4

μr=800

To find

Reluctance (S)

Formula used

S=

=

Solution

S = 3.98X105A/wb

……………………………………………………………………………………………………..

P4) Calculate the mmf required for the air gap with kg = 1.1, Lg =2mm, Bg

=1.5Wb/m2

Given data

Kg=1.1

Lg=2mm=2x10-3m

Bg=1.5wb/m2

To find

Mmf for airgap

Formula

Mmf = 800000kg lg Bg

Solution

Mmf = AT=8x105x1.1x2x10-3x1.5

Mmf = 2640A

Mmf = 2640AT

……………………………………………………………………………………………………………

P5) Calculate the mmf required for one air gap of a dc machine with an axial

length of 20 cm (no ducts) and a pole are 18 cm. The slot pitch is 27 mm, slot

opening 12 mm, air gap 6 mm and the useful flux per pole 25 mWb.

carter's coefficient for slot as 0.3.

Given data

Length L = 20cm = 20x10-2m

Pole arc b = 18cm = 18x10-2m

Slot pitch Ys = 27mm

Slot opening Wo = 12mm

No ducts Kg = Kgs

Airgap lg = 6mm = 6x10-3

Flux / pole Ф = 25mwb = 25x10-3wb

Kcs = 0.3

To find

Mmf required for airgap

Formula

Mmf required for airgap ATg = 800000kg lg Bg

Take

Formula for Kg and Bg

Since there are no ducts

Kg = Kgs

Kgs = gap contraction factor for slots

Kgs =

Kgs =

Kgs = 1.1538

For Bg

We know that

Bav =

=

,Ψ=

, pole arc – b

Pole pitch -

Flux density at the centre of the pole Bg =

Bg =

Bg =

Bg =

Bg =

=

Bg=

Bg= 0.6944 wb /m2

Soln

ATg = 800000 *Kg*Bg*lg

= 800000*1.1538*0.6944*6*10-3

ATg = 3845.75 AT

……………………………………………………………………………………………………………

P6) A 15 KW, 230 V, 4- pole dc machine has the following data: armature

diameter = 0.25 m, armature core length = 0.125 m, length of air gap at pole

center = 2.5 mm, flux per pole = 11.7 x 10-3 Wb, (pole arc/pole pitch) = 0.66.

Calculate the mmf required for air gap (i) if the armature surface is treated

as smooth (ii) if the armature is slotted and the gap contraction factor is 1.18.

Given data

Power developed = 15KW

Armature diameter D = 0.25m

Armature core length L = 0.125m

Length of air gap lg=2.5mm

Flux per pole Ф = 11.7*10-3wb

Pole arc (b) / pole pitch () = Ψ = 0.66

No of poles p=4

Gap contraction factor Kg=1.18

To find

Mmf required for airgap

1.

For smooth armature

2. For slotted armature

Formula

i)Mmf required for airgap with smooth armature ATg=800000 Bg lg

ii) mmf required for airgap with slotted armature ATg = 800000 Kg Bg lg

To find Bg

Bg = Bav / Ψ

Bav =

Bav =

Bav =0.47 wb /m2

Flux density at the centre of the pole

Bg = Bav / Ψ

Bg=0.4767 / 0.66

Bg=0.7223wb/m2

i)

Mmf required for airgap with smooth armature ATg=800000 Bg lg

= 800000*0.7223*2.5*10-3

ATg = 1445AT

ii) mmf required for airgap with slotted armature ATg = 800000 Kg Bg lg

= 800000 * 1.18*0.7223*2.5*10-3

ATg = 1705AT

………………………………………………………………………………………………………………

P7) Determine the air-gap length of a dc machine from the following particulars:

gross-length of core = 0.12m, number of ducts = one and is 10 mm wide, slot

pitch = 25 mm, slot width = 10 mm, carter's coefficient for slots and ducts =

0.32, gap density at pole center = 0.7 Wb/m2; field mmf/pole = 3900 AT, mmf

required for iron parts of magnetic circuit = 800AT,

Given data

Gross length L = 0.12m

No of ducts nd=1

Wd=10mm

Slot pitch Ys = 25mm

Slot width Wt = 10mm

Kcs = Kcd = 0.32

Gap density Bg=0.7 wb/m2

Mmf per pole = 3900AT

Mmf per iron = 800AT

To find

Airgap length lg=?

Formula

We know that

Mmf for airgap ATg = 800000 Kg Bg lg

lg = ATg /800000 Kg Bg

soln

mmf for airgap

ATg = mmf per pole – mmf for iron parts

ATg =3900 – 800

ATg = 3100AT

Gap contraction factor for slots

Kgs = Ys / (Ys – KcsWt)

= 25 / (25-0.32*10)

Kgs = 1.1468

Gap contraction factor for ducts

Kgd

=

Kgd =

Kgd = 1.02

Total gap contraction factor

Kg =Kgs * Kgd

Kg = 1.1468 * 1.02

Kg = 1.1782

lg=ATg / 800000*Bg*Kg

= 3100 / 800000*0.7*1.1782

lg=4.678*10-3

lg=4.7mm

……………………………………………………………………………………………………………

P8 ) The following data refers to a 20KW,2 pole DC motor ,Air gap =2.5mm,Area

under

each

pole

=

20x10-3m,air

gap

flux

density

=0.8wb/m2,vertical

displacement of rotor =0.4mm.calculate the unbalanced magnetic pull acting

downwards if the poles are located 45 degree with horizontal axis.

Given data

P= 20KW

p=2

lg=2.5mm

Area /pole Ap =20*10-3m

Airgap flux density Bg=0.8wb/m2

Displacement of rotor e= 0.4mm

θ=45˚

To find

Unbalanced magnetic pull acting downwards

Formula

Unbalanced magnetic pull due to 2 poles = 4ApPm (e /lg ) sin2θ

To find Pm

Magnetic pull per unit area = Pm = ½ B2 / μo

Soln

Pm = ½ B2 / μo = ½ (0.82 / 4π*10-7)

Pm = 254.64 *103N/m2

Unbalanced magnetic pull due to 2 poles = 4ApPm (e /lg ) sin2θ

= 4* 20*10-3 * 254.64*103*(0.4/2.5)*(sin45)2

Unbalanced magnetic pull due to 2 poles = 1629.7 ~1630N

………………………………………………………………………………………………………………

P9 ) Calculate the unbalanced magnetic pull of 4 pole DC machine having air gap

flux density of 0.85wb/m2, and a gap length of 2mm. the area of each pole is

24x10-3m2 and poles are symmetrically mounted. The accentricity is 15% in the

air gap.

Given data

p=4

lg=2mm

B=0.85wb/m2

Ap=24*103m2

Accentricity= e = 15% of lg

To find

Unbalanced magnetic pull due to four poles = p*Ap*Pm*(e/lg)

Formula

Magnetic pull per unit area Pm = ½ B2 / μo

Pm = ½ 0.852 / 4π*10-7

Pm= 287.4736*103 N/m2

e=15% of lg

e=15 /100*2

e=0.3mm

Unbalanced magnetic pull due to four poles = p*Ap*Pm*e/lg

= 4* 24*10-3*287.47 *103*(0.3/2)

Unbalanced magnetic pull due to four poles

=4139.6 N

……………………………………………………………………………………………………………

P10 )Calculate the apparent flux density at a section of the teeth of an armature

of a DC machine from the following data at that section, slot pitch=24mm, slot

width=tooth width=12mm, length of armature core including 5 ducts of 10mm

each=0.38m, iron stacking factor=0.92, true flux density in teeth at that section

is 2.2wb/m2 for which the mmf is 70,000AT/m.

Given data

Slot pitch Ys = 24mm

Slot width = tooth width

Ws = 12mm

L = 0.38m

Wt =12mm

Ducts = 5 nos

Wd= 10mm

Stacking factor Sf= 0.92

B real = 2.2wb/m2

at=70000AT/m

To find

Apparent flux density Bapp =?

Formula

Bapp = Breal + [μo at (Ks-1)]

Soln

Ks =

Li = stacking factor * (core length – total width of ducts )

Li = Sf ( L -5Wd)

Li = 0.92* ( 0.38 – 5*10*10-3)

Li = 0.3036

Ks =

=

Ks = 2.5

Bapp = Breal + [μo at (Ks-1)]

= 2.2 +4π*10-7*70000(2.5-1)

B

app

= 2.332 wb/m2

……………………………………………………………………………………………………………….

P11) Find the permeability at the root of the teeth of a DC machine armature

from the following data, slot pitch 2.1cm,tooth width at the root 1.07cm,gross

length 32cm,stacking factor=0.9 real flux density at the root of the teeth

2.25tesla,apparent flux density at the root 2.36tesla.

Given data

slot pitch 2.1cm = Ys = 2.1cm

tooth width Wt = 1.07cm

gross length L = 32cm= 32*10-2m

stacking factor Sf = 0.9

Breal = 2.25 tesla

Bapp = 2.36 tesla

To find

Permeability = ?

Formula

Breal = μ at

real

μ= Breal / at

real

Bapp = Breal +4π*10-7atreal (Ks-1)

Ks =

Ks =

( Li = SfL)

Soln

Bapp = Breal +4π*10-7atreal (Ks-1)

atreal = Bapp - Breal / μo(ks-1)

To find

Ks =

Ks =

Ks = 2.181

atreal

= Bapp - Breal / μo(ks-1)

= 2.36-2.25 / 4π*10-7(2.181-1)

atreal = 74120 AT/m

To find

μ= Breal / atreal

μ = 2.25 / 74120

μ = 30.356*10-6 H/m

……………………………………………………………………………………………………………….

P12)Calculate the mmf for air gap in a three phase induction motor from the

following data stator bore 500mm,core length = 220mm,stator slots 76,rotor

slots 94,slot opening 2mm,air gap length 0.9mm,take Kgd=1.15 and air gap flux

density 0.54wb/m2

Given data

Stator bore D = 500mm

Core length L = 220mm

Stator slots Ss = 76

Rotor slots Sr = 94

Slot opening Wos = 2mm

Wor = 2mm

Air gap length lg=0.9mm

Kgd = 1.15

Bav = 0.54wb/m2

To find

Mmf for air gap

Formula

Mmf for air gap = 800000 Bav Kg lg

Total gap contraction factor Kg = Kgs*Kgd

Soln

Carter’s co efficient for stator slots Kcs = 1/ (1+5lg/Wos)

Kcs =

Kcs = 0.3077

Kcss =Kcsr = 0.3077

Gap contraction factor for stator slots Kgss =

Gap contraction factor for rotor slots Kgsr =

Stator slot pitch Yss =

= π *500 / 76 = 20.67mm

Rotor slot pitch Ysr =

= π (500-2*0.9)/ 94 = 16.65mm

Kgss =

Kgss = 1.0307

Kgsr =

Kgsr = 1.0307

Kgs= Kgss *Kgsr

Kgs = 1.0307 *1.0307

Kgs = 1.0703

Total gap contraction factor

Kg = Kgs *Kgd

Kg = 1.0703*1.15

Kg= 1.2308

Mmf for air gap = 800000 Bav Kg lg

= 800000 *0.54*1.203*0.9*10-3

Mmf for air gap = 478.5AT

……………………………………………………………………………………………………………….

P13) University repeated question

Calculate mmf required for the air gap of a machine having core length of 0.32m

including 4 ducts of 10mm each ,pole arc of 0.29m,slot pitch of 65.4mm ,slot

opening of 5mm,air gap length of 5mm,flux per pole of 52mwb,given carter’s

coefficient is 0.18 for opening /gap =1 and is 0.28 opening / gap =2 .

Given data

L= 0.32m

nd=4

Wd=10mm

Wo = 5mm

Lg=5mm

b=0.29m

Ф = 52*10-3wb

Ys = 65.4mm

Kcs = 0.18

Kcd = 0.28

Find

Mmf required for air gap =?

Formula

Mmf = 800000 Bg Kg lg

Soln

Bg=Bav / Ψ

= pФ / πDLb

[ Ψ = b / ]

= pФπD / πDLbp

Bg = Ф / L*b

Bg = 52*10-3 / 0.32*0.29

Bg = 0.56

Kg = Kgs *Kgd

Kgs =

= 65.4*10-3 / 65.4*10-3-0.18*5*10-3

Kgs = 1.01

Kgd =

= 0.32 / 0.32 –(0.28*4*10*10-3)

Kgd = 1.003

Kg = Kgs *Kgd

Kg = 1.01*1.003

Kg= 1.013

ATg = 800000 *0.56*1.013*5*10-3

ATg = 2269.12 AT

…………………………………………………………………………………………………………

UNIT II

DC MACHINES

Constructional details- Output equation - Choice of specific electric and

magnetic loadings - Separation of D and L for rotating machines. Estimation of

number of conductors / turns - Coils - armature Slots - Conductor dimension Slot dimension. Choice of number of poles - Length of air gap - Design of field

system, Interpoles, Commutator and Brushes.

Consists of

- Constructional Elements

- Output Equation

- Choice of specific loadings

- Selection of number of poles

- Length of airgap

- Armature design

- Field system design

- Commutator and brushes

- Efficiency and Losses

2.1 CONSTRUCTIONAL ELEMENTS

(i) Armature

(1) winding

(2) core

(3) commutator

(ii) Field

(1) winding

(2) core

(3) pole shoe

(iii) Frame.

A.MUMTHAJ,AP/ EEE

EMD

Page 6 6

2.2 OUTPUT EQUATION

The output of a machine can be expressed in terms of its main dimensions,

specific magnetic and electric loadings and speed.

Pa=CoD2Ln

Where Output coefficient Co=¶2Bavac*10-3

The equation which relates the power output to D.L,Bav,ac and n of the machines is

known as input equation.

Induced emf in armature

E = ФZNp / 60*a

E = ФZnp /a

------------------------------------------------(1)

The conductors are connected in parallel paths ,if a – number of parallel path,then

Current through each conductor is

Iz= Ia/ a

Or

Ia = Iz a

------------------------(2)

We know that

Specific magnetic loading Bav = pФ / πDL

Or

pФ = πDLBav ------------(3)

Specific electric loading ac = Iz z / πD

Or

Iz z = πD ac ---------------(4)

In dc generator

Power generated in the armature = induced emf * armature current

In dc motor

Power generated in the armature = induced emf(back emf) * armature current

Power generated in the armature Pa = E Ia*10-3 in KW ---------------(5)

A.MUMTHAJ,AP/ EEE

EMD

Page 6 7

Substituting E and Ia from eqn 1 and eqn 2 in eqn 5

(5) ------------

Pa = (ФZnp / a ) * aIz *10-3

Pa = pФ*Iz z *n *10-3

------------------------(6)

Substituting pФ and Iz z value in eqn (6)

Pa= πDLBav*πDac*n*10-3

Pa = π2Bavac*10-3*D2Ln

Pa = CoD2Ln

--------------------------------------------------(7)

Where Co = π2Bavac*10-3

Co – o/p co efficient

D2L – volume of active part

Pa volume of active part *speed

-----------------------------*---------------------------------