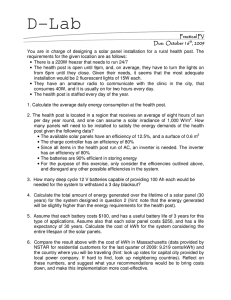

SLIDE 8 The energy performance was optimized under different parameters, starting off with orientation , the building is oriented so as to ensure maximum daylight reception while reducing heat gain. The orientation also helps facilitate natural ventilation considering the predominant wind direction The staggered form provide mutual shading that help in reducing heat tin the building, the simulations for the same have been shown. SLIDE 9 The size of openings along with their orientation help with lighting up 80 percent of the place naturally. SLIDE 10 Energy efficient LED fixtures with dimmable controls were used in order to reduce energy consumption. In a comparison drawn between LED fixtures used,CFL and Fluorescent tube, it can understood that the energy consumption reduces by 45 percent.The dimmable controls also reduce energy consumption by 30 percent. The building area method was used to arrive at a light power density of 4.417 for the interiors and 0.6 for the exterior conforming to IGBC guidelines SLIDE 11 BEE 5 star rated equipments are used that has help reduce the energy consumption by 12.47 percent in comparison to baseline scenario taken from NBC SLIDE 12 The building utilizes 2 types of renewable energy sources- Solar and Biogas 2 3Kwp solar panels are utilized on the terrace over an area of 32sqm that produces 9260.2Kwh annually thereby satisfying the energy requirements of the building 6697.5 Kwh and making the building net positive. The feasibility of these solar panels are also analysed for return on investment SLIDE 13 In addition to this Portable biogas has also been used that utilizes waste from the kitchen,farm animal sheds The portable biogas unit installed on site serves 3 requirements: 1. Eliminating the biowaste within site. 2. Energy production for stand-by apart from solar modules. 3. production of fuel for traditional gas stove cooking systems in the kitchen. And produces 2449 kWh per annum SLIDE 14 The building achieves an EPI of 22.171 with the aid of various strategies that the graph demonstrates SLIDE 15 These are the electrical and plumbing layouts, along with the working of the renewable energy systems SLIDE 16 Light-weight filler slabs of 200mm thick with earthen cups as filler materials been used which saves energy consuming concrete which accounts for 20% of total cost, composite slab of coconut husk/coir sandwiched between foam concrete panels of 100mm thick have been used for roofing which gives us a U- value of 0.8. Eco sensitivity of the project is realized by opting for local materials like porotherm clay blocks (8km from site), tree bark, coconut shell, (within site). The usage of steel is reduced by 6 tonns.