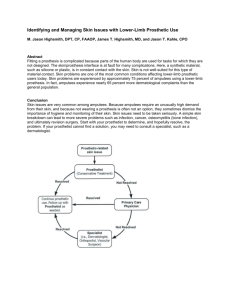

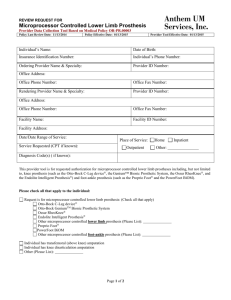

MATERIALS USED IN MAXILLOFACIAL PROSTHESIS 1 Introduction Definition History Review of literature Maxillofacial Impression materials and advancements Maxillofacial Prosthetic Materials Auxillary Maxillofacial Materials Discussion Conclusion Reference 2 INTRODUCTION Facial defects can result from trauma, treatment of neoplasm’s, or congenital malformations. More often facial defects referred to the Prosthodontist for restorations are usually the result of surgical resection of tumors. Restoration of facial defects is a difficult challenge for both the surgeon and the Prosthodontist. Both surgical reconstructions and Prosthodontic restoration have distinct limitations. 3 The surgeon is limited by the availability of tissue, the compromise of the local vascular bed by radiation in tumor patients, the need for periodic visual inspections of an oncology defects and the physical condition of the patient. The Prosthodontist is limited by the inadequate materials available for facial restoration, movable tissue bed, difficulty in retaining large prosthesis and patient acceptance. 4 Maxillofacial prosthesis :Any prosthesis used to replace part or all of the stomatognathic and/or craniofacial structures 5 There are two ways of presenting an overview of the subspecialty of maxillofacial prosthesis. One way is by viewing the patient ‘being treated’ and the other is by the ‘type of prosthesis’ that is prepared for the patient. 6 I ) Patient wise, they are classified as: 1. Surgical - The defect to be restored was created by a definitive surgical procedure. Ex: Cancer patients 2. Congenital - The defect is a result of congenital or developmental anomaly. Ex: cleft lip /palate and syndromes of head and neck. 3. Traumatic - The defect of the head and neck is a result of a traumatic experience in automobile accidents, industrial accidents or suicidal attempts. 7 II) By type of prosthesis, they can be classified as: 1. Extra oral - Facial restorations. Ex: Nasal prosthesis, orbital, ocular auricular 2. Intra oral. Ex: Obturator, speech aids, modified complete or partial dentures and infant feeding prosthesis. 8 HISTORY: Even before dentistry attained its status as a profession, some surgeons had recognized the limitations inherent in grafting tissue for repair of certain maxillofacial deficiencies and had argued the use of prosthesis as an alternate method. Artificial eye and foot found in Egyptian mummy, the use of artificial eye and noses by the Indians and the Chinese lead us to think that they applied their skill to prosthetic restoration also. 9 BEFORE 1600 AD Ambroise pare, (1510-1590) the famous French surgeon appears to be the first medical writer on this subject. He recommended a prosthetic nose, which could be made of gold, silver, paper and linen cloth glued together. He also described the fabrication of an auricular prosthesis. 10 1600-1800 Maxillofacial prosthetics owes much to Pierre fauchard (1678-1761). monumental contribution Fauchard to made prosthetic a facial reconstruction, he made a silver mask to replace the lost portion of the mandible for a french soldier. This prosthesis was constructed under the direction of a military surgeon, in collaboration with a silversmith for french artillery. The victim later came to be known as the “GUNNER WITH THE SILVER MASK”. 11 1800-1900 William Morton (1819-1868) also did some pioneer work is Maxillofacial prosthetics. He constructed a nose out of porcelain for a Boston lady who had lost her own from a malignant disease. Dr. Morton attached the nose to her spectacles. Frenchman Claude martin published a book in 1819 and described using a ceramic material to fabricate a nasal prosthesis. 12 1900-1940 Upham (1901), a Boston dentist described the use of vulcanite rubber for the fabrication of nasal and auricular prosthesis. In time, however some workers showed dissatisfaction with vulcanite due to their poor color stability, translucency and rigidity. 13 In Germany (1913), the gelatin - Glycerin compounds attracted much attention due to their ease to manipulate, pliability, translucency and adaptability of intrinsic coloring to match the skin. But this material lasted only a few days or a week. Bulbulian Clarke then introduced prevulcanized latex which was used with water soluable dyes. 14 1940-1960 Acrylic resin polymers were introduced and replaced older vulcanite rubber. Its translucency, colorability attractive and to ease most of processing clinicians. was Transparent photographic paints, acrylic resin polymer stains, water color, oil colors were also used. 15 1960- 1970 Silicone elastomers were introduced Barnhard was the first to use silicone and coloring the facial prosthesis by combining a silicone rubber base material with acrylic resin polymer stains. Tashma used dry earth pigments.. Schaaf described the use of artist oil paint. Fine described the use of colored nylon flocking 16 1970-1990 Different types of elastomers came into market. Lontz – polysiloxane elastomers Gonzalez - polyurethane elastomers Lewis - Siphenylenes Turner - isophorone polyurethane Drane and udagama - Silastic medical adhesive silicone type A 17 1990- to present Advances in polymer chemistry has renewed interest in developing new materials Gentleman-polyphosphazenes Silicone block polymers 18 REVIEW OF LITERATURE 19 Aziz T, Waters M, Jagger R J. Biomed Mater Res B Appl Biomater. 2003; 65 :252. Development of a new poly(dimethylsiloxane) maxillofacial prosthetic material. A new poly(dimethylsiloxane) material with improved mechanical properties was compared to commercially available materials. The formulations developed were based on condensation chemistry containing a poly(dimethylsiloxane), hydroxy-end-blocked hydrophobic silica filler, silane cross-linking agents, and a tin catalyst. 20 A formulation was developed with a base polymer mix of 80%:20% high- to low-molecular- weight polymers into which 20% w/w filler was added. This formulation had a tear strength better than compared to the commercial materials 21 Bellamy KE, Waters MG. Biomed Mater Eng. 2005;15:21-7. Designing a prosthesis to simulate the elastic properties of skin. They discussed a three-layered maxillofacial prosthesis consisting of a silicone rubber base layer, an inner gel layer and an outer polymeric coating (to simulate the elastic properties of skin). Gels were made by the addition of both low and high molecular weight unreactive silicone fluids. The results of the study shows that the gel produced, closely simulates the elastic properties of skin when bonded to a base silicone rubber layer. Further clinical trials are needed. 22 FOR MODELING OF AN EXTRA-ORAL IMPRESSION • Conventional method (using impression material) • CT and MRI • 3-D optical scanner (light source) 23 IMPRESSION MATERIALS PLASTER OF PARIS Highly accurate in reproducing details But it is lengthy and time consuming technique. Used mainly to reinforce alginate impression. 24 RUBBER BASE IMPRESSION MATERIAL Provides good details Mainly for intra oral use Expensive 25 ALGINATE Most widely used Excellent reproduction of details Overall cost is reasonable 26 Disadvantage of conventional impression Discomfort to the patient. Deformation of the soft tissue because of the weight caused by the impression material. Master cast for the reconstruction of the orbital defects usually show the remaining eye closed, so the technician must rely on other data (e.g.photographs) for the design of the orbital structures. Testing ability of the clinician. 27 CT AND MRI The difficulties encountered while using impression material was overcome by the use of CT AND MRI CT AND MRI scan the defect area and a CAD model of the defective area and the prosthesis pattern is designed. The prosthesis pattern is obtained by a procedure known as rapid prototyping. 28 Disadvantage Radiation is more with CT Length of the time that the patient is required to be exposed and remain motionless- during MRI scanning 29 OPTICAL THREE DIMENSIONAL SCANNER Newer device used to scan the facial defect and reproduce a model It is a mobile multi-view 3D measuring system based on self calibration projection technology. It facilitate the fully automatic recording of the body parts from various direction in one measuring process 30 31 A transmission grating with parallel lines inside the projector produced a fringe pattern on the face These pattern are recorded by camera and transmitted to the PC The generated CAD model is converted into a physical model by means of a rapid prototyping procedure. 32 33 ADVANTAGE The body parts are exposed to light and recorded optically. Time taken for measurement-10 to 20 seconds. Accuracy- 100µm. 34 RAPID PROTOTYPING Rapid prototyping, operate on the principle of depositing materials in layers or slices to build up a model rather than forming a model from a solid block. The use of a CT OR MRI allows parts of the body to be serially recorded slice by slice. Similarly, an object can be reproduced slice by slice using the three dimensional computed data in conjunction with a rapid prototyping machine 35 STEREOLITHIOGRAPHY It is a method of rapid prototyping that uses data obtained from CT OR MRI scan stored in 3dimensional form 36 Works based on the principle of curing liquid photomer into specific shape STEREOLITHIOGRAPHY A vat which can be lowered and raised filled with photocurable liquid acrylate polymer Laser generating U-V beam focused in x-y directions is The beam cures the portion of photo polymer and produces a solid body This process is repeated till the level b is reached as shown in the figure Now the plat form is lowered by distance ab Then another portion of the cylinder is shaped till the portion is reached 37 MATERIALS USED IN MAXILLOFACIAL PROSTHESIS 38 Generally an ideal material should have the following characteristics – Non-toxic. Odorless. High tear strength. High edge strength. Ease of processing. Dimensionally stable during and after processing. Ease of intrinsic and extrinsic coloring with commercially available colorants. Ease of repair and refabrication if needed. 39 Chemically inert after processing. Non-porous after processing. Long shelf life. Long working time. No water sorption. Translucent. Softness compatible to tissue. Usable life of two years or more. 40 A number of materials are available and have been used for facial prosthesis. The materials currently in use are: I. ACRYLIC RESINS The material is readily available and most dentists are familiar with its physical to chemical properties and processing techniques. These materials can be successfully employed in specific types of facial defects particularly those in which little movement occurs in the tissue bed during function. 41 Heat polymerizing MMA is preferred over the autopolymerizing form because of the presence of free toxic tertiary amines in the later. Facial prosthesis made serviceable up of to this 2 material years but remains required occasional repainting of the surface. With age, however the prosthesis becomes shiny and crazing is noted. 42 Advantages: a. Both intrinsic and extrinsic coloration can be performed. b. Has good edge strength c. Alterations can be easily affected. d. Compatible with most adhesive systems e. Color stability is good in heat polymerized MMA. f. Can be easily relined with tissue conditioner of denture liner. 43 Disadvantages: a) Rigidity, therefore its usefulness is compromised in highly movable tissue beds leading discomfort and expose of margins. b) High thermal conductivity. c) Duplication is not possible because of destruction of the mould during removal from flasks. 44 II. ACRYLIC CO-POLYMERS Conta and Hildested did extensive study on this material but did not receive wide acceptance, despite being soft and elastic because of a number of objectionable properties like poor edge strength, poor durability, degradation when exposed to sunlight. Disadvantages: Processing and Coloration are difficult. The completed restoration often tacky, predisposing to dust collection and staining 45 III. VINYL POLYMERS AND COPOLYMERS a. Commonly marketed as (Realistic and Mediplast, prototype III) Is a flexible plastic material basically plasticized polyvinyl Chlorides (PVC) or copolymer of Polyvinyl acetate. The primary deficiency arises from the leaching of the plasticizer and resulting hardening of the prosthesis. The lifespan as reported by Castleberry (1973) has been extended to 9-11 months. 46 Advantages: Adaptable to both extrinsic and intrinsic coloration. Flexible. Disadvantages: Migration of plasticizer leading to discoloration and hardening. Easily get stained when exposed to ultra-violet light, peroxide and ozone. 47 Poor edge strength. Tend to absorb sebaceous secretions, cosmetics and solvents. They soil easily because of surface tackiness. Metal moulds are required, as curing is accomplished at high temperatures 48 IV. POLYURETHANE ELASTOMERS: (Epithane - 3) These elastomers are called so because they contain urethane linkages. They arise from two major reactants. In the presence of a catalyst, a polymer terminating with an isocynate is combined with one terminating with a hydroxyl group. Varying the amount of isocynate will change the physical properties of the final product. 49 They are quite elastic and flexible especially well suited to defects with movable tissue bed. Isocynate are moisture sensitive and when water contamination occurs, gas bubbles causes defects and poor curing of the material. The reaction must be carried out in a dry atmosphere. The processing temperature is 100o C. 50 Advantages: Good edge strength. Can be colored both intrinsically and extrinsically. Superior cosmetic results when compared to other materials currently available. Stone molds are acceptable but care should be taken to thoroughly dehydrate before processing. 51 Disadvantages: Difficult to process consistency. Isocyanides, as these compounds are toxic and moisture sensitive due to which gas bubbles can accumulate and cause defects and poor curing. Extrinsic coloration tends to wear off rapidly. Clinically, the life range from minimum 3 months to maximum 6 months. Poor compatibility with existing adhesive systems. 52 V. SILICONE ELASTOMER The silicones are probably the most widely used materials for facial restoration. Silicones are a combination of organic and inorganic compounds. The first step in their production is the reduction of silica to elemental silicon. Then by various reactions the silicone is combined with methyl chloride to form dimethyl dichlorosixane, which when it reacts with water 53 forms a polymer. These polymers are translucent, watery white fluids whose viscosity is determined by length of the polymer chain. Polydimethyl Siloxane commonly referred to as silicone is made from these silicone fluid polymers. Most rubbery forms are compounded with fillers that provide additional strength. Additives are used to provide color. Antioxidants and vulcanizing agents are used to transform the raw mass from or plastic to a rubbery -resin during processing. 54 The long-chained polymer which is crosslinked create a network that can be separated only with difficulty. This network makes the silicones especially resistant to degradation from UV light exposure. 55 The process of cross-linking the polymers is referred to as vulcanization. Vulcanization occurs both with and without heat and depends on the catalytic or cross-linking agents utilized. Depending on the method of vulcanization, two forms are available: 1. Those that require heat - Heat vulcanized (HTV) 2. Those that vulcanize at room temperatureRoom temperature vulcanized (RTV) 56 Silicones are classified into four groups according to their application 1. Implant grade- material that can be implanted interstitially. 2. Medical grade- for maxillofacial silicones. external use eg- 3. Clean grade. 4. Industrial grade- both are used for industrial application. 57 Heat Vulcanized Silicones (HTV): Supplied as one component or two component putty. The catalyst or vulcanizing agent is dichlorobenzoyl peroxide or platinum salt, depending on the type of polymerization. Various amounts of filler are added to these polymers depending on the degree of hardness, strength and elongation desired. The more filler, the harder and less resilient the compounded rubber will be. 58 The filler is very pure finely divided silica with a particle size of about 30. Co-Polymers like methyl vinyl or methyl phenyl siloxy radical are added for softness and tear strength. Advantages: a. Exhibit excellent thermal stability. b. Color stable. c. Biologically inert. 59 Disadvantages: a. Do not posses sufficient elasticity to function in movable tissue bed. b. Poor edge strength. c. Are opaque and have lifeless appearance. 60 Room temperature silicones (RTV) It is a viscous silicone polymer that includes a filler and catalyst, which also acts as crosslinking agent. Stannous octoate is the common catalyst used. Filler, like diatomaceous earth are added to increase strength. The properties of RTV are similar to the HTV types, except for the ease of processing of RTV’s. 61 Advantages: Same as HIV Silicones. Easy to process and stone molds can be used. Disadvantages: Same as HTV silicones except for its ease in processing. 62 FOAMING SILICONES It is a form of RTV silicone. They reduce the weight of prosthesis because of formation of bubbles within the mass. The basic silicone has an additive so that a gas is released, when catalyst stannous octoate is introduced. The gas forms bubbles within the vulcanizing silicone. After the silicone is processed, the gas is eventually released leaving a spongy material. And the formation of bubbles within the mass can cause the volume to increase by as much as seven times. 63 DISADVANTAGE Has reduced strength. Susceptible to tearing. Because of these problems its use is limited. 64 VI. SIPHENYLENES: (polytetramethylsiphenylenesiloxanedimethylsiloxane) These belong to silicone family that contain methyl and phenyl group. It is a pourable, viscous, room temperature vulcanizing liquid. Three component kit Consist of a base resin crosslinking agent- tetrapropoxysilane catalyist- organotin Siphenylenes elastomers feels like skin. 65 Are biocompatible, resistance to degradation on exposure to ultraviolet light and heat. Have good edge strength and colorability. Advantage: Edge strength and colorability is superior to silicones. Disadvantages: Not enough clinical trials have been done due to limited research on this material. High cost. 66 SILICONE BLOCK POLYMERS Developed to improve some of the weakness of silicone elastomers. Incorporates poly methyl methacrlyate into silicone block. Has been found to be more tear resistant than conventional cross linked silicone polymers. 67 POLYPHOSPHAZENES It has been developed for resilient denture liner. Properties of this material is been modified to satisfy the requirements for fabrication of maxillofacial material. 68 AUXILLARY MAXILLOFACIAL MATERIALS: Primers These are used to promote bonding of silicone and other maxillofacial material. 69 FACIAL PROSTHETIC ADHESIVES Facial prosthesis may be retained by mechanical means or by the use of adhesives. 70 No one adhesive will behave in the same way to different patient. This mainly due to adhesive reacting to various skin types, ie oily, dry, flaky etc and each skin type will exhibit varying degree of retention. 71 They can be classified as Pastes. (PSA 1) Liquids [paintable (pros-Aide, DC-355) or spray-on (DC MED)]. Double sided tapes( 3M biface tape). 72 TISSUE CONDITIONING Used to prevents the skin damage when removing the adhesives. It forms a protective barrier. Comfeel protective film It contains ethoxyethyl acid co-polymer ethyl acetate When applied it forms a chemical film that is compatible with adhesives, so increasing the adhesion qualities of the prosthesis to the skin 73 Skin prep protective dressing (Smith & Nephew Inc) are used to enhance the prosthesis adhesion and to protect the skin from trauma. Composition Isopropyl alcohol. Butyl esters of poly vinyl methacrylate/ methyl methacrylate copolymer. Acteyl tributyl citrate 74 Technique of application of adhesives Apply the adhesive to 6 to 7mm of the periphery of the fitting surface To prevent the break down of the fine thin edges, leave the last 4mm without any adhesives, instead Vaseline may be applied to them to make the margin disappear 75 ADHESIVE REMOVER The biggest problem as far as the patient is concerned is the removal of the remaining residual adhesive from the skin. 76 Plaster remover. Zoff prosthetic cleanser. Trichloroethane Thackeray cleanser. Acetone. Krylon medican spirit gum remover Uni-solve adhesive remover Isoparaffin. Isopropyl alcohol. Dipropylene glycol methyl ether. Aloe extract. 77 Technique of removal To remove the prosthesis Lift the edge using a cotton bud or gauze soaked in the remover, slowly working around and under the fitting surface, lifting the prosthesis away from the skin as you go. 78 To clean the adhesive from the skin Soak a piece of gauze in the remover and by gently rubbing and turning the gauze constantly. Finish off by washing with soap and water. 79 To clean the prosthesis Initially rub the thumb over the fitting surface, causing the adhesive to “ball” for easy removal. Finally use the gauze soaked in remover to clean the fitting surface. If still traces of adhesive remain soak the prosthesis in the solvent for one or two minutes and then use a gauze swab. 80 DISCUSSION Since the sixteenth century acquired surgical defects have replacements been restored constructed from by a prosthetic variety of materials and techniques. The cosmetic and functional disabilities following radical surgery for oral and paraoral cancer are significant and disabling. Definitive reconstruction should be performed wherever possible as part of the ablative procedure. 81 When definitive reconstruction is coordinated and combined with maxillofacial prosthetic rehabilitation, head and neck defects can be restored to near-normal function and appearance in many cases. The traditional concept of a onetime prosthesis that supplies the patient's requirements through the course of life is no longer realistic or valid. 82 Identification of the variable factors that influence the serviceability of prostheses for the treatment of jaw defects is important and useful information for the patient, the family of the patient, the rehabilitative team, and third-party payers. 83 CONCLUSION Jaw defects affect many vital functions (that is, respiration, mastication, deglutition, speech, and aesthetics). Ideally, any anatomic defect should be surgically reconstructed. However, when surgical reconstruction is contraindicated, prosthetic reconstruction must be employed to restore anatomy, function, and aesthetics. 84 Effective communication between the surgeon and the maxillofacial Prosthodontist is essential for developing a realistic treatment plan or rehabilitation of patients undergoing resection. Preoperative consultations allow the prosthodontist to make recommendations to the surgeon to achieve better prosthetic results. 85 The team concept, in which the head and neck surgeon, speech pathologist, radiation oncologist, maxillofacial Prosthodontist, and other members of the health profession function together in planning the rehabilitation and primary modes of therapy, ensures the patient's early and successful rehabilitation 86 REFERENCE Maxillo Facial Rehabilitation – Prosthodontic and surgical consideration. JOHN BEUMER. Clinical Maxillofacial Prosthetics THOMAS D. TAYLOR. Prosthetic rehabilitationKEITH F THOMAS. 87 88